Copper Paste Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438195 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Copper Paste Market Size

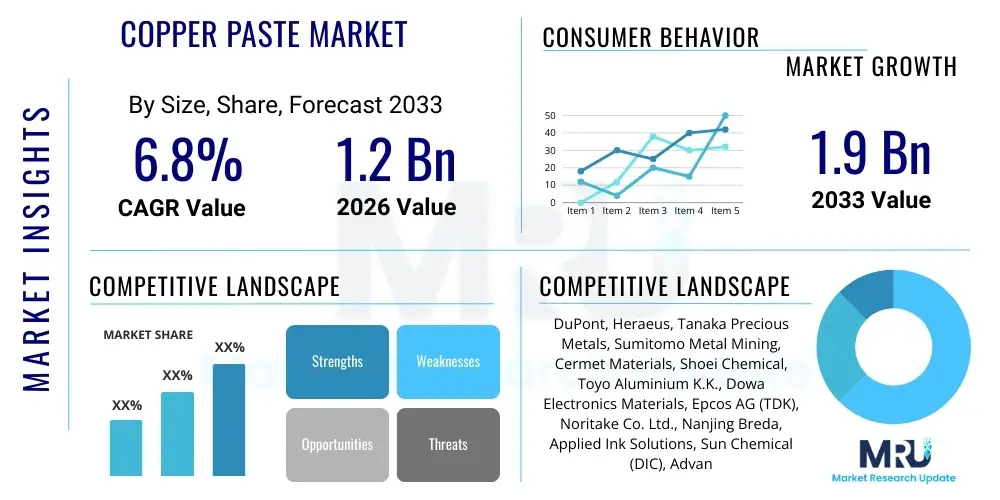

The Copper Paste Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 1.9 Billion by the end of the forecast period in 2033.

This substantial growth is primarily fueled by the accelerating demand for advanced electronic components across key industrial sectors, particularly automotive, telecommunications, and consumer electronics. Copper paste, known for its high conductivity, cost-effectiveness compared to silver paste, and excellent solderability, is becoming the material of choice for various applications, including thick film circuits, printed electronics, and solar cell metallization. The shift towards miniaturization and high-performance devices necessitates materials that can maintain integrity and functionality under demanding operating conditions, positioning copper paste as a critical enabling technology.

Furthermore, the rapid expansion of the electric vehicle (EV) market and the deployment of 5G infrastructure are significant contributors to the market expansion. EVs rely heavily on sophisticated power electronics and battery management systems where robust conductive materials are essential. Similarly, 5G technology demands high-frequency performance and reliability in antennas and passive components, areas where specialized copper pastes offer superior solutions. Regulatory push for green electronics and the focus on reducing reliance on precious metals also favor the adoption of copper-based solutions, solidifying the forecast trajectory for the market.

Copper Paste Market introduction

The Copper Paste Market encompasses the manufacturing, distribution, and application of highly conductive compositions containing micron or nano-sized copper particles suspended in an organic vehicle system. These pastes are crucial functional materials, typically applied through methods such as screen printing, ink-jet printing, or dispensing, and subsequently cured or sintered to form durable, conductive tracks or interconnects. Copper paste serves as a cost-effective alternative to traditional silver-based conductive materials, offering comparable electrical performance for many high-volume applications, particularly in sectors where material cost optimization is paramount. Major applications span thick film hybrid integrated circuits, electrode formation in Multilayer Ceramic Capacitors (MLCCs), photovoltaic (PV) solar cell front and rear side metallization, Radio-Frequency Identification (RFID) tags, and the expanding field of flexible and wearable electronics. The primary benefits of using copper paste include superior conductivity, excellent corrosion resistance after proper processing, compatibility with a wide range of substrates, and significant cost advantages over precious metal pastes. Driving factors for market expansion include the global surge in semiconductor production, increased adoption of renewable energy sources (solar), continuous advancements in 3D printing of electronics, and the fundamental need for reliable and high-density electronic packaging solutions.

Copper Paste Market Executive Summary

The Copper Paste Market is exhibiting robust growth, driven by fundamental shifts in global business trends, including the accelerated digitalization of industries and massive investments in sustainable energy infrastructure. Key business trends indicate a strong move towards developing nano-copper pastes, offering finer resolution printing capabilities essential for miniaturization in consumer electronics and advanced packaging. Segmentation trends show the application in photovoltaic (PV) cells dominating the consumption volume due to global solar energy mandates, although the electronics segment (driven by 5G and IoT) is expected to show the highest growth rate. Regionally, the Asia Pacific (APAC) market, spearheaded by China, Japan, South Korea, and Taiwan, maintains its undisputed leadership owing to the concentration of major electronics manufacturing hubs, semiconductor fabrication plants, and PV cell production facilities. Manufacturers are actively pursuing strategic collaborations and mergers to secure raw material supply chains and to expand their technological portfolios, particularly in highly specialized pastes designed for high-temperature and harsh environment applications. Overall, the market remains competitive, with emphasis placed on R&D to enhance stability, reduce sintering temperatures, and improve long-term reliability of copper-based interconnects.

AI Impact Analysis on Copper Paste Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Copper Paste Market predominantly revolve around how AI can optimize the material science involved in paste formulation, enhance manufacturing process efficiency, and facilitate predictive quality control. Users are keen on understanding if AI algorithms can accelerate the development of novel copper nano-particles, predict the performance characteristics (such as resistivity and printability) based on varying organic vehicle compositions, and minimize defects during the complex screen-printing and sintering processes. The consensus expectation is that AI tools, particularly Machine Learning (ML) and computer vision, will revolutionize the R&D pipeline by enabling rapid simulation and material discovery, allowing manufacturers to quickly customize paste properties for specific end-user requirements, such as ultra-low-temperature sintering necessary for flexible substrates. This transformation is anticipated to lead to faster time-to-market for specialized pastes and a significant reduction in production waste, thereby optimizing overall operational expenditure within the highly technical manufacturing landscape of conductive materials.

- AI optimizes paste formulation by using machine learning models to correlate material inputs (copper particle size, shape, solvent type) with desired output characteristics (conductivity, adhesion, viscosity).

- Predictive maintenance implemented through AI minimizes downtime in high-volume production lines for screening and firing, ensuring consistent quality and yield maximization.

- Computer vision systems powered by AI enhance quality control, automatically detecting minute defects in printed patterns before sintering, which is critical for high-reliability applications like automotive electronics.

- AI accelerates R&D cycles by simulating sintering behavior and thermal stress, reducing the need for extensive physical prototyping and experimental testing.

- Supply chain optimization using AI tools allows manufacturers to predict copper raw material price fluctuations and manage inventory efficiently, mitigating cost volatility risks.

DRO & Impact Forces Of Copper Paste Market

The Copper Paste Market is governed by a dynamic interplay of market Drivers, Restraints, and Opportunities (DRO), which collectively constitute the Impact Forces influencing its trajectory. The primary Driver is the overwhelming economic incentive to substitute expensive silver paste with copper paste across industries, alongside the aggressive expansion of the solar energy and EV sectors, which demand robust, cost-effective conductive solutions. The Restraints mainly center on the inherent tendency of copper to oxidize, requiring complex and often costly nitrogen or reducing atmosphere processing during sintering, which adds manufacturing complexity and limits adoption in certain low-tech applications. Furthermore, stringent environmental regulations regarding the disposal of solvents and organic vehicles used in paste formulations pose regulatory hurdles. Opportunities are vast, focused on developing highly stable, oxidation-resistant copper pastes that can be sintered in air at lower temperatures, opening doors to new markets like advanced flexible substrates and printed sensors. The cumulative impact forces suggest a strong market acceleration, provided R&D efforts successfully mitigate the oxidation challenge and streamline processing requirements, ensuring copper paste achieves its full potential as the preferred conductive material for next-generation electronics.

Segmentation Analysis

The Copper Paste Market is comprehensively segmented based on its physical properties, composition types, and diverse application areas, allowing for a detailed analysis of specific demand drivers and end-user preferences. Segmentation by type primarily differentiates between the copper particle structure (nano vs. micron) and the binding mechanism (fritted vs. fritless), each catering to distinct performance and temperature requirements. Application segmentation is crucial, highlighting the major demand centers, including Photovoltaics (PV), which dominates volume, and the rapidly growing Electronics segment, which drives innovation in high-resolution printing. Furthermore, the market can be segmented by the method of deposition, such as screen printing or dispensing, influencing the paste's rheological properties required by manufacturers. Understanding these segments is vital for stakeholders to tailor product offerings, align manufacturing capabilities, and focus strategic marketing efforts on the most lucrative and technologically demanding end-use markets.

- By Type:

- Nano Copper Paste

- Micron Copper Paste

- By Sintering Mechanism:

- Fritted Paste (utilizing glass/ceramic binders)

- Fritless Paste (relying solely on particle-to-particle bonding)

- By Application:

- Photovoltaic (Solar Cells)

- Electronics (MLCCs, Semiconductors, Passive Components)

- Automotive Electronics (Sensors, Power Modules)

- Printed and Flexible Electronics

- LED Lighting

- Others (RFID, Medical Devices)

- By Processing Method:

- Screen Printing Paste

- Dispensing Paste

Value Chain Analysis For Copper Paste Market

The value chain for the Copper Paste Market begins with the Upstream Analysis, which involves the critical extraction and refinement of high-purity copper, followed by sophisticated processing steps to synthesize uniformly sized, often spherical, nano or micron copper particles. These powder manufacturers are the foundational element, ensuring the required purity and morphology essential for high-performance paste. Midstream activities involve the core paste formulation process, where specialized chemical companies blend the copper powder with complex organic vehicles, binders, solvents, and dispersants, utilizing proprietary recipes to achieve specific rheological and electrical properties required for various printing techniques. The Downstream Analysis focuses on the distribution channels, which are typically direct sales channels serving large original equipment manufacturers (OEMs) in the PV and electronics sectors, and specialized distributors serving smaller application houses. Direct channels facilitate deep technical collaboration between paste manufacturers and end-users, crucial for optimizing paste performance for specific substrate and firing processes. Indirect channels leverage regional distributors capable of providing localized technical support and maintaining shorter lead times. This structure ensures that technical expertise is integrated throughout the supply chain, moving from high-purity raw materials to highly reliable final electronic components.

Copper Paste Market Potential Customers

Potential customers for Copper Paste are highly concentrated within advanced manufacturing sectors that require high-performance, conductive interconnects at an optimized cost structure. The largest volume consumers are Photovoltaic (PV) cell manufacturers, utilizing copper paste extensively for the formation of front and rear electrodes necessary for power generation efficiency. A significant and rapidly growing customer base includes manufacturers of Multilayer Ceramic Capacitors (MLCCs) and other passive electronic components, where copper paste is used to form internal electrodes, replacing expensive palladium-silver alloys. Furthermore, the automotive industry, particularly suppliers focused on electric vehicle battery management systems (BMS), power modules, and advanced sensors, represents a high-value customer segment due to the stringent requirements for durability and thermal stability. Other critical end-users include producers of flexible printed circuit boards (FPCBs), wearable electronics developers, and manufacturers of high-density semiconductor packaging solutions, all of whom seek reliable, high-resolution printing capabilities offered by advanced copper pastes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 1.9 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | DuPont, Heraeus, Tanaka Precious Metals, Sumitomo Metal Mining, Cermet Materials, Shoei Chemical, Toyo Aluminium K.K., Dowa Electronics Materials, Epcos AG (TDK), Noritake Co. Ltd., Nanjing Breda, Applied Ink Solutions, Sun Chemical (DIC), Advanced Nanotech, Ningbo Ronzin Chemical. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Copper Paste Market Key Technology Landscape

The Copper Paste Market is driven by several pivotal technological advancements aimed at overcoming copper’s inherent oxidation challenges and enhancing performance metrics. A primary area of innovation is the synthesis of high-quality nano-copper powder, where techniques like chemical reduction and physical vapor deposition are employed to achieve narrow particle size distribution and control morphology, crucial for optimizing paste rheology and conductivity after sintering. Another key technological focus is the formulation of advanced organic vehicles and binders, specifically designed to protect the copper particles from oxidation during storage and printing, and to volatilize cleanly at controlled temperatures. This includes the development of 'fritless' or reactive organic binders that eliminate the need for traditional glass frits, enabling lower sintering temperatures compatible with flexible polymer substrates. Furthermore, additive manufacturing techniques, particularly specialized inkjet printing and aerosol jetting of copper paste, are gaining traction, demanding ultra-fine, highly stable paste formulations that can achieve sub-micron line widths, opening new possibilities for high-density interconnects and 3D printed electronics. Success in this market is intrinsically linked to the ability to combine stable nanoparticle synthesis with proprietary low-oxygen processing chemistries.

The transition to green electronics and high-frequency applications mandates continuous technological upgrades in copper paste manufacturing. Specifically, advancements in air-sinterable copper pastes represent a significant breakthrough, mitigating the capital expense and operational complexity associated with inert atmosphere firing. These specialized pastes often incorporate complex surface chemistries or unique reducing agents within the organic vehicle that react during heating, effectively cleaning the copper particle surface and allowing metallic bonding in ambient conditions. Another critical technology involves the utilization of highly dispersed metal oxide dopants within the paste formulation; these dopants enhance adhesion to various substrates (ceramic, glass, polymer films) and improve the mechanical strength and electromigration resistance of the resulting copper tracks, extending the lifespan and reliability of the electronic device. As performance demands escalate, especially in high-power applications like EV inverters, the thermal conductivity and current-carrying capacity of the resulting copper layer are becoming key performance indicators, pushing technological efforts towards highly packed microstructures post-sintering.

Beyond material science, the technology landscape includes the integration of advanced process control systems to ensure batch-to-batch consistency—a necessity for high-reliability components. Manufacturers are investing heavily in real-time monitoring of particle dispersion, viscosity measurement, and shear-thinning behavior, often using inline sensors and big data analytics to adjust production parameters dynamically. This technological sophistication in manufacturing ensures that the rheology of the paste remains optimized for high-speed printing techniques, reducing defects such as voiding, bridging, and insufficient wetting. Finally, the growing convergence of copper paste with flexible substrate technologies, such as polyimide and PET, is driving the need for ultra-low-temperature processing protocols, below 200 degrees Celsius, which is technologically challenging but essential for unlocking the potential of wearable and flexible electronics markets globally.

Regional Highlights

- Asia Pacific (APAC): APAC is the dominant market for copper paste, attributed to being the global manufacturing hub for electronics, semiconductors, and solar cells. Countries like China, South Korea, Japan, and Taiwan host the largest production capacities for MLCCs, advanced packaging, and PV modules, driving massive internal demand. The strong governmental support for renewable energy in China further solidifies its leading position in PV applications.

- North America: North America is a significant market focused heavily on high-value, high-reliability applications, particularly in aerospace, defense electronics, and advanced automotive power electronics (EV manufacturing). Growth is propelled by ongoing R&D in flexible electronics and the adoption of printed electronic sensors in IoT devices.

- Europe: Europe holds a strong position driven by the automotive sector (especially in Germany and France) and robust investment in renewable energy projects. The region emphasizes high-quality, specialized copper pastes conforming to strict environmental regulations (RoHS, REACH), pushing innovation towards greener, solvent-free formulations.

- Latin America (LATAM): The LATAM market is emerging, characterized by increasing industrialization and rising adoption of solar energy, particularly in countries like Brazil and Mexico. The demand is primarily focused on micron-sized copper pastes for cost-sensitive traditional electronic assemblies and regional PV projects.

- Middle East and Africa (MEA): Growth in MEA is highly localized, driven by infrastructure development and large-scale solar power projects in the Gulf Cooperation Council (GCC) countries. The market for copper paste here is predominantly project-based, serving the requirements of new energy generation facilities and limited domestic electronics assembly.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Copper Paste Market.- DuPont de Nemours, Inc.

- Heraeus Holding GmbH

- Tanaka Precious Metals

- Sumitomo Metal Mining Co., Ltd.

- Cermet Materials, Inc.

- Shoei Chemical Inc.

- Toyo Aluminium K.K.

- Dowa Electronics Materials Co., Ltd.

- Epcos AG (TDK Corporation)

- Noritake Co. Ltd.

- Nanjing Breda Advanced Materials Co., Ltd.

- Advanced Nanotech

- Applied Ink Solutions

- Sun Chemical (DIC Corporation)

- Ningbo Ronzin Chemical Co., Ltd.

- InkTec Co., Ltd.

- Saint-Gobain S.A.

- Novacentrix

- Alpha Assembly Solutions (MacDermid Enthone)

- PV-Tech Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Copper Paste market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of copper paste over silver paste in electronics manufacturing?

The primary advantage of copper paste is its significant cost-effectiveness, offering comparable high electrical conductivity at a fraction of the material cost of silver. Copper also provides superior electromigration resistance, making it suitable for high-current density applications and ensuring long-term device reliability.

What is the main technical challenge associated with using copper paste?

The main technical challenge is the high susceptibility of copper to oxidation when heated in air. Most high-performance copper paste applications require stringent processing conditions, typically involving sintering in an inert (nitrogen) or reducing atmosphere, which increases manufacturing complexity and equipment costs.

How is the growth of the electric vehicle (EV) sector impacting copper paste demand?

The EV sector significantly boosts copper paste demand, particularly for use in robust power modules (inverters, converters) and battery management systems (BMS). Copper paste is essential for forming reliable, conductive interconnects that can handle high currents and maintain performance under elevated operating temperatures required by EV components.

What is the difference between fritted and fritless copper pastes?

Fritted copper pastes use glass or ceramic binders (frits) to enhance adhesion to the substrate, typically requiring high sintering temperatures. Fritless pastes rely on organic or reactive metal compounds that decompose at lower temperatures, making them ideal for temperature-sensitive substrates like flexible polymers used in printed electronics.

Which geographical region dominates the consumption of copper paste and why?

The Asia Pacific (APAC) region dominates the consumption of copper paste, primarily due to its massive concentration of global electronics manufacturing bases, including semiconductor fabrication, MLCC production, and the world's largest photovoltaic cell manufacturing capacity, necessitating high volumes of conductive materials.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Copper Paste Market Size Report By Type (Low Temperature Sintered, Medium Temperature Sintered, High Temperature Sintered), By Application (Printed Electronics, PV Industry, Other), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Copper Paste Market Statistics 2025 Analysis By Application (Printed Electronics, PV), By Type (Low Temperature Sintered, Medium Temperature Sintered, High Temperature Sintered), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Copper Paste Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Low Temperature Sintered, Medium Temperature Sintered, High Temperature Sintered), By Application (Printed Electronics, PV Industry, LED Application for thermal Dissipation, Other), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager