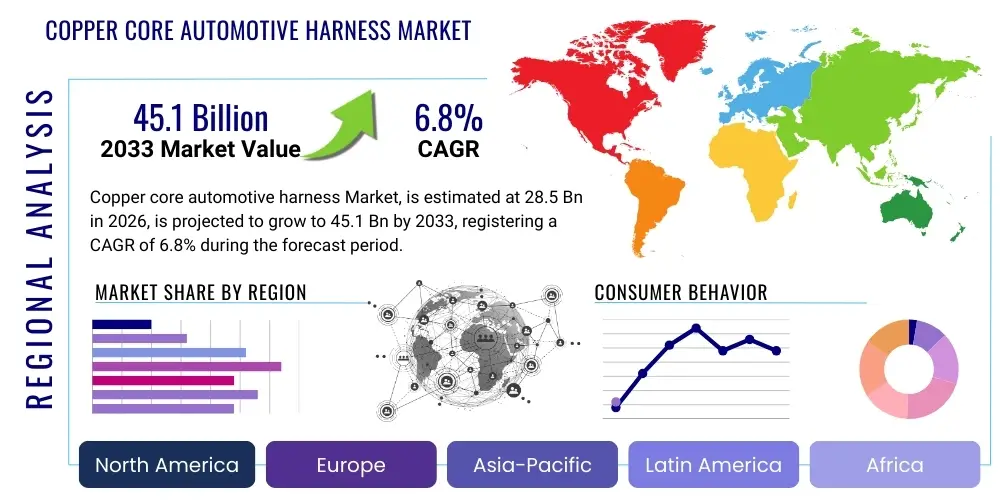

Copper core automotive harness Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440341 | Date : Jan, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Copper core automotive harness Market Size

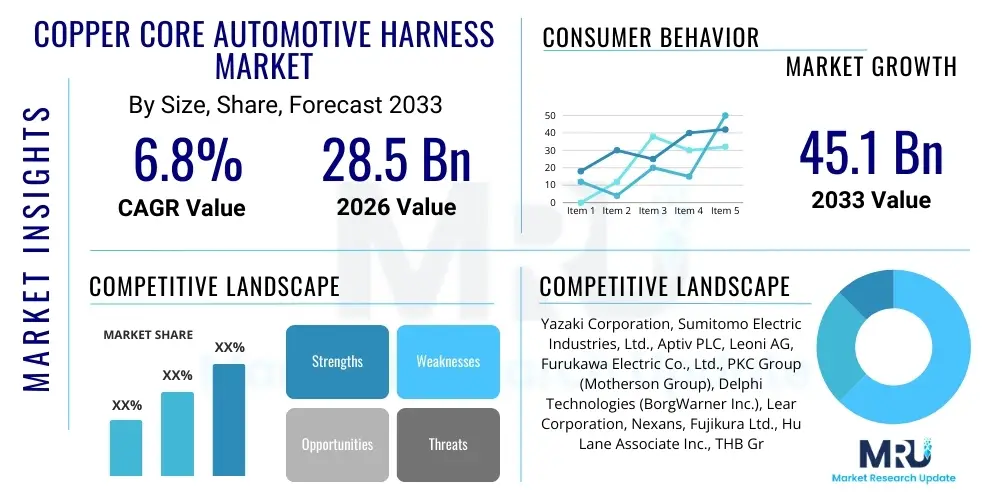

The Copper core automotive harness Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 28.5 billion in 2026 and is projected to reach USD 45.1 billion by the end of the forecast period in 2033.

Copper core automotive harness Market introduction

The Copper core automotive harness market encompasses the design, manufacturing, and distribution of electrical wiring systems that utilize copper as the primary conductor material within vehicles. These intricate networks of wires, connectors, and terminals are essential for transmitting power, data, and control signals throughout an automobile, enabling the functionality of various electronic components, sensors, and actuators. As the backbone of a vehicle's electrical architecture, copper core harnesses ensure reliable communication and power delivery, supporting everything from engine management and safety systems to infotainment and advanced driver-assistance systems (ADAS).

Product descriptions for copper core automotive harnesses typically highlight their superior electrical conductivity, durability, and cost-effectiveness compared to alternative materials. These harnesses are engineered to withstand the harsh automotive environment, including extreme temperatures, vibrations, and exposure to chemicals. Major applications span across the entire vehicle, including powertrain systems (engine and transmission control), chassis systems (ABS, ESP, suspension), body electronics (lighting, power windows, central locking), safety systems (airbags, seatbelt pretensioners), and increasingly complex infotainment and ADAS modules (sensors, cameras, radar units). The inherent robustness and reliability of copper make it an industry standard.

The benefits of utilizing copper in automotive harnesses are manifold, including its excellent thermal conductivity, corrosion resistance, and ductility, which facilitates ease of manufacturing and installation. These advantages contribute significantly to the overall performance, safety, and longevity of modern vehicles. Driving factors for market growth include the escalating demand for electric vehicles (EVs) and hybrid electric vehicles (HEVs), which require more extensive and complex wiring for battery management and high-voltage power distribution. Furthermore, the proliferation of advanced electronics, sensor technology, and connectivity features in conventional internal combustion engine (ICE) vehicles continues to drive the demand for sophisticated copper core harness solutions, necessitating higher data transfer rates and greater power capacity.

Copper core automotive harness Market Executive Summary

The Copper core automotive harness market is undergoing significant transformation, driven by robust business trends centered on technological innovation, strategic collaborations, and global supply chain optimization. Original Equipment Manufacturers (OEMs) and Tier-1 suppliers are investing heavily in advanced manufacturing techniques, such as automation and modularization, to enhance production efficiency and reduce costs. There is a discernible trend towards lightweighting and miniaturization of harnesses to accommodate space constraints and contribute to overall vehicle weight reduction, despite copper's density. Furthermore, the increasing complexity of vehicle electronics, particularly with the advent of ADAS and autonomous driving features, is spurring demand for high-speed data transmission capabilities and robust power delivery systems, necessitating continuous R&D in harness design and materials.

Regionally, the market exhibits diverse growth patterns. Asia Pacific, particularly China, India, and Japan, remains the dominant force due to its large automotive production base, rapid adoption of electric vehicles, and expanding consumer markets. Europe is characterized by stringent emission regulations and a strong push for electrification, fostering innovation in advanced harness solutions for premium and luxury vehicles. North America is experiencing steady growth, propelled by robust demand for SUVs, trucks, and the accelerating transition to EVs, alongside significant investments in connected car technologies. Latin America and the Middle East & Africa regions are emerging markets, showing potential for growth as automotive manufacturing capabilities expand and vehicle penetration increases, driven by urbanization and improving economic conditions.

Segment-wise, the market is primarily influenced by vehicle type, application, and component. The passenger car segment holds the largest share, driven by increasing sales and technological integration. However, the commercial vehicle segment is also experiencing notable growth, particularly in last-mile delivery and electric bus applications. In terms of application, powertrain and body electronics segments continue to dominate, but ADAS and infotainment systems are demonstrating the fastest growth rates due to the surge in demand for smart and safe vehicles. Component-wise, the demand for high-performance connectors and terminals is rising alongside the complexity of wiring, necessitating solutions that ensure signal integrity and robust connections in demanding operating environments. The ongoing shift towards higher voltage systems in EVs further segments the market based on voltage requirements, impacting material choices and insulation types.

AI Impact Analysis on Copper core automotive harness Market

Common user questions regarding AI's impact on the Copper core automotive harness market frequently revolve around how AI can enhance manufacturing efficiency, optimize design processes, and improve product reliability. Users are keen to understand if AI can predict failures, streamline supply chains, or even facilitate the integration of harnesses into autonomous driving platforms. Concerns often include the initial investment cost for AI implementation, the need for specialized skills, and data security. Expectations are high for AI to revolutionize traditional manufacturing paradigms, offering solutions for complex routing, fault detection, and personalized harness designs, ultimately leading to cost reductions and performance improvements across the automotive value chain.

- AI-driven design optimization for complex harness routing and packaging, reducing material waste and assembly time.

- Predictive maintenance for manufacturing equipment, minimizing downtime and increasing production efficiency.

- Automated quality inspection systems utilizing computer vision and machine learning to detect defects in wires, connectors, and insulation with high accuracy.

- Enhanced supply chain management through AI algorithms for demand forecasting, inventory optimization, and logistics planning, ensuring timely delivery of copper and other components.

- Development of smart harnesses with embedded sensors and AI capabilities for real-time monitoring of electrical performance and predictive fault detection within the vehicle.

- Personalization and customization of harness designs through generative AI, catering to specific vehicle models and optional features more efficiently.

- AI-powered simulations for stress testing and durability analysis of harnesses, accelerating product development cycles.

- Optimized factory floor operations, including robotic assembly and automated material handling, guided by AI for maximum throughput.

- Data analytics to identify trends in material usage, energy consumption, and production bottlenecks, leading to continuous process improvement.

DRO & Impact Forces Of Copper core automotive harness Market

The Copper core automotive harness market is influenced by a dynamic interplay of drivers, restraints, opportunities, and broader impact forces. Key drivers include the relentless growth in automotive production globally, particularly in emerging economies, coupled with the increasing electrification of vehicles. The rising adoption of advanced driver-assistance systems (ADAS), infotainment systems, and other sophisticated electronics in both conventional and electric vehicles significantly boosts demand for complex wiring solutions. Moreover, the inherent reliability and superior electrical conductivity of copper continue to make it the preferred material. Urbanization and improving disposable incomes in developing regions also contribute to higher vehicle sales and, consequently, increased demand for harnesses.

Conversely, the market faces several restraints. Volatility in copper prices can directly impact manufacturing costs and profit margins, creating uncertainty for market players. The ongoing trend towards lightweighting in automobiles, aimed at improving fuel efficiency and reducing emissions, could potentially encourage the adoption of alternative materials like aluminum or fiber optics, challenging copper's dominance, especially in less demanding applications. Furthermore, the complexity of designing and manufacturing sophisticated harnesses requires significant capital investment and skilled labor, posing barriers to entry and operational challenges. Global supply chain disruptions, as witnessed during recent crises, also represent a significant restraint due to the highly interconnected nature of automotive manufacturing.

Despite these challenges, substantial opportunities exist. The rapid acceleration in electric vehicle (EV) and hybrid electric vehicle (HEV) production presents a massive growth avenue, as these vehicles require higher voltage harnesses and more extensive wiring for battery management systems and charging infrastructure. The continuous evolution of autonomous driving technologies and connected car features necessitates advanced harness designs capable of handling high-speed data transmission and ensuring signal integrity, opening doors for innovation. Moreover, the development of modular and standardized harness designs, coupled with automation in manufacturing, can lead to significant cost efficiencies and quicker time-to-market. The aftermarket for replacement harnesses also offers a steady revenue stream, driven by vehicle longevity and repair needs. These opportunities are further amplified by a broader set of impact forces including geopolitical stability, trade policies, and environmental regulations which collectively shape the global automotive industry landscape.

Segmentation Analysis

The Copper core automotive harness market is comprehensively segmented across various parameters including vehicle type, application, component, voltage, and end-use, allowing for a detailed understanding of market dynamics and growth opportunities within specific niches. Each segment plays a crucial role in shaping demand and technological advancements, reflecting the diverse requirements of the modern automotive industry. Analyzing these segments helps in identifying key growth areas, competitive landscapes, and strategic entry points for market participants, facilitating tailored product development and marketing strategies to cater to distinct customer needs and technological shifts.

- By Vehicle Type:

- Passenger Cars (Sedans, SUVs, Hatchbacks)

- Commercial Vehicles (Light Commercial Vehicles, Heavy Commercial Vehicles, Buses, Trucks)

- By Application:

- Powertrain Systems (Engine Control, Transmission Control)

- Body Electronics (Lighting, Power Windows, Central Locking, HVAC)

- Chassis Systems (ABS, ESP, Suspension, Steering)

- Safety Systems (Airbags, Seatbelt Pretensioners)

- Infotainment & Telematics (Navigation, Audio, Connectivity)

- Advanced Driver-Assistance Systems (ADAS) (Sensors, Cameras, Radar)

- Battery Management Systems (BMS) (for EVs/HEVs)

- High Voltage Power Distribution (for EVs/HEVs)

- By Component:

- Wires & Cables (Low Voltage, High Voltage)

- Connectors (Sealed, Unsealed, Specific Application)

- Terminals

- Relays & Fuses

- Clips & Ties

- Insulation Tapes & Sleeves

- Grommets

- By Voltage:

- Low Voltage (<60V)

- High Voltage (>60V)

- By End-Use:

- OEM (Original Equipment Manufacturer)

- Aftermarket

Value Chain Analysis For Copper core automotive harness Market

The value chain for the Copper core automotive harness market begins with the upstream segment, which involves the sourcing and processing of raw materials. This primarily includes the mining and refining of copper, followed by its conversion into various wire gauges and strands. Other crucial raw materials include plastics for insulation and sheathing (PVC, XLPE, TPE), as well as materials for connectors and terminals (brass, tin, precious metals for plating). Key upstream players are metal suppliers, chemical companies, and specialized material manufacturers who provide these foundational components to harness manufacturers. Quality and consistent supply of these raw materials are critical for the downstream processes, influencing both the cost and performance of the final product.

Moving downstream, the value chain encompasses the actual manufacturing and assembly of the automotive harnesses. This stage involves cutting wires to specific lengths, stripping insulation, crimping terminals, and then assembling these components into complex networks according to vehicle designs. This process can be highly automated, utilizing robotic systems for efficiency and precision, or involve significant manual labor for intricate assemblies. Harness manufacturers, often Tier-1 suppliers to automotive OEMs, play a central role here, leveraging their expertise in design, engineering, and production to meet stringent automotive standards. They are responsible for testing and quality control to ensure reliability and compliance with safety regulations before distribution.

Distribution channels for copper core automotive harnesses are predominantly direct, especially for OEM applications. Harness manufacturers establish long-term contracts and direct supply relationships with automotive OEMs (Original Equipment Manufacturers) to integrate their products directly into vehicle assembly lines. This direct model ensures seamless integration, just-in-time delivery, and adherence to specific design requirements. For the aftermarket segment, distribution often involves a mix of direct sales to large fleet operators, partnerships with automotive parts distributors, and sales through independent wholesalers and retailers. Indirect channels also include collaborations with repair shops and service centers, providing replacement harnesses. The efficiency of these channels is critical for ensuring that both new vehicle production and maintenance operations are supported effectively, minimizing delays and operational costs across the automotive ecosystem.

Copper core automotive harness Market Potential Customers

The primary potential customers for the Copper core automotive harness market are the automotive Original Equipment Manufacturers (OEMs). These include global automotive giants producing passenger cars, commercial vehicles, and specialty vehicles, as well as emerging EV manufacturers. OEMs rely on harness suppliers to deliver complete, integrated wiring systems that are custom-designed for their specific vehicle platforms, ensuring seamless functionality of all electrical and electronic components. The relationships between harness suppliers and OEMs are often long-term and collaborative, involving joint design and engineering efforts from the early stages of vehicle development to optimize performance, cost, and manufacturability.

Beyond direct OEM engagement, Tier-1 automotive component suppliers also represent a significant customer segment. These companies might purchase specialized harnesses or sub-assemblies for their modules, such as advanced infotainment systems, ADAS units, or powertrain control units, which are then supplied to OEMs as part of a larger system. For instance, a company specializing in dashboard assemblies might procure specific copper core harnesses to integrate various displays, switches, and connectivity ports before delivering the complete module to the vehicle manufacturer. This indirect supply chain highlights the intricate network of relationships within the automotive industry where specialized suppliers collaborate to build complex vehicle systems.

Furthermore, the aftermarket segment constitutes another important customer base, albeit with different purchasing dynamics. This includes independent repair shops, authorized service centers, fleet management companies, and individual vehicle owners seeking replacement or upgrade harnesses. While the volume per transaction might be smaller compared to OEM orders, the cumulative demand from the aftermarket ensures a consistent revenue stream, driven by the longevity of vehicles and the need for repairs or modifications over their operational lifespan. Companies operating in this space focus on providing robust, often standardized, replacement parts that are compatible with a wide range of vehicle models, emphasizing availability, durability, and cost-effectiveness for repair and maintenance purposes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 28.5 Billion |

| Market Forecast in 2033 | USD 45.1 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Yazaki Corporation, Sumitomo Electric Industries, Ltd., Aptiv PLC, Leoni AG, Furukawa Electric Co., Ltd., PKC Group (Motherson Group), Delphi Technologies (BorgWarner Inc.), Lear Corporation, Nexans, Fujikura Ltd., Hu Lane Associate Inc., THB Group, Kyongshin Industrial Co., Ltd., Prysmian Group, DRÄXLMAIER Group, Kromberg & Schubert, Coroplast Group, Yura Corporation, Qingdao Huatong, Sichuan Huawei Wire and Cable |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Copper core automotive harness Market Key Technology Landscape

The Copper core automotive harness market is continuously evolving through significant technological advancements aimed at enhancing performance, reducing weight, and improving manufacturing efficiency. One of the primary technological shifts involves the development of high-speed data transmission cables and connectors. With the proliferation of ADAS, autonomous driving, and advanced infotainment systems, there is an increasing need for harnesses capable of handling gigabit-level data rates with minimal signal loss and interference. Technologies like shielded twisted pair (STP) and fiber optic integration for specific high-bandwidth applications, while not replacing copper entirely, are influencing copper harness design to complement these systems and ensure robust, high-integrity data pathways for critical vehicle functions.

Another crucial area of technological focus is miniaturization and lightweighting. While copper is denser than alternative materials like aluminum, innovations in insulation materials, conductor designs (e.g., thinner gauge wires), and connector technologies are allowing harness manufacturers to significantly reduce the overall size and weight of wiring assemblies. Advanced polymer insulations (such as XLPE and TPE) offer superior thermal resistance, flexibility, and reduced thickness, contributing to weight savings without compromising electrical performance or durability. Furthermore, compact connector designs and modular harness architectures are being developed to optimize packaging space within increasingly crowded vehicle platforms, facilitating easier assembly and repair while reducing material usage.

Manufacturing processes are also undergoing a revolution, driven by automation and Industry 4.0 principles. Advanced robotic systems are employed for precise wire cutting, stripping, crimping, and routing, significantly improving production speed, accuracy, and consistency. Machine vision systems, often integrated with AI, are used for real-time quality inspection, detecting flaws in wiring or connections that would be difficult to identify manually. Moreover, digital twin technology and simulation tools are being utilized for virtual prototyping and testing of harness designs, allowing engineers to optimize layouts, analyze stress points, and identify potential issues before physical production. This integration of smart manufacturing technologies enhances operational efficiency, reduces waste, and supports the rapid development cycles demanded by the automotive industry.

Regional Highlights

- Asia Pacific (APAC): Dominates the global market due to its position as the largest automotive manufacturing hub, with countries like China, Japan, India, and South Korea leading in vehicle production. The rapid adoption of electric vehicles, increasing disposable incomes, and the presence of major automotive OEMs and component suppliers drive significant demand for copper core automotive harnesses in this region. Government initiatives promoting local manufacturing and electric mobility further fuel market expansion.

- Europe: A mature market characterized by stringent emission regulations and a strong emphasis on vehicle safety and luxury. Countries such as Germany, France, and the UK are at the forefront of automotive innovation, particularly in premium and electric vehicle segments. This region witnesses high demand for technologically advanced and high-performance copper core harnesses to support complex ADAS, infotainment systems, and robust EV powertrains.

- North America: Exhibits steady growth, propelled by the robust demand for light trucks and SUVs, alongside a significant push towards vehicle electrification. The United States, in particular, is a key market due to its large automotive consumer base and substantial investments in connected car technologies and autonomous driving research. The presence of major automotive giants and a well-developed aftermarket sector contribute to sustained demand.

- Latin America: An emerging market with significant growth potential, driven by increasing automotive production in countries like Brazil and Mexico. Economic development, urbanization, and rising middle-class incomes are leading to higher vehicle sales. The market here is characterized by a growing demand for cost-effective and reliable harness solutions as local manufacturing capabilities expand.

- Middle East and Africa (MEA): A relatively smaller but rapidly growing market, influenced by increasing foreign investments in automotive manufacturing and rising vehicle penetration rates. Countries in the GCC region are investing in diversifying their economies, including the automotive sector. While still in nascent stages compared to other regions, the expanding automotive assembly plants and infrastructure development present future growth opportunities for copper core automotive harnesses.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Copper core automotive harness Market.- Yazaki Corporation

- Sumitomo Electric Industries, Ltd.

- Aptiv PLC

- Leoni AG

- Furukawa Electric Co., Ltd.

- PKC Group (Motherson Group)

- Delphi Technologies (BorgWarner Inc.)

- Lear Corporation

- Nexans

- Fujikura Ltd.

- Hu Lane Associate Inc.

- THB Group

- Kyongshin Industrial Co., Ltd.

- Prysmian Group

- DRÄXLMAIER Group

- Kromberg & Schubert

- Coroplast Group

- Yura Corporation

- Qingdao Huatong

- Sichuan Huawei Wire and Cable

Frequently Asked Questions

What is a copper core automotive harness?

A copper core automotive harness is an organized assembly of copper wires, terminals, and connectors that transmit electrical power, signals, and data throughout a vehicle. It acts as the central nervous system, enabling various electronic components from the engine to infotainment systems to function seamlessly and reliably.

Why is copper preferred for automotive harnesses over other materials?

Copper is highly preferred due to its superior electrical conductivity, excellent thermal conductivity, corrosion resistance, and ductility. These properties ensure efficient power and data transmission, durability in harsh automotive environments, and ease of manufacturing and installation, making it ideal for critical vehicle systems.

How do electric vehicles (EVs) impact the demand for copper core automotive harnesses?

EVs significantly increase demand for copper core harnesses. They require more extensive and higher-voltage wiring for battery management systems, power distribution, and charging infrastructure, often leading to a substantial increase in the copper content per vehicle compared to traditional internal combustion engine vehicles.

What are the primary applications of copper core automotive harnesses?

Copper core automotive harnesses are crucial for diverse applications, including powertrain systems (engine, transmission), chassis systems (ABS, ESP), body electronics (lighting, power windows), safety systems (airbags), infotainment, telematics, and advanced driver-assistance systems (ADAS) that rely on complex sensor networks.

What technological advancements are shaping the copper core automotive harness market?

Key advancements include the development of high-speed data transmission cables for ADAS, miniaturization and lightweighting through advanced insulation materials, and the widespread adoption of automation and AI in manufacturing processes to improve efficiency, precision, and quality control in production.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager