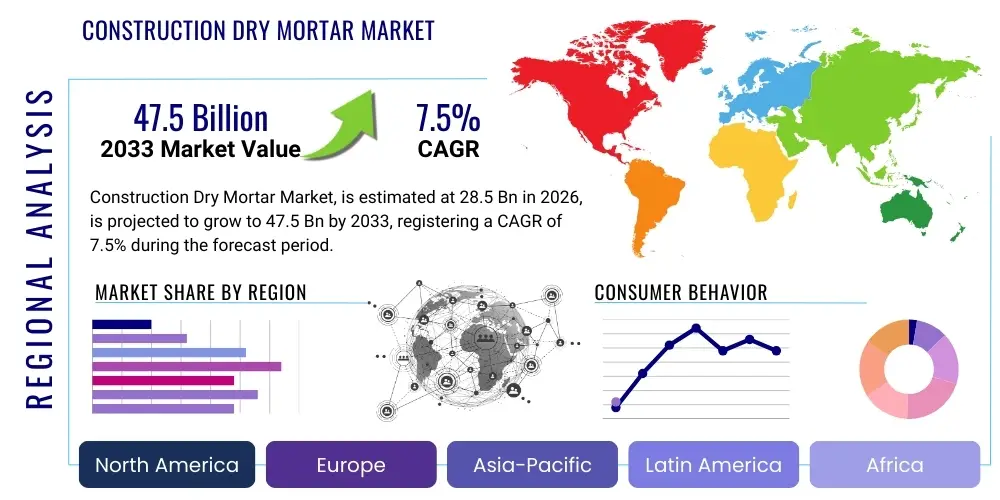

Construction Dry Mortar Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439219 | Date : Jan, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Construction Dry Mortar Market Size

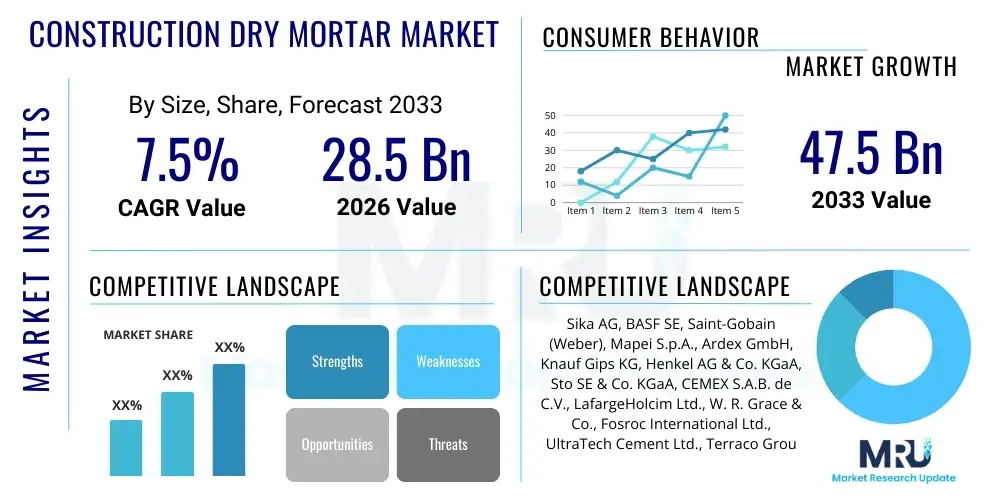

The Construction Dry Mortar Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 28.5 billion in 2026 and is projected to reach USD 47.5 billion by the end of the forecast period in 2033.

Construction Dry Mortar Market introduction

The construction dry mortar market encompasses a wide array of factory-blended mixtures of inorganic binders, aggregates, additives, and polymers, delivered in a dry, ready-to-use form. These specialized formulations require only the addition of water at the job site, offering enhanced convenience, consistency, and performance compared to traditional site-mixed mortars. Products range from sophisticated tile adhesives, renders, and plasters to self-leveling compounds, grouts, and repair mortars, each engineered for specific building applications. Their superior characteristics, such as improved workability, adhesion, durability, and reduced material waste, make them indispensable in modern construction practices across residential, commercial, and infrastructure projects. The market is propelled by rapid urbanization, extensive infrastructure development, increasing demand for high-performance and sustainable building materials, and the critical need for efficient and consistent construction processes.

These advanced mortar solutions are designed to address diverse construction challenges, ranging from structural integrity and thermal insulation to aesthetic finishing and repair works. Key applications include external thermal insulation composite systems (ETICS), flooring solutions, masonry work, and façade finishes, alongside specialized uses in waterproofing and concrete repair. The inherent benefits of dry mortars, such as superior quality control due to factory pre-mixing, enhanced durability, reduced labor intensity, and minimized on-site mixing errors, contribute significantly to project efficiency and longevity. Furthermore, their versatility allows for customization to specific climatic conditions and performance requirements, ensuring optimal results in various construction environments. The driving factors for market expansion are deeply rooted in global construction trends, including the shift towards prefabrication and modular construction, the imperative for sustainable and green building materials, and the continuous innovation in polymer and additive technologies that improve mortar performance and application versatility.

The market's evolution is also characterized by a growing emphasis on environmental considerations, leading to the development of eco-friendly dry mortar formulations with reduced carbon footprints and improved energy efficiency. Manufacturers are increasingly investing in research and development to produce high-performance, sustainable products that meet stringent regulatory standards and consumer demands for green building solutions. This focus on innovation not only broadens the application scope of dry mortars but also enhances their competitive edge against traditional alternatives. The inherent advantages of dry mortars, such as precise composition, extended shelf life, and ease of transportation and storage, further solidify their position as a preferred choice in the global construction industry. This dynamic landscape, driven by technological advancements and evolving construction demands, positions the dry mortar market for sustained growth, offering significant opportunities for manufacturers, suppliers, and construction professionals alike.

Construction Dry Mortar Market Executive Summary

The Construction Dry Mortar Market is experiencing robust growth, primarily fueled by the accelerating pace of global urbanization, extensive infrastructure development projects, and a surging demand for high-performance and sustainable building materials. Business trends indicate a strong move towards factory-produced, quality-controlled construction solutions that minimize on-site labor and waste while maximizing durability and efficiency. This shift is particularly evident in emerging economies where rapid construction is underway, and in developed regions focusing on renovation, repair, and green building initiatives. Manufacturers are increasingly investing in automation and specialized production lines to meet diverse product specifications and maintain consistent quality. Strategic partnerships and mergers are also prevalent as companies seek to expand their geographic reach, technological capabilities, and product portfolios, consolidating market presence and enhancing competitive advantage.

Regionally, Asia Pacific stands out as the dominant growth engine, driven by massive investments in residential and commercial infrastructure in countries like China, India, and Southeast Asian nations. North America and Europe demonstrate mature market characteristics, with growth primarily stemming from renovation, retrofitting, and the adoption of advanced, eco-friendly dry mortar systems. Latin America and the Middle East & Africa regions are witnessing significant expansion due to urbanization projects, tourism-related infrastructure development, and diversification away from hydrocarbon-dependent economies. Each region presents unique challenges and opportunities, influenced by local construction practices, regulatory frameworks, and economic cycles, necessitating tailored market penetration strategies. The demand for energy-efficient building solutions and stringent environmental regulations are particularly shaping regional market dynamics, pushing for innovative product development and application techniques.

From a segmentation perspective, specialized products such as tile adhesives and plasters continue to hold substantial market shares due to their widespread use in both new construction and renovation activities. Self-leveling compounds are gaining traction, especially in commercial and industrial flooring applications, driven by the demand for smooth, durable, and rapidly installed floor finishes. The repair mortar segment is also witnessing steady growth, propelled by the aging infrastructure in developed countries and the need for cost-effective maintenance solutions. Furthermore, the market is seeing increased adoption of dry mortars in external insulation and finish systems (EIFS) and external thermal insulation composite systems (ETICS), underscoring the broader trend towards energy-efficient building envelopes. The versatility and performance advantages across various product types and applications underpin the market's resilience and potential for sustained expansion, with continuous innovation in binder chemistry and additive technology further enhancing product capabilities and market penetration.

AI Impact Analysis on Construction Dry Mortar Market

Users frequently inquire about how artificial intelligence (AI) will transform the traditionally manual processes within the construction dry mortar market, specifically focusing on improved formulation accuracy, automated quality control, optimized supply chains, and enhanced predictive maintenance for production equipment. There is significant interest in AI's potential to revolutionize product development through data-driven insights into material properties and performance, leading to more sustainable and high-performing mortar solutions. Concerns often revolve around the initial investment costs, the need for skilled personnel to implement and manage AI systems, and the potential disruption to established manufacturing and application practices. However, expectations are high for AI to drive unprecedented efficiencies, reduce material waste, accelerate innovation, and elevate overall product quality across the industry value chain.

- AI-driven optimization of dry mortar formulations, enhancing performance characteristics and reducing material consumption through predictive modeling.

- Automated quality control systems on production lines, utilizing computer vision and machine learning for real-time defect detection and consistency monitoring.

- Predictive maintenance for manufacturing equipment, minimizing downtime and increasing operational efficiency through AI-powered anomaly detection.

- Supply chain optimization, leveraging AI for demand forecasting, inventory management, and logistics planning to reduce costs and improve delivery times.

- Enhanced R&D capabilities through AI analysis of material science data, accelerating the development of novel binders, additives, and sustainable formulations.

- Smart application guidance and robotics integration for on-site mortar application, improving precision, speed, and safety in complex tasks.

- Data analytics for market trend identification, enabling manufacturers to tailor product offerings to evolving customer needs and regional demands.

- Improved environmental footprint assessment and optimization throughout the product lifecycle, from raw material sourcing to end-of-life considerations, using AI.

- Augmented reality (AR) and AI for training construction personnel on optimal dry mortar mixing and application techniques, ensuring consistent quality.

DRO & Impact Forces Of Construction Dry Mortar Market

The Construction Dry Mortar Market is significantly influenced by a complex interplay of driving forces, restraining factors, and emerging opportunities that collectively shape its growth trajectory and competitive landscape. Key drivers include accelerating urbanization and infrastructure development, particularly in developing economies, alongside a growing global demand for high-performance, sustainable, and convenient building materials. However, the market faces restraints such as volatile raw material prices, stringent environmental regulations, and a shortage of skilled labor for application. Despite these challenges, substantial opportunities arise from the increasing adoption of green building practices, the proliferation of smart city initiatives, and continuous innovation in product formulations and application technologies, all of which contribute to an evolving market dynamic.

Drivers:

One of the primary drivers propelling the construction dry mortar market is the relentless pace of global urbanization and the corresponding surge in infrastructure development. As populations migrate to urban centers worldwide, there is an escalating need for residential, commercial, and industrial buildings, as well as critical infrastructure such as roads, bridges, and public facilities. Dry mortars, with their inherent advantages of superior quality, ease of application, and reduced construction time, are ideally suited to meet the demands of rapid and high-volume construction projects. This growth is particularly pronounced in emerging economies across Asia Pacific, Latin America, and the Middle East, where government-backed initiatives and private sector investments are fueling large-scale building endeavors, thereby driving substantial demand for reliable and efficient construction materials.

Furthermore, the increasing global emphasis on sustainable construction and green building practices acts as a significant catalyst for the dry mortar market. Modern construction projects are increasingly required to adhere to stringent environmental standards and achieve various sustainability certifications. Dry mortars contribute to these objectives by offering formulations with lower carbon footprints, improved energy efficiency in buildings (e.g., through external thermal insulation systems), and reduced waste generation on construction sites compared to traditional wet mixes. Innovations in dry mortar technology, such as the incorporation of recycled materials and the development of low-emission formulations, further align these products with sustainability goals, making them an attractive choice for environmentally conscious developers and builders. This trend is expected to intensify as regulatory pressures and consumer awareness regarding eco-friendly construction continue to grow.

Another crucial driver is the rising demand for high-performance building materials that offer enhanced durability, aesthetic appeal, and functional properties. Contemporary architecture and engineering demand materials that can withstand harsh environmental conditions, provide long-term structural integrity, and offer specialized performance characteristics like waterproofing, fire resistance, and acoustic insulation. Dry mortars, through precise formulation and the inclusion of advanced additives, deliver these superior properties consistently. This demand extends beyond new construction to extensive renovation and repair projects, especially in developed regions where aging infrastructure and buildings require robust and long-lasting restoration solutions. The consistency and quality control offered by factory-mixed dry mortars ensure reliable performance, minimizing rework and extending the lifecycle of structures, thereby offering significant value proposition to the construction industry.

Restraints:

A significant restraint impacting the construction dry mortar market is the volatility in raw material prices. Dry mortars rely on key components such as cement, sand, gypsum, and various chemical additives and polymers. The prices of these raw materials are subject to fluctuations due to global supply chain disruptions, energy costs, geopolitical events, and economic shifts. Such volatility directly affects the manufacturing costs of dry mortars, leading to unpredictable pricing for end-users and potentially eroding profit margins for producers. This uncertainty can deter investment in new production capacities and limit the ability of manufacturers to offer competitive pricing, especially in price-sensitive markets. Companies must implement robust sourcing strategies and engage in hedging to mitigate these financial risks, which adds another layer of complexity to their operations.

Moreover, the construction dry mortar market faces challenges from increasingly stringent environmental regulations. Governments worldwide are imposing stricter limits on emissions, waste disposal, and the use of certain chemicals in construction materials to promote sustainability and protect public health. While dry mortars generally offer environmental advantages over traditional mixes, compliance with evolving regulations can necessitate significant investments in research and development for new, eco-friendly formulations and cleaner production processes. This not only increases operational costs but also extends product development cycles, potentially slowing market innovation. Manufacturers must continually adapt their product portfolios and manufacturing practices to meet these evolving standards, which can be a complex and resource-intensive endeavor, particularly for smaller market players.

The shortage of skilled labor for the proper application of dry mortars also presents a considerable restraint. While dry mortars are designed for ease of use, achieving optimal performance requires adherence to specific mixing ratios, application techniques, and curing conditions. A lack of trained professionals can lead to improper application, resulting in suboptimal performance, increased material waste, and potential structural issues. This challenge is particularly acute in developing regions where formal training programs are less prevalent, but it also affects developed markets struggling with an aging workforce and a dwindling pool of new talent entering the construction trades. To counteract this, manufacturers and industry associations are investing in training programs and developing user-friendly application tools, but overcoming this widespread skill gap remains a persistent hurdle for market growth and the consistent delivery of high-quality construction outcomes.

Opportunities:

The burgeoning trend of green building and sustainable infrastructure development presents a significant opportunity for the construction dry mortar market. With a global push towards reducing the environmental footprint of the built environment, there is an escalating demand for construction materials that contribute to energy efficiency, resource conservation, and improved indoor air quality. Dry mortars, particularly those formulated with recycled content, low volatile organic compounds (VOCs), and insulating properties, are perfectly positioned to capitalize on this trend. Manufacturers can innovate by developing new eco-friendly product lines, obtaining relevant sustainability certifications (e.g., LEED, BREEAM), and actively promoting the environmental benefits of their solutions. This strategic alignment with green building initiatives opens up new market segments and strengthens the value proposition of dry mortars, appealing to environmentally conscious developers and governments.

The continuous technological advancements in formulation chemistry and application techniques also offer substantial growth opportunities. Research and development efforts are leading to the creation of next-generation dry mortars with enhanced performance characteristics such as faster curing times, superior flexibility, improved water resistance, and greater adhesion to diverse substrates. Innovations in polymer modification, nano-technology, and additive development are expanding the functional capabilities of dry mortars, enabling their use in more challenging and specialized applications, from high-rise structures to marine environments. Furthermore, advancements in automated mixing and spraying equipment are improving on-site efficiency and consistency, making dry mortars even more attractive to contractors. Investing in R&D and intellectual property will be key for companies looking to gain a competitive edge and unlock new market potential through superior product offerings.

The expansion into emerging markets, coupled with increasing disposable incomes and government investments in infrastructure, represents another substantial opportunity for the dry mortar market. Countries in Asia Pacific, Latin America, and Africa are experiencing rapid economic growth and urbanization, leading to massive construction booms. These regions often lack established traditional wet mix practices or have high labor costs for conventional methods, making factory-produced dry mortars an attractive and efficient alternative. As these economies mature and living standards rise, the demand for higher quality, durable, and aesthetically pleasing construction will escalate. Market players can leverage these demographics by establishing local production facilities, tailoring products to regional climatic conditions and building codes, and developing robust distribution networks to effectively penetrate these high-growth potential markets.

Segmentation Analysis

The Construction Dry Mortar Market is meticulously segmented to provide a granular understanding of its diverse components and dynamics. This segmentation is primarily based on product type, application, and end-use, allowing for precise market analysis and strategic planning. Each segment reflects unique material requirements, performance expectations, and market drivers, influencing product development and distribution strategies across the globe. Understanding these distinctions is crucial for identifying key growth areas and tailoring solutions to specific industry needs, ranging from specialized adhesives for high-end finishes to robust repair mortars for infrastructure projects.

- By Product Type:

- Tile Adhesives

- Plasters and Renders

- Masonry Mortars

- Grouts

- Self-Leveling Compounds

- Repair Mortars

- Waterproofing Mortars

- External Thermal Insulation Composite Systems (ETICS) Mortars

- Other Specialty Dry Mortars

- By Application:

- Residential Construction

- Commercial Construction

- Industrial Construction

- Infrastructure Projects (Roads, Bridges, Tunnels, etc.)

- By End-Use:

- New Construction

- Renovation and Repair

- By Region:

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Value Chain Analysis For Construction Dry Mortar Market

The value chain for the Construction Dry Mortar Market is a complex and interconnected network, beginning with the sourcing of raw materials and culminating in the end-user application of the finished product. Upstream activities involve the extraction and processing of essential components such as cement, aggregates (sand, limestone), gypsum, and the manufacturing of various chemical additives and polymers. These raw material suppliers form the foundational layer, providing critical inputs whose quality and cost directly influence the final product. Midstream operations encompass the sophisticated manufacturing processes where these dry ingredients are precisely blended in automated facilities to create the diverse range of dry mortar products, emphasizing quality control and consistency. This stage includes research and development efforts to formulate high-performance and specialized mortars, crucial for market competitiveness.

Downstream activities focus on the distribution and marketing of dry mortar products to a wide array of customers. This involves a multi-channel approach, leveraging both direct and indirect distribution networks. Direct channels typically involve sales teams engaging directly with large construction companies, government contractors, and specialized applicators, often for major projects or custom formulations. Indirect channels, which are more prevalent for broader market reach, include wholesalers, distributors, hardware stores, and building material retailers. These intermediaries play a vital role in reaching smaller contractors, individual builders, and DIY customers, ensuring product availability and offering technical support. Effective logistics and inventory management are paramount across these channels to ensure timely delivery and minimize costs.

The success of the value chain is heavily dependent on robust relationships between all stakeholders. Manufacturers often work closely with raw material suppliers to secure stable, high-quality inputs and manage cost fluctuations. Simultaneously, strong partnerships with distributors and retailers are essential for market penetration, product visibility, and customer service. Technical support and training provided by manufacturers to their distribution partners and end-users are also critical, ensuring proper product application and maximizing performance. The entire chain is underpinned by a continuous feedback loop from end-users, which informs product development and process improvements, driving innovation and market responsiveness. This intricate interplay of procurement, production, distribution, and customer engagement defines the efficiency and competitiveness of the construction dry mortar market.

Construction Dry Mortar Market Potential Customers

The potential customers for the Construction Dry Mortar Market are incredibly diverse, spanning the entire spectrum of the building and construction industry. These end-users typically include large-scale construction companies engaged in major residential, commercial, and infrastructure projects, who value the consistent quality, efficiency, and performance benefits of factory-blended mortars for their extensive needs. Also prominent are small to medium-sized contractors and independent builders, who benefit from the convenience, reduced on-site labor requirements, and ease of application that dry mortars offer, particularly for renovation and smaller new-build projects. Specialized applicators, such as tiling contractors, plastering firms, and flooring specialists, form another crucial customer segment, relying on specific dry mortar formulations engineered for their niche applications to achieve optimal results and meet stringent quality standards.

Beyond traditional construction entities, the market also targets real estate developers who prioritize speed of construction, durability, and cost-effectiveness in their projects. Government agencies involved in public works and infrastructure maintenance are significant buyers, utilizing dry mortars for repair, rehabilitation, and new development of roads, bridges, and municipal buildings. Furthermore, individual homeowners engaging in DIY projects, home improvement, or minor repairs also represent a growing customer base, accessible through retail channels. Architects and structural engineers, while not direct buyers, are influential in specifying dry mortar products due to their performance characteristics and compliance with building codes and design objectives, effectively driving demand through their recommendations and material selections for projects.

The increasing focus on sustainable construction and energy efficiency has also expanded the customer base to include developers and contractors specializing in green buildings and eco-friendly projects. These clients actively seek dry mortar solutions that contribute to environmental certifications, offer superior insulation properties, or incorporate recycled materials. The versatility of dry mortars means they cater to a broad spectrum of needs, from foundational masonry work to intricate decorative finishes and critical structural repairs. Therefore, understanding the varied requirements and purchasing behaviors of these diverse customer segments, from large institutional buyers to individual consumers, is paramount for manufacturers to effectively position their products, develop targeted marketing strategies, and maintain a competitive edge in this dynamic market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 28.5 Billion |

| Market Forecast in 2033 | USD 47.5 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sika AG, BASF SE, Saint-Gobain (Weber), Mapei S.p.A., Ardex GmbH, Knauf Gips KG, Henkel AG & Co. KGaA, Sto SE & Co. KGaA, CEMEX S.A.B. de C.V., LafargeHolcim Ltd., W. R. Grace & Co., Fosroc International Ltd., UltraTech Cement Ltd., Terraco Group, Dryvit Systems, Inc., ParexGroup (a subsidiary of Sika AG), Baumit GmbH, CP-Chem Ltd., Fassa Bortolo S.p.A., HB Fuller Company. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Construction Dry Mortar Market Key Technology Landscape

The Construction Dry Mortar Market is characterized by a dynamic and evolving technology landscape, with continuous advancements aimed at enhancing product performance, sustainability, and application efficiency. A pivotal aspect of this landscape involves sophisticated binder technologies, moving beyond traditional Portland cement to include various supplementary cementitious materials (SCMs) like fly ash, ground granulated blast-furnace slag (GGBS), and silica fume. These SCMs not only improve strength, durability, and workability but also contribute significantly to the environmental profile of dry mortars by reducing the reliance on high-carbon footprint clinker. Furthermore, the development of specialized polymer binders, such as redispersible polymer powders (RDPs), is critical for imparting flexibility, adhesion, water resistance, and freeze-thaw stability, allowing dry mortars to meet diverse and demanding performance specifications across various applications.

Another significant technological thrust is in the realm of advanced additive chemistry. This includes the integration of high-performance superplasticizers, rheology modifiers, air-entraining agents, and accelerators or retarders that precisely control the setting time, flowability, and workability of the mortar. Fibers, both synthetic (e.g., polypropylene, polyester) and natural (e.g., cellulose), are increasingly incorporated to enhance flexural strength, crack resistance, and overall durability, especially in renders and repair mortars. Moreover, hydrophobic agents and crystalline waterproofing additives are crucial for developing water-resistant and self-sealing dry mortars, expanding their utility in moisture-prone environments. These chemical additives are meticulously selected and dosed to optimize the fresh and hardened properties of the mortar, ensuring consistent and predictable performance on site, which is vital for quality assurance in large-scale construction projects.

Beyond material science, the technology landscape also encompasses sophisticated manufacturing and application technologies. Automated batching and mixing plants ensure precise proportioning of raw materials, minimizing human error and guaranteeing consistent product quality. Advanced packaging solutions are being developed to extend shelf life and protect dry mortars from moisture, which is critical for maintaining product integrity during storage and transportation. On the application front, innovations include specialized mixing equipment that ensures homogeneous water dispersion, and mechanized application tools such as spray machines and pumps that enhance speed, efficiency, and uniformity of mortar application, particularly for large surfaces like plasters and renders. The integration of digital tools for quality control, performance tracking, and even AI-driven formulation optimization represents the cutting edge, promising to further revolutionize the development and deployment of dry mortar solutions by offering greater precision, sustainability, and operational efficiency across the construction value chain.

Regional Highlights

- Asia Pacific: This region dominates the construction dry mortar market, primarily driven by rapid urbanization, extensive infrastructure development, and burgeoning construction activities in countries like China, India, and Southeast Asian nations. The demand for affordable housing, commercial complexes, and modern transportation networks fuels significant consumption of various dry mortar products. Government initiatives supporting smart cities and green building projects further accelerate market growth, making it a pivotal region for manufacturers and investors.

- Europe: A mature market characterized by stringent building regulations, a strong emphasis on energy efficiency, and a robust renovation sector. Growth here is primarily driven by the retrofitting of old buildings, the adoption of advanced thermal insulation systems (ETICS/EIFS), and a preference for high-quality, sustainable building materials. Western European countries lead in innovation and specialized dry mortar applications, while Eastern Europe presents growth opportunities through ongoing infrastructure upgrades and economic development.

- North America: This region exhibits steady growth, largely propelled by increasing residential and commercial construction, significant investments in infrastructure repair and maintenance, and a rising adoption of sustainable building practices. The demand for high-performance and labor-efficient dry mortar solutions, particularly in tile adhesives, grouts, and repair mortars, is strong. Technological advancements and the integration of automation in construction processes also contribute to market expansion.

- Latin America: Characterized by emerging economies and growing urbanization, Latin America presents substantial opportunities for the dry mortar market. Countries like Brazil, Mexico, and Argentina are witnessing increased construction activities, particularly in the housing and commercial sectors. Investment in infrastructure development and a rising awareness of quality construction materials are key drivers. However, economic volatility and geopolitical factors can influence market growth in certain areas.

- Middle East & Africa (MEA): This region is experiencing significant growth fueled by massive construction projects related to urbanization, economic diversification, and major events (e.g., Expo, World Cup). Saudi Arabia, UAE, and Qatar are leading with ambitious development plans. The demand for high-performance dry mortars in extreme climatic conditions, coupled with a focus on sustainable and resilient construction, drives market expansion. African countries are also showing promising growth as infrastructure development accelerates.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Construction Dry Mortar Market.- Sika AG

- BASF SE

- Saint-Gobain (Weber)

- Mapei S.p.A.

- Ardex GmbH

- Knauf Gips KG

- Henkel AG & Co. KGaA

- Sto SE & Co. KGaA

- CEMEX S.A.B. de C.V.

- LafargeHolcim Ltd.

- W. R. Grace & Co.

- Fosroc International Ltd.

- UltraTech Cement Ltd.

- Terraco Group

- Dryvit Systems, Inc.

- ParexGroup (a subsidiary of Sika AG)

- Baumit GmbH

- CP-Chem Ltd.

- Fassa Bortolo S.p.A.

- HB Fuller Company

Frequently Asked Questions

What are the primary benefits of using construction dry mortar over traditional site-mixed mortar?

Construction dry mortars offer superior consistency and quality control due to factory pre-mixing, significantly reducing on-site mixing errors and ensuring predictable performance. They provide enhanced workability, adhesion, and durability, leading to longer-lasting structures and reduced maintenance. Additionally, dry mortars minimize material waste, simplify logistics, and often accelerate construction timelines due to their ready-to-use nature, contributing to overall project efficiency and cost savings.

How do environmental regulations impact the growth and innovation within the dry mortar market?

Environmental regulations significantly influence the dry mortar market by driving demand for sustainable and eco-friendly formulations. Manufacturers are compelled to invest in R&D to develop low-VOC, energy-efficient, and recycled-content mortars, aligning with green building standards and certifications like LEED. While these regulations can increase development costs and necessitate production adjustments, they also foster innovation, open new market segments, and enhance the market's long-term sustainability by promoting responsible material usage.

Which geographical region is expected to lead the growth in the Construction Dry Mortar Market, and why?

The Asia Pacific region is projected to lead the growth in the Construction Dry Mortar Market. This dominance is attributed to rapid urbanization, extensive infrastructure development projects, and massive government investments in residential and commercial construction across countries like China, India, and Southeast Asian nations. The region's expanding population and economic growth fuel a consistent demand for efficient, high-quality, and cost-effective building materials, making it a high-growth epicenter.

What role does artificial intelligence (AI) play in the future development of dry mortar products?

AI is set to revolutionize dry mortar development by enabling data-driven optimization of formulations, predicting material performance, and enhancing quality control. AI can analyze vast datasets of material properties to accelerate the creation of novel, high-performance, and sustainable mortar solutions. Furthermore, AI-powered systems can optimize manufacturing processes, improve supply chain efficiency, and facilitate predictive maintenance of equipment, ultimately leading to more innovative products and streamlined production.

What are the key factors driving the demand for specialized dry mortar products like tile adhesives and self-leveling compounds?

The demand for specialized dry mortar products is driven by evolving construction practices and stringent performance requirements. Tile adhesives benefit from increasing aesthetic demands in residential and commercial spaces, requiring strong, flexible, and waterproof bonds for various tile types. Self-leveling compounds are crucial for creating perfectly smooth and durable subfloors, essential for modern flooring installations (e.g., LVT, epoxy coatings) in high-traffic commercial and industrial settings, where rapid application and consistent flatness are paramount for efficiency and finish quality.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager