Constant Velocity Universal Joint Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439158 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Constant Velocity Universal Joint Market Size

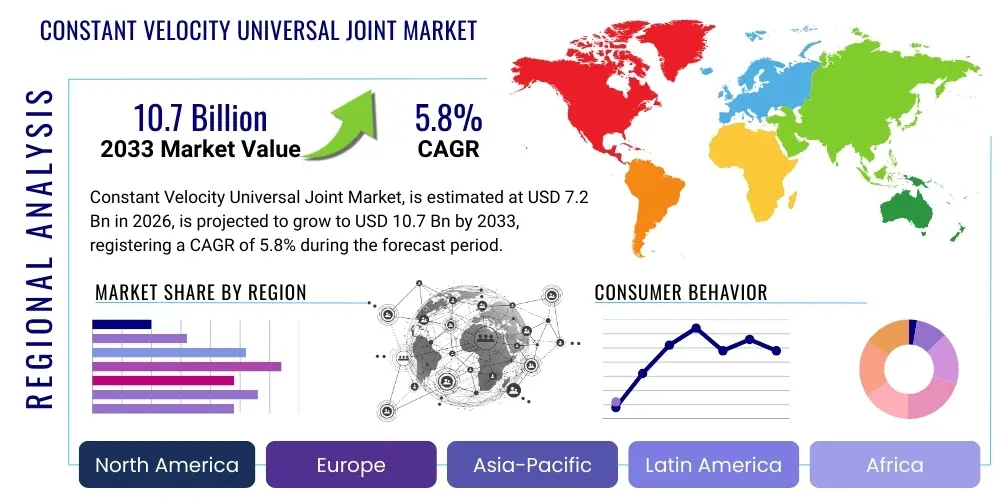

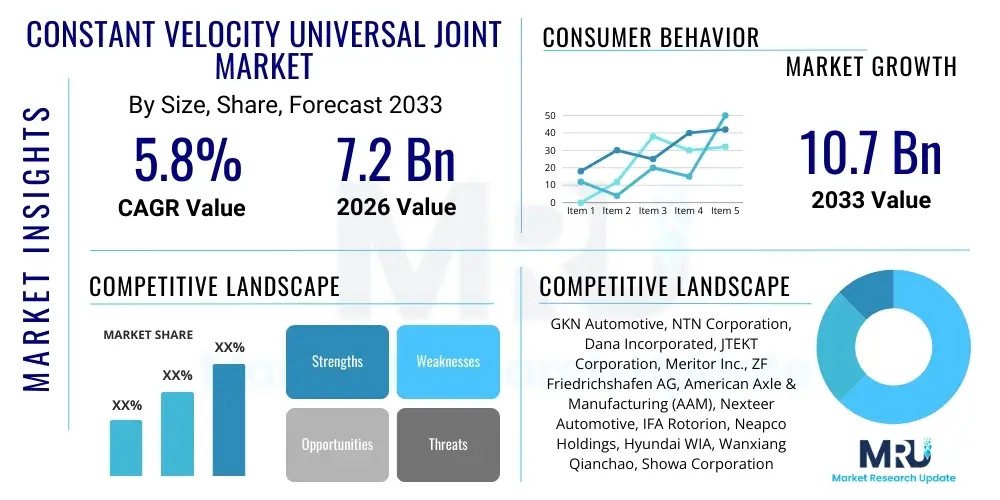

The Constant Velocity Universal Joint Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 7.2 Billion in 2026 and is projected to reach USD 10.7 Billion by the end of the forecast period in 2033.

Constant Velocity Universal Joint Market introduction

The Constant Velocity Universal Joint (CVUJ), commonly known as the CV joint, is a mechanical component integral to the powertrain system, primarily responsible for transferring torque from the transmission or differential to the wheels at a constant rotational speed, regardless of the operating angle. This crucial function enables the wheels to move up and down with suspension travel without affecting the speed of rotation, ensuring smooth power delivery and maximizing vehicle control. CV joints are essential in front-wheel-drive (FWD), all-wheel-drive (AWD), and increasingly in rear-wheel-drive (RWD) vehicles employing independent suspension systems, allowing for the stable transmission of power under dynamic conditions.

The core applications of CV joints lie overwhelmingly within the automotive sector, encompassing passenger cars, light commercial vehicles (LCVs), and heavy-duty trucks. Beyond standard road vehicles, CV joints are also utilized in industrial machinery, agricultural equipment, and specialized off-road vehicles where consistent power transmission through varying angles is required. The primary benefits of using CV joints include superior efficiency in power transfer, reduced vibration and noise compared to older universal joints, and the capability to operate at higher articulation angles. These attributes are vital for modern vehicle design, particularly as manufacturers strive for enhanced comfort, performance, and efficiency.

Market growth is predominantly driven by the continuous expansion of the global automotive manufacturing sector, especially the surging demand for vehicles equipped with FWD and AWD configurations. Furthermore, the rapid adoption of electric vehicles (EVs) and hybrid vehicles is providing a significant impetus, as these powertrains also rely heavily on high-performance CV joints optimized for instant torque delivery and reduced weight. Strict regulatory standards concerning vehicle safety and performance, coupled with rising disposable incomes in emerging economies leading to higher vehicle ownership, further cement the necessity and demand for robust CV joint systems globally.

Constant Velocity Universal Joint Market Executive Summary

The Constant Velocity Universal Joint Market is experiencing robust expansion, driven primarily by favorable macroeconomic trends in global automotive production and a profound shift towards electric mobility. Business trends indicate a focus on material science innovation, particularly the adoption of lightweight, high-strength steels and composite materials to enhance fuel efficiency and accommodate the demanding torque characteristics of electric vehicles. Key manufacturers are consolidating their market position through strategic acquisitions and forging long-term partnerships with major automotive OEMs to secure supply chains and capitalize on next-generation vehicle platforms. The competitive landscape is characterized by intense R&D investment aimed at developing CV joints that offer higher articulation angles, superior durability, and reduced vibrational harmonics.

Regionally, the Asia Pacific (APAC) continues its dominance, fueled by the massive automotive production hubs in China, Japan, India, and South Korea, which cater both to domestic consumption and global export markets. North America and Europe, while established, are projected to show accelerated growth rates, largely attributable to stringent emission regulations compelling the market towards hybrid and electric vehicle architectures, requiring specialized and high-precision CV joint solutions. Latin America and the Middle East & Africa (MEA) are emerging as high-potential markets due to rising urbanization, infrastructural development, and increasing foreign investment in localized vehicle assembly plants, leading to greater demand for essential drivetrain components.

Segment trends reveal that the fixed-type CV joint segment holds the largest market share due to its widespread application in the inboard side of the driveshaft assembly. However, the plunging-type CV joint segment is forecast to exhibit the fastest growth, especially within high-performance and electric vehicle applications where greater plunge length is required to accommodate larger suspension travel and powertrain vibrations. By vehicle type, passenger cars remain the largest application segment, yet the battery electric vehicle (BEV) segment is rapidly increasing its proportional contribution, necessitating CV joints specifically designed for high rotational speeds and immediate, high-intensity torque delivery characteristic of EV motors.

AI Impact Analysis on Constant Velocity Universal Joint Market

User inquiries regarding AI's influence on the CVUJ market frequently center on how artificial intelligence can optimize the design, manufacturing efficiency, and predictive maintenance of these critical drivetrain components. Key user concerns revolve around whether AI-driven simulation tools can significantly reduce the weight of CV joints without compromising strength, how machine learning can enhance quality control during high-volume production, and the potential for AI algorithms to predict failure points in installed CV joints, thereby improving overall vehicle reliability and minimizing downtime. There is also significant interest in the use of Generative Design models to explore novel, high-performance geometries currently inaccessible through traditional CAD methods.

The implementation of AI and machine learning (ML) models is poised to revolutionize the Constant Velocity Universal Joint manufacturing lifecycle. In the design phase, AI-powered topology optimization and generative design software allow engineers to quickly iterate on complex geometries, leading to lighter, more durable, and cost-effective CV joint assemblies tailored precisely for specific vehicle performance requirements, particularly for high-torque electric powertrains. Furthermore, during the actual production process, ML algorithms are deployed to analyze real-time sensor data from forging, machining, and heat treatment lines, optimizing parameters instantly to reduce material waste, minimize defects, and ensure consistent quality control at high throughput levels.

Beyond the factory floor, AI integration extends into the operational phase through advanced vehicle diagnostics. Predictive maintenance systems utilize ML models trained on vast datasets of vibration, temperature, and torque profiles to identify subtle anomalies indicative of impending CV joint failure. This capability significantly shifts maintenance strategies from reactive replacement to proactive servicing, which is particularly valuable for fleet operators and commercial vehicle sectors where vehicle uptime is paramount. Ultimately, AI fosters an ecosystem of continuous improvement, enabling manufacturers to achieve higher product performance thresholds while simultaneously lowering operational costs and enhancing consumer safety.

- AI-driven Generative Design optimizes CV joint geometry for weight reduction and increased strength, crucial for EV performance.

- Machine Learning enhances quality control in forging and heat treatment processes, reducing defect rates and material scrap.

- Predictive maintenance algorithms use sensor data to forecast CV joint wear and failure, maximizing vehicle uptime.

- AI simulation models accelerate testing and validation cycles for new material compositions and design configurations.

- Automated vision systems powered by AI improve inspection accuracy during assembly, ensuring dimensional precision.

DRO & Impact Forces Of Constant Velocity Universal Joint Market

The Constant Velocity Universal Joint Market is strongly influenced by several interconnected factors encompassing technological push, economic demand, and regulatory pressures. The primary drivers are the escalating global production of passenger vehicles, particularly the growing market share of All-Wheel Drive and Front-Wheel Drive architectures that necessitate CV joints for optimal performance. Crucially, the rapid transition towards electric vehicles acts as a powerful driver, as EV powertrains require specialized CV joints capable of managing higher instantaneous torque and rotational speeds than traditional internal combustion engine (ICE) vehicles. Opportunities exist in the development of lightweight, robust, and noise-dampening CV joint solutions tailored specifically for the silent operation and high-performance demands of the EV segment.

Conversely, the market faces significant restraints. Fluctuations in raw material prices, particularly steel and specialized alloys required for CV joint manufacturing, place constant pressure on manufacturers' profit margins. Furthermore, the stringent quality and safety requirements mandate complex and expensive manufacturing processes, creating high barriers to entry for new players. The increasing lifespan and durability of modern CV joints, while beneficial for consumers, can slightly temper the demand for aftermarket replacements. The integration challenge of designing CV joints that seamlessly accommodate increasingly complex independent suspension systems and specialized driveline layouts in high-end vehicles also poses a technical restraint.

The impact forces driving the market are primarily demand-side related. Technological advancements in vehicle dynamics and chassis systems constantly raise the performance bar for CV joints, pushing manufacturers towards continuous innovation in materials and design. The ongoing trend of vehicle electrification dictates the future trajectory, forcing components to be lighter and more efficient. The market resilience, however, is bolstered by the essential, non-negotiable role CV joints play in vehicle operation, ensuring stable and reliable power delivery, which means that irrespective of economic cycles, the demand for this core component remains stable proportional to vehicle production volumes.

Segmentation Analysis

The Constant Velocity Universal Joint Market is meticulously segmented based on joint type, application, and vehicle type, allowing for precise market targeting and strategic analysis. Segmentation by joint type distinguishes between fixed joints, typically used on the wheel side (outboard), and plunging joints, used on the transmission side (inboard), each designed to handle specific movement requirements related to suspension travel. Application segmentation covers their usage across both OEM (Original Equipment Manufacturer) requirements during new vehicle production and the robust aftermarket segment catering to repairs and replacements, while vehicle type segmentation delineates demand across passenger cars, commercial vehicles, and off-highway equipment.

The fixed joint category, encompassing Rzeppa and tripod designs, currently dominates the market due to its necessity in delivering torque at higher steering angles, a ubiquitous feature in modern FWD and AWD cars. However, the fastest-growing segment is the plunging joint category, which includes tripod and double offset designs. These joints are seeing heightened adoption due to their superior ability to compensate for axial length changes caused by suspension movement, a feature highly valued in performance vehicles and long-travel suspension systems utilized in SUVs and trucks. Furthermore, the ongoing standardization of component specifications across global vehicle platforms influences manufacturing scales and efficiency within these segments.

Analysis by end-use highlights that the OEM segment accounts for the larger revenue share, directly tied to global vehicle production volumes. Nevertheless, the aftermarket segment provides critical profitability and stability, driven by the vast global vehicle parc and the need for periodic maintenance and replacement of worn components. The increasing average age of vehicles on the road, particularly in developed economies, ensures sustained demand for high-quality replacement CV joints, encouraging manufacturers to maintain robust distribution channels for this segment.

- By Joint Type:

- Fixed CV Joint (e.g., Rzeppa)

- Plunging CV Joint (e.g., Tripod, Double Offset)

- By Application:

- OEM (Original Equipment Manufacturer)

- Aftermarket

- By Vehicle Type:

- Passenger Cars

- Light Commercial Vehicles (LCVs)

- Heavy Commercial Vehicles (HCVs)

- Electric Vehicles (EVs)

- By Material Type:

- Steel (Carbon Steel, Alloy Steel)

- Aluminum and Composites (Emerging)

Value Chain Analysis For Constant Velocity Universal Joint Market

The Constant Velocity Universal Joint value chain begins with the upstream procurement of specialized raw materials, primarily high-strength, wear-resistant steel alloys and precise forging materials, which are critical for the durability and performance of the joint components. Upstream activities involve sophisticated metallurgical processes and material testing to ensure compliance with stringent automotive standards regarding fatigue life and load-bearing capacity. Suppliers of raw materials and specialized forging blanks hold significant leverage, especially given the strict quality control required, and strategic partnerships between CV joint manufacturers and metal suppliers are essential to mitigate price volatility and ensure a consistent supply of certified materials.

The core manufacturing process constitutes the midstream segment, encompassing precision forging, complex machining, specialized heat treatment (such as carburizing), and grinding operations to achieve the necessary dimensional accuracy and surface hardness. CV joint manufacturers invest heavily in highly automated production lines and quality assurance technologies to minimize tolerances and maximize production efficiency. Following manufacturing, assembly involves incorporating specialized seals, boots, and lubrication systems, which are vital for protecting the joint from contaminants and extending its operational life. Intellectual property related to joint design and specific manufacturing techniques provides a competitive advantage in this segment.

Downstream activities include the distribution and integration into the final application. Direct distribution channels involve supplying completed CV joint assemblies and driveshafts directly to Original Equipment Manufacturers (OEMs) for integration into new vehicle production lines. Indirect distribution channels focus on the global aftermarket, utilizing vast networks of independent distributors, wholesalers, and retail chains that supply garages and independent repair shops with replacement units. The complexity of the global supply chain, involving just-in-time delivery schedules for OEMs and widespread inventory management for the aftermarket, necessitates highly efficient logistics and strong partnerships with third-party logistics (3PL) providers to maintain market responsiveness.

Constant Velocity Universal Joint Market Potential Customers

Potential customers for Constant Velocity Universal Joints are diverse but highly concentrated within the mobility and heavy machinery sectors, primarily encompassing large-scale vehicle manufacturers who incorporate these components into their drivetrain systems. This group includes global automotive OEMs such as General Motors, Toyota, Volkswagen Group, Ford, and Stellantis, as well as emerging electric vehicle manufacturers like Tesla, Lucid, and Rivian, who require custom-engineered CV joints to manage their high-torque, battery-electric platforms. These customers prioritize components that offer superior reliability, reduced weight, and integration ease to meet performance targets and comply with safety regulations.

Another significant customer segment is the expansive global aftermarket, which consists of national and regional automotive parts distributors, major retail auto parts chains, and professional repair and maintenance workshops. These buyers drive demand for replacement CV joints, focusing intensely on quality-to-price ratio, availability, and warranty support. Aftermarket consumers often seek robust, easily installable solutions that meet or exceed OEM specifications. The continued aging of the global vehicle fleet ensures stable and recurring demand from this customer base, making them critical partners for sustaining revenue growth for CV joint suppliers.

Furthermore, specialized industrial and heavy-duty sectors represent niche, yet valuable, customers. This includes manufacturers of agricultural machinery (tractors, harvesters), construction equipment (excavators, loaders), and specialized off-road vehicles (military and mining equipment). These applications require extremely durable and heavy-duty CV joints designed to withstand harsh operating environments, high loads, and continuous duty cycles. Suppliers catering to this segment must meet highly specialized performance metrics, often involving customized material specifications and stringent testing protocols to ensure operational resilience in extreme conditions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 7.2 Billion |

| Market Forecast in 2033 | USD 10.7 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | GKN Automotive, NTN Corporation, Dana Incorporated, JTEKT Corporation, Meritor Inc., ZF Friedrichshafen AG, American Axle & Manufacturing (AAM), Nexteer Automotive, IFA Rotorion, Neapco Holdings, Hyundai WIA, Wanxiang Qianchao, Showa Corporation, Bharat Forge, Hitachi Astemo. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Constant Velocity Universal Joint Market Key Technology Landscape

The Constant Velocity Universal Joint market is continuously evolving through technological advancements aimed at optimizing torque capacity, reducing noise, vibration, and harshness (NVH), and minimizing overall weight to support stringent fuel economy and performance mandates. A primary focus lies in advanced material engineering, specifically the deployment of high-grade, micro-alloyed steels and advanced surface treatments, such as specialized nitriding and carbonitriding processes, which significantly enhance the fatigue life and wear resistance of the bearing surfaces and tracks. This material innovation is critical for CV joints operating under the high-stress conditions imposed by turbocharged engines and the instantaneous torque delivery of electric powertrains.

Another significant technological thrust is the emphasis on developing lightweight design methodologies. Manufacturers are increasingly utilizing precision forging and flow forming techniques to achieve near-net-shape components, minimizing waste and enhancing structural integrity. Furthermore, the integration of advanced computational fluid dynamics (CFD) and finite element analysis (FEA) software allows for the precise optimization of joint geometry, reducing mass in non-critical areas while maintaining or increasing strength in load-bearing zones. For electric vehicles, specific R&D efforts are concentrated on silent operation, leading to the development of enhanced grease formulas and improved boot materials that maintain sealing integrity under high rotational speeds and thermal stress, effectively mitigating NVH issues that are more pronounced in silent EVs.

Looking ahead, the shift towards modular driveline systems in both hybrid and pure electric platforms is necessitating highly compact and customizable CV joint solutions. The trend is moving towards components that can handle higher articulation angles (e.g., higher angle plunging joints) and offer better compliance with complex multi-link suspension setups. Smart manufacturing technologies, including highly automated robotics and sensors for real-time quality monitoring, are essential components of the modern CV joint production facility, ensuring consistency and achieving the tight tolerances required for high-speed operation. The focus remains squarely on delivering components that are durable, highly efficient, and integrated seamlessly into the advanced electronic controls of modern vehicles.

Regional Highlights

Regional dynamics play a crucial role in shaping the Constant Velocity Universal Joint Market, influenced by regional vehicle production volumes, regulatory environments, and the speed of electric vehicle adoption. Asia Pacific (APAC) dominates the global market, largely due to China and India's status as global manufacturing powerhouses with soaring domestic demand for automobiles. Japan and South Korea contribute significantly through established, high-volume manufacturing bases for global OEMs. The region’s strength is rooted in both the sheer volume of production and the widespread use of FWD architectures, although the rapid electrification initiatives in China are driving specific demand for next-generation CV joints optimized for EV assembly.

North America and Europe represent mature, high-value markets characterized by a strong consumer preference for large SUVs, light trucks, and premium vehicles, frequently equipped with complex AWD systems. This drives demand for specialized, high-performance CV joints capable of managing greater weight, higher torque, and extended durability requirements. Furthermore, Europe is at the forefront of the global electric vehicle transition, mandated by strict CO2 emission targets. This regulatory environment fuels innovation, making Europe a key regional hub for the adoption of lightweight, highly efficient CV joint technologies designed specifically for hybrid and battery electric vehicle platforms.

Latin America and the Middle East & Africa (MEA) are characterized by developing manufacturing capabilities but exhibit high growth potential. Latin America, particularly Brazil and Mexico, serves as important regional production bases for global OEMs, generating steady demand for CV joints both for new vehicles and a substantial aftermarket fueled by challenging road conditions. The MEA region is witnessing growing foreign investment and infrastructure development, which, alongside increasing disposable incomes, supports long-term growth in vehicle ownership and subsequent demand for drivetrain components and robust aftermarket maintenance services.

- Asia Pacific (APAC): Dominates the market share due to high-volume automotive manufacturing (China, India, Japan) and robust consumer demand for passenger vehicles; key growth driver is EV market expansion.

- Europe: High-value market segment driven by stringent emission regulations and rapid acceleration of EV and hybrid vehicle production; focus on premium, lightweight, and high-precision CV joints.

- North America: Significant market driven by high demand for SUVs and light trucks requiring high-torque AWD systems; strong aftermarket presence due to aging vehicle fleet.

- Latin America: Emerging market characterized by regional manufacturing hubs and a substantial demand for durable aftermarket components due to poor road conditions.

- Middle East and Africa (MEA): Growth attributed to infrastructure investment, increasing vehicle penetration, and reliance on imported automotive parts for maintenance.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Constant Velocity Universal Joint Market.- GKN Automotive

- NTN Corporation

- Dana Incorporated

- JTEKT Corporation

- Meritor Inc.

- ZF Friedrichshafen AG

- American Axle & Manufacturing (AAM)

- Nexteer Automotive

- IFA Rotorion

- Neapco Holdings

- Hyundai WIA

- Wanxiang Qianchao

- Showa Corporation

- Bharat Forge

- Hitachi Astemo

- Addax Driveshafts

- NKN Ltd.

- Qingdao Globalstar CV Joint Co., Ltd.

- Sichuan Jian'an Group

- Metaldyne Performance Group (MPG)

Frequently Asked Questions

Analyze common user questions about the Constant Velocity Universal Joint market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary driving factor for the Constant Velocity Universal Joint Market growth?

The primary driving factor is the escalating global production of passenger vehicles, particularly the widespread adoption of Front-Wheel Drive and All-Wheel Drive configurations, coupled with the rapid, worldwide transition towards electric vehicles (EVs) which require highly specialized, torque-resistant CV joints.

How are electric vehicles impacting the demand and design of CV joints?

EVs significantly impact the market by demanding CV joints capable of handling high instantaneous torque delivery, operating at reduced noise levels (NVH), and possessing lighter weight for improved battery range. Manufacturers are focusing on advanced materials and high-angle plunging joint designs to meet these specific EV requirements.

Which geographical region holds the largest market share for CV universal joints?

The Asia Pacific (APAC) region currently holds the largest market share, driven primarily by the massive scale of automotive manufacturing in countries like China, India, and South Korea, catering to both expansive domestic markets and global export demands.

What are the key technological advancements expected in the CV joint industry?

Key technological advancements focus on lightweighting through precision forging and the use of specialized steel alloys, coupled with the integration of AI-driven generative design tools to optimize joint geometry for enhanced fatigue resistance and noise reduction, particularly for high-speed EV applications.

Is the aftermarket segment for Constant Velocity Universal Joints growing?

Yes, the aftermarket segment demonstrates steady growth, supported by the increasing average age and size of the global vehicle fleet, which necessitates ongoing maintenance, repair, and replacement of drivetrain components, ensuring stable revenue generation for suppliers.

What is the difference between fixed and plunging CV joints?

Fixed CV joints, like the Rzeppa type, transmit torque at constant velocity and are typically used on the outboard (wheel) side where high steering angles are needed. Plunging CV joints, such as the tripod type, allow for axial movement (plunge) along the shaft, necessary to accommodate changes in length due to suspension travel, and are usually fitted on the inboard (transmission) side.

What raw materials are critical for manufacturing CV joints?

The manufacturing of high-performance CV joints relies heavily on specialized high-strength materials, primarily alloy steels (such as high-carbon or chrome-molybdenum steel) that undergo complex heat treatments to achieve the required hardness, toughness, and superior wear resistance necessary for bearing surfaces.

How does quality control impact the cost structure in CV joint manufacturing?

Quality control is a major cost driver due to the extremely tight dimensional tolerances and stringent metallurgical requirements. Manufacturers must invest significantly in advanced inspection equipment, automated monitoring systems, and rigorous testing protocols to prevent defects, as failure of a CV joint can lead to catastrophic vehicle breakdown.

Are CV joints used in heavy commercial vehicles (HCVs)?

While traditional universal joints (U-joints) were more common in HCVs, modern heavy commercial vehicles, particularly those utilizing independent suspension systems or complex multi-axle configurations, are increasingly adopting large, heavy-duty CV joints to provide smoother, more efficient power transfer and enhanced driver comfort, especially in urban transport applications.

What are the typical operating temperature challenges faced by CV joints?

CV joints face thermal challenges arising from friction and close proximity to engine components and brakes. Operating temperatures can degrade lubricants and damage the protective rubber boots (gaiters). Manufacturers address this by developing high-performance, heat-resistant greases and specialized thermoplastic or silicone boots to ensure long-term sealing integrity and component protection.

How does the shift towards autonomous vehicles affect CV joint demand?

The shift towards autonomous vehicles (AVs) indirectly supports CV joint demand as AVs rely heavily on robust, highly reliable driveline systems, often utilizing AWD or complex electric drive systems. Furthermore, AV component suppliers demand zero-failure rate components, pushing CV joint manufacturers to further enhance quality and precision.

What role does lubrication play in CV joint lifespan?

Lubrication is paramount; the specialized high-pressure, molybdenum-based grease used inside the CV joint minimizes friction between the balls and races, dissipates heat, and prevents corrosion. Failure of the protective boot leading to grease loss or contamination is the leading cause of CV joint failure, making lubricant retention critical for maximizing lifespan.

What is meant by the term "driveshaft boot integrity" in the context of CV joints?

"Driveshaft boot integrity" refers to the condition and sealing capability of the protective rubber or thermoplastic bellows (boot) surrounding the CV joint. Maintaining integrity is essential as the boot prevents road contaminants (dirt, water, grit) from entering the joint and retains the critical internal grease, thereby preserving the joint's function and extending its operational life.

How do global trade tensions and tariffs impact the Constant Velocity Universal Joint Market?

Global trade tensions and the imposition of tariffs primarily affect the market by increasing the cost of imported raw materials (steel, alloys) and finished components, leading to supply chain disruptions and forcing OEMs and suppliers to localize manufacturing or absorb higher operational costs, thereby influencing final vehicle pricing.

What are the competitive strategies adopted by leading CV joint manufacturers?

Leading manufacturers employ strategies such as aggressive R&D investment focused on lightweight materials and NVH reduction, forging strong, long-term supply agreements with major global OEMs, strategic vertical integration (controlling raw material sourcing to assembly), and expanding manufacturing footprints in high-growth regions like APAC.

Is there a trend toward consolidation among CV joint manufacturers?

Yes, the industry exhibits a trend toward consolidation, driven by the necessity for economies of scale, access to specialized patented technologies, and the need to offer comprehensive driveline solutions to global vehicle platforms. Mergers and acquisitions are common methods used to secure market share and enhance technological capabilities.

How important is standardization in CV joint design across different vehicle models?

Standardization is highly important, especially for mass-market vehicles. It allows manufacturers to utilize modular designs and high-volume production techniques, driving down unit costs and simplifying inventory management for both OEMs and the aftermarket. However, high-performance or specialized EV applications often require proprietary, customized designs.

What is the main environmental concern related to CV joint production?

The main environmental concern centers around the energy-intensive nature of steel production and subsequent forging processes. Efforts are being made to mitigate this through improved material recycling, highly efficient manufacturing processes, and the exploration of lightweight, lower-carbon footprint materials such as aluminum alloys and composites in non-critical areas.

How does the demand for higher articulation angles influence CV joint design?

Increased demand for higher articulation angles, common in SUVs and off-road vehicles with long suspension travel, requires specialized CV joint designs (like double offset plunging joints) and optimized ball-race geometry to maintain constant velocity and minimize friction even when operating at extreme angles, ensuring stable power delivery.

What is the role of simulation software in modern CV joint development?

Simulation software, including Finite Element Analysis (FEA) and fatigue modeling, is crucial. It allows engineers to digitally test various design iterations under simulated real-world conditions (load, speed, temperature) before physical prototyping. This drastically reduces development time and cost while optimizing component strength, weight, and lifespan.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager