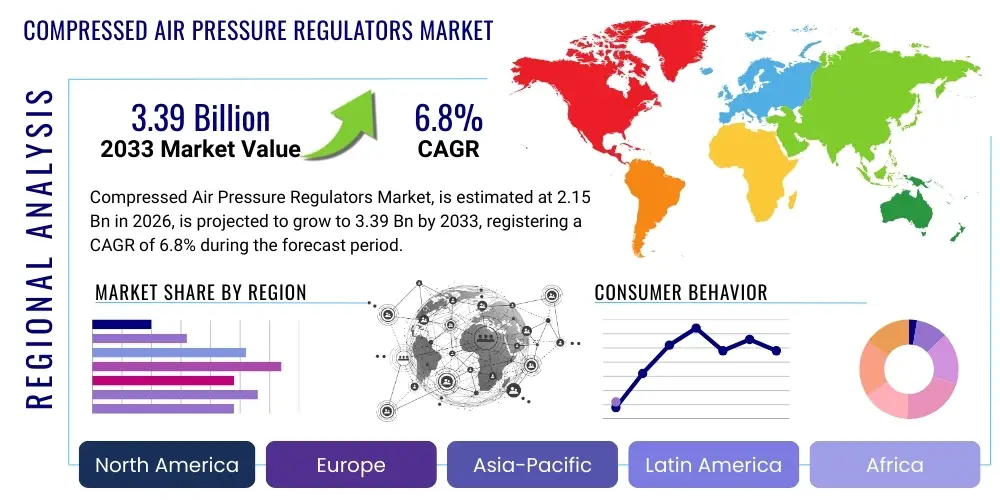

Compressed Air Pressure Regulators Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440054 | Date : Jan, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Compressed Air Pressure Regulators Market Size

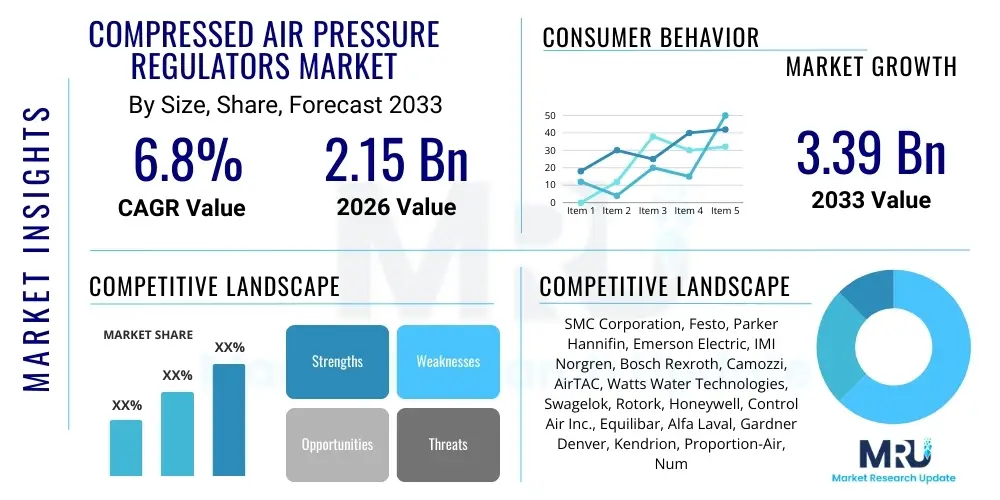

The Compressed Air Pressure Regulators Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 2.15 Billion in 2026 and is projected to reach USD 3.39 Billion by the end of the forecast period in 2033.

Compressed Air Pressure Regulators Market introduction

The Compressed Air Pressure Regulators Market encompasses devices critical for maintaining a consistent and controlled output pressure in pneumatic systems, irrespective of fluctuations in inlet pressure or varying flow demands. These essential components are designed to protect downstream equipment, optimize system performance, and ensure operational safety and efficiency across a wide array of industrial and commercial applications. By precisely managing air pressure, regulators prevent damage to delicate instruments, reduce energy consumption, and facilitate consistent process quality.

Product descriptions typically highlight features such as material construction (e.g., brass, stainless steel, aluminum), port size, pressure range, and flow capacity, catering to diverse operational requirements. Major applications span manufacturing automation, where they are integral to robotic systems and assembly lines; the automotive sector for paint shops and assembly; the healthcare industry for medical gases; and the food and beverage industry for pneumatic controls in processing and packaging. They are also vital in energy generation, oil and gas, and various process industries requiring precise fluid control.

The primary benefits derived from the deployment of compressed air pressure regulators include enhanced energy efficiency through optimized air usage, prolonged lifespan of pneumatic tools and machinery, improved process accuracy, and increased worker safety by preventing over-pressurization. The market’s growth is significantly driven by the accelerating pace of industrial automation, the imperative for energy conservation, the growing demand for high-precision manufacturing processes, and the continuous expansion of global manufacturing capabilities, particularly in emerging economies.

Compressed Air Pressure Regulators Market Executive Summary

The Compressed Air Pressure Regulators Market is undergoing significant transformation, driven by advancements in industrial automation and the push for greater operational efficiency. Key business trends include the increasing integration of smart technology and IoT capabilities into pressure regulators, enabling remote monitoring, predictive maintenance, and adaptive control. There is a growing emphasis on modular designs and compact solutions to meet the demands of sophisticated, space-constrained industrial setups. Sustainability initiatives are also influencing product development, with a focus on energy-efficient designs and durable, long-lasting materials to reduce waste and operational costs for end-users.

Regionally, Asia Pacific stands out as a dominant force, fueled by rapid industrialization, expanding manufacturing bases, and significant investment in automation technologies, particularly in countries like China, India, and Southeast Asian nations. North America and Europe, while mature markets, are experiencing growth through the adoption of advanced, high-precision, and digitally integrated regulators, alongside a strong replacement market for existing industrial infrastructure. Latin America and the Middle East & Africa are emerging as high-potential regions, driven by infrastructure development and the growth of local manufacturing and processing industries.

Segment trends indicate a robust demand for electronic pressure regulators due to their superior precision and integration capabilities within automated systems, offering greater control and data feedback compared to traditional mechanical types. The market is also seeing increased segmentation based on end-use applications, with specialized regulators designed for high-purity environments in pharmaceuticals and semiconductors, or high-flow applications in heavy industry. Furthermore, the rising awareness of compressed air system inefficiencies is driving demand for regulators that offer enhanced energy-saving features, contributing to overall operational cost reduction for businesses across all sectors.

AI Impact Analysis on Compressed Air Pressure Regulators Market

Users frequently inquire about how Artificial Intelligence (AI) can revolutionize the efficiency and reliability of compressed air systems. Common questions revolve around AI’s potential for predictive maintenance, optimizing energy consumption, facilitating real-time adaptive control, and enabling the development of truly smart, self-adjusting pressure regulation systems. There is also considerable interest in the practical implementation costs, the integration challenges with existing infrastructure, and the data security implications associated with AI-powered solutions in industrial environments. Stakeholders are keen to understand the tangible benefits AI can deliver in terms of operational uptime, cost savings, and enhanced process stability, alongside the necessary investments in sensor technology and data analytics platforms.

- Predictive maintenance capabilities through AI algorithms analyzing operational data to anticipate regulator failures, reducing unscheduled downtime.

- Optimized energy consumption by dynamically adjusting pressure settings based on real-time demand patterns, minimizing air leakage and wastage.

- Adaptive control systems that leverage AI to self-learn and fine-tune pressure outputs for varying process conditions, ensuring greater precision and stability.

- Enhanced remote monitoring and diagnostics through AI-driven analytics platforms, providing actionable insights into system performance and health.

- Improved fault detection and isolation, allowing for quicker identification and resolution of anomalies in the compressed air network.

- Facilitation of digital twin technology, where AI simulates regulator performance for design optimization and operational forecasting.

- Integration with broader industrial IoT (IIoT) ecosystems, enabling seamless data exchange and coordinated control across diverse plant equipment.

- Development of autonomous pressure regulation units that can learn and adapt without constant human intervention, increasing system resilience.

DRO & Impact Forces Of Compressed Air Pressure Regulators Market

The Compressed Air Pressure Regulators Market is primarily driven by the escalating demand for industrial automation across various manufacturing sectors, which necessitates precise and reliable control over pneumatic systems. The increasing adoption of Industry 4.0 paradigms, integrating IoT, AI, and advanced analytics into factory operations, further propels the need for smart and highly efficient pressure regulation solutions. Additionally, stringent safety regulations and environmental standards globally compel industries to invest in high-quality, energy-efficient regulators that minimize air wastage and reduce operational costs, thereby enhancing sustainability efforts and worker safety. The expansion of manufacturing capabilities in emerging economies and the continuous development of advanced pneumatic applications in sectors like healthcare, automotive, and food & beverage also contribute significantly to market growth.

However, the market faces several restraints, including the significant initial capital investment required for upgrading to advanced or smart pressure regulation systems, particularly for small and medium-sized enterprises. The relative commoditization of basic mechanical regulators, leading to price erosion and intense competition, can also challenge market participants focusing on entry-level products. Furthermore, the lack of a skilled workforce capable of installing, maintaining, and troubleshooting complex, digitally integrated pneumatic systems poses a practical barrier to the wider adoption of cutting-edge solutions. Economic uncertainties and fluctuations in raw material prices, such as metals and polymers, can impact production costs and market pricing strategies, potentially hindering market expansion.

Opportunities in the market are vast, particularly in the ongoing development and commercialization of IoT-enabled and AI-powered smart regulators that offer enhanced diagnostic capabilities, predictive maintenance, and real-time adaptive control. The increasing demand for customized pressure regulation solutions tailored for niche applications, such as high-purity requirements in semiconductor manufacturing or explosive environments in oil and gas, presents significant growth avenues. Furthermore, expansion into untapped or underserved geographical regions, especially in Latin America and the Middle East & Africa, where industrialization is accelerating, offers substantial potential. Continuous innovation in materials science to develop more durable, lightweight, and corrosion-resistant regulators also opens new market segments and performance benchmarks.

Several impact forces exert influence over the Compressed Air Pressure Regulators Market. Technological advancements represent a primary force, with ongoing innovations in sensor technology, embedded software, and connectivity solutions driving the evolution of regulator capabilities. Regulatory changes, particularly concerning energy efficiency and industrial safety, compel manufacturers to innovate and end-users to upgrade their systems, directly impacting product development and market demand. Broader economic growth and industrial output levels dictate the overall demand for pneumatic equipment, including regulators, as industrial expansion correlates with increased capital expenditure. Lastly, volatility in raw material prices, coupled with supply chain disruptions, can significantly affect manufacturing costs and the ultimate pricing of compressed air pressure regulators, influencing market competitiveness and profitability.

Segmentation Analysis

The Compressed Air Pressure Regulators Market is meticulously segmented to provide a granular understanding of its diverse landscape and cater to a wide array of industrial and commercial requirements. This segmentation allows for a detailed analysis of market dynamics across various product types, operational mechanisms, material compositions, and end-use applications, providing clarity on consumer preferences, technological adoption rates, and regional demand patterns. Understanding these segments is crucial for manufacturers to tailor their product offerings, for distributors to optimize supply chains, and for end-users to make informed purchasing decisions based on their specific operational needs and budgetary considerations. The interplay between these segments often dictates market trends and innovation pathways, fostering competition and driving efficiency across the industry value chain.

- By Product Type:

- Standard Regulators

- High-Pressure Regulators

- High-Flow Regulators

- Miniature Regulators

- Specialty Regulators (e.g., medical, cleanroom)

- By Mechanism:

- Spring-Loaded Regulators (Diaphragm, Piston)

- Pilot-Operated Regulators

- Electronic Regulators

- By Material:

- Brass Regulators

- Stainless Steel Regulators

- Aluminum Regulators

- Plastic/Composite Regulators

- By Port Size:

- 1/8 inch to 1/4 inch

- 3/8 inch to 1/2 inch

- 3/4 inch to 1 inch

- Above 1 inch

- By End-Use Industry:

- Automotive

- Manufacturing & Automation (General Industry)

- Food & Beverage

- Pharmaceutical & Healthcare

- Chemical & Petrochemical

- Oil & Gas

- Energy & Power

- Water & Wastewater Treatment

- Pulp & Paper

- Aerospace & Defense

- Others (e.g., Textile, Mining)

- By Application:

- General Purpose Air Systems

- Precision Control Systems

- Process Control

- Robotics & Automation

- Pneumatic Tools

- Packaging Machinery

- Medical Devices

Value Chain Analysis For Compressed Air Pressure Regulators Market

The value chain for the Compressed Air Pressure Regulators Market begins with upstream activities involving the sourcing and processing of raw materials such as various grades of brass, stainless steel, aluminum alloys, and high-performance polymers, along with specialized elastomers for seals and diaphragms. Key component manufacturers supply essential parts like springs, gauges, fittings, and electronic sensors for smart regulators. The quality and cost-effectiveness of these upstream inputs directly influence the final product's performance, durability, and market competitiveness. Efficient supplier relationships and robust quality control at this stage are paramount for maintaining product integrity and managing production costs within the highly competitive market landscape.

Further along the chain, the manufacturing phase involves precision machining, assembly, testing, and quality assurance processes, where raw materials and components are transformed into finished compressed air pressure regulators. Manufacturers invest heavily in R&D to develop innovative designs, improve performance characteristics, and integrate advanced functionalities such as IoT connectivity and predictive analytics. This stage also includes compliance with various international standards and certifications, ensuring product safety and reliability. The efficiency of manufacturing operations, including automation and lean production techniques, plays a critical role in controlling production costs and meeting market demand effectively.

Downstream activities primarily focus on the distribution and sales of the finished regulators to end-users. Distribution channels are multifaceted, encompassing both direct and indirect approaches. Direct channels involve manufacturers selling directly to large industrial clients, OEMs, or through their own sales teams and online platforms, allowing for greater control over customer relationships and pricing. Indirect channels leverage a network of specialized industrial distributors, wholesalers, retailers, and value-added resellers (VARs) who provide local presence, technical support, and inventory management. These indirect partners often serve a broader customer base, including smaller businesses and maintenance, repair, and overhaul (MRO) operations. The effectiveness of these distribution networks is crucial for market penetration, customer reach, and efficient product delivery, ensuring that regulators reach a diverse range of industries and applications promptly and reliably.

Compressed Air Pressure Regulators Market Potential Customers

Potential customers for compressed air pressure regulators represent a broad spectrum of industrial and commercial entities that rely heavily on pneumatic systems for their operations. These end-users span across diverse sectors, each with specific requirements for pressure control, ranging from precision and stability to flow capacity and material compatibility. The core clientele includes large-scale manufacturing plants in industries such as automotive, electronics, heavy machinery, and general automation, where pneumatic tools, robotic systems, and assembly lines are integral to production processes.

Beyond traditional manufacturing, the food and beverage industry constitutes a significant customer segment, utilizing regulators in processing, packaging, and sorting machinery, often requiring specific hygienic and corrosion-resistant materials. Pharmaceutical and healthcare sectors are also key buyers, with a demand for high-purity and precise medical gas regulators for applications in laboratories, hospitals, and medical device manufacturing. Chemical and petrochemical plants, as well as oil and gas facilities, require robust and explosion-proof regulators capable of handling aggressive media and extreme environmental conditions.

Furthermore, emerging customer segments include data centers for cooling systems, HVAC installations in commercial buildings, and utility providers for water and wastewater treatment plants. Essentially, any industry that employs compressed air for power, control, or processing functions, from small workshops using pneumatic hand tools to sophisticated automated factories, represents a potential customer for compressed air pressure regulators, driving consistent demand across the global industrial landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.15 Billion |

| Market Forecast in 2033 | USD 3.39 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SMC Corporation, Festo, Parker Hannifin, Emerson Electric, IMI Norgren, Bosch Rexroth, Camozzi, AirTAC, Watts Water Technologies, Swagelok, Rotork, Honeywell, Control Air Inc., Equilibar, Alfa Laval, Gardner Denver, Kendrion, Proportion-Air, Numatics (ASCO), Wilkerson |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Compressed Air Pressure Regulators Market Key Technology Landscape

The Compressed Air Pressure Regulators Market is increasingly shaped by advancements in several key technological areas, moving beyond purely mechanical designs to embrace digital and smart capabilities. Central to this evolution is the integration of advanced microcontrollers and embedded systems, which provide the computational power necessary for precise digital control, data processing, and communication. These microcontrollers enable regulators to perform complex functions, such as proportional pressure control, flow compensation, and diagnostic self-checks, significantly enhancing their accuracy and responsiveness in dynamic industrial environments.

Furthermore, the widespread adoption of sophisticated sensor technology, including highly accurate pressure, flow, and temperature sensors, is critical. These sensors provide real-time data on system performance, allowing regulators to adapt their output based on actual operating conditions and external influences. Coupled with the integration of Internet of Things (IoT) modules, these smart regulators can connect to broader industrial networks, facilitating remote monitoring, data logging, and predictive maintenance. This connectivity supports the transition towards Industry 4.0 paradigms, where data-driven insights are used to optimize entire compressed air systems, not just individual components.

Innovations in materials science also play a vital role, leading to the development of more durable, lightweight, and corrosion-resistant materials for regulator bodies, diaphragms, and seals. These advanced materials extend product lifespan, reduce maintenance requirements, and enable regulators to operate reliably in harsh or specialized environments, such as high-purity applications or corrosive chemical processing. Additionally, the proliferation of digital communication protocols like Ethernet/IP, PROFINET, and Modbus TCP/IP allows seamless integration of smart regulators into existing Programmable Logic Controller (PLC) and Distributed Control System (DCS) architectures, enabling centralized control and automation. The incorporation of predictive algorithms and machine learning capabilities further transforms these devices into intelligent components capable of self-optimization and early fault detection, fundamentally changing how compressed air systems are managed and maintained for peak efficiency.

Regional Highlights

- North America: A mature market characterized by high adoption of automation and advanced manufacturing techniques. Demand is driven by replacement cycles, integration of smart factory solutions, and strict industrial safety standards. The US and Canada are key contributors, focusing on energy efficiency and precision control in aerospace, automotive, and healthcare sectors.

- Europe: Similar to North America, Europe demonstrates a strong emphasis on Industry 4.0 initiatives, sustainability, and high-quality engineering. Germany, Italy, and the UK are prominent markets, with significant demand from automotive, machinery manufacturing, and food & beverage industries, pushing for highly efficient and robust pressure regulation solutions.

- Asia Pacific (APAC): The fastest-growing region, propelled by rapid industrialization, expanding manufacturing bases, and increasing foreign direct investment in countries like China, India, Japan, South Korea, and Southeast Asian nations. This region is a major hub for electronics, automotive, textiles, and general manufacturing, driving substantial demand for both basic and advanced pressure regulators.

- Latin America: An emerging market experiencing consistent growth due to infrastructure development, burgeoning manufacturing sectors, and increasing industrial automation in countries like Brazil, Mexico, and Argentina. The demand is particularly strong in automotive, mining, and food processing industries, focusing on cost-effective yet reliable solutions.

- Middle East and Africa (MEA): This region is characterized by significant investments in oil & gas, petrochemicals, construction, and nascent manufacturing industries. Countries like Saudi Arabia, UAE, and South Africa are driving demand for robust, high-performance regulators capable of operating in challenging environmental conditions, often prioritizing durability and specialized applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Compressed Air Pressure Regulators Market.- SMC Corporation

- Festo

- Parker Hannifin

- Emerson Electric

- IMI Norgren

- Bosch Rexroth

- Camozzi

- AirTAC

- Watts Water Technologies

- Swagelok

- Rotork

- Honeywell

- Control Air Inc.

- Equilibar

- Alfa Laval

- Gardner Denver

- Kendrion

- Proportion-Air

- Numatics (ASCO)

- Wilkerson

Frequently Asked Questions

What is a compressed air pressure regulator?

A compressed air pressure regulator is a pneumatic device designed to reduce and maintain a constant output pressure in a compressed air system, regardless of fluctuations in the inlet pressure or variations in downstream flow demand. It ensures stable and controlled pressure for pneumatic tools and equipment.

Why is pressure regulation important in industrial systems?

Pressure regulation is crucial for protecting downstream equipment from damage due to over-pressurization, optimizing energy consumption by preventing air wastage, improving process consistency and accuracy, and enhancing operational safety. It ensures reliable and efficient performance of pneumatic machinery.

What are the key types of compressed air pressure regulators?

Key types include spring-loaded regulators (diaphragm and piston designs), which use a spring to balance pressure; pilot-operated regulators, which use a small pilot valve for control; and electronic regulators, which offer precise digital control and integration with automation systems.

How does Industry 4.0 impact the Compressed Air Pressure Regulators Market?

Industry 4.0 significantly impacts the market by driving demand for smart, IoT-enabled regulators with connectivity for remote monitoring, data analytics, and predictive maintenance. This integration enables greater system efficiency, reduced downtime, and enhanced overall operational control within automated factory environments.

What factors should be considered when selecting a compressed air pressure regulator?

Key factors include the required output pressure range, maximum inlet pressure, desired flow rate, port size, operating temperature, type of media (air quality), material compatibility (e.g., brass, stainless steel), required precision level, and environmental conditions. Specific application requirements also dictate features like smart capabilities or certifications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager