Conalbumin Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439186 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Conalbumin Market Size

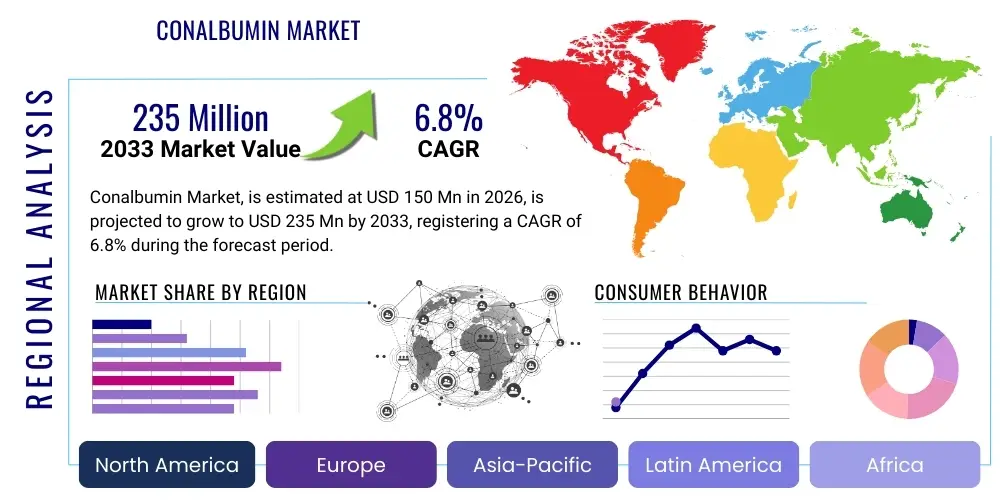

The Conalbumin Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 150 Million in 2026 and is projected to reach USD 235 Million by the end of the forecast period in 2033. This consistent growth trajectory is primarily driven by the escalating demand for high-value functional proteins in the nutraceutical and food fortification sectors, coupled with increased research activities exploring conalbumin's antimicrobial and iron-chelating properties. Market expansion is further supported by advancements in protein separation and purification technologies, enabling the production of high-purity conalbumin suitable for premium applications such as infant formula and specialized medical foods.

Conalbumin Market introduction

The Conalbumin Market encompasses the global trade and utilization of conalbumin, also known as ovotransferrin, which is a major globular glycoprotein found in avian egg white. This product is highly valued for its natural iron-binding capabilities, which are crucial for maintaining iron homeostasis, and its potent antimicrobial activity. Conalbumin functions as a critical component in various biological systems and is increasingly being leveraged across industrial sectors due to its functional versatility. The primary commercial production involves sophisticated chromatographic separation techniques to isolate the protein from egg white, ensuring high purity levels necessary for sensitive applications like pharmaceuticals and diagnostics, thereby positioning it as a premium ingredient in the protein sector.

Product descriptions emphasize conalbumin's role as a natural preservative and functional ingredient. Its major applications span nutraceuticals, where it is used in supplements targeting anemia and immune support; functional foods, utilized for shelf-life extension and nutritional enhancement; and in biomedical research for microbial inhibition studies and cell culture media enrichment. The driving factors propelling this market include rising consumer awareness regarding preventative health, the global shift towards natural and bio-based preservatives over synthetic alternatives, and continuous scientific validation of conalbumin's broad spectrum of biological activities, including antioxidant and immunomodulatory effects. Furthermore, its inclusion in infant nutrition formulas is gaining traction due to its similarity to human lactoferrin, promoting gut health and iron absorption.

Key benefits associated with conalbumin extend beyond its nutritional profile. Its strong binding affinity for ferric ions (Fe3+) makes it an effective chelator, mitigating oxidative stress and inhibiting the growth of iron-dependent pathogens. This intrinsic property makes it highly attractive for the preservation of delicate food products and the development of novel therapeutic agents. The market growth is also facilitated by continuous process optimization in extraction methodologies, reducing production costs and enhancing scalability, which allows market participants to meet the burgeoning demand from the booming functional ingredient sector. Regulatory acceptance across major economies further bolsters its integration into mainstream consumer products.

Conalbumin Market Executive Summary

The Conalbumin Market is characterized by robust growth underpinned by strong business trends centered on vertical integration and technological innovation in purification processes. Leading market participants are investing heavily in improving yield and achieving ultra-high purity grades (above 95%) to comply with stringent pharmaceutical and infant formula quality standards. Strategic alliances between egg processors and specialized biotechnology firms are becoming common, aimed at securing stable raw material supply chains and optimizing downstream processing efficiency. This business environment fosters competitive differentiation based not only on price but crucially on the purity and functional attributes of the final conalbumin product, driving a trend toward specialized, high-margin applications.

Regional trends indicate that North America and Europe currently dominate the market, primarily due to established nutraceutical industries, high per capita spending on health supplements, and strong regulatory frameworks supporting functional food ingredients. However, the Asia Pacific (APAC) region is projected to exhibit the highest CAGR during the forecast period. This accelerated growth in APAC is fueled by expanding middle-class populations, increased adoption of Western dietary habits, and significant governmental focus on improving infant and maternal nutrition, particularly in emerging economies like China and India. Local companies in APAC are rapidly scaling up domestic production capabilities to cater to this growing regional demand, potentially shifting the global supply equilibrium.

Segment trends highlight the dominance of the Application segment, particularly within nutraceuticals and research and diagnostics. The purity level segment, especially the "Above 95%" grade, is seeing rapid value growth, reflecting the premiumization of the market where high-specification conalbumin is required for injectable therapeutics and advanced laboratory assays. The End-User segment shows substantial demand from the Food & Beverage Industry, driven by the clean label trend and the search for natural alternatives to synthetic food stabilizers and preservatives. Manufacturers are increasingly focusing R&D efforts on developing novel encapsulation methods to stabilize conalbumin and enhance its bioavailability when incorporated into diverse food matrices.

AI Impact Analysis on Conalbumin Market

Common user inquiries regarding AI's influence on the Conalbumin market typically revolve around efficiency improvements in protein production, predictive quality control, and the acceleration of R&D for novel conalbumin derivatives. Users frequently ask if AI can optimize chromatographic separation parameters to maximize yield and purity, thereby reducing operational expenditure. They are also keen on understanding how machine learning algorithms can analyze complex biological data to identify new bioactive peptides derived from conalbumin or predict its interaction profile with specific pathogens, potentially leading to new drug development. The key themes summarized are optimization (production efficiency), innovation (drug discovery), and supply chain resilience (demand forecasting and risk management).

AI and machine learning (ML) are set to revolutionize the bioprocessing stage, particularly the ultrafiltration and ion-exchange chromatography steps critical for conalbumin purification. By utilizing predictive modeling, AI systems can dynamically adjust flow rates, pH levels, and buffer concentrations in real-time, minimizing batch variation and maximizing the yield of target protein fractions. This level of precision significantly reduces waste and energy consumption, leading to a substantial decrease in the cost of goods sold for high-purity conalbumin. Furthermore, AI-driven image analysis can be applied to quality control, rapidly assessing the structural integrity and aggregation state of the isolated protein, ensuring superior product consistency compared to traditional methods.

In the research domain, AI accelerates the discovery of new applications for conalbumin. ML models can sift through vast genomic and proteomic datasets to identify synergistic effects when conalbumin is combined with other bioactives, or pinpoint specific structural modifications (e.g., hydrolysis) that enhance its antimicrobial efficacy against antibiotic-resistant strains. This predictive capability allows researchers to bypass lengthy and expensive wet-lab experimentation for initial screening, significantly shortening the time-to-market for innovative conalbumin-based health products or targeted diagnostic reagents. AI also plays a crucial role in sophisticated market forecasting, allowing producers to accurately predict demand fluctuations in sensitive sectors like infant nutrition, thereby optimizing inventory and mitigating supply chain risks.

- AI optimizes chromatographic parameters for maximal conalbumin yield and purity.

- Machine learning models predict novel bioactive peptide sequences derived from conalbumin.

- Predictive maintenance in bioprocessing reduces equipment downtime and operational costs.

- AI-driven analysis accelerates R&D for antimicrobial and antioxidant formulations.

- Advanced analytics improve supply chain forecasting for critical raw material (egg white) sourcing.

DRO & Impact Forces Of Conalbumin Market

The dynamics of the Conalbumin Market are shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively form the Impact Forces dictating market trajectory. Key drivers include the surging global demand for natural, high-performance functional ingredients, especially in the health and wellness sector, and the conclusive scientific evidence supporting conalbumin's antimicrobial, antioxidant, and iron transport properties. These biological activities provide a compelling competitive advantage over synthetic alternatives. However, the market faces significant restraints, primarily stemming from the reliance on a single, volatile raw material source—poultry egg production—which is susceptible to disease outbreaks (like avian influenza), weather conditions, and fluctuating feed costs. Furthermore, the complexity and high operational cost of achieving pharmaceutical-grade purity represent a barrier to entry for smaller manufacturers.

Opportunities for growth are concentrated in the clinical and therapeutic applications of conalbumin. Its structural similarity to lactoferrin opens avenues for its integration into advanced infant formula and as a potential therapeutic agent for managing iron deficiency and combating hospital-acquired infections. The rising trend of 'nutri-cosmetics' also presents a niche opportunity for conalbumin derivatives in high-end personal care products, leveraging its antioxidant and skin-soothing properties. Strategic partnerships focused on developing plant-based or fermentation-derived alternatives to egg-sourced conalbumin (though currently nascent) represent a long-term opportunity to mitigate raw material supply volatility and broaden market acceptance among vegan consumers.

The impact forces currently exert a strong positive pressure, primarily driven by the escalating demand from the nutraceutical sector, which outweighs the constraints related to raw material cost and availability. The most significant impact force is regulatory scrutiny combined with consumer demand for transparency, pushing manufacturers to invest in verifiable purity standards and sustainable sourcing practices. The industry must consistently balance the high cost of advanced purification techniques against the market's willingness to pay a premium for high-quality, bio-functional ingredients. Successful market participants are those who manage raw material contracts effectively while simultaneously pioneering cost-effective, scalable purification technologies to maintain competitive pricing structures.

Segmentation Analysis

The Conalbumin Market segmentation provides a granular view of demand patterns based on purity levels, specific applications, and distinct end-user industries. This structured analysis is essential for market players to tailor their product offerings, pricing strategies, and distribution channels to meet the diverse requirements across different sectors. The market is fundamentally segmented based on the technical specifications required by the purchaser—specifically, the percentage of conalbumin purity—which directly correlates with its suitability for high-stakes applications such as parenteral nutrition or infant milk powder formulations versus lower-grade applications in bulk animal feed or general functional foods. Understanding these segment dynamics is crucial for forecasting investment returns.

Segmentation by application reveals that the nutraceutical and functional food sectors account for the largest market share, leveraging conalbumin's general health benefits and preservative qualities. However, the fastest growth is observed in the research & diagnostics segment, demanding the highest purity grades for precise laboratory protocols, ELISA kits, and cell culture media additives. The distinct needs of each application segment—from bulk ingredients in food processing to highly refined specialty chemicals in pharmaceuticals—necessitate different manufacturing and quality assurance methodologies, thus shaping competitive activity within those specific niches.

The End-User segmentation categorizes demand based on institutional consumption patterns, with pharmaceutical and biotechnology companies representing the highest value segment due to their stringent quality requirements and typically higher volume orders for clinical use. The increasing investment in personalized nutrition and advanced biological research globally will continue to amplify the demand within these high-value segments, forcing manufacturers to adhere to GMP (Good Manufacturing Practice) standards and secure necessary regulatory certifications to serve these critical end-users effectively. The constant innovation in product delivery systems further drives specialization within these segmented markets.

- By Purity Level:

- 90%-95%

- Above 95% (High Purity)

- By Application:

- Nutraceuticals

- Functional Foods

- Cosmetics

- Research & Diagnostics

- Infant Formula

- By End-User:

- Food & Beverage Industry

- Pharmaceutical & Biotechnology Companies

- Research Institutions and Academia

Value Chain Analysis For Conalbumin Market

The value chain for the Conalbumin Market initiates with upstream activities centered on the procurement and processing of raw egg white, the primary source material. This stage is dominated by large-scale egg production facilities and specialized fractionation companies that separate egg components. Upstream efficiency relies heavily on logistical excellence and quality control to ensure the microbial integrity of the liquid egg white before processing. Key considerations at this stage include minimizing contamination risks, rapid chilling, and ensuring a steady supply, as the biological nature of the material dictates a time-sensitive and temperature-controlled handling protocol crucial for preserving the conalbumin's native structure and function for downstream refinement.

The core midstream process involves complex biochemical manufacturing, primarily utilizing sophisticated protein purification techniques such as ion-exchange chromatography, size-exclusion chromatography, and ultrafiltration. This stage adds the highest value, transforming the crude egg white fraction into refined, high-purity conalbumin. Manufacturers must adhere to rigorous quality standards, often complying with food safety certifications (HACCP, ISO) or pharmaceutical guidelines (GMP), depending on the target end-use. Direct distribution typically involves selling high-purity grades directly to pharmaceutical R&D labs and infant formula producers, ensuring traceability and controlled handling throughout the supply route.

Downstream activities focus on formulating the refined conalbumin into final consumer products, encompassing its integration into nutraceutical capsules, functional beverages, or diagnostic kits. Distribution channels are highly varied; indirect channels utilize specialized ingredient distributors with expertise in temperature-sensitive biological products, supplying smaller food manufacturers or cosmetic firms. Direct distribution is favored for large B2B transactions with major global food and pharma companies, facilitating greater technical support and quality assurance oversight. The final stage involves marketing and sales, where product efficacy and purity certifications are emphasized to the end consumers and professional buyers, reinforcing the premium positioning of the product.

Conalbumin Market Potential Customers

Potential customers for conalbumin are highly diverse, spanning industries that require high-purity, bio-functional ingredients with iron-chelating and antimicrobial properties. The largest segment of potential customers includes large multinational Food & Beverage corporations specializing in functional foods, fortified beverages, and clean-label products. These companies utilize conalbumin primarily as a natural preservative to extend shelf life, replace synthetic chelators, and enhance the nutritional profile of their offerings. Specific buyers within this segment include manufacturers of sports nutrition bars, dairy substitutes, and premium packaged foods seeking natural fortification agents.

A high-value customer base exists within the Pharmaceutical and Biotechnology sector. These customers—ranging from drug developers to contract manufacturing organizations (CMOs)—purchase high-grade conalbumin (often >95% purity) for specialized applications. This includes its use as a standard or component in diagnostic reagents, as an ingredient in complex cell culture media used for vaccine and therapeutic protein production, and increasingly, as an active pharmaceutical ingredient (API) precursor or delivery vehicle in novel drug formulations targeting inflammation and microbial infections. These buyers prioritize quality documentation, regulatory compliance (e.g., European Pharmacopoeia standards), and consistent batch quality above all else.

Furthermore, institutions involved in cutting-edge research and specialized nutrition constitute a rapidly growing segment of potential customers. This includes university research laboratories, governmental food safety agencies, and specialized infant formula manufacturers. Infant formula producers are crucial buyers due to the drive to mimic the functional properties of human milk, incorporating conalbumin to support iron absorption and provide natural antimicrobial protection to newborns. Research institutions use the product extensively in biochemical assays to study iron metabolism, antimicrobial resistance mechanisms, and protein structure, often requiring small volumes of exceptionally high purity material.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 150 Million |

| Market Forecast in 2033 | USD 235 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Thermo Fisher Scientific, Merck KGaA, Sigma-Aldrich, Bio-Rad Laboratories, Abcam, Novus Biologicals, Creative Enzymes, Avantor, NeovaTech, Biovision, Santa Cruz Biotechnology, LGC Standards, Cayman Chemical, ProteoGenix, ProSpec-Tany, Fitzgerald Industries, Cusabio, Angiocrine Bioscience |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Conalbumin Market Key Technology Landscape

The technological landscape of the Conalbumin Market is primarily defined by sophisticated bioseparation and purification methodologies essential for isolating the protein from the complex mixture of egg white components. The backbone technology involves various forms of chromatography, predominantly ion-exchange chromatography (IEX) and hydrophobic interaction chromatography (HIC), optimized for scaling up production while maintaining the native tertiary structure of the conalbumin. Recent innovations focus on continuous chromatography systems, such as Simulated Moving Bed (SMB) technology, which offers enhanced efficiency, reduced solvent usage, and significantly lower operating costs compared to traditional batch processing, thereby making high-volume, high-purity production more economically viable and environmentally sustainable for leading manufacturers.

In addition to chromatography, advanced membrane separation techniques, including ultrafiltration (UF) and diafiltration (DF), are critical for concentrating and desalting the protein solution post-chromatography. These membrane processes are vital for achieving the high concentration factors and low mineral content required for premium applications, particularly in infant nutrition where strict compositional limits are enforced. The technological advancements here focus on developing fouling-resistant membranes and optimizing transmembrane pressure to maximize throughput without denaturing the sensitive protein structure. Furthermore, the integration of automated process analytical technology (PAT) allows for real-time monitoring of purity and yield, ensuring immediate adjustments to maintain product specifications throughout the entire purification train.

The emerging technological focus includes novel stabilization and delivery systems. Techniques such as microencapsulation and liposomal delivery are being researched and adopted to protect conalbumin's bioactivity when incorporated into challenging food matrices or for targeted delivery in the human body. These technologies enhance the stability of conalbumin against thermal processing, pH variations, and enzymatic degradation, thereby widening its applicability in functional foods and therapeutic products. Furthermore, advancements in enzymatic hydrolysis are enabling the production of specific conalbumin peptides (hydrolysates) with enhanced functional properties, such as increased bioavailability and modified antimicrobial spectra, creating a new generation of conalbumin-derived ingredients for specialized markets.

Regional Highlights

- North America: This region holds a significant market share, driven by a mature and highly innovative nutraceutical industry and substantial investment in biomedical research. The United States, in particular, showcases high consumer acceptance of fortified foods and dietary supplements containing functional proteins like conalbumin. Stringent quality standards and a high prevalence of contract manufacturing organizations (CMOs) specializing in high-purity bioprocessing contribute to market valuation. Demand is particularly strong from companies targeting immune health and anti-aging applications, benefiting from favorable regulatory clarity regarding novel ingredients.

- Europe: Characterized by strict food safety and novel food regulations (EFSA), the European market focuses on high-quality, traceable sourcing and sustainable production methods. Germany, France, and the UK are key markets, utilizing conalbumin in premium functional foods and specialized medical nutrition. The region is witnessing increased adoption of conalbumin as a clean label preservative, replacing synthetic stabilizers. Growth is steady, supported by strong academic research into the protein’s clinical potential and a consumer base willing to pay a premium for certified natural ingredients.

- Asia Pacific (APAC): APAC is the fastest-growing region, propelled by rapid economic development, increasing disposable incomes, and large population bases in China and India. The core driver is the exploding demand for high-quality infant formula, where conalbumin is increasingly incorporated for its nutritional and immunological benefits. Local governments are focusing on nutritional improvement, creating a favorable regulatory environment. While purity standards are rising, market volume is predominantly driven by the functional food and beverage segments, requiring localized sourcing strategies to manage logistical costs.

- Latin America (LATAM): This region represents an emerging market, currently dominated by imports of high-purity conalbumin used in clinical settings and high-end cosmetics. Brazil and Mexico are the primary consumers, where expanding middle classes are adopting Western-style health supplements. The market faces challenges related to infrastructure and the lack of robust local high-purity protein fractionation capabilities, leading to reliance on international suppliers. Opportunities exist for international players to establish localized distribution partnerships and tap into the growing demand for sports and active nutrition products.

- Middle East and Africa (MEA): The MEA market is small but growing, focused primarily on pharmaceutical applications and premium infant nutrition, particularly in the Gulf Cooperation Council (GCC) countries. High healthcare spending in countries like Saudi Arabia and UAE drives demand for high-specification diagnostic and therapeutic products. The market growth is constrained by high import duties and limited domestic production, making it highly sensitive to global supply chain disruptions and currency fluctuations. The major opportunity lies in the burgeoning clinical research sector requiring reliable, high-purity biological reagents.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Conalbumin Market.- Thermo Fisher Scientific

- Merck KGaA

- Sigma-Aldrich

- Bio-Rad Laboratories

- Abcam

- Novus Biologicals

- Creative Enzymes

- Avantor

- NeovaTech

- Biovision

- Santa Cruz Biotechnology

- LGC Standards

- Cayman Chemical

- ProteoGenix

- ProSpec-Tany

- Fitzgerald Industries

- Cusabio

- Angiocrine Bioscience

Frequently Asked Questions

Analyze common user questions about the Conalbumin market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function and commercial application of Conalbumin?

Conalbumin, also known as ovotransferrin, is primarily utilized for its potent iron-chelating properties and broad-spectrum antimicrobial activity. Commercially, it is extensively used in the nutraceutical sector for immune support and iron deficiency supplements, as a natural preservative in functional foods, and as a critical component in advanced research and diagnostic reagents requiring high-purity protein standards.

How is high-purity Conalbumin typically manufactured, and what technologies are crucial?

High-purity conalbumin is typically manufactured using advanced chromatographic separation techniques, predominantly ion-exchange chromatography (IEX), followed by ultrafiltration and diafiltration. Crucial technologies include continuous chromatography systems like SMB, which ensure high yield, superior purity levels (Above 95%), and cost-effective scaling necessary for pharmaceutical and infant formula grade production.

Which segments are driving the fastest growth rate in the Conalbumin Market?

The fastest growth rates are observed in the Research & Diagnostics and the Infant Formula application segments. The demand for ultra-high purity conalbumin (>95%) for complex biochemical assays and the increasing global adoption of fortified infant nutrition mimicking natural immunological benefits are the primary drivers accelerating these specific market segments.

What major restraints affect the Conalbumin supply chain and market growth?

The primary restraint is the market's dependence on the volatile supply of raw egg white, which is susceptible to unpredictable factors like avian influenza outbreaks, stringent animal welfare regulations, and fluctuations in feed and commodity costs. Additionally, the capital intensity and technical complexity associated with achieving pharmaceutical-grade purity act as a significant market barrier.

How does Conalbumin contribute to the 'clean label' and natural preservative trend in the food industry?

Conalbumin is highly valued in the 'clean label' movement because it is a naturally derived protein with intrinsic antimicrobial and antioxidant properties. By chelating metal ions (especially iron), it inhibits microbial growth and oxidative spoilage in foods, allowing manufacturers to replace synthetic chemical preservatives and stabilizers with a naturally sourced, bio-functional ingredient, meeting consumer demand for cleaner ingredient lists.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager