Continuous Screen Changers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431623 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Continuous Screen Changers Market Size

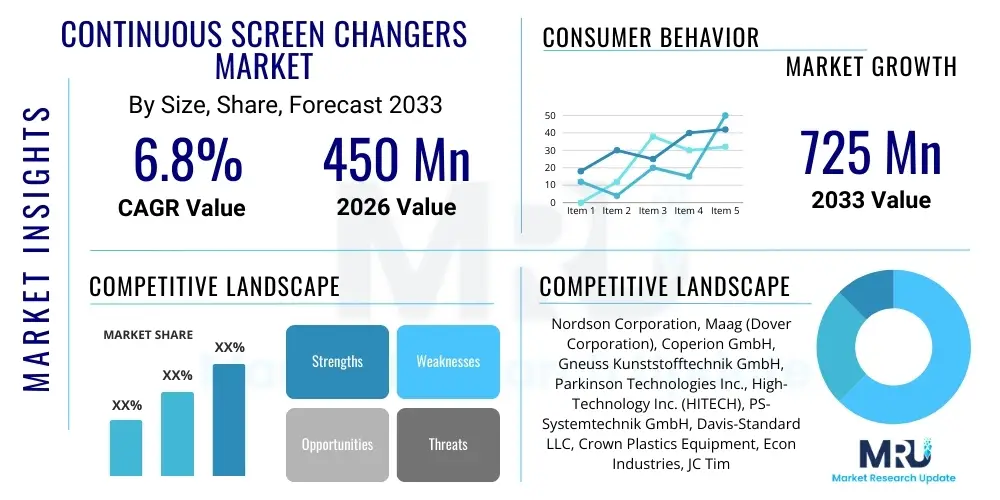

The Continuous Screen Changers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 725 Million by the end of the forecast period in 2033.

Continuous Screen Changers Market introduction

Continuous Screen Changers (CSCs) are essential components in polymer processing lines, designed to maintain melt filtration efficiency without interrupting production flow. These systems utilize hydraulic power or gear mechanisms to cycle fresh filter screens into the melt stream while removing contaminated screens, thereby ensuring non-stop operations in high-volume manufacturing environments. The core function of a CSC is to remove solid contaminants—such as burnt particles, gels, or foreign debris—from the polymer melt before it enters the die, crucial for maintaining end-product quality, especially in sensitive applications like film, fiber, and compounding.

The primary applications of Continuous Screen Changers span across the plastics industry, including extrusion processes for packaging materials, high-performance engineering plastics, recycling operations (where contaminants are prevalent), and masterbatch production. The growing demand for high-quality recycled polymers (rPET, rHDPE) mandates the use of highly efficient filtration systems, positioning CSCs as indispensable technology. Furthermore, the push towards automated manufacturing and reducing operational downtime provides significant momentum for market adoption globally.

Key benefits derived from implementing continuous screen changing technology include superior product consistency, prolonged equipment life (especially downstream components like dies and pumps), and substantial reduction in waste material generated during screen changes. Driving factors for market expansion include stringent quality standards in industries like medical packaging and automotive components, the global focus on sustainability pushing plastic recycling rates, and the inherent need for process stability in large-scale extrusion plants. The shift from manual or discontinuous screen changers to automated, continuous systems is a fundamental trend underpinning market growth.

Continuous Screen Changers Market Executive Summary

The Continuous Screen Changers market is poised for robust expansion, driven primarily by the escalating demand for high-quality, contaminate-free polymer products and the increasing necessity for zero-downtime production cycles across the global plastics industry. Business trends indicate a strong move toward advanced automation features, including self-cleaning mechanisms and integration with Industry 4.0 monitoring systems, allowing processors to optimize filtration timing and minimize polymer degradation. Key manufacturers are focusing on developing specialized systems capable of handling extremely high viscosity polymers and demanding high-pressure applications common in engineering plastics and demanding film production, ensuring broader applicability across diverse processing needs.

Regionally, the Asia Pacific (APAC) market, spearheaded by China and India, remains the dominant growth engine, fueled by massive investments in new extrusion capacity, particularly in packaging, infrastructure, and textile manufacturing. North America and Europe demonstrate mature market conditions but exhibit strong demand for highly sophisticated, large-format screen changers for high-capacity recycling plants and specialized medical/automotive polymer production. Regulatory pressure in Europe, mandating higher recycled content in packaging, directly stimulates investment in robust CSCs capable of filtering heavily contaminated recycled feedstocks effectively and reliably.

Segment trends highlight the dominance of the Slide Plate (Double Plate) segment due to its reliability and proven performance across various applications, although the backflush and continuous belt filter segments are gaining traction, especially in ultra-fine filtration requirements and highly contaminated waste streams. The extrusion application segment holds the largest market share, intrinsically linked to the global production volume of plastic pipes, profiles, sheets, and films. Innovations are focused on optimizing screen life and reducing shear stress on sensitive polymers, appealing to processors seeking both efficiency and material integrity.

AI Impact Analysis on Continuous Screen Changers Market

User inquiries regarding AI's influence on Continuous Screen Changers frequently revolve around predictive maintenance capabilities, optimal screen change scheduling, and real-time process control integration. Users are concerned with how AI can minimize unplanned downtime, calculate the precise contamination load to maximize screen utilization before fouling affects melt quality, and integrate filtration data seamlessly with broader plant ERP/MES systems. The primary expectations center on using machine learning algorithms to move beyond simple pressure differential triggers to complex predictive models based on throughput, polymer type, viscosity changes, and historical contaminant profiles, thus achieving true operational efficiency.

AI's initial integration in the CSC market is focused on enhancing sensor data utilization. Traditionally, screen changes are initiated manually or via basic high-pressure alarms. AI algorithms, however, can analyze continuous sensor streams (pressure, temperature, melt flow rate, motor load) to detect subtle, often non-linear patterns indicative of impending screen failure or necessary change, weeks in advance. This shift from reactive or predetermined maintenance schedules to condition-based predictive maintenance significantly elevates the reliability of the entire extrusion line, crucial for processes demanding tight tolerances and continuous operation.

Furthermore, AI-driven process optimization allows for dynamic adjustment of extrusion parameters in response to changes in melt filtration resistance. For example, if contamination levels spike due to variability in recycled feedstock, an AI-enabled system could communicate necessary, minimal adjustments to extruder screw speed or temperature profiles to temporarily compensate until the screen change is executed smoothly. This level of adaptive control minimizes energy waste, prevents material degradation caused by excessive shear, and ensures product homogeneity, maximizing the return on investment for high-end CSC equipment.

- Predictive Maintenance Scheduling: AI models analyze pressure trends and polymer contamination profiles to predict optimal screen change timing, drastically reducing unscheduled downtime.

- Automated Process Optimization: Machine learning algorithms adjust upstream extrusion parameters (e.g., screw RPM, heater zones) dynamically based on real-time filtration resistance data.

- Enhanced Data Analysis: AI aggregates sensor data from pressure transducers and flow meters to diagnose filtration efficiency and identify specific contamination sources.

- Remote Monitoring and Diagnostics: Cloud-based AI systems allow for remote operational oversight and automated reporting on filtration performance metrics (AEO: maximizing uptime through smart diagnostics).

- Supply Chain Integration: Prediction of wear part requirements (screens, seals) based on operational intensity, optimizing inventory management (GEO: efficiency in parts procurement).

DRO & Impact Forces Of Continuous Screen Changers Market

The Continuous Screen Changers market is shaped by a powerful confluence of drivers such as global plastic consumption growth and rising quality mandates, moderated by high initial investment costs and the complexity associated with processing highly sensitive materials. Opportunities abound in niche markets like bioplastics and advanced recycling, while the impact forces center on technological maturity and regulatory compliance pushing for enhanced melt purity. The necessity for minimizing operational disruption in high-volume production lines serves as the primary inertial force propelling market adoption, overshadowing concerns related to equipment complexity.

Drivers: The fundamental driver is the global expansion of polymer processing capacity, particularly in APAC, coupled with the increasing integration of recycled materials into mainstream products. Recycled polymers inherently contain higher levels of impurities, requiring more robust and continuously operating filtration solutions. Furthermore, the production of extremely thin films and high-specification fibers demands near-perfect melt purity, making continuous, automatic filtration non-negotiable. The push for greater automation and reduced manual intervention in manufacturing also accelerates the replacement of older, discontinuous screen changers with modern, highly efficient continuous units.

Restraints: Significant restraints include the high capital expenditure required for continuous screen changing systems compared to traditional manual or shuttle-type systems, which can deter small to medium-sized enterprises (SMEs). Additionally, the operational complexity associated with maintaining seals and hydraulics in high-temperature, high-pressure environments requires specialized training and maintenance expertise. In certain highly abrasive or corrosive applications, the lifespan of internal components, including the filters and sealing elements, can be shortened, leading to higher operational costs (OPEX) and potential processor reluctance.

Opportunities: Major opportunities reside in the development of specialized filtration solutions for demanding applications, such as high-temperature engineering polymers (PEEK, PTFE) and materials sensitive to shear stress, requiring specialized melt pumps integrated with the CSC. The booming chemical recycling sector and the processing of novel bioplastics represent untapped segments requiring unique filtration technologies to handle diverse feedstock characteristics. Market players also have opportunities in providing comprehensive digital service packages and predictive maintenance subscriptions, maximizing equipment uptime and generating recurring revenue streams.

Segmentation Analysis

The Continuous Screen Changers market is extensively segmented based on the mechanism of operation, the specific application in the polymer process, and the type of material being processed. Mechanism segmentation differentiates between the prevalent slide plate systems and emerging belt and piston types, reflecting varying demands for screen area and degree of automation. Application segmentation highlights the crucial role of CSCs in extrusion and compounding, the two processes most reliant on consistent melt quality and non-stop operation. Material segmentation addresses the unique filtration challenges posed by standard polymers versus highly contaminated recycled materials and specialized high-performance engineering plastics, driving market demand for tailored equipment specifications.

- By Mechanism Type: Slide Plate/Double Plate Screen Changers, Continuous Belt Screen Changers, Hydraulic Piston Screen Changers, Backflush Screen Changers.

- By Application: Extrusion (Film, Sheet, Pipe & Profile, Fiber), Compounding & Pelletizing, Recycling.

- By Polymer Type: Commodity Plastics (PE, PP, PVC), Engineering Plastics (PC, ABS, Nylon), Recycled Polymers (rPET, rHDPE), Specialty Polymers.

- By End-Use Industry: Packaging, Automotive, Construction, Consumer Goods, Medical, Agriculture.

- By Region: North America, Europe, Asia Pacific, Latin America, Middle East & Africa.

Value Chain Analysis For Continuous Screen Changers Market

The value chain for the Continuous Screen Changers market begins with the upstream sourcing of specialized raw materials, primarily high-grade steels, advanced alloys for internal components (to withstand high pressure and temperature), and sophisticated hydraulic or mechanical drive components. The upstream segment is characterized by reliance on precision engineering suppliers who provide durable components like specialized gearboxes, high-temperature seals, and sensor technology crucial for reliable continuous operation. Quality control at this stage is paramount, as component failure directly translates to production downtime for the end-user.

The core manufacturing stage involves the precision machining and assembly of the screen changer units. Manufacturers often specialize in proprietary sealing technologies and filter element designs (e.g., specific mesh counts or layered filter packs) optimized for various polymer viscosities and contamination levels. Direct distribution channels, involving the equipment manufacturer selling directly to large polymer processors or EPC contractors, are common for high-value, customized systems, facilitating direct technical support and integration consulting necessary for complex setups.

Downstream analysis focuses on the end-users—large compounding companies, film extruders, pipe manufacturers, and recycling facilities. These end-users integrate the CSC into their primary processing lines. Post-sale activities, including installation, commissioning, maintenance services, and the crucial supply of consumable filter screens and sealing elements, form a significant part of the value chain. Indirect distribution often utilizes specialized local agents or distributors in nascent markets, who provide localized support and quicker access to spare parts, maintaining the high operational demands of continuous systems.

Continuous Screen Changers Market Potential Customers

The primary purchasers and end-users of Continuous Screen Changers are entities deeply involved in high-volume, continuous polymer processing where product quality and zero downtime are paramount operational objectives. This primarily includes large-scale extrusion companies specializing in blown and cast films for food and non-food packaging, sheet extrusion for thermoforming applications, and manufacturers producing high-pressure pipes and profiles for infrastructure projects. These customers seek CSCs to ensure strict quality adherence and maximize machine utilization rates, often running equipment 24/7.

A second major customer segment comprises polymer compounders and masterbatch producers. These companies manipulate polymer characteristics by mixing additives, fillers, or colorants, requiring extremely clean melts to ensure consistent product homogeneity and prevent specks or flow disruptions in the final pellets. For compounders handling abrasive fillers or highly sensitive materials, the choice of CSC mechanism often leans towards models that minimize shear and provide large filtration surface areas, demanding high-end, specialized equipment tailored to viscosity ranges.

Crucially, the fastest-growing customer base is the plastic recycling industry. Modern recycling facilities processing post-consumer and post-industrial waste face significant challenges related to contaminant variability and concentration (e.g., paper, wood, aluminum, different polymer types). These customers require robust, high-capacity CSCs, often employing backflush capabilities or continuous belt systems, designed to handle extreme contamination loads without process interruption. Investment in advanced filtration is mandatory for recyclers aiming to produce near-virgin quality resins (AEO: targeting plastic recycling sector needs for contaminant management).

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 725 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Nordson Corporation, Maag (Dover Corporation), Coperion GmbH, Gneuss Kunststofftechnik GmbH, Parkinson Technologies Inc., High-Technology Inc. (HITECH), PS-Systemtechnik GmbH, Davis-Standard LLC, Crown Plastics Equipment, Econ Industries, JC Times, FIMIC srl, MAS Anlagenbau, Xaloy Extrusion, Colines S.p.A., Soni Plastics Engineering, Filtec Precise Inc., S&P Extrusion Technology, Jiangsu Jwell Machinery Co. Ltd., Nanjing Haisi Extrusion Equipment Co. Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Continuous Screen Changers Market Key Technology Landscape

The technological landscape of the Continuous Screen Changers market is defined by advancements aimed at improving sealing integrity, increasing filtration area within compact footprints, and enhancing automation and control. Key innovations center on optimized sealing systems, such as improved ceramic or metallic seals, which minimize polymer leakage during the changeover process and extend service life, particularly critical when processing high-viscosity or abrasive polymers under extreme pressure. Furthermore, manufacturers are focusing on designing filter elements that offer higher effective surface area (e.g., layered mesh packs or cylindrical filters) to maximize throughput and time between screen changes, a direct value proposition to high-capacity processors.

A significant shift involves the integration of advanced process monitoring and control technologies. Modern CSCs incorporate high-precision pressure transducers positioned strategically before and after the filtration unit, offering real-time data on melt flow resistance. This data is increasingly integrated with PLC systems that automate the screen change based not just on set pressure limits, but on rate of pressure rise, enabling proactive rather than reactive management of the filtration process. This automated intelligence minimizes melt flow interruptions and ensures a seamless transition, crucial for quality consistency in thin-gauge products.

The push for sustainability is driving innovation in continuous belt and backflush systems. Continuous belt screen changers, using a roll of inexpensive, disposable mesh, are becoming preferred in heavily contaminated recycling lines due to their ability to provide continuous, high-volume filtration without manual intervention or system stoppage. Backflush technology represents a leap forward by allowing a localized cleaning of filter elements using pressurized melt, significantly extending the life of reusable filters and reducing waste. Future developments will focus heavily on materials science to develop seals and components compatible with the aggressive conditions found in chemical recycling and high-temperature bioplastic processing environments.

Regional Highlights

- Asia Pacific (APAC): Dominates the global market volume due to rapid industrialization, massive investments in packaging manufacturing (especially in China, India, and Southeast Asia), and burgeoning infrastructure projects driving demand for PVC and HDPE pipe extrusion. The shift toward modernizing manufacturing facilities to meet global export standards further mandates the adoption of continuous filtration systems for quality assurance. This region is the primary consumer of medium to large capacity CSC units.

- North America: Characterized by high technological maturity and strong demand driven by the highly competitive recycling sector and specialized, high-precision manufacturing (automotive, medical). The market here favors high-capacity, highly automated CSCs, often integrated with complex data acquisition systems for regulatory reporting and efficiency optimization. Adoption is also spurred by domestic requirements for high-quality engineering plastics.

- Europe: Exhibits high growth, particularly in the recycling segment, fueled by strict EU mandates concerning plastic waste and recycled content inclusion (AEO: focus on EU recycling policies). Germany and Italy are major manufacturing hubs, emphasizing sophisticated, energy-efficient CSCs, including advanced backflush and continuous belt systems, to handle complex mixed plastic waste streams efficiently and sustainably.

- Latin America (LATAM): A developing market with increasing investment in basic infrastructure and domestic polymer production, driving steady demand for standard slide plate CSCs in pipe and profile extrusion. Market growth is closely tied to economic stability and foreign direct investment in local manufacturing plants.

- Middle East & Africa (MEA): Growth is primarily concentrated in Gulf Cooperation Council (GCC) countries due to large petrochemical production bases and ongoing construction booms. The market is emerging, focusing initially on standard filtration solutions for large-scale compounding and local film production, with potential for rapid expansion contingent on industrial diversification efforts.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Continuous Screen Changers Market.- Nordson Corporation

- Maag (Dover Corporation)

- Coperion GmbH

- Gneuss Kunststofftechnik GmbH

- Parkinson Technologies Inc.

- High-Technology Inc. (HITECH)

- PS-Systemtechnik GmbH

- Davis-Standard LLC

- Crown Plastics Equipment

- Econ Industries

- JC Times

- FIMIC srl

- MAS Anlagenbau

- Xaloy Extrusion

- Colines S.p.A.

- Soni Plastics Engineering

- Filtec Precise Inc.

- S&P Extrusion Technology

- Jiangsu Jwell Machinery Co. Ltd.

- Nanjing Haisi Extrusion Equipment Co. Ltd.

Frequently Asked Questions

Analyze common user questions about the Continuous Screen Changers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of a continuous screen changer over a manual screen changer?

The primary advantage of a Continuous Screen Changer (CSC) is its ability to perform screen changes without interrupting the melt flow or production line, ensuring zero downtime, maximizing throughput, and maintaining consistent product quality and gauge control (AEO: minimizing production downtime).

Which mechanism type is most suitable for highly contaminated recycled plastic streams?

Continuous Belt Screen Changers or robust backflush-enabled Slide Plate systems are typically most suitable for highly contaminated recycled streams, as they offer large filtration areas and mechanisms for automated removal or cleaning of the saturated filter media without stopping the process (AEO: contamination management in recycling).

How does the Continuous Screen Changers market benefit from regulatory pressure on plastic recycling?

Regulatory pressure, particularly in Europe and North America, mandates higher inclusion of recycled content, which typically contains higher levels of impurities. This directly increases demand for sophisticated, high-capacity Continuous Screen Changers essential for achieving the required melt purity for recycled resin applications (AEO: impact of sustainability mandates on machinery adoption).

What is the expected Compound Annual Growth Rate (CAGR) for the Continuous Screen Changers Market?

The Continuous Screen Changers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between the forecast period of 2026 and 2033, driven by global extrusion capacity expansion and modernization initiatives.

In what applications is melt filtration purity most critical for using CSCs?

Melt filtration purity is most critical in the production of thin films (for packaging or optical uses), high-specification fibers and filaments, and high-quality engineering plastic components, where even microscopic contaminants can cause product failure or visual defects (AEO: quality control in high-precision polymer manufacturing).

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Continuous Screen Changers Market Statistics 2025 Analysis By Application (Plastic, Resin, Rubber), By Type (Single Piston, Double Piston), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Discontinuous Screen Changers Market Statistics 2025 Analysis By Application (Electrical and Electronic, Packaging, Building and Construction, Automotive), By Type (Manual, Hydraulic), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Discontinuous Screen Changers Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Single-Piston, Double-Piston), By Application (Plastic, Resin, Rubber, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager