Continuous Flow Photochemical Reactors Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433254 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Continuous Flow Photochemical Reactors Market Size

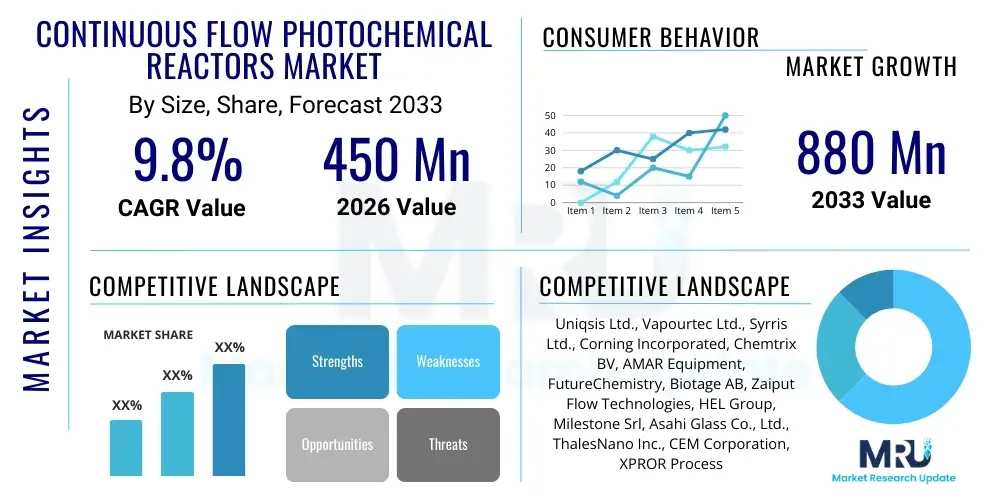

The Continuous Flow Photochemical Reactors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 880 Million by the end of the forecast period in 2033.

Continuous Flow Photochemical Reactors Market introduction

The Continuous Flow Photochemical Reactors Market encompasses advanced chemical synthesis equipment designed to perform reactions utilizing light energy (photons) in a continuous, uninterrupted flow environment. Unlike traditional batch reactors, flow photochemical reactors offer precise control over parameters such as residence time, light intensity, temperature, and mixing, leading to enhanced selectivity, higher yields, and improved safety, particularly when handling hazardous or unstable intermediates. This technology is critical for advancing green chemistry principles and process intensification in various industries, including pharmaceuticals, fine chemicals, and materials science. The core of the product involves specialized reactor designs, often utilizing microfluidics or mesoscale channels, coupled with highly efficient light sources like Light Emitting Diodes (LEDs) or high-intensity lamps, ensuring uniform irradiation and efficient photon utilization.

Major applications of continuous flow photochemical reactors span a wide array of synthetic transformations, including oxidations, reductions, cyclizations, and isomerizations that are challenging or inefficient under thermal conditions. In the pharmaceutical sector, these reactors are increasingly employed for the rapid synthesis of complex Active Pharmaceutical Ingredients (APIs) and novel drug candidates, allowing for better scale-up and economic viability. The inherent safety benefits of using flow chemistry, such as minimized holdup volumes and rapid quenching capabilities, make photoredox catalysis and other high-energy light-driven processes far more manageable and industrially scalable compared to traditional batch methodologies.

The primary driving factors propelling this market include the global push for sustainable manufacturing processes (green chemistry), stringent regulatory requirements mandating safer and more efficient production methods, and the growing demand for complex chemical entities that necessitate highly selective synthetic routes. The shift from mercury lamps to energy-efficient and monochromatic LED light sources has further lowered operating costs and increased the precision of photochemistry, democratizing access to this technology across academic research labs and industrial manufacturing facilities worldwide. Furthermore, ongoing innovation in reactor materials, optics, and integration with automation platforms is enhancing throughput and reliability, solidifying the market's upward trajectory.

Continuous Flow Photochemical Reactors Market Executive Summary

The Continuous Flow Photochemical Reactors Market is experiencing significant acceleration driven by the convergence of process intensification needs and breakthroughs in LED technology. Current business trends indicate a strong move toward highly modular and scalable reactor systems, allowing seamless transition from laboratory optimization to pilot production and full manufacturing scale. Key industry players are focusing on developing integrated platforms that combine photochemistry with downstream processing steps, such as inline purification and analysis, thereby maximizing process efficiency and minimizing waste. There is a palpable trend towards collaboration between equipment manufacturers and specialized contract research and manufacturing organizations (CROs/CMOs), which are adopting flow photochemistry to provide advanced synthetic services for complex molecule creation, positioning them competitively in the outsourced drug development pipeline.

Regionally, North America and Europe currently dominate the market share, fueled by high levels of R&D investment in pharmaceutical and fine chemical sectors, coupled with strict environmental regulations that favor continuous processing over traditional batch methods. However, the Asia Pacific region, particularly China and India, is emerging as the fastest-growing market segment, attributed to rapid industrialization, increasing governmental support for advanced manufacturing techniques, and the burgeoning presence of generic drug manufacturers seeking cost-effective and high-throughput synthesis methods. Latin America and MEA are showing steady, albeit slower, adoption rates, primarily driven by investments in localized specialty chemical production and material science research.

Segmentation trends highlight the increasing importance of microreactors, favored in early-stage R&D due to their superior heat and mass transfer characteristics, alongside the rising adoption of mesoscale and pilot-scale systems for industrial production. By end-user, the pharmaceutical and biotechnology sector remains the primary revenue generator, owing to the high value and complexity of their target molecules, while the academic and research segment provides the critical foundation for technological innovation. Furthermore, the light source segment is unequivocally shifting towards UV-Vis LED systems, displacing traditional high-pressure mercury and halogen lamps due to their longevity, energy efficiency, and ability to deliver monochromatic, precise wavelengths crucial for specific chemical transformations, thereby reinforcing the overall market shift toward sophisticated, controlled photoprocesses.

AI Impact Analysis on Continuous Flow Photochemical Reactors Market

User queries regarding the impact of Artificial Intelligence (AI) on the Continuous Flow Photochemical Reactors Market center predominantly on themes of autonomous synthesis optimization, predictive modeling of reaction outcomes, and accelerating materials discovery. Common concerns revolve around how AI can manage the complex interplay between light intensity, flow rate, and reactant concentration to achieve optimal photon efficiency and selectivity, tasks that are notoriously complex in traditional experimentation. Users expect AI to reduce the extensive time and resources currently dedicated to screening reaction conditions and identifying ideal reactor geometries, moving towards a 'self-optimizing' photochemical manufacturing environment. Specifically, there is high interest in how machine learning algorithms can predict the stability and degradation pathways of intermediates under continuous high-energy irradiation, ensuring robust and scalable processes.

The primary influence of AI lies in its capability to rapidly interpret vast datasets generated by high-throughput screening of photochemical reactions conducted in flow reactors. By integrating sophisticated cheminformatics with machine learning, AI models can establish structure-property relationships correlating molecular characteristics with reactivity and selectivity under specific flow conditions. This capability allows researchers to move beyond traditional trial-and-error methodologies, accelerating the identification of viable synthetic routes and optimizing operational parameters like residence time and radiant power with minimal experimental input. Furthermore, AI is crucial for real-time process monitoring and control; algorithms analyze inline spectroscopic data (such as Raman or IR) to detect deviations instantly and autonomously adjust flow parameters, ensuring continuous product quality and yield maximization.

The application of AI extends significantly into the realm of reactor design and process scale-up. Generative design models are being trained on large datasets of successful flow reactor configurations and photochemical processes to propose novel, highly efficient reactor geometries optimized for photon distribution and fluid dynamics. This is particularly relevant for scaling reactions that suffer from light penetration limitations. By simulating and optimizing complex multiphysics parameters—including radiation transfer, turbulent mixing, and heat dissipation—AI minimizes the iterative physical prototyping phase, drastically reducing the time-to-market for new photochemical products and improving the overall sustainability and energy efficiency of the manufacturing process.

- AI-driven autonomous optimization of flow rates and light intensity for maximal photon efficiency.

- Machine learning models predicting reaction selectivity and yield under various flow photochemical conditions.

- Accelerated discovery of novel photocatalysts and photoactive materials using predictive algorithms.

- Real-time monitoring and control through AI analysis of inline spectroscopic data (Process Analytical Technology - PAT).

- Simulation and generative design of novel, high-efficiency reactor geometries optimized for scale-up.

- Enhanced safety protocols by predicting and mitigating potential runaway reactions or decomposition events in flow.

DRO & Impact Forces Of Continuous Flow Photochemical Reactors Market

The Continuous Flow Photochemical Reactors Market is fundamentally shaped by a robust interplay between compelling technological drivers and inherent operational challenges, tempered by significant untapped market opportunities. The core driver is the imperative for Process Intensification (PI), enabling faster reaction kinetics, better product quality, and reduced solvent usage compared to traditional batch methods. Conversely, the market faces restraints stemming from the high initial capital investment required for specialized equipment and the necessity for highly trained personnel skilled in both photochemistry and flow dynamics. Opportunities abound in the burgeoning fields of sustainable energy (e.g., solar fuel generation) and customized specialty polymers, where light-driven synthesis offers unique pathways. These forces collectively dictate the adoption curve, with strong regulatory backing for green chemistry amplifying the impact of drivers while the technical complexity acts as a gatekeeper for smaller enterprises.

The primary Drivers include the superior reaction control offered by flow systems, allowing precise management of highly exothermic or unstable photochemical intermediates, significantly improving safety and reducing side product formation. The rapid adoption of high-power, monochromatic LED light sources has been a crucial enabler, offering high energy efficiency and tunability specific to chromophore absorption bands, maximizing quantum yield. Restraints largely concern the difficulty in scaling reactions that exhibit poor light penetration depth, requiring complex reactor geometries (like falling film or spinning disk reactors) to maintain efficiency. Furthermore, handling slurries or poorly soluble reactants in micro/meso channels presents fouling and clogging issues, limiting the applicability of continuous flow reactors in certain industrial processes.

Opportunities are primarily concentrated in the synthesis of high-value, complex molecules, particularly stereoisomers and chiral compounds, where photochemistry offers unparalleled selectivity. The market stands to gain significantly from the increasing demand for outsourced continuous manufacturing services (CMOs) specializing in flow chemistry. The strong Impact Forces affecting the market include technological advancements in miniaturization and automation, which continually drive down operational costs and increase accessibility. Regulatory pressure, particularly environmental standards, acts as a perpetual positive force, compelling chemical manufacturers to switch to resource-efficient and safer continuous processing platforms, thus ensuring steady demand growth for continuous flow photochemical reactor solutions across all major chemical producing regions.

Segmentation Analysis

The Continuous Flow Photochemical Reactors Market is comprehensively segmented based on three primary dimensions: the type of Reactor Design, the Light Source utilized, and the End-User Industry. This segmentation provides a crucial framework for understanding market dynamics, target audience profiles, and technology adoption rates. Reactor design segmentation differentiates systems based on scale and geometry, ranging from highly controlled microreactors suited for research and optimization to larger, more scalable mesoscale and industrial-sized falling film or coiled reactors designed for production volume. The selection of the appropriate reactor type is highly dependent on the specific quantum yield requirements, the throughput demanded by the application, and the physical properties (viscosity, absorbance) of the reactants being processed.

The Light Source segmentation is undergoing rapid evolution, shifting from traditional, broad-spectrum light sources, such as high-pressure mercury and xenon lamps, to highly specific and efficient Light Emitting Diodes (LEDs). LED technology, spanning UV, Visible, and specialized wavelength ranges, dominates new installations due to its energy efficiency, low maintenance, and the ability to selectively target specific photoexcitation events, minimizing unwanted side reactions. The choice of light source directly influences the efficiency and scalability of the photochemical process, with LEDs enabling highly reproducible and economically viable industrial implementations. Finally, the End-User segmentation highlights the pharmaceutical and biotechnology sectors as the largest consumers, driven by the synthesis needs for complex APIs and novel scaffolds, followed closely by the academic research and specialty chemicals industries, which leverage the technology for fundamental discoveries and advanced material synthesis.

- By Reactor Type:

- Microreactors (Microfluidic chips and small channel reactors)

- Mesoscale Reactors (Coiled flow reactors, tube-in-tube systems)

- Large-Scale/Industrial Reactors (Falling film reactors, stirred tank reactors with external irradiation)

- By Light Source:

- UV-LED Systems

- Visible-LED Systems

- Traditional Lamps (Mercury, Xenon, Halogen)

- By Application:

- Photoredox Catalysis

- C-H Activation

- Oxidation and Reduction Reactions

- Polymer Synthesis and Modification

- Isomerization and Cycloaddition Reactions

- By End User:

- Pharmaceutical and Biotechnology Companies

- Specialty and Fine Chemical Manufacturers

- Academic and Research Institutions

- Cosmetics and Consumer Goods Industry

Value Chain Analysis For Continuous Flow Photochemical Reactors Market

The value chain for Continuous Flow Photochemical Reactors begins with the Upstream Analysis, which involves the critical supply of highly specialized components necessary for reactor manufacturing. This segment includes suppliers of advanced materials such such as chemically resistant glass, quartz, specialized polymers (e.g., PTFE, PEEK), and exotic metals necessary for constructing the flow channels and reaction zones. Equally important is the sourcing of high-power, high-efficiency monochromatic LEDs, cooling systems, and precise fluidic control components like high-pressure pumps and back-pressure regulators. Quality and availability of these specialized inputs, particularly for microfluidic chips and specialized optics, directly influence the cost structure and performance capabilities of the final reactor unit, necessitating strong partnerships between manufacturers and material suppliers to ensure compliance with stringent chemical inertness and optical transmission requirements.

Midstream activities encompass the actual design, engineering, and manufacturing of the integrated flow reactor systems. This involves sophisticated engineering expertise to optimize reactor geometry for efficient light delivery and mass transfer, coupled with the integration of complex control software for automated operation and Process Analytical Technology (PAT) integration. Manufacturing typically involves cleanroom environments for microreactor fabrication and high-precision machining for mesoscale systems. Distribution channels are generally categorized into Direct and Indirect Sales. Direct sales are often utilized for large industrial-scale systems requiring extensive customization, installation support, and specialized training, facilitating a high level of customer relationship management and technical consultation from the vendor. Indirect channels primarily involve specialized distributors, scientific equipment suppliers, and regional agents who handle sales and service for smaller, standardized laboratory-scale systems, particularly serving the academic and early-stage R&D markets globally.

Downstream analysis focuses on the application and end-user adoption of the reactors. This includes specialized Contract Research Organizations (CROs) and Contract Manufacturing Organizations (CMOs) that leverage these systems to offer advanced synthetic services, thereby acting as key adopters and promoters of the technology. The end-users—primarily pharmaceutical and specialty chemical companies—integrate these reactors into their R&D or production lines. The final layer involves post-sale support, training, software updates, and maintenance, which are crucial for ensuring the long-term operational success and reliability of these complex photochemical synthesis platforms, thus securing customer loyalty and repeat business. The entire chain emphasizes intellectual property management and specialized technical expertise in photochemistry and fluidics, creating significant barriers to entry for non-specialized competitors.

Continuous Flow Photochemical Reactors Market Potential Customers

The primary cohort of potential customers for Continuous Flow Photochemical Reactors consists of entities heavily involved in complex organic synthesis and high-value chemical manufacturing where safety, efficiency, and yield are paramount. The dominant segment is the Pharmaceutical and Biotechnology industry, particularly companies engaged in the discovery and development of Active Pharmaceutical Ingredients (APIs), especially those requiring non-thermal, highly selective transformations such as photoredox catalysis, which are often utilized to create novel or patented synthetic routes. These buyers prioritize systems that offer robust scalability from discovery to clinical trials, minimal batch variability, and strict compliance with Good Manufacturing Practice (GMP) standards, seeking to leverage flow technology to shorten development timelines and reduce costs associated with traditional multi-step batch synthesis.

Another significant customer base comprises specialty and fine chemical manufacturers who produce niche, high-purity chemical intermediates, agrochemicals, and electronic chemicals. These buyers are motivated by the need for process intensification to handle sensitive or hazardous reagents (like strong oxidizers or highly energetic intermediates) safely in confined environments, often aiming for continuous production to maintain high-volume, consistent product streams. Furthermore, academic research institutions and governmental laboratories represent a persistent and necessary segment of potential customers, serving as early adopters for cutting-edge microfluidic photochemical systems and contributing significantly to the fundamental understanding and methodological development that feeds into industrial applications. These institutions are vital for validating new reactor designs and pioneering novel synthetic methodologies.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 880 Million |

| Growth Rate | 9.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Uniqsis Ltd., Vapourtec Ltd., Syrris Ltd., Corning Incorporated, Chemtrix BV, AMAR Equipment, FutureChemistry, Biotage AB, Zaiput Flow Technologies, HEL Group, Milestone Srl, Asahi Glass Co., Ltd., ThalesNano Inc., CEM Corporation, XPROR Process Development. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Continuous Flow Photochemical Reactors Market Key Technology Landscape

The technological landscape of Continuous Flow Photochemical Reactors is defined by rapid innovation aimed at optimizing photon delivery, enhancing fluid dynamics, and ensuring scalability. A central technological pillar is the pervasive adoption of Light Emitting Diode (LED) technology, specifically monochromatic UV and Visible LEDs. This shift enables precise control over the wavelength used, which is critical for maximizing quantum efficiency and minimizing side product formation, an impossibility with broad-spectrum lamps. Modern systems integrate high-power LED arrays directly adjacent to the flow channel, often utilizing sophisticated heat management systems (thermoelectric coolers or fluid jackets) to maintain isothermal reaction conditions, thereby preventing thermal degradation or explosion risks associated with high-energy photochemical processes.

Reactor design technologies are bifurcating between microfluidics and specialized mesoscale systems. Microfluidic reactors, built often from glass, quartz, or highly resistant polymers, excel in research and optimization due to their large surface-area-to-volume ratio, which provides exceptional mass and heat transfer, allowing for safer handling of explosive intermediates and maximizing light penetration. For industrial scale-up, technologies such as coiled tube reactors and falling film reactors are crucial. Coiled reactors are optimized for continuous, moderate-to-high throughput, while falling film reactors address the challenge of scaling highly light-attenuating reactions by exposing a thin film of liquid to the light source, thus mitigating depth penetration issues and enhancing overall reaction robustness.

Furthermore, the integration of advanced automation and Process Analytical Technology (PAT) defines the state-of-the-art systems. Modern flow photochemical setups utilize automated pump controls, pressure sensors, and sophisticated software for flow rate programming and residence time distribution management. Real-time monitoring via inline spectroscopy (FTIR, UV-Vis, or Raman) allows for instantaneous confirmation of conversion and purity, enabling closed-loop control systems. These integrated technologies facilitate true continuous manufacturing, ensure compliance, and drastically reduce the labor and time required for process development, representing a major technological leap from traditional, batch-based photochemical synthesis methods.

Regional Highlights

- North America: This region maintains its leadership position primarily due to the intense concentration of major pharmaceutical and biotechnology companies and substantial government funding directed towards advanced manufacturing and sustainable chemistry initiatives. The United States, in particular, drives adoption through its focus on developing continuous manufacturing methods for API production, often incentivized by regulatory bodies seeking enhanced quality assurance. The regional market benefits from a robust ecosystem of specialized technology developers and a high willingness to invest in high-capital, high-efficiency equipment. Adoption rates are particularly high in academic research and contract manufacturing organizations (CMOs) servicing complex drug synthesis needs, solidifying North America's status as a hub for commercializing flow photochemistry.

- Europe: Europe represents a mature market, strongly influenced by the EU's stringent REACH regulations and the overall commitment to Green Chemistry principles outlined in various strategic research agendas. Countries like Germany, Switzerland, and the UK possess strong traditions in fine chemical and specialty material production, leading to high adoption of continuous flow systems to improve safety and environmental performance. The market here emphasizes robust, industrial-scale reactors designed for long-term continuous operation, often focused on applications in polymer modification and complex material synthesis beyond just pharmaceuticals. The integration of continuous reactors into existing chemical infrastructure is a key regional trend.

- Asia Pacific (APAC): APAC is projected to exhibit the fastest growth over the forecast period, fueled by rapid expansion in the Chinese and Indian generic drug manufacturing sectors and increasing investment in domestic specialty chemical production across South Korea and Japan. While initially lagging in adoption, the region is now prioritizing process intensification to compete globally on efficiency and quality. The market is characterized by a high demand for cost-effective, scalable solutions. Government policies supporting industrial automation and modernization are key accelerators, pushing local manufacturers to invest in cutting-edge flow technology to meet international safety and environmental standards, particularly targeting high-throughput synthesis.

- Latin America (LATAM): The LATAM market is in an early-to-mid stage of adoption, with growth concentrated mainly in Brazil and Mexico, driven by localized pharmaceutical production and chemical processing centers. Adoption is often linked to technology transfer from multinational corporations establishing local production facilities. The market is price-sensitive, often favoring more standardized and entry-level mesoscale flow systems over high-end microfluidic research platforms. Growth hinges on sustained economic stability and increased investment in regional R&D infrastructure to support broader industrial integration of continuous technologies.

- Middle East and Africa (MEA): MEA currently holds the smallest market share but shows nascent growth potential, particularly in the UAE and Saudi Arabia, driven by diversification efforts away from oil reliance toward specialty chemicals, petrochemicals, and localized pharmaceutical production. Investments are strategic, often focused on establishing world-class research centers and pilot facilities that incorporate modern continuous flow technologies. Market expansion is dependent on significant infrastructure development and the creation of highly skilled labor pools capable of operating and maintaining advanced photochemical flow systems, often acquired through international joint ventures.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Continuous Flow Photochemical Reactors Market.- Uniqsis Ltd.

- Vapourtec Ltd.

- Syrris Ltd.

- Corning Incorporated

- Chemtrix BV

- AMAR Equipment

- FutureChemistry

- Biotage AB

- Zaiput Flow Technologies

- HEL Group

- Milestone Srl

- Asahi Glass Co., Ltd. (AGC)

- ThalesNano Inc.

- CEM Corporation

- XPROR Process Development

- Phoenix Flow Reactors

- IKA Werke GmbH & Co. KG

- Schott AG

- Ritter GmbH

- Fluigent S.A.

Frequently Asked Questions

Analyze common user questions about the Continuous Flow Photochemical Reactors market and generate a concise list of summarized FAQs reflecting key topics and concerns.What specific advantages do continuous flow photochemical reactors offer over traditional batch photochemical systems?

Continuous flow photochemical reactors provide superior advantages in terms of safety, control, and efficiency. They minimize handling of hazardous intermediates through reduced reaction volumes (holdup volume), enable precise control over irradiation time and temperature via continuous fluid motion, and maximize photon efficiency due to optimized light penetration in small channels. This leads to higher reaction selectivity, better reproducibility, and easier scale-up, aligning with modern industrial safety and economic requirements for complex synthesis.

How is the transition from traditional lamps to LED technology impacting the market?

The shift to LED technology is profoundly impacting the market by offering monochromatic, highly stable light sources across UV and Visible spectra. LEDs are energy-efficient, have long operational lifetimes, and allow specific tuning to match the absorption maximum of photocatalysts or reactants. This specificity enhances reaction selectivity, lowers operating costs, simplifies cooling requirements, and makes photochemical processes more viable for industrial continuous manufacturing environments.

What are the primary technical challenges faced during the industrial scale-up of flow photochemistry?

Key challenges during industrial scale-up include maintaining homogeneous light distribution across larger channel diameters, effectively managing the heat generated by high-power light sources, and mitigating fouling or clogging issues when handling complex reaction mixtures or slurries. Solutions involve moving from simple microchannels to specialized geometries like falling film or large-bore coiled reactors and incorporating robust inline Process Analytical Technology (PAT) systems for quality control.

Which end-user segment drives the highest demand and why?

The Pharmaceutical and Biotechnology segment drives the highest demand. This is primarily due to their need for synthesizing complex, high-value Active Pharmaceutical Ingredients (APIs) and novel chemical scaffolds with extreme precision and high selectivity. Flow photochemistry allows them to utilize photoredox catalysis and other light-driven reactions that are difficult or impossible in batch, offering proprietary synthetic routes, accelerated development timelines, and compliance with stringent quality standards necessary for drug manufacturing.

How does the integration of Artificial Intelligence (AI) enhance the performance of continuous flow photochemical processes?

AI enhances performance by enabling autonomous optimization of reaction parameters (flow rate, light intensity, temperature) and predicting complex reaction outcomes with minimal experimental iterations. Machine learning models interpret large datasets from high-throughput screening, accelerating catalyst selection and process development. AI also facilitates real-time monitoring and control using PAT tools, ensuring continuous process stability and maximizing product yield while minimizing waste generation.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager