Control Foot Switches Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432214 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Control Foot Switches Market Size

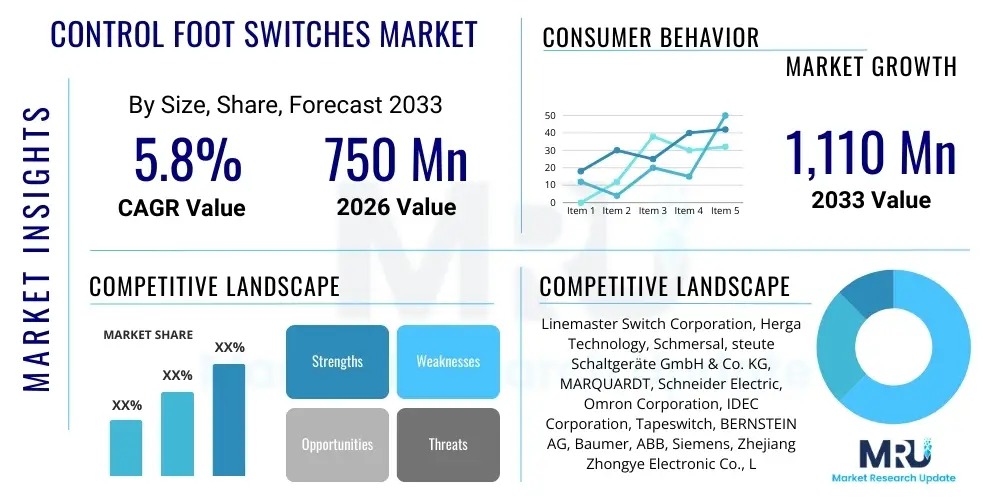

The Control Foot Switches Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $750 Million in 2026 and is projected to reach $1,110 Million by the end of the forecast period in 2033.

Control Foot Switches Market introduction

The Control Foot Switches Market encompasses the production, distribution, and utilization of specialized electrical switching devices actuated by the operator's foot. These devices are crucial for hands-free operation in various demanding environments, enhancing efficiency, safety, and ergonomics. Core products range from simple single-pedal switches used for machinery activation to complex multi-pedal systems integrated with sophisticated electronic controls, often featuring rugged enclosures designed to withstand harsh industrial conditions or demanding sterile medical environments. The switches are fundamentally designed to provide momentary or sustained contact closure, ensuring precise control over machinery, instruments, and other electronic equipment, thereby freeing the operator's hands for detailed work or manual adjustments.

Major applications for control foot switches span across critical sectors including medical, industrial automation, welding, textile machinery, and specialized office or commercial equipment. In the medical field, they are indispensable for controlling imaging devices (like X-ray and fluoroscopy machines), surgical equipment, and dental drills, where sterile, hands-free operation is mandatory. Industrially, they are used to manage power presses, shearing machines, and robotic arms, providing an essential safety cutoff mechanism or operational start/stop functionality. The key benefits driving adoption include improved safety protocols by allowing quick disconnection or activation, enhanced ergonomic workflow by reducing operator strain, and significant increases in operational efficiency through swift, intuitive control inputs.

Driving factors sustaining market growth are primarily linked to stringent occupational safety regulations globally, which mandate fail-safe and easily accessible machine controls. Furthermore, the accelerating trend of industrial automation, particularly in developing economies, requires reliable and durable interface solutions like foot switches to integrate seamlessly with automated production lines. Technological advancements, such as the incorporation of wireless connectivity, greater ingress protection (IP) ratings, and ergonomic design refinements tailored to specific occupational needs, further propel market expansion by offering versatile and high-performance switching solutions suitable for diverse, high-specification applications, from precision robotics to heavy manufacturing.

Control Foot Switches Market Executive Summary

The global Control Foot Switches Market demonstrates resilient growth, underpinned by critical requirements for operational safety and productivity gains across manufacturing and healthcare sectors. Current business trends indicate a strong shift towards highly customized and application-specific solutions, moving away from generic products. This customization is particularly evident in the demand for robust switches with higher IP ratings (IP67 and above) capable of resisting dust, liquids, and extreme temperatures, catering to heavy-duty industrial environments such as mining and shipbuilding. Furthermore, the integration of advanced features like USB interfaces and wireless (Bluetooth/RF) connectivity is rapidly defining the premium segment, addressing the need for flexibility and reduced cable clutter in modern workplaces, especially in surgical theaters and advanced CNC operations.

Regionally, Asia Pacific (APAC) is emerging as the fastest-growing market, primarily fueled by massive government investment in infrastructure and the expansion of the industrial automation base in countries like China, India, and South Korea. North America and Europe, while mature, maintain leading market share due to the dominance of advanced medical device manufacturing and stringent regulatory frameworks demanding high-quality, certified control components. These mature regions prioritize ergonomic design and adherence to complex global safety standards (e.g., IEC, UL), driving the adoption of high-reliability, fault-tolerant switches. European regulations regarding machinery safety are particularly influential, necessitating continuous innovation in switch design and monitoring capabilities.

Segment trends highlight the growing prominence of multi-pedal and programmable foot switches, offering operators greater functionality and personalized control profiles. The wired segment still commands the largest volume due to reliability and cost-effectiveness in fixed installations, but the wireless segment is experiencing rapid value growth, especially in applications requiring high mobility, such as portable medical diagnostics and field repairs. Segmentation by application confirms that the industrial sector remains the largest revenue contributor, yet the medical sector represents the highest growth potential due to ongoing technological advancements in imaging and surgical robotics that require ultra-precise and often sterile control interfaces, pushing manufacturers toward specialized silicone-protected and antimicrobial designs.

AI Impact Analysis on Control Foot Switches Market

Analysis of common user questions regarding AI's impact on Control Foot Switches reveals a concentrated interest in how AI can enhance safety, enable predictive maintenance, and integrate these traditional controls into smart factory ecosystems. Users frequently ask if AI will replace physical controls entirely or how foot switches can become "smart" peripherals. The core concern centers around leveraging AI-driven data analytics—generated either by the switch itself (via integrated sensors monitoring actuation force, frequency, and degradation) or by the machine it controls—to move beyond simple on/off functionality. Key expectations include using machine learning algorithms to monitor operational patterns, flag ergonomic stress indicators, and predict component failure before it impacts production, thereby transforming the foot switch from a passive input device into an active data node within the Industrial Internet of Things (IIoT).

AI's primary influence is not about replacing the physical act of control—which often needs to be tactile and instantaneous for safety—but about optimizing the performance and lifespan of both the switch and the machine. For instance, AI algorithms can analyze actuation force data collected by strain gauges within the switch mechanism. If the force required to activate the switch increases gradually, the AI can alert maintenance staff to potential internal corrosion or mechanical wear, preventing catastrophic failure and unplanned downtime. Furthermore, in highly regulated fields like surgery, AI can monitor the usage patterns of sterile foot switches, ensuring adherence to optimal procedural timing and potentially linking operator fatigue (as inferred from inconsistent pedal presses) to process quality degradation.

The integration of AI-enabled analytics transforms the value proposition of control foot switches from a commodity component to a crucial data point in a smart manufacturing or healthcare system. This shift encourages manufacturers to incorporate more sophisticated sensors and communication modules, driving up the Average Selling Price (ASP) for advanced models. AI ensures that the physical interface remains safe and ergonomic while simultaneously providing actionable intelligence for operational optimization and regulatory compliance reporting, thus ensuring the foot switch's continued relevance in the age of digitalization and automation.

- Predictive maintenance analytics based on actuation frequency and force monitoring.

- Integration into smart factory ecosystems using embedded ML models for anomaly detection.

- Enhanced operator safety through AI monitoring of usage patterns and fatigue detection.

- Optimization of ergonomic design based on long-term data analysis of pedal use and operator efficiency.

- Facilitation of complex multi-step processes through AI-guided programmable switch sequences.

DRO & Impact Forces Of Control Foot Switches Market

The Control Foot Switches Market is significantly shaped by a dynamic interplay of Drivers, Restraints, and Opportunities, resulting in specific Impact Forces that direct strategic decisions. A primary driver is the global emphasis on occupational safety standards, particularly in heavy industry and manufacturing, which mandates the use of reliable, hands-free controls to mitigate risks associated with machinery operation. This is complemented by the pervasive trend of automation and robotics across multiple sectors; as complex assembly and processing lines are deployed, the need for robust, instantaneous, and ergonomically sound start/stop mechanisms increases exponentially, ensuring smooth production flow and operator protection. Furthermore, the expanding medical sector, particularly in advanced surgical and diagnostic imaging equipment, consistently demands specialized, high-precision, and sterile foot switches, representing a constant source of innovation and market demand.

Conversely, significant restraints hinder growth, notably the high initial cost and complexity associated with specialized, high-specification switches, especially wireless and certified medical-grade variants. These switches require advanced circuitry, certified materials, and adherence to rigorous testing, making them substantially more expensive than basic mechanical switches, which can pose a barrier to adoption for small and medium-sized enterprises (SMEs). Additionally, the rapid development of alternative control technologies, such as voice control and gesture recognition, especially in non-critical or less tactile-dependent environments, poses a long-term substitution threat. Furthermore, compatibility issues arising from integrating specialized foot switches into disparate legacy machinery and proprietary control systems often complicate large-scale implementation projects, requiring bespoke engineering solutions.

Opportunities for market growth are abundant, chiefly driven by the development and standardization of wireless control technology, offering greater flexibility, reduced installation costs, and improved workplace mobility, particularly beneficial in open-plan industrial or medical settings. There is also a substantial opportunity in providing highly customized, multi-functional switches that can be programmed for complex machine sequences, moving beyond simple binary control. The core Impact Forces dictate that manufacturers must prioritize R&D in wireless communication reliability (minimizing latency and interference), material science (creating more durable and antimicrobial casings), and adherence to diverse global safety certifications. The strongest impact force remains regulatory pressure, continually forcing quality upgrades and defining the minimum acceptable standards for new product introductions across all key application segments.

Segmentation Analysis

The Control Foot Switches market is highly segmented based on core product characteristics, connectivity type, application complexity, and the material used in construction, reflecting the diverse and specialized requirements of end-users. Segmentation analysis provides crucial insights into which product types are driving growth and where technological investment is most required. The primary differentiator often lies in the number of pedals and the nature of the control signal, ranging from simple momentary switches to complex multi-pedal units featuring internal electronics for analogue signal output or sequential control programming.

Connectivity remains a vital segmentation axis, separating traditional wired solutions, favored for their reliability and resistance to interference in high-EMI industrial settings, from increasingly popular wireless solutions. Wireless foot switches, utilizing protocols like Bluetooth, RF, and proprietary low-latency radio, appeal to applications demanding mobility and freedom from cable management, such as in certain medical procedures or remote control of industrial vehicles. The application segmentation demonstrates the breadth of demand, requiring switches to meet distinct regulatory and environmental criteria, from sterile, waterproof designs in healthcare to extremely rugged, explosion-proof casings in mining or chemical processing.

Material segmentation also plays a crucial role in determining durability, weight, and suitability for specific environments. Metal enclosures (aluminum, cast iron, steel) are favored in heavy industry for robustness and impact resistance, while high-grade plastics and silicon are commonly used in medical and office settings for lighter weight, ergonomic comfort, and ease of sterilization. Understanding these segments is key for manufacturers to tailor their product lines to specific compliance standards and performance expectations, ensuring optimal market penetration across demanding vertical sectors.

- Type: Single Pedal, Dual Pedal, Triple Pedal, Multi-function/Programmable Switches.

- Connectivity: Wired, Wireless (Bluetooth, Radio Frequency, Proprietary Low Latency).

- Operating Mechanism: Momentary Action, Maintained Action, Non-Contact (Optical/Capacitive).

- Application: Medical (Surgical, Imaging, Dental), Industrial Automation (CNC, Welding, Robotics), Office Equipment, Textile Industry, General Purpose Machinery.

- Material: Metal Casing (Aluminum, Cast Iron), Plastic/Polymer Casing, Silicone/Antimicrobial Materials.

- Voltage/Current Rating: Low Voltage (LV), High Voltage (HV).

Value Chain Analysis For Control Foot Switches Market

The value chain for the Control Foot Switches Market begins with the upstream procurement of specialized raw materials, primarily high-durability metals (e.g., die-cast aluminum, stainless steel) for heavy-duty casings and high-grade polymers/silicone for sealing, ergonomic features, and medical applications. Crucially, the upstream supply also involves the acquisition of precision electronic components, including microswitches, Hall effect sensors, wireless transceiver modules, and advanced wiring harnesses. Manufacturers must maintain robust supply chain resilience, especially concerning the sourcing of certified, long-life components, as product failure often has high operational and safety consequences. Cost optimization at this stage is critical, balancing material quality with the need for competitive pricing in the mass-market industrial segment.

The core manufacturing and assembly stage involves integrating these components, requiring specialized engineering expertise in mechanical design, electrical safety, and enclosure integrity (IP ratings). This stage also includes rigorous quality control and certification processes, which are particularly intensive for switches destined for regulated sectors like medical or explosive atmospheres (ATEX/IECEx). Midstream value creation is driven by proprietary design patents focusing on ergonomic comfort, tamper-proofing, and enhancing signal reliability, particularly crucial for wireless and low-latency control systems. Manufacturers who excel at modular design and rapid customization gain a significant competitive edge.

Downstream analysis highlights diverse distribution channels, primarily categorized into Direct and Indirect routes. Direct sales are common for large volume Original Equipment Manufacturers (OEMs), where the switch is integrated into the final machinery (e.g., a welding robot or a specialized X-ray machine). This requires long-term contractual relationships and collaborative design input. Indirect distribution involves leveraging specialized industrial distributors, electrical component wholesalers, and Maintenance, Repair, and Operations (MRO) suppliers, who serve the replacement market and smaller volume end-users. The fastest-growing downstream channel involves specialized e-commerce platforms and technical component resellers, offering global reach and detailed product specifications for highly niche applications, facilitating quick access to highly specialized, certified foot switches.

Control Foot Switches Market Potential Customers

The primary potential customers and buyers of Control Foot Switches are diverse industrial, medical, and commercial entities that require hands-free, reliable activation mechanisms for their operational equipment. A significant segment comprises Original Equipment Manufacturers (OEMs) specializing in industrial automation machinery, including CNC machine tool builders, robotic system integrators, welding equipment manufacturers, and specialized textile machinery producers. These buyers demand switches that offer extreme durability, precise actuation, high ingress protection (IP ratings), and seamless electronic compatibility with complex control logic, often purchasing large volumes based on rigorous stress testing and long-term reliability guarantees.

The medical device industry forms another critical customer base, encompassing manufacturers of advanced surgical tables, fluoroscopy equipment, dental operatory systems, and diagnostic imaging hardware. For this segment, procurement criteria are exceptionally strict, centering on switches that are certified for use in sterile environments, often requiring antimicrobial coatings, waterproof silicone sealing, and compliance with medical standards such such as IEC 60601-1. Procurement decisions here are heavily influenced by regulatory approval and patient safety considerations, leading to high-value, low-volume purchases of specialized and often custom-designed switches that must endure repeated sterilization cycles.

Beyond OEMs, the MRO (Maintenance, Repair, and Operations) market constitutes a stable source of demand. End-users, ranging from small fabrication shops to large automotive assembly plants, regularly replace worn-out or damaged foot switches to ensure continuity of safety and operations. These buyers prioritize product availability, ease of installation, and compatibility with a wide range of existing legacy machinery. Emerging customer segments include specialized providers of ergonomic office solutions and gaming peripherals, seeking robust, programmable switches to enhance user input flexibility, though these remain niche compared to the dominant industrial and medical sectors.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $750 Million |

| Market Forecast in 2033 | $1,110 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Linemaster Switch Corporation, Herga Technology, Schmersal, steute Schaltgeräte GmbH & Co. KG, MARQUARDT, Schneider Electric, Omron Corporation, IDEC Corporation, Tapeswitch, BERNSTEIN AG, Baumer, ABB, Siemens, Zhejiang Zhongye Electronic Co., Ltd., PEDALPAQ, Pizzato Elettrica, Euro-Tech, OEM Controls, Altech Corporation, Dewan Controls. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Control Foot Switches Market Key Technology Landscape

The technological evolution within the Control Foot Switches market is centered around enhancing reliability, connectivity, and user safety across highly specialized applications. A significant development is the widespread adoption of Hall effect sensing technology, replacing traditional mechanical microswitches in high-precision and high-durability applications. Hall effect sensors utilize magnetic fields to determine pedal position, eliminating physical wear and tear on contact points, resulting in significantly extended operational lifecycles and enhanced positional accuracy—a necessity in sensitive medical imaging or high-speed machining processes. This transition minimizes maintenance requirements and reduces the likelihood of intermittent signal failure, which is critical for machine safety protocols.

Connectivity solutions represent the second pillar of technological advancement. While traditional hard-wired switches utilizing robust cabling (often armored or jacketed) remain the industry standard for maximum reliability and power transmission, the demand for high-performance wireless foot switches is accelerating. Modern wireless solutions leverage low-latency, robust communication protocols (such as proprietary 2.4 GHz RF or industrial Bluetooth Low Energy) specifically designed to prevent signal dropout and latency, which is unacceptable in critical control applications. Furthermore, many advanced models now incorporate fieldbus communication interfaces (e.g., Ethernet/IP, Profibus, CAN bus) to enable seamless integration into sophisticated Programmable Logic Controller (PLC) and distributed control systems, allowing the switch to communicate diagnostic status and operational data.

Ergonomic and material science innovations also form a crucial part of the technology landscape. Manufacturers are increasingly utilizing advanced polymers and rugged metal alloys to achieve higher IP ratings, making switches impervious to harsh contaminants and cleaning agents. For medical applications, the use of antimicrobial silicone and sealed enclosures that withstand aggressive chemical sterilization is standard practice. Furthermore, sophisticated ergonomic design principles are being employed to reduce operator fatigue over long shifts. Features such as adjustable pedal height, optimized pivot points, and tactile feedback systems ensure comfort and prevent accidental actuation, directly contributing to improved productivity and adherence to long-term workplace safety standards.

Regional Highlights

- North America: Dominates the market value, driven by a large, established medical device manufacturing sector, stringent safety regulations (OSHA), and early adoption of advanced industrial robotics. High demand for custom, certified medical-grade foot switches and wireless solutions for factory modernization projects.

- Europe: Characterized by high standards for quality, reliability, and machinery safety (CE marking and EU directives). Germany, in particular, shows robust demand due to its leadership in high-precision engineering and automotive manufacturing. Strong emphasis on ATEX-certified switches for potentially explosive atmospheres.

- Asia Pacific (APAC): Exhibits the highest growth potential, fueled by rapid industrialization, large-scale investment in automation infrastructure (e.g., China’s "Made in China 2025" initiative), and expanding healthcare facilities in India and Southeast Asia. The region is cost-sensitive but rapidly moving towards high-specification components, particularly in electronics manufacturing.

- Latin America: A growing market, characterized by increasing mechanization in mining and basic manufacturing. Demand often focuses on cost-effective, robust, and general-purpose industrial switches, with regulatory standards gradually catching up to global benchmarks.

- Middle East and Africa (MEA): Emerging market primarily driven by infrastructure projects, oil and gas sector demands, and nascent medical facility upgrades. Demand is highly localized and centers on switches capable of withstanding extreme environmental conditions (heat, dust), driving interest in highly sealed, high-IP rated metal switches.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Control Foot Switches Market.- Linemaster Switch Corporation

- Herga Technology

- Schmersal

- steute Schaltgeräte GmbH & Co. KG

- MARQUARDT

- Schneider Electric

- Omron Corporation

- IDEC Corporation

- Tapeswitch

- BERNSTEIN AG

- Baumer

- ABB

- Siemens

- Zhejiang Zhongye Electronic Co., Ltd.

- PEDALPAQ

- Pizzato Elettrica

- Euro-Tech

- OEM Controls

- Altech Corporation

- Dewan Controls

Frequently Asked Questions

Analyze common user questions about the Control Foot Switches market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of wireless control foot switches over traditional wired models?

Wireless control foot switches offer significant advantages in mobility, reducing tripping hazards associated with cables, and speeding up installation. They are essential in dynamic environments like surgical theaters or temporary industrial setups where cable management is challenging. Modern wireless models ensure minimal latency and high resistance to signal interference.

Which industry applications require the most rigorous certification and specialized control foot switches?

The Medical sector, particularly surgical and diagnostic imaging applications, requires the most rigorous certification (e.g., IEC 60601-1) due to patient safety mandates. These switches must be sealed (IPX8), often antimicrobial, and capable of withstanding aggressive sterilization processes. The Industrial sector, specifically mining and chemical processing, requires ATEX/IECEx certification for use in explosive atmospheres.

How does the IP rating (Ingress Protection) relate to the durability and selection of foot switches?

The IP rating indicates the degree of protection against dust and water ingress. Higher IP ratings (e.g., IP67 or IP68) signify superior durability, making the switch suitable for harsh industrial environments, wet conditions, or applications requiring frequent wash-downs, ensuring long operational life and maintaining electrical integrity against environmental hazards.

What technological advancements are driving the growth of the multi-function programmable switch segment?

Growth is driven by the integration of microcontrollers and advanced sensors (like Hall effect). These technologies enable the switch to provide variable analogue outputs or execute complex, programmable sequences, moving beyond simple binary control, which is essential for modern CNC machines and sophisticated robotic systems requiring multi-step, hands-free operation.

What is the projected impact of automation and robotics on the demand for control foot switches?

Automation and robotics significantly increase the demand for control foot switches, particularly for safety and emergency stop functions. As automation complexity grows, the need for reliable, instantaneous, and tactile human-machine interfaces remains critical, ensuring operators can initiate controlled stops or manual overrides swiftly and safely, integrating the switch as a fundamental safety component in the robotic ecosystem.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager