Construction Industry Core Drill Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433024 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Construction Industry Core Drill Market Size

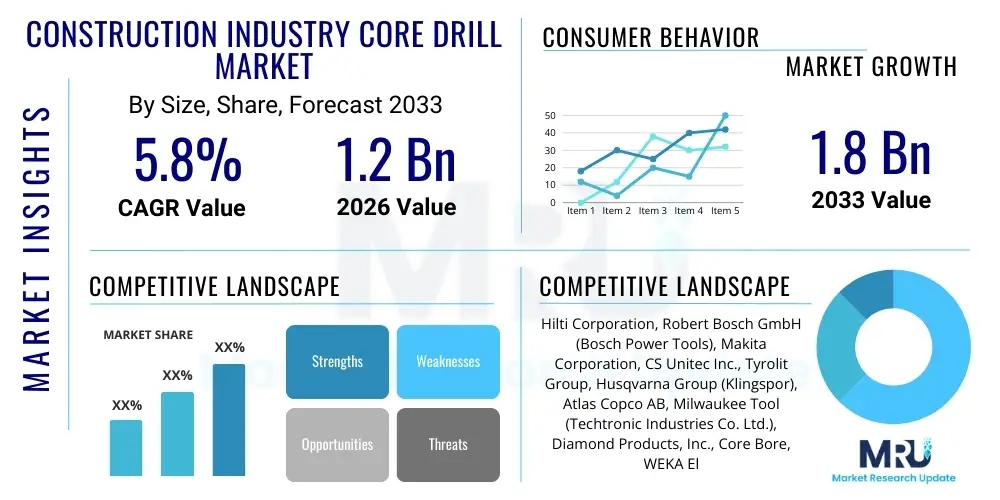

The Construction Industry Core Drill Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 1.8 Billion by the end of the forecast period in 2033. This growth trajectory is fundamentally supported by robust global investment in infrastructure renewal and the escalating demand for accurate, non-destructive testing (NDT) capabilities within structural engineering projects. The shift toward sustainable construction practices, requiring precise utility penetration and material sampling without compromising structural integrity, further reinforces the market’s positive outlook.

The market expansion is particularly evident across emerging economies in the Asia Pacific region, driven by rapid urbanization and large-scale public-private partnership (PPP) projects focused on transportation and residential development. Mature markets, such as North America and Europe, contribute substantially through technological upgrades, demanding advanced core drilling solutions that incorporate automation and dust suppression systems to comply with stringent occupational safety regulations. The increasing preference for diamond core drilling techniques over conventional methods, owing to superior cutting speed and reduced vibration, is a pivotal factor influencing overall market valuation and sustained growth throughout the forecast period.

Construction Industry Core Drill Market introduction

The Construction Industry Core Drill Market encompasses specialized equipment designed to extract cylindrical samples (cores) from hard materials like concrete, asphalt, masonry, and reinforced structures. Core drills utilize diamond-impregnated bits and powerful motors, ranging from handheld electric models to large, truck-mounted hydraulic systems, ensuring precision cutting for applications spanning utility installation, material testing, and structural modification. These tools are indispensable in modern construction, facilitating the creation of clean openings for plumbing, electrical conduits, HVAC systems, and the crucial inspection of material composition and structural integrity of existing buildings and infrastructure.

The primary applications of core drilling equipment include infrastructure projects (roads, bridges, tunnels), commercial building construction (high-rises, hospitals, data centers), and renovation activities requiring precise hole boring through reinforced concrete. Key benefits offered by high-quality core drills include minimized structural damage, high operational efficiency, reduced noise and dust pollution when utilizing wet drilling methods, and the ability to penetrate high-density materials, including those embedded with heavy steel rebar. The precision inherent in core drilling is paramount, especially in post-tensioned concrete structures where location accuracy is critical to avoiding damage to embedded cables.

Market growth is significantly driven by global investment in resilient infrastructure, particularly following governmental stimulus packages aimed at economic recovery and modernization. The mandatory requirement for core sample collection in quality assurance protocols for civil engineering projects, coupled with the rising global focus on retrofitting existing structures for seismic and environmental resistance, acts as a primary market accelerant. Furthermore, advancements in battery technology powering cordless core drills are enhancing portability and usability on remote construction sites, thereby broadening the practical application scope for contractors globally.

Construction Industry Core Drill Market Executive Summary

The global Construction Industry Core Drill Market is characterized by robust business trends centered on technological innovation, focusing heavily on efficiency, safety, and operational integration. Key companies are prioritizing the development of next-generation core drilling systems featuring advanced automation capabilities, real-time data monitoring, and enhanced dust control mechanisms to adhere to increasingly strict construction site health and safety standards. Furthermore, strategic mergers and acquisitions, along with increased collaboration between equipment manufacturers and diamond segment suppliers, are shaping the competitive landscape, leading to optimization in supply chain management and product customization for specific drilling environments.

Regionally, the Asia Pacific region dominates the demand landscape, exhibiting the highest growth rate due to massive governmental spending on new urban centers, high-speed rail networks, and substantial energy infrastructure projects. North America and Europe maintain stable, mature markets distinguished by high adoption rates of premium, high-power hydraulic drilling systems and sophisticated slurry management technology. Trend analysis indicates a strong shift toward environmentally friendly solutions, particularly dry core drilling technologies that minimize water usage, appealing strongly to projects in water-scarce regions or those prioritizing green building certifications.

Segment trends underscore the dominance of the electrical and handheld core drill segment by volume, driven by residential and small-scale commercial applications. However, the hydraulic core drill segment is projected to show the fastest value-based growth, largely utilized in heavy civil engineering and large demolition or refurbishment projects requiring maximum torque and continuous duty cycles. The application segment remains heavily concentrated in infrastructure development and utility installation, where the demand for precise, large-diameter drilling is consistently high, necessitating heavy-duty, rig-mounted drilling solutions.

AI Impact Analysis on Construction Industry Core Drill Market

User inquiries regarding AI's impact on the Construction Industry Core Drill Market primarily revolve around operational efficiency gains, predictive maintenance capabilities, and enhanced drilling precision. Users are concerned with how AI can minimize downtime by predicting equipment failure, optimize drilling parameters (speed, feed rate, torque) based on real-time material analysis (concrete density, rebar location), and ultimately reduce operational costs. The summary of user expectations indicates a strong desire for AI integration to shift core drilling from a highly skilled, manual task to a semi-automated, data-driven process, improving core sample quality and reducing the risk of hitting embedded utilities or structural elements.

- AI-powered predictive maintenance scheduling reduces unexpected equipment failure and downtime.

- Machine learning algorithms optimize drilling parameters based on instantaneous feedback regarding material density and resistance.

- Integration with Building Information Modeling (BIM) systems allows AI to guide drill positioning, ensuring compliance with structural blueprints.

- Automated slurry management systems utilizing AI for real-time viscosity and pH control optimize wet drilling efficiency.

- Enhanced safety protocols through AI monitoring of operator fatigue and anomalous machine behavior.

- Data analytics derived from smart core drills inform manufacturers about design flaws and operational weak points, accelerating product refinement.

DRO & Impact Forces Of Construction Industry Core Drill Market

The Core Drill Market is significantly influenced by a complex interplay of Drivers, Restraints, and Opportunities, shaping the overall market trajectory. Primary driving forces include the sustained global wave of urbanization and population growth, which necessitates constant expansion and upgrading of utility networks, transportation infrastructure, and residential complexes. This continuous construction activity mandates the regular use of core drilling for utility conduits, ventilation systems, and essential material testing procedures. Simultaneously, the increasingly stringent quality control standards in civil engineering projects, demanding reliable core samples for material analysis, further solidify the market demand.

However, the market faces notable restraints, chiefly related to the high initial capital investment required for heavy-duty, professional-grade core drilling rigs and advanced diamond tooling. Furthermore, the operational challenges associated with slurry management in wet drilling—including disposal costs and environmental regulations regarding contaminated water—present a barrier, particularly for small to medium-sized contractors. Skilled labor shortages capable of operating and maintaining technologically sophisticated drilling equipment efficiently also hamper faster adoption in certain geographic regions, necessitating simplified operational interfaces.

Significant opportunities arise from the increasing adoption of cordless and battery-powered core drills, improving site flexibility and reducing reliance on traditional power sources, aligning with industry desires for mobile and efficient tools. Moreover, the burgeoning demand for specialized drilling techniques in restoration and retrofitting projects for historic or aging structures presents a lucrative niche, requiring custom diamond tooling and low-vibration drilling solutions. The development of advanced, integrated dust suppression and slurry recycling systems offers manufacturers a pathway to overcome environmental and logistical restraints, thereby opening up new market segments, particularly in densely populated urban construction zones.

Segmentation Analysis

The Construction Industry Core Drill Market is segmented primarily based on the equipment type (Drilling Method, Operation Mode, and Power Source), application, and region, allowing for granular analysis of demand patterns and technological adoption across various industry verticals. Understanding these segments is crucial for manufacturers to tailor product specifications, ranging from robust hydraulic systems used in tunneling to lightweight handheld electric drills suitable for residential plumbing. The complexity of construction materials, varying from standard cured concrete to heavily reinforced high-strength materials, directly influences the required torque and durability characteristics, driving specialized tool development within each segment.

The segmentation by Operation Mode, particularly the distinction between handheld and rig-mounted systems, is critical. Handheld drills dominate smaller diameter and low-volume tasks, valued for their portability, while rig-mounted systems are essential for large-diameter holes, deep drilling, and projects requiring high precision and stability, such as bridge construction and major infrastructure upgrades. The continuous innovation in diamond tooling composition, catering to specific aggregate hardness and rebar concentrations, represents a vital sub-segment, ensuring optimal performance and minimizing operational wear across diverse construction environments.

Analysis confirms that the application segment involving utility installation (e.g., electrical conduits, water piping) remains the largest contributor to market revenue, reflecting the constant requirement for penetrating finished structures for system integration. However, the segment related to structural renovation and demolition is showing accelerated growth, fueled by the global trend toward repurposing existing commercial real estate and the need for structural assessment via non-destructive core extraction. The market dynamics within each segment are further shaped by regional construction standards, safety regulations, and prevailing wage structures, dictating the preference for automated versus manually operated equipment.

- By Type (Drilling Method):

- Wet Core Drilling Systems

- Dry Core Drilling Systems

- By Operation Mode:

- Handheld Core Drills (Electric, Cordless)

- Rig-Mounted Core Drills (Hydraulic, Pneumatic, Electric)

- By Power Source:

- Electric Core Drills (Corded and Cordless)

- Hydraulic Core Drills

- Pneumatic Core Drills

- By Application:

- Infrastructure Development (Roads, Bridges, Tunnels)

- Utility Installation (Plumbing, HVAC, Electrical)

- Structural Renovation and Demolition

- Material Testing and Quality Control

- By End-User:

- Construction Contractors

- Utility Companies

- Testing Laboratories

- Demolition and Salvage Experts

- By Core Diameter Size:

- Small Diameter (Under 50 mm)

- Medium Diameter (50 mm - 150 mm)

- Large Diameter (Above 150 mm)

Value Chain Analysis For Construction Industry Core Drill Market

The value chain for the Construction Industry Core Drill Market begins with upstream activities focused on the procurement of raw materials, primarily high-grade steel and industrial diamonds used for manufacturing core bits. Upstream analysis involves specialized suppliers providing sophisticated electric motors, hydraulic components, and precision mechanical parts necessary for robust drill assembly. Key cost drivers at this stage include the price volatility of industrial diamond synthetics and specialized steel alloys required to withstand the high stress and vibration inherent in concrete drilling. Strategic partnerships with reliable material suppliers are crucial for maintaining manufacturing margins and product quality consistency.

The middle segment of the value chain involves the manufacturing, assembly, and testing of the core drilling systems and corresponding diamond consumables. Manufacturers invest heavily in R&D to enhance motor efficiency, reduce vibration, and improve the longevity and cutting speed of the diamond segments. Distribution channels represent a critical link, segmented into direct sales to large construction firms and indirect distribution through specialized industrial equipment rental companies and regional tool distributors. Rental companies play a significant role, particularly for high-cost, specialized hydraulic rigs, allowing smaller contractors access without substantial capital expenditure.

Downstream analysis focuses on the end-user interaction, encompassing after-sales service, technical support, and the provision of replacement diamond core bits, which act as a high-margin recurring revenue stream. The successful integration of digital platforms for equipment monitoring and predictive maintenance further optimizes the downstream value capture. Direct distribution often emphasizes customized training and specialized applications support, while indirect channels rely on broad availability and efficient logistics. The effectiveness of the value chain relies heavily on the quality and performance of the diamond segments, as they directly impact the contractor’s operational efficiency and project timeline adherence.

Construction Industry Core Drill Market Potential Customers

The primary consumers and end-users of Construction Industry Core Drill equipment are highly diversified across the construction ecosystem, ranging from large, multinational engineering, procurement, and construction (EPC) firms to specialized concrete cutting subcontractors. These customers utilize core drills extensively for large-scale infrastructure projects, including highway expansion, tunnel boring, and the construction of deep foundations where precise, high-volume hole cutting is mandatory. For these large buyers, factors such as machine reliability, duty cycle, integrated safety features (like clutch protection and dust control), and rapid access to specialized tooling are paramount purchasing criteria.

A second major customer segment includes utility companies and specialized Mechanical, Electrical, and Plumbing (MEP) contractors. These professionals rely on smaller, highly maneuverable handheld and light rig-mounted core drills for fitting new services, running conduits, and performing small-diameter penetrations during commercial building fit-outs and residential renovations. For this segment, portability, ease of setup, and compatibility with various power sources (especially battery technology) are key purchasing factors, as they frequently operate in confined spaces or existing structures where accessibility is limited.

Furthermore, independent material testing laboratories and academic research institutions constitute a crucial niche market. These customers require extremely high-precision core drilling equipment to extract pristine, uncontaminated samples for concrete quality analysis, asphalt integrity testing, and forensic engineering investigations. Their demand focuses on minimal sample damage, consistent core dimensions, and documentation capabilities, often favoring highly stable, laboratory-grade drilling apparatus with advanced controls and minimal vibration levels to ensure the integrity of the collected material for accurate scientific assessment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 1.8 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hilti Corporation, Robert Bosch GmbH (Bosch Power Tools), Makita Corporation, CS Unitec Inc., Tyrolit Group, Husqvarna Group (Klingspor), Atlas Copco AB, Milwaukee Tool (Techtronic Industries Co. Ltd.), Diamond Products, Inc., Core Bore, WEKA Elektrowerkzeuge GmbH, Eibenstock, DR. SCHULZE GmbH, Rems-Werk, Golz GmbH, Norton Clipper (Saint-Gobain Abrasives), Dymacut Diamond Tools, Lissmac Maschinenbau GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Construction Industry Core Drill Market Key Technology Landscape

The technological landscape of the Construction Industry Core Drill Market is rapidly evolving, driven by the need for enhanced performance, improved ergonomics, and greater site safety. Key innovations center on the transition towards high-capacity, brushless motor technology in electric drills, which significantly improves power-to-weight ratio, extends tool life, and allows for continuous operation without the overheating issues common in older motor designs. Furthermore, advanced vibration dampening systems are being integrated into both handheld and rig-mounted units to minimize operator fatigue and improve drilling accuracy, which is crucial when performing intricate cuts in densely reinforced concrete structures.

Another dominant technological trend is the proliferation of connectivity and IoT features in professional-grade core drills. This includes integrated sensors that monitor torque, pressure, temperature, and drilling depth in real-time, providing valuable data back to the operator and project manager. This data-driven approach facilitates superior quality control, ensures adherence to drilling specifications, and enables predictive maintenance algorithms that prevent unscheduled equipment failure. Manufacturers are also developing modular systems that allow users to easily switch between dry and wet drilling modes, often incorporating patented vacuum dust extraction ports that meet increasingly strict environmental and occupational health standards for silica dust mitigation.

The innovation extends significantly into the consumables sector, particularly diamond segment technology. New manufacturing processes are leading to the development of highly specialized diamond matrices tailored for specific aggregate types, such as high-performance concrete or refractory materials. These segment advancements involve sophisticated laser welding and sintering techniques, enhancing the bond between the diamond grit and the metal matrix. This results in superior cutting speed and exceptional lifespan, dramatically reducing the total cost of ownership for professional contractors and boosting overall project productivity on challenging job sites.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to register the fastest growth in the core drill market, propelled by colossal infrastructure investment in China, India, and Southeast Asian nations. Rapid urbanization and massive public sector spending on smart cities, expressways, and energy plants necessitate extensive core drilling for utility conduits and material testing. The large market size is also influenced by competitive pricing and the high volume demand for electric and entry-level hydraulic drilling systems, although the trend towards advanced safety features is accelerating due to international project standards.

- North America: North America represents a mature, high-value market characterized by early adoption of advanced technology and a strong focus on worker safety and equipment automation. Demand is dominated by replacement cycles in aging infrastructure (bridges, pipelines) and significant commercial renovation projects. The preference leans heavily towards high-power, reliable hydraulic systems and premium cordless electric drills equipped with sophisticated dust collection and slurry management solutions to comply with OSHA regulations.

- Europe: The European market demonstrates steady growth, driven primarily by stringent energy efficiency mandates for buildings, leading to extensive retrofitting and structural modification projects. Strict environmental regulations favor equipment that minimizes noise pollution and efficiently manages concrete slurry waste. Germany, the UK, and France are key contributors, emphasizing precision engineering, ergonomic design, and integration with digital construction methodologies like BIM.

- Latin America (LATAM): The LATAM region offers considerable growth potential, although market development is uneven. Construction activity in countries like Brazil and Mexico, particularly in mining infrastructure and urban residential development, boosts core drill demand. The market here is sensitive to economic fluctuations and often favors cost-effective, durable equipment. Increased foreign direct investment in public works is expected to gradually elevate the demand for higher-specification drilling tools.

- Middle East and Africa (MEA): Growth in the MEA region is strongly tied to large-scale, high-profile projects in the GCC nations (e.g., Saudi Arabia’s Vision 2030 and UAE construction booms) which demand heavy-duty, state-of-the-art drilling equipment for complex architectural and infrastructure endeavors. The African segment, while smaller, is growing due to industrialization and resource extraction projects, with a strong demand for robust, easily maintainable tools capable of operating in harsh environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Construction Industry Core Drill Market.- Hilti Corporation

- Robert Bosch GmbH (Bosch Power Tools)

- Makita Corporation

- CS Unitec Inc.

- Tyrolit Group

- Husqvarna Group (Klingspor)

- Atlas Copco AB

- Milwaukee Tool (Techtronic Industries Co. Ltd.)

- Diamond Products, Inc.

- Core Bore

- WEKA Elektrowerkzeuge GmbH

- Eibenstock (Elektrowerkzeuge GmbH Eibenstock)

- DR. SCHULZE GmbH

- Rems-Werk (Christian Föll & Söhne GmbH & Co. KG)

- Golz GmbH

- Norton Clipper (A division of Saint-Gobain Abrasives)

- Dymacut Diamond Tools (A subsidiary focusing on advanced tooling)

- Lissmac Maschinenbau GmbH (Specializing in construction technology)

- Clipper Corporation (Providing robust professional tools)

- Zhuomao Technology Co., Ltd. (A leading Asian manufacturer)

Frequently Asked Questions

Analyze common user questions about the Construction Industry Core Drill market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between wet and dry core drilling methods?

Wet core drilling uses water to cool the diamond segment and flush out slurry, minimizing dust and heat, ideal for hard concrete and larger diameter holes. Dry core drilling uses no water, relying on air cooling and specialized segment design, best suited for masonry, brick, or situations where water usage is prohibited or impractical.

How does the integration of cordless technology affect professional core drilling operations?

Cordless technology, powered by high-voltage lithium-ion batteries, significantly enhances mobility and accessibility on job sites, eliminating the need for generators or long extension cords. This allows for faster setup and greater flexibility, particularly in high-rise construction, remote locations, and indoor renovation projects, improving overall productivity.

Which application segment holds the largest share in the Construction Industry Core Drill Market?

The Utility Installation segment (including plumbing, electrical, and HVAC conduit creation) currently holds the largest market share. The continuous demand for new building systems and the retrofitting of existing structures ensure steady, high-volume requirement for precise and clean core penetrations.

What major regulatory factors influence the core drill market growth, particularly in mature economies?

Stringent occupational health and safety regulations, such as those governed by OSHA and regional equivalents, significantly influence the market. These regulations enforce strict limits on silica dust exposure and mandate minimum requirements for vibration control, driving manufacturers to invest heavily in integrated dust suppression and advanced ergonomic designs.

What are the key performance indicators (KPIs) for selecting the appropriate diamond core bit?

Key selection criteria include the diamond segment concentration and quality, the bonding matrix composition (which must match the hardness of the material being drilled), and the expected lifespan and cutting speed. The diameter and length of the core bit must also align precisely with the project specifications and the capacity of the core drill rig.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager