Compound Miter Saws Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433702 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Compound Miter Saws Market Size

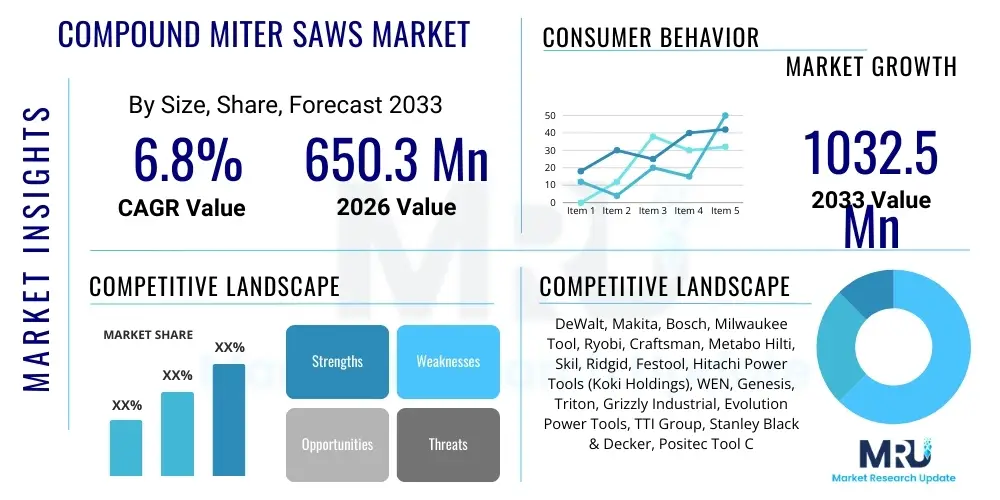

The Compound Miter Saws Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 650.3 Million in 2026 and is projected to reach USD 1032.5 Million by the end of the forecast period in 2033.

Compound Miter Saws Market introduction

The Compound Miter Saws Market encompasses the global trade and utilization of precision cutting tools designed primarily for making accurate crosscuts and miter cuts (angles) in materials, predominantly wood, but also plastics and certain non-ferrous metals. These tools are indispensable in construction, professional carpentry, framing, and detailed woodworking applications, offering superior versatility compared to standard miter boxes or simple circular saws. The "compound" feature refers to the blade's ability to tilt (bevel) while swinging horizontally (miter), enabling users to execute complex compound angles required for crown molding, baseboards, and intricate joinery in a single setup.

Major applications of compound miter saws include residential and commercial construction, remodeling projects, furniture manufacturing, and the burgeoning DIY (Do-It-Yourself) market. Key benefits driving adoption include enhanced accuracy, reduced material waste, and significantly improved operational efficiency on job sites. The availability of sliding models further expands their utility, allowing for the cutting of wider stock that standard models cannot accommodate. Product innovation focuses heavily on safety features, portability (especially cordless models), and integration of laser guides for improved cut precision.

Driving factors propelling market expansion include robust growth in the global construction sector, particularly in emerging economies undergoing rapid urbanization, and a persistent demand for high-quality, durable power tools among professional tradespeople. Furthermore, technological advancements, such as high-efficiency brushless motors in cordless units and improved dust extraction systems, are continually refreshing the market, encouraging replacement cycles and attracting new users seeking optimal performance and compliance with evolving health and safety standards.

Compound Miter Saws Market Executive Summary

The Compound Miter Saws Market is characterized by intense competition among established power tool manufacturers focusing on innovation in portability and precision. Business trends indicate a significant shift toward cordless (battery-powered) compound miter saws, driven by the need for mobility and operational flexibility on construction sites where power access may be limited. Professional users are increasingly prioritizing dual-bevel sliding models, which offer maximum versatility and accuracy for complex tasks like cutting wide decking or intricate trim work. Strategic mergers, acquisitions, and collaborations aimed at enhancing distribution networks and leveraging advanced motor technologies define the current competitive landscape, ensuring rapid deployment of new product features such as integrated digital displays for angle settings and enhanced cutting capacity.

Geographically, North America and Europe remain mature, high-value markets, driven by stringent quality standards in construction and a substantial professional user base with high purchasing power. However, the Asia Pacific (APAC) region is forecasted to exhibit the highest growth trajectory, primarily fueled by massive infrastructure investments, rapid residential construction activities in countries like China and India, and the rising availability of reliable, locally manufactured and globally branded tools. Latin America and the Middle East & Africa (MEA) are also showing promising growth, attributed to urbanization projects and the increasing replacement of manual tools with mechanized power equipment across various industries.

Segmentation analysis reveals that the Dual-Bevel segment commands a significant market share due to its functional superiority in complex angle cuts, making it the preferred choice for professional contractors. Concurrently, the DIY and Hobbyists segment is expanding rapidly, bolstering demand for entry-level and mid-range single-bevel models. The Cordless power source category is witnessing faster adoption rates than the traditional corded segment, despite higher initial costs, due to the critical importance of jobsite efficiency and safety. Manufacturers are strategically expanding their product portfolios across these segments to capture both the professional and consumer markets effectively.

AI Impact Analysis on Compound Miter Saws Market

User queries regarding AI in the Compound Miter Saws Market primarily revolve around two themes: autonomous operation and predictive maintenance. Users frequently ask if AI integration will lead to fully automated cutting systems on job sites, reducing the need for manual skilled labor, and how AI can ensure perfect cut accuracy every time. A secondary, but critical, area of inquiry concerns the use of machine learning algorithms to monitor tool health, predict potential mechanical failures before they occur, and optimize battery performance and charging cycles in high-demand cordless units. The key concern is centered on the cost implications of integrating such advanced technology and whether it provides tangible ROI over traditional high-end tools.

While the mechanical nature of the compound miter saw limits full autonomy in the near term, AI is already beginning to influence manufacturing processes and user experience. Generative design tools powered by AI are optimizing the saw's structural components for reduced weight and increased rigidity, enhancing portability without sacrificing durability or accuracy. Furthermore, in high-precision industrial fabrication settings, computer vision systems, often leveraging AI, are being deployed to verify cut quality immediately post-operation, ensuring compliance with strict tolerance requirements, thus drastically reducing the need for manual quality control checks and minimizing errors in complex assembly projects.

The most immediate and widespread application of AI/ML is evident in advanced diagnostics and operational efficiency features. Sophisticated sensors integrated into premium models collect data on motor temperature, vibration patterns, blade resistance, and battery discharge rates. Machine learning models interpret this data to provide predictive maintenance alerts via connected apps, notifying users when the blade needs sharpening or if a component is nearing failure. This proactive approach minimizes costly downtime for professional contractors and extends the overall lifespan of the tool, fundamentally changing how tool maintenance is managed on busy sites.

- AI-Driven Generative Design: Optimizes saw frame geometry for strength-to-weight ratio.

- Predictive Maintenance: ML algorithms analyze sensor data to forecast component failure and optimize service schedules.

- Enhanced Accuracy Verification: Computer vision systems check cut tolerances in industrial environments.

- Optimized Cordless Performance: AI manages battery discharge curves and thermal loading for peak efficiency.

- Supply Chain Optimization: AI predicts demand fluctuations, improving manufacturer production planning and tool availability.

DRO & Impact Forces Of Compound Miter Saws Market

The Compound Miter Saws Market is highly sensitive to macroeconomic factors, particularly global infrastructure spending and residential housing starts, which act as primary drivers. Technological innovation, specifically the advancement in battery technology (increasing runtime and power output in cordless models), significantly influences adoption rates. Conversely, the market faces restraints such as the high initial investment cost associated with premium, feature-rich sliding dual-bevel models, which can deter small contractors or price-sensitive DIY users. Opportunities lie in developing specialized, application-specific saws and expanding into emerging economies where rapid industrialization fuels demand for mechanized precision cutting tools. These forces collectively dictate market momentum, competitive strategy, and product development cycles.

The dominant impact forces shaping the competitive strategy include product differentiation through digital integration (laser guides, connectivity, and digital angle settings) and focusing on safety mechanisms, which are increasingly mandated by regulatory bodies globally. Furthermore, the push for environmental sustainability is an emerging force, driving manufacturers to develop more energy-efficient motors and utilize sustainable materials in tool construction. The shift toward direct-to-consumer online sales channels, often bypassing traditional retail, also compels established brands to rethink their distribution and pricing strategies, increasing market transparency and competition.

Restraints such as the inherent safety risks associated with high-speed cutting tools necessitate continuous investment in safety features, adding to manufacturing costs. The cyclical nature of the construction industry also means that demand can fluctuate sharply during economic downturns, impacting market stability. However, the opportunity presented by the large-scale replacement cycle of older, corded tools with advanced, efficient cordless alternatives provides a strong counterbalance, sustaining demand even during moderate construction slowdowns. Ultimately, the market trajectory is heavily influenced by the balance between technological cost reduction and increasing performance expectations from end-users.

Compound Miter Saws Market DRO & Impact Forces Summary:

- Drivers: Global growth in residential and commercial construction; technological advancements in cordless tool efficiency (battery life and power); increasing demand for precision in woodworking applications.

- Restraints: High initial cost of professional-grade sliding dual-bevel models; inherent safety risks requiring continuous investment in complex safety features; dependence on the cyclical construction industry.

- Opportunities: Expanding DIY market adoption in developed and emerging regions; development of integrated smart features (digital angle setting, connectivity); growth of specialized materials cutting applications.

- Impact Forces: Technological parity necessitating differentiation through ergonomics and IoT features; stringent global safety regulations (e.g., CE, OSHA); pressure for sustainable manufacturing practices.

Segmentation Analysis

The Compound Miter Saws Market is meticulously segmented based on product type, power source, end-user application, and cutting capacity, allowing for granular analysis of demand trends and strategic positioning. Segmentation by type—Single-Bevel, Dual-Bevel, and Sliding Compound—reveals user preferences dictated by complexity and budget. Dual-Bevel saws, while often more expensive, dominate the professional segment due to their ability to cut all required angles without flipping the workpiece. The Sliding Compound segment further enhances utility by accommodating significantly wider boards, essential for flooring and large trim projects.

Segmentation by power source, primarily Corded versus Cordless, is currently undergoing the most significant transformation. While corded models remain crucial for continuous, high-power applications in fixed workshops, the Cordless segment, powered by high-voltage lithium-ion batteries, is experiencing explosive growth. This shift is driven by the practical benefits of mobility, reduced tripping hazards, and rapidly improving battery technology that rivals corded power output, making cordless saws viable for all but the most demanding industrial tasks.

End-user segmentation clearly distinguishes between Professional Contractors (framers, finish carpenters, general contractors) and DIY/Hobbyists. Professional users prioritize durability, accuracy, and brand reliability, justifying investment in premium brands. Conversely, the DIY segment drives volume for entry-level and mid-range tools, focusing on ease of use and affordability. Analyzing these segments is critical for manufacturers in tailoring marketing campaigns, optimizing feature sets, and setting appropriate pricing strategies across different tiers of the market.

- By Type:

- Single-Bevel Compound Miter Saws

- Dual-Bevel Compound Miter Saws

- Sliding Compound Miter Saws

- By Power Source:

- Corded Miter Saws

- Cordless (Battery-Powered) Miter Saws

- By Application/End-User:

- Professional Construction & Contracting (Framing, Finish Carpentry)

- Woodworking and Cabinet Making

- Industrial Fabrication & Manufacturing

- DIY and Hobbyist Users

- By Cutting Capacity/Blade Size:

- 8-inch to 10-inch Blade Saws (DIY/Light Professional)

- 12-inch Blade Saws (Standard Professional)

Value Chain Analysis For Compound Miter Saws Market

The value chain for the Compound Miter Saws Market begins with upstream activities involving raw material procurement, primarily steel, aluminum, high-grade plastics, and complex electronic components for motors and control boards. Key component suppliers include specialized manufacturers of electric motors (especially brushless DC motors), lithium-ion battery cells, and high-precision casting firms. Efficiency in upstream sourcing and maintaining stable relationships with electronic component suppliers are paramount, especially given global supply chain volatility affecting microchips and battery technology necessary for modern smart tools.

The core manufacturing stage involves sophisticated assembly and quality control. Leading market players focus on in-house manufacturing or highly controlled outsourced production to maintain proprietary motor technologies, ensuring power output and durability meet professional standards. Distribution forms the critical intermediary stage, utilizing both direct and indirect channels. Direct channels include manufacturer websites and specialized business-to-business (B2B) sales for large corporate contracts or specialized industrial applications. Indirect channels, which form the majority of sales, rely heavily on large home improvement retailers (e.g., Home Depot, Lowe's), dedicated tool distributors, and e-commerce platforms.

Downstream analysis focuses on the end-user interaction, encompassing installation, usage, maintenance, and eventual replacement. The high average selling price of professional saws necessitates robust post-sales support, warranty services, and the availability of replacement parts, particularly blades, brushes (for older models), and batteries. The increasing reliance on e-commerce means that logistics and rapid fulfillment services are now critical differentiators in the value chain, ensuring tools reach job sites quickly and reliably. The lifecycle management—from manufacturing efficiency to end-of-life recycling—is a growing consideration, influenced by increasing environmental regulatory pressures across the globe.

Compound Miter Saws Market Potential Customers

The primary customers for Compound Miter Saws are broadly categorized into professional trade groups requiring high precision and durability, and consumer groups seeking ease of use and value. Professional contractors, including residential and commercial framers, dedicated finish carpenters, and specialized cabinet makers, constitute the highest-value customer segment. These users require sliding dual-bevel models, often 12-inch, with maximum cutting capacity and advanced features like digital miter displays and integrated dust management systems. Their purchasing decisions are driven by total cost of ownership (TCO), reliability, and integration within existing cordless platforms (e.g., 20V or 60V systems).

A rapidly expanding customer base is the DIY and home renovation enthusiast market. These buyers, particularly prevalent in North America and Europe, seek manageable, often 10-inch, single-bevel saws that balance performance with a lower entry price point. They are highly influenced by online reviews, instructional content, and promotional bundled deals offered by large retailers. Manufacturers target this group by prioritizing user-friendly features, clear safety instructions, and effective marketing emphasizing simplicity and accessibility for home improvement projects. Brand loyalty in this segment is less rigid than among professionals, often shifting based on promotional offers and retail availability.

Furthermore, industrial and educational institutions represent specialized but significant customers. Manufacturing units, especially those involved in prototyping, custom packaging, or specialized wood components, require industrial-grade saws for continuous, high-volume operation, prioritizing robust build quality and compatibility with factory automation systems. Technical schools and vocational training centers represent another distinct customer type, purchasing durable, often standardized, units for teaching purposes, where safety features and longevity are the main purchasing criteria, ensuring tools withstand heavy institutional use.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 650.3 Million |

| Market Forecast in 2033 | USD 1032.5 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | DeWalt, Makita, Bosch, Milwaukee Tool, Ryobi, Craftsman, Metabo Hilti, Skil, Ridgid, Festool, Hitachi Power Tools (Koki Holdings), WEN, Genesis, Triton, Grizzly Industrial, Evolution Power Tools, TTI Group, Stanley Black & Decker, Positec Tool Corporation, Apex Tool Group |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Compound Miter Saws Market Key Technology Landscape

The contemporary Compound Miter Saws market is defined by technological advancements focused primarily on efficiency, accuracy, and mobility. Brushless motor technology represents a foundational shift, offering significantly improved power-to-weight ratios, extended battery life in cordless applications, and superior durability compared to older brushed motors. These motors reduce friction and heat, allowing high-voltage cordless saws (e.g., 60V systems) to effectively rival the power output traditionally reserved for corded, high-amperage machines, thereby addressing a long-standing constraint in the cordless segment.

Precision and ease of use are enhanced through sophisticated laser guidance systems and digital angle readout technology. Advanced models now feature electronic measurement systems that display miter and bevel angles on a screen, eliminating guesswork and significantly speeding up setup time, which is critical on professional job sites where minutes equate to money. Furthermore, improvements in sliding mechanisms, often utilizing complex rail systems or glide arms (as seen in certain premium brands), have reduced the physical footprint of the saws while maintaining smooth, non-binding operation and allowing for deeper, more accurate crosscuts on wider material.

Connectivity and smart tool features are emerging as critical differentiators. Some high-end compound miter saws can be paired via Bluetooth or Wi-Fi to a user's mobile device. This connectivity allows for functions such as integrated inventory tracking, remote diagnostics, performance data logging (e.g., cuts per minute, usage time), and integration into fleet management software used by large construction firms. Coupled with improved dust extraction shrouds and standardized vacuum port interfaces, the current technology landscape emphasizes not just cutting power, but also safety, efficiency monitoring, and overall jobsite management integration.

Regional Highlights

Regional dynamics are critical in understanding the global Compound Miter Saws Market, as construction practices, tool preferences, and regulatory environments vary significantly.

- North America: This region holds a leading market share driven by a robust professional construction industry, high consumer spending on home improvement, and a strong preference for 12-inch sliding dual-bevel models. Adoption of high-voltage cordless platforms is highest here, fueled by market leaders like DeWalt and Milwaukee. Stringent safety standards and high labor costs further incentivize the adoption of high-precision, efficient tools.

- Europe: Characterized by high environmental and safety regulations, the European market shows strong demand for precision and advanced dust extraction features. Germany, the UK, and France are key contributors. Festool and Bosch have significant influence, catering to highly skilled finish carpenters and emphasizing lightweight, integrated systems for jobsite mobility.

- Asia Pacific (APAC): Expected to register the highest Compound Annual Growth Rate (CAGR). This growth is primarily fueled by accelerated urbanization, massive government investment in infrastructure, and the expansion of domestic manufacturing capabilities in China, India, and Southeast Asia. The market here is segmented, with demand for both low-cost, high-volume tools and high-end professional equipment for large commercial projects.

- Latin America (LATAM): Growth is steady, driven by urbanization and industrial expansion in Brazil and Mexico. Price sensitivity is higher, leading to strong demand for mid-range, durable tools that offer a reliable balance between cost and performance. Corded tools still maintain a significant presence due to lower battery technology penetration.

- Middle East and Africa (MEA): Large-scale development projects, particularly in the UAE and Saudi Arabia, are driving demand for professional-grade power tools. The market is highly reliant on imports, with purchasing decisions heavily influenced by the ability of tools to withstand harsh operating conditions (heat and dust) prevalent in the region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Compound Miter Saws Market.- DeWalt (Stanley Black & Decker)

- Makita Corporation

- Robert Bosch Tool Corporation

- Milwaukee Tool (TTI Group)

- Ryobi (TTI Group)

- Craftsman (Stanley Black & Decker)

- Metabo Hilti

- Skil (Positec Tool Corporation)

- Ridgid (Emerson Electric)

- Festool GmbH

- Koki Holdings Co., Ltd. (Hitachi Power Tools)

- WEN Products

- Genesis Tool and Supply

- Triton Tools

- Grizzly Industrial Inc.

- Evolution Power Tools

- Apex Tool Group

- Positec Tool Corporation

- Snap-on Incorporated

- Chervon Group (EGO, Flex)

Frequently Asked Questions

Analyze common user questions about the Compound Miter Saws market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between a single-bevel and dual-bevel compound miter saw?

A single-bevel saw can only tilt (bevel) in one direction (usually left), requiring the user to flip the material to achieve the opposite angle. A dual-bevel saw can tilt in both the left and right directions, allowing the user to make all required cuts for complex applications like crown molding without repositioning the workpiece, thus saving time and enhancing accuracy.

Why are cordless compound miter saws becoming preferred over corded models?

Cordless models, powered by advanced lithium-ion battery platforms (e.g., 40V or 60V systems), offer unparalleled mobility and operational efficiency on job sites lacking immediate power access. Recent technological improvements in brushless motors ensure that cordless saws can match the sustained power and cutting capacity previously only available in corded professional tools, justifying the higher initial investment.

Which geographical region is expected to show the highest growth rate for compound miter saws?

The Asia Pacific (APAC) region is projected to exhibit the highest CAGR through the forecast period. This growth is driven by substantial public and private investment in residential, commercial, and infrastructure development, particularly in highly populous and rapidly industrializing nations such as China, India, and key Southeast Asian countries.

What is the significance of the sliding feature in compound miter saws?

The sliding feature allows the saw head to move horizontally along rails, dramatically increasing the cross-cutting capacity. This enables users to cut significantly wider stock—such as 12-inch or 16-inch decking, shelving, and stair treads—that would be impossible with a non-sliding saw of the same blade diameter, making it essential for professional framers and deck builders.

How do safety features influence the design and cost of modern miter saws?

Modern miter saws integrate sophisticated safety features such as electric brakes (stopping the blade almost instantly), enhanced blade guards, and improved dust extraction systems to comply with international regulations (like OSHA). These innovations, while adding to the manufacturing complexity and overall tool cost, are crucial for minimizing operational hazards and protecting users, especially in professional environments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager