Conductive Ink Pen Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432123 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Conductive Ink Pen Market Size

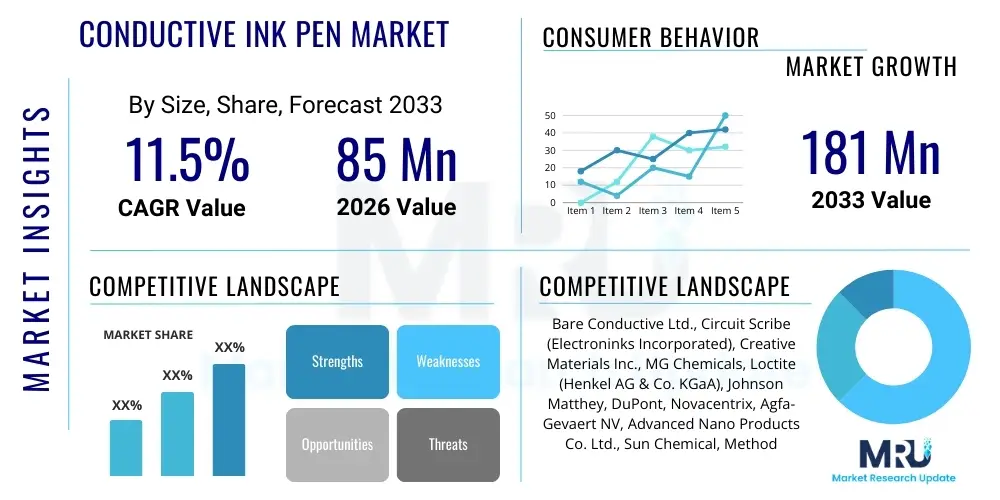

The Conductive Ink Pen Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 11.5% between 2026 and 2033. The market is estimated at USD 85 million in 2026 and is projected to reach USD 181 million by the end of the forecast period in 2033.

Conductive Ink Pen Market introduction

The Conductive Ink Pen Market encompasses specialized writing instruments utilizing inks embedded with highly conductive materials, such as silver, copper, or carbon nanoparticles. These pens are primarily designed to draw circuits, repair electrical connections, and create functional prototypes on various substrates, including paper, plastics, and fabrics. This innovation bridges the gap between traditional drawing and functional electronics, offering immediate, low-cost prototyping solutions across multiple industries. The unique capability of these pens to cure quickly and adhere robustly makes them indispensable for both educational purposes and complex professional applications where rapid circuit modification is necessary.

Major applications for conductive ink pens include prototyping flexible electronics, repairing PCB traces, creating radio frequency identification (RFID) antennas, and designing wearable sensors. Their primary benefit lies in their simplicity and accessibility, allowing non-specialists to engage in electronics design without requiring complex fabrication equipment like etching baths or lithography tools. This democratization of circuit design capabilities is a significant driving factor, particularly within the educational sector (STEM fields) and among hobbyists and startups focused on rapid product iteration and proof-of-concept development.

Driving factors for market growth are strongly tied to the expansion of the Internet of Things (IoT) ecosystem, which necessitates increasingly flexible and customized electronic components. Furthermore, the rising demand for efficient and localized repair solutions for consumer electronics, coupled with advancements in material science that reduce the cost and improve the conductivity of silver and copper nanoparticle inks, contribute substantially to the market's upward trajectory. The increasing focus on creating smart packaging and functional textiles also generates continuous demand for high-performance, easy-to-apply conductive materials.

Conductive Ink Pen Market Executive Summary

The Conductive Ink Pen Market is characterized by robust growth driven primarily by increasing adoption in educational technology and rapid prototyping segments globally. Business trends indicate a shift toward developing specialized ink formulations, particularly those featuring lower resistance and improved flexibility for use in advanced flexible and stretchable electronics. Key market players are focusing on strategic partnerships with educational institutions and open-source hardware communities to expand product visibility and utilization among a broader demographic. Furthermore, environmental considerations are beginning to influence product development, pushing manufacturers toward less toxic solvent bases and more sustainable metal precursors.

Regional trends highlight the Asia Pacific (APAC) as the fastest-growing region, fueled by massive manufacturing bases for consumer electronics and a strong emphasis on technological education in countries like China, Japan, and South Korea. North America and Europe maintain significant market shares, driven by high R&D spending, active maker cultures, and the established presence of large aerospace and defense contractors utilizing these pens for quick component repairs and customized sensor integration. The market structure remains moderately fragmented, with a few specialized material science companies dominating high-performance ink production, while numerous smaller entities compete fiercely in the consumer and educational segments.

Segmentation trends show that the silver-based conductive ink pen segment dominates in terms of revenue due to superior conductivity and reliability, despite their higher cost. However, the copper and carbon-based segments are experiencing rapid volume growth, particularly in cost-sensitive applications like educational kits and low-frequency circuit drawing. In terms of application, R&D and prototyping consistently hold the largest market share, though the consumer electronics repair segment is poised for significant expansion as the durability and ease of use of these pens improve, facilitating DIY repair initiatives and extending product lifecycles.

AI Impact Analysis on Conductive Ink Pen Market

Common user questions regarding the impact of Artificial Intelligence on the Conductive Ink Pen Market frequently revolve around how AI-driven design tools will integrate with manual circuit creation, whether AI can optimize ink material composition, and if AI will lead to the automated replacement of manual prototyping methods. Users are concerned about whether their ability to rapidly prototype using physical tools will become obsolete as sophisticated AI design algorithms take over, generating fully optimized designs that bypass the 'sketching' phase. Conversely, there is significant interest in using AI to analyze circuit drawings created by these pens to provide immediate feedback on electrical performance, layout efficiency, and potential fault points, effectively turning the pen into a smart design input device.

The key thematic convergence is that AI is unlikely to replace the physical act of using conductive pens but will instead augment it, transforming manual prototyping into an 'assisted intelligence' workflow. AI algorithms are already being deployed to analyze the complex rheology and nanoparticle suspension stability necessary for highly consistent ink flow, directly improving the manufacturing quality of the pens themselves. Furthermore, in educational contexts, AI-powered systems can interpret user-drawn circuits and offer real-time diagnostic guidance, accelerating the learning curve for electronics students. This symbiosis ensures the continued relevance of the conductive pen as an intuitive physical interface for circuit design, enhanced by digital intelligence.

AI's influence is expected to particularly impact the customization and personalized manufacturing segments. For example, AI could analyze a user's specific application requirements (e.g., flexibility tolerance, required resistance, operational temperature) and recommend the precise conductive ink pen formulation and substrate combination, optimizing material selection at the individual user level. This shift from generalized product offerings to hyper-personalized material solutions, guided by AI analysis of design parameters, significantly elevates the utility and precision of conductive ink pens in professional settings, confirming their role as critical tools in the iterative design process rather than being relegated by automation.

- AI-driven optimization of conductive nanoparticle synthesis and ink formulation for improved consistency and lower resistance.

- Integration of AI image recognition software to instantly analyze hand-drawn circuits and provide real-time electrical performance diagnostics and fault detection.

- Development of AI-powered design tools that translate conceptual sketches drawn with conductive pens into formalized CAD or PCB layouts.

- Enhanced personalized material recommendation systems utilizing machine learning to match specific ink types to complex application requirements (e.g., stretchable electronics, high-frequency use).

- AI utilization in quality control during the manufacturing process to monitor ink dispensing mechanisms and ensure uniform line width and conductivity.

DRO & Impact Forces Of Conductive Ink Pen Market

The Conductive Ink Pen Market is propelled by strong drivers centered around the global acceleration of rapid prototyping methodologies and the increasing accessibility of electronics design tools. Key restraints include the inherent limitations in conductivity compared to traditionally manufactured PCBs and the relatively high cost of silver-based formulations, which restricts broader adoption in highly price-sensitive consumer markets. Opportunities are abundant, specifically in developing novel ink chemistries that utilize cheaper, highly conductive alternatives (like graphene or advanced copper compounds) and expanding applications into large-format printed electronics and high-volume smart packaging. These forces create a dynamic environment where technological innovation directly impacts market equilibrium and expansion potential.

Drivers primarily include the burgeoning interest in DIY electronics and the rise of the maker movement globally, alongside significant institutional investment in STEM education utilizing hands-on prototyping tools. The rapid development cycle required for IoT devices and flexible sensors demands instantaneous feedback and modification capabilities, which conductive pens uniquely offer. Conversely, the market faces constraints due to durability issues; lines drawn with these pens are often susceptible to abrasion and chemical degradation compared to industrial-grade components. Furthermore, the maximum achievable current density and conductivity levels of pen-drawn traces may not meet the stringent requirements of high-power or high-speed digital circuits, thus limiting their professional use primarily to low-power signaling and conceptual prototyping.

Opportunities for exponential growth exist in leveraging advancements in nano-material science to overcome current conductivity limitations, potentially allowing conductive pens to enter the mainstream manufacturing repair market rather than just the prototype phase. The integration of conductive inks into functional textiles and biomedical sensors represents a high-growth avenue, requiring flexible, non-toxic, and washable traces. The impact forces affecting the market are fundamentally technological and economic; the decreasing price point of nanomaterials (economic impact) coupled with improved ink delivery systems (technological impact) exerts positive upward pressure. Regulatory scrutiny over heavy metal usage (environmental/social impact) serves as a moderating force, compelling manufacturers to innovate cleaner, safer alternatives, thereby influencing material selection and R&D direction globally.

Segmentation Analysis

The Conductive Ink Pen Market is systematically segmented based on the type of conductive material used, the primary application, and the end-use industry. This structure allows for precise market analysis regarding specific demand drivers and competitive landscapes within specialized niches. The material segmentation (Silver, Copper, Carbon, and Graphene) is critical, as it directly correlates with performance characteristics such as electrical conductivity, cost, and flexibility. The application segmentation differentiates between general prototyping, repair, R&D, and decorative purposes, highlighting the breadth of usage from specialized engineering labs to consumer hobby markets.

Analysis of these segments reveals that while Silver-based pens dominate in high-performance, critical repair applications due to their high electrical stability, Copper and Carbon segments are rapidly gaining traction, driven by their significant cost advantages and suitability for large-scale educational programs and entry-level prototyping where absolute conductivity is less paramount. Geographic segmentation remains crucial, linking market demand directly to regional manufacturing activity and educational policies. The robustness of the segmentation framework allows stakeholders to tailor their product offerings and marketing strategies to specific, high-potential market sub-segments, optimizing resource allocation and accelerating targeted growth.

Further detailed analysis shows that the end-use industry segmentation—spanning Consumer Electronics, Automotive, Healthcare, and Education—exhibits distinct growth patterns. The Healthcare segment, driven by the need for customized, disposable biosensors and wearable diagnostics, represents a high-value, niche market demanding non-toxic and highly flexible inks. Conversely, the Education segment relies on volume and affordability, necessitating cost-effective carbon or copper formulations. This granular segmentation provides a clear roadmap for manufacturers looking to diversify their portfolio beyond traditional electronics repair and prototyping.

- Material Type:

- Silver Ink Pens

- Copper Ink Pens

- Carbon Ink Pens

- Graphene and other Nanomaterial Ink Pens

- Application:

- Circuit Prototyping and Design

- PCB Trace Repair and Modification

- Educational and Hobbyist Applications

- R&D and Sensor Development

- Decorative and Art Applications

- End-Use Industry:

- Consumer Electronics

- Education and STEM

- Automotive and Aerospace

- Healthcare and Wearables

- Industrial and Manufacturing

- Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East & Africa (MEA)

Value Chain Analysis For Conductive Ink Pen Market

The value chain for the Conductive Ink Pen Market begins with upstream activities focused heavily on the sourcing and synthesis of conductive nanomaterials, primarily silver, copper, and specialized carbon or graphene particles. This upstream segment is highly specialized and requires sophisticated chemical engineering and material science expertise to ensure uniform particle size, stability in suspension, and optimal conductivity. Key challenges at this stage include managing the fluctuating commodity prices of metals and maintaining the proprietary chemical formulas that determine ink viscosity and curing properties, which are critical for the downstream pen manufacturing process.

Midstream activities involve the formulation of the conductive ink, including adding solvents, binders, and stabilizing agents, followed by the actual manufacturing, assembly, and packaging of the pen apparatus itself. Quality control at this stage is crucial, focusing on the consistent flow rate, tip durability, and shelf life of the final product. Distribution channels for conductive ink pens are bifurcated: direct distribution primarily targets large industrial clients, R&D labs, and educational distributors that require bulk or specialized technical support. Indirect distribution, encompassing e-commerce platforms, electronics component retailers, and hobbyist stores, serves the broader consumer and small-to-medium enterprise (SME) market, capitalizing on the product's accessible nature.

Downstream activities include marketing, sales, and end-user engagement, where the product's value proposition—rapid prototyping and accessible repair—is communicated. The proximity to end-users is vital; direct engagement through specialized forums, technical workshops, and collaboration with STEM educators helps drive adoption and feedback for product improvement. The efficiency of the value chain is determined by the ability of manufacturers to secure stable, low-cost access to high-quality nanomaterials (upstream efficiency) and their effectiveness in reaching geographically dispersed niche markets through optimized e-commerce and retail partnerships (downstream efficiency).

Conductive Ink Pen Market Potential Customers

The primary potential customers and end-users of conductive ink pens span several distinct sectors, unified by the common need for rapid, localized, and flexible electronic circuit creation or repair. The largest customer segment encompasses researchers and developers in institutional settings and private R&D labs who utilize these pens for designing customized sensors, testing new circuit topologies quickly, and performing low-volume, specialized additive manufacturing. These users prioritize high conductivity, durability, and precise application mechanisms, often opting for premium silver-based solutions to guarantee performance repeatability in experimental conditions.

A rapidly expanding segment consists of educational institutions, ranging from primary schools integrating basic electronics into STEM curricula to universities utilizing the pens in engineering coursework. This customer base seeks highly safe, non-toxic, and affordable carbon or copper-based pens in bulk, prioritizing ease of use and pedagogical value over maximum conductivity. The DIY hobbyist and maker community constitutes a significant consumer market, leveraging the pens for personal projects, creative electronics art, and quick home repairs of common electronic gadgets, driven largely by affordability and accessibility through major online retail channels.

Furthermore, established industrial customers in the aerospace, defense, and automotive sectors represent high-value targets, utilizing conductive pens for mission-critical, localized PCB trace repairs in complex equipment where replacing an entire circuit board is impractical or too costly. This application demands extremely reliable, military-grade compatible inks. Emerging customer groups include manufacturers of flexible electronics and smart packaging, who are starting to integrate conductive pen technology into their workflows for customized component marking or prototyping flexible circuit layouts before scaling up to industrial printing methods.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 85 million |

| Market Forecast in 2033 | USD 181 million |

| Growth Rate | 11.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bare Conductive Ltd., Circuit Scribe (Electroninks Incorporated), Creative Materials Inc., MG Chemicals, Loctite (Henkel AG & Co. KGaA), Johnson Matthey, DuPont, Novacentrix, Agfa-Gevaert NV, Advanced Nano Products Co. Ltd., Sun Chemical, Methode Electronics, Inc., Creative Materials Inc., Poly-Ink, Vorbeck Materials, Fujikura Ltd., Heraeus Group, Cima NanoTech, Pchem Associates Inc., Shenzhen Nanomaterials Technology Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Conductive Ink Pen Market Key Technology Landscape

The technology underpinning the Conductive Ink Pen Market is primarily rooted in advanced nanomaterial synthesis and precision dispensing systems. The core innovation involves creating stable suspensions of conductive nanoparticles (typically 1-100 nm in size) within a volatile solvent base and a polymer binder system. Silver nanoparticles remain the gold standard due to their intrinsically high conductivity and resistance to oxidation, requiring sophisticated chemical processes to prevent aggregation and maintain uniform dispersion, which is crucial for achieving continuous, low-resistance traces when drawn. Alternative technologies are rapidly emerging, focusing on high-aspect-ratio nanomaterials like Graphene and Carbon Nanotubes (CNTs) to enhance mechanical flexibility and reduce material cost, pushing the boundaries of stretchable electronics applications.

Beyond the ink chemistry, a significant technological component is the pen tip design and reservoir system, which dictates the performance, line width consistency, and reliability of the drawing process. Manufacturers employ specialized capillary or spring-loaded dispensing mechanisms engineered to handle the high viscosity of nanoparticle inks without clogging while ensuring a continuous, controlled flow rate. Recent technological developments involve thermally curable inks and UV-curable inks, which dramatically reduce the drying time and improve the durability and adhesion strength of the drawn traces, moving the pens closer to suitability for semi-permanent or professional application environments. This focus on rapid curing is essential for speeding up the prototyping and repair cycle.

Current R&D efforts are heavily concentrated on developing highly conductive, non-toxic, and economically viable ink formulations, particularly copper-based inks that must overcome the severe challenge of copper oxidation. Innovations include encapsulated copper nanoparticles or the use of specific surface treatments that protect the metal from air exposure until curing. Furthermore, the integration of smart sensor technology within the pen itself is a futuristic development; incorporating small sensors or microprocessors could enable the pen to measure the resistance of the line being drawn in real-time, providing immediate electrical feedback to the user, effectively merging the physical tool with digital diagnostics for enhanced accuracy and learning.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market, largely due to its dominance in global electronics manufacturing (China, South Korea, Japan) and massive investments in advanced educational programs (STEM). The high volume of PCB fabrication and the subsequent need for precise, localized repair solutions drive the professional segment. Furthermore, the region is a global hub for flexible electronics and smart textile innovation, accelerating the adoption of novel, high-performance conductive inks.

- North America: Characterized by high R&D spending and a strong 'maker' culture, North America holds a significant market share. Demand is primarily driven by academic research institutions, defense contractors utilizing rapid prototyping for specialized electronic components, and a robust consumer market for DIY electronics kits. This region often leads in adopting premium, silver-based inks for critical, high-performance applications.

- Europe: Growth in Europe is steady, fueled by the automotive and aerospace industries requiring fast, reliable trace repair, alongside strong governmental support for technological education across member states. Central European countries are major consumers of these pens for industrial maintenance applications and institutional research into sensor technology and IoT integration. Sustainability regulations are notably influencing a shift toward environmentally friendly, non-silver ink formulations.

- Latin America (LATAM): This region is an emerging market, driven primarily by expanding educational initiatives focusing on practical engineering skills and the nascent growth of localized electronics assembly industries in countries like Brazil and Mexico. The market here is highly price-sensitive, leading to a preference for more economical carbon and copper-based conductive pens, focusing on volume and accessibility.

- Middle East and Africa (MEA): Currently the smallest market, MEA shows future potential tied to increased government investment in technology infrastructure and smart city development (UAE, Saudi Arabia). The adoption is still early stage, concentrating mostly within specialized university engineering departments and industrial maintenance operations, often importing high-end products for strategic technical applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Conductive Ink Pen Market.- Bare Conductive Ltd.

- Circuit Scribe (Electroninks Incorporated)

- Creative Materials Inc.

- MG Chemicals

- Loctite (Henkel AG & Co. KGaA)

- Johnson Matthey

- DuPont

- Novacentrix

- Agfa-Gevaert NV

- Advanced Nano Products Co. Ltd.

- Sun Chemical

- Methode Electronics, Inc.

- Poly-Ink

- Vorbeck Materials

- Fujikura Ltd.

- Heraeus Group

- Cima NanoTech

- Pchem Associates Inc.

- Shenzhen Nanomaterials Technology Co., Ltd.

- Taiyo Ink Mfg. Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Conductive Ink Pen market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference in performance between silver and carbon conductive ink pens?

Silver-based conductive ink pens offer significantly superior electrical conductivity and reliability, making them ideal for high-performance circuit repair and professional R&D. Carbon-based pens are substantially cheaper and more flexible but possess higher electrical resistance, restricting their use mainly to low-power circuits, general prototyping, and educational applications.

In which applications are conductive ink pens replacing traditional Printed Circuit Boards (PCBs)?

Conductive ink pens are generally used to augment, not replace, traditional PCBs. They are critical tools for rapid prototyping, localized repair of PCB traces that fail inspection, customized small-scale wearable sensor design, and creating conceptual electronic sketches, offering immediate, on-the-spot modification capabilities that rigid PCBs cannot.

Are there environmentally friendly alternatives to heavy metal-based conductive inks?

Yes, ongoing research focuses on developing high-performance alternatives utilizing materials such as advanced carbon nanotubes (CNTs), graphene, and specialized hybrid polymers. These materials offer reduced toxicity and improved flexibility, addressing sustainability concerns while maintaining suitable conductivity for many low-voltage and flexible electronic applications.

How long do traces drawn with a conductive ink pen typically last?

The lifespan depends heavily on the ink formulation (e.g., silver inks generally last longer) and environmental factors. High-quality, properly cured traces on stable substrates can last for years under normal indoor conditions. However, traces are generally less resistant to abrasion, moisture, and chemical exposure compared to industrial etching processes and may require protective clear coats for enhanced durability.

What is driving the growing demand for conductive ink pens in the education sector?

The demand is driven by the global focus on experiential STEM education and the 'maker movement.' Conductive pens provide a safe, accessible, and intuitive way for students to learn fundamental electronics principles by physically drawing and testing circuits, greatly accelerating the understanding of concepts like connectivity, resistance, and circuit design compared to purely theoretical instruction.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager