Coriolis Mass Flowmeters Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432313 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Coriolis Mass Flowmeters Market Size

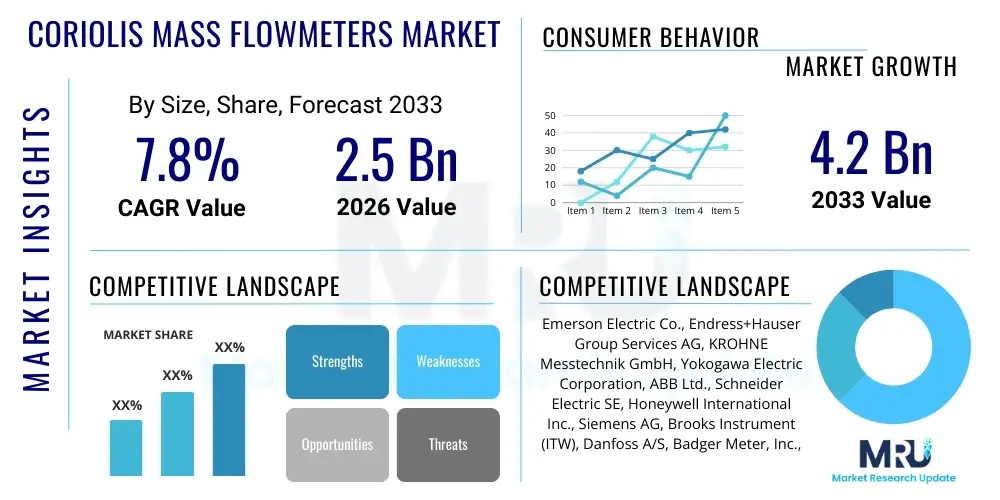

The Coriolis Mass Flowmeters Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 2.5 Billion in 2026 and is projected to reach USD 4.2 Billion by the end of the forecast period in 2033.

Coriolis Mass Flowmeters Market introduction

The Coriolis Mass Flowmeters Market encompasses advanced industrial instrumentation designed for the precise measurement of mass flow rate, density, and temperature of liquids and gases across diverse process industries. These meters operate on the fundamental principle of the Coriolis effect, where the inertia imparted by the fluid flowing through a set of vibrating tubes causes a measurable phase shift or twist. This measured deflection is directly proportional to the mass flow rate, providing a highly accurate measurement independent of fluid physical properties such as viscosity, pressure, or temperature, a crucial differentiator from traditional volumetric metering technologies. This inherent capability for direct mass measurement positions Coriolis technology as indispensable for critical applications where material balance accuracy is paramount, including custody transfer and regulatory reporting.

The primary product portfolio within this technology segment includes specialized mechanical designs, such as robust U-shaped tubes for high-pressure industrial applications and straight-tube configurations preferred in sanitary and low-shear environments, demanding minimal fluid obstruction. Major applications span high-value streams in petrochemical refining, complex blending and batching operations in the pharmaceutical sector, precise ingredient dosing in food and beverage production, and large-scale natural gas measurement in midstream pipeline operations. The core benefits derived from adopting Coriolis flowmeters are centered around their multi-variable measurement capability (mass flow, density, temperature, and volume) from a single device, unparalleled measurement stability, and drastically reduced maintenance requirements due to the absence of moving internal parts.

Driving factors propelling market expansion include the stringent global regulatory landscape requiring enhanced custody transfer accuracy, the widespread industrial imperative to optimize resource utilization through precise material tracking, and continuous technological advancements improving sensor sensitivity and operational stability in challenging environments (e.g., multiphase flow, high viscosity). Furthermore, the integration of these meters into modern Industrial Internet of Things (IIoT) platforms enables enhanced remote diagnostics and predictive maintenance capabilities, significantly improving the total cost of ownership and operational uptime. The market's resilience is tied directly to sustained capital investment across energy, chemical processing, and life sciences sectors globally.

Coriolis Mass Flowmeters Market Executive Summary

The Coriolis Mass Flowmeters market demonstrates a robust growth trajectory, underpinned by escalating demand for verifiable measurement accuracy across high-stakes industrial processes and critical revenue points. Current business trends are characterized by fierce competition among key manufacturers focusing on miniaturization, enhancing the meters' immunity to external process noise, and developing specialized algorithms for superior gas flow measurement accuracy. A notable shift includes the move towards providing integrated solutions that bundle sophisticated diagnostic software and remote calibration services, effectively evolving the revenue model from hardware sales to value-added service contracts. Strategic consolidation, particularly in niche measurement segments like micro-flow, remains a key avenue for market share expansion and technological capability acquisition.

Regionally, the market exhibits divergent maturity levels. North America and Western Europe maintain their position as technological leaders, primarily driven by replacement cycles, regulatory adherence (especially in emissions monitoring and custody transfer), and deep integration with advanced factory automation systems (Industry 4.0). The highest acceleration in growth is consistently observed in the Asia Pacific region, fueled by rapid industrialization, large-scale infrastructure projects, and significant capacity build-up in chemical, power, and food processing sectors. This region's demand is focused on acquiring high-precision technology for new installations, making price-to-performance ratio a critical competitive factor. Conversely, the Middle East is heavily invested in Coriolis technology for large-bore pipeline and LNG applications, directly linking meter accuracy to vast national export revenues.

Segment-wise, the market is primarily led by the liquid flow measurement category, sustaining high volumes due to applications across all major industrial verticals. However, the gas flow measurement segment is gaining prominence, particularly within the midstream oil and gas sector and the emerging hydrogen distribution infrastructure, demanding high-pressure, high-accuracy meters. In terms of design, straight-tube flowmeters are increasingly encroaching on the market share traditionally held by bent-tube models, driven by the expanding requirements for sanitary processes and applications involving highly viscous fluids where minimizing pressure drop is a design priority. The overall market is poised for sustained expansion, contingent upon global stability in capital expenditure within the heavy industry domain.

AI Impact Analysis on Coriolis Mass Flowmeters Market

Common user questions regarding the intersection of Artificial Intelligence (AI) and Coriolis technology frequently address the potential for AI to resolve long-standing measurement challenges, specifically in non-ideal process conditions such as high levels of entrained gas or severe fluid aeration. Users are keenly interested in how machine learning algorithms can analyze complex, noisy vibrational data from the flow tubes to extract cleaner flow signals, thereby significantly extending the operational window and reliability of the meters beyond current physical limitations. There is also a strong expectation that AI will redefine maintenance paradigms, shifting from scheduled calibration routines to truly predictive, condition-based servicing, enabling unparalleled operational efficiency by minimizing unnecessary process shutdowns and calibration expenses. This signifies a user demand for Coriolis meters to become self-aware and autonomous diagnostic units, leveraging deep data analysis capabilities to optimize their own performance and warn of incipient failure long before critical degradation occurs.

- AI algorithms enable enhanced signal processing and compensation, dramatically improving accuracy when measuring difficult, multiphase fluids (e.g., slurries or aerated liquids).

- Machine Learning models analyze continuous sensor health data to predict internal tube corrosion or scaling, providing early warnings for preventative maintenance actions.

- The use of AI-driven diagnostics standardizes and automates calibration verification procedures, potentially reducing the frequency of physical, high-cost field calibration visits.

- AI integration allows meters to dynamically self-adjust measurement parameters in response to shifting process conditions (e.g., rapid temperature or pressure spikes), maintaining optimal performance.

- Predictive analytics optimize inventory control and custody transfer auditing by correlating flow patterns across multiple sensors and identifying anomalies suggestive of leakage or measurement drift.

- Generative AI tools assist in real-time interpretation of complex meter diagnostics and troubleshooting guides for field technicians, speeding up resolution times.

DRO & Impact Forces Of Coriolis Mass Flowmeters Market

The market for Coriolis Mass Flowmeters is primarily driven by the mandatory requirements for high-precision measurement, particularly in custody transfer applications where trade transactions rely on verified accuracy, compelling industries like oil, gas, and chemicals to adopt the superior technology. Strong drivers also include the global focus on energy efficiency and environmental compliance, requiring precise measurement of fuels, flare gases, and specialty chemicals. Significant opportunities are emerging from the decarbonization movement, specifically the increasing global infrastructure for Liquefied Natural Gas (LNG) and the anticipated build-out of the hydrogen economy, both demanding highly robust and accurate cryogenic or high-pressure flow measurement solutions, areas where Coriolis technology inherently excels.

Conversely, the market faces significant restraints, chiefly the substantially higher initial capital investment compared to alternative flow measurement devices (such as turbine or magnetic flowmeters), which can deter adoption in budget-sensitive projects or non-critical applications. Furthermore, the sensitivity of Coriolis meters to certain installation parameters, particularly external vibration sources, requires careful engineering and sometimes costly mitigation efforts. The complexity involved in size selection and configuration, especially for extremely viscous or high-pressure media, mandates specialized technical expertise, creating a barrier to entry for smaller users lacking specialized instrumentation teams.

Impact forces are centered on two major technological and economic shifts: the accelerating pace of industrial digitalization and the intense focus on Total Cost of Ownership (TCO). The market is being fundamentally reshaped by the need for flowmeters to not only measure but also communicate comprehensive diagnostic data seamlessly (IIoT). Manufacturers are compelled to integrate advanced onboard intelligence to justify the high initial cost by demonstrating superior long-term reliability and reduced maintenance burden. This focus on long-term economic value, coupled with non-negotiable regulatory compliance demands (such as API and OIML standards), ensures sustained technological innovation and stable demand, mitigating risks associated with cyclical industrial downturns.

Segmentation Analysis

The Coriolis Mass Flowmeters market segmentation is highly specialized, reflecting the diverse physical and chemical properties of the fluids measured and the stringent operational requirements of end-user industries. Analyzing the market through the lens of tube design (U-Shaped vs. Straight Tube) highlights the trade-offs between robustness/capacity and ease of cleaning/low pressure drop, with strategic importance placed on the Straight Tube design due to its growing relevance in hygienic and shear-sensitive fluid applications. Segmentation by Fluid Type (Liquid vs. Gas) is crucial, as gas applications require highly sophisticated density measurement compensation and specialized calibration, whereas liquid applications focus more on density and temperature compensation for complex chemical mixtures and emulsions.

Further delineation by Application (Custody Transfer vs. Process Control) reveals differing demands for certification and regulatory compliance; meters used in custody transfer must meet metrological standards (e.g., OIML R 117), driving higher-specification hardware and services. The segmentation by End-User Industry is perhaps the most defining factor, demonstrating vertical-specific requirements: Oil & Gas demands high-pressure, large-bore meters for corrosive media; Pharmaceuticals require 3-A sanitary certified, highly polished stainless steel meters; and Food & Beverage necessitates cleanable, low-shear, straight-tube designs. This detailed segmentation allows manufacturers to target R&D efforts and marketing strategies toward niche applications with the highest growth and profitability potential.

- By Tube Design:

- U-Shaped/Bent Tube

- Straight Tube

- By Fluid Type:

- Liquid Flow Measurement

- Gas Flow Measurement

- By Application:

- Custody Transfer

- Process Control & Monitoring

- Metering & Dosing

- By Material:

- Stainless Steel (316L, Duplex)

- Hastelloy (C-22, C-276)

- Titanium

- Others (Tantalum, Zirconium)

- By End-User Industry:

- Oil & Gas (Upstream, Midstream, Downstream)

- Chemical & Petrochemical

- Food & Beverage

- Pharmaceutical & Biotechnology

- Water & Wastewater

- Power Generation

- Pulp & Paper

Value Chain Analysis For Coriolis Mass Flowmeters Market

The Coriolis Mass Flowmeter value chain initiates in the highly specialized upstream segment, focusing on the procurement of critical, high-performance metallic alloys—predominantly corrosion-resistant stainless steel and exotic materials like Hastelloy and Titanium. This stage demands stringent material certification and precise machining capabilities, given that the integrity and geometry of the vibrating flow tubes are paramount to measurement accuracy. Core value creation at this stage is rooted in proprietary sensor design, vibration isolation mechanisms, and the development of high-speed Digital Signal Processing (DSP) electronics, transforming raw material into a highly sophisticated, patent-protected measurement instrument. Outsourcing is often utilized for standardized components, but core sensor assembly remains tightly controlled by the key market leaders.

The midstream phase involves meter assembly, calibration, and certification. Calibration is a crucial value-add step, requiring specialized, traceable calibration rigs capable of handling diverse fluid types and flow rates, often necessitating high-pressure or cryogenic facilities. Quality control ensures compliance with international standards (e.g., ISO 17025). The distribution channel, forming the downstream segment, is highly reliant on expert knowledge; direct sales teams manage large-scale strategic accounts and specialized custody transfer projects, ensuring customized engineering and installation support. Indirect distribution, leveraging system integrators and technically proficient resellers, provides local market access, immediate inventory, and first-line application assistance, which is vital for quick adoption in emerging markets.

The post-sales segment, increasingly important in generating recurring revenue, includes lifecycle services such as remote monitoring via cloud platforms, on-site diagnostics, re-calibration, and mandatory recertification. This emphasizes a shift toward service-level agreements, providing customers with guaranteed measurement certainty. The seamless flow of information between the meter (via advanced protocols) and the customer’s enterprise systems (DCS/ERP) is a key differentiator, where the efficiency of the distribution and integration partners dictates the overall customer experience and long-term satisfaction with the meter’s operational performance.

Coriolis Mass Flowmeters Market Potential Customers

The primary cohort of potential customers for Coriolis Mass Flowmeters comprises entities operating high-value, highly regulated, or safety-critical processes where measurement uncertainty directly translates to significant financial loss, regulatory penalties, or safety hazards. Within the Oil & Gas sector, this includes national and international energy companies (NOCs/IOCs) in upstream exploration (multi-phase flow measurement), midstream transport (custody transfer at pipeline junctions and terminals), and downstream refining (complex blending and inventory tracking). These customers prioritize accuracy, robustness, and compliance with API standards for revenue protection.

The Chemical and Petrochemical industries represent another core customer base, relying on Coriolis meters for stoichiometry control in reactor feedstock metering, precise catalyst injection, and managing high-corrosion or temperature processes. Given the inherent danger and high cost associated with chemical reaction failures, these customers demand reliable, durable meters, often specified in exotic materials like Hastelloy. Similarly, customers in the Pharmaceutical and Biotechnology sectors require the highest level of hygienic compliance (3-A, FDA) for batching, filtration, and Clean-in-Place (CIP) verification, making straight-tube Coriolis designs essential for process integrity and final product quality assurance.

Expanding customer segments include utilities in Power Generation, particularly those managing steam turbine balance or transitioning to cleaner fuels like natural gas and hydrogen, demanding highly responsive and accurate gas flow measurement. Furthermore, specialized manufacturing environments, such as those producing high-performance coatings, paints, or precision adhesives, utilize micro-flow Coriolis meters for minute, yet critical, dosing applications. These diverse end-users are united by the fact that the cost savings derived from the Coriolis meter's superior accuracy and multi-variable output justify the premium price point over the instrument's entire lifecycle.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.5 Billion |

| Market Forecast in 2033 | USD 4.2 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Emerson Electric Co., Endress+Hauser Group Services AG, KROHNE Messtechnik GmbH, Yokogawa Electric Corporation, ABB Ltd., Schneider Electric SE, Honeywell International Inc., Siemens AG, Brooks Instrument (ITW), Danfoss A/S, Badger Meter, Inc., Vögtlin Instruments GmbH, GF Piping Systems (Georg Fischer), Baker Hughes Company, Toshiba Infrastructure Systems & Solutions Corporation, METTLER TOLEDO, TrigasFI, Rota Yokogawa, Faure Herman, Heinrichs Messtechnik GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Coriolis Mass Flowmeters Market Key Technology Landscape

The technological landscape of the Coriolis Mass Flowmeters market is predominantly driven by advancements in Digital Signal Processing (DSP) and computational fluid dynamics (CFD) modeling, aimed at maximizing measurement fidelity under challenging operational conditions. Modern Coriolis meters utilize highly sophisticated, high-speed DSP chipsets to execute advanced filtering algorithms that effectively isolate the minute Coriolis signal from pervasive background noise, external pipe vibrations, and inherent fluid noise. This technological specialization allows the meters to achieve stable and accurate readings even when handling low-flow regimes or fluids containing moderate levels of entrained gas, thereby significantly extending the viable application range beyond traditional capabilities and ensuring reliable performance in demanding midstream oil & gas applications.

Material science remains a critical area of innovation, focusing on developing proprietary alloys and advanced coatings to enhance sensor tube durability and corrosion resistance, essential for highly aggressive chemical and high-temperature environments. Furthermore, mechanical design innovation continues to refine tube geometries—specifically optimizing straight-tube designs to offer the same level of robustness and high capacity as U-tubes, while benefiting from lower pressure drop and superior drainability required by sanitary standards. Specialized sensor mounting techniques and internal vibration isolation systems are also continually evolving to minimize cross-talk and improve signal-to-noise ratios, allowing for deployment in previously infeasible high-vibration areas.

Crucially, the integration of smart electronics and communication protocols defines the contemporary technology landscape. The adoption of Industrial Ethernet standards (e.g., PROFINET, EtherNet/IP) alongside standard fieldbus protocols facilitates high-volume, bi-directional data exchange between the meter and control systems. This enables sophisticated remote health monitoring, automated diagnostics compliant with NAMUR NE 107 standards, and the implementation of patented features such as "zero verification" or self-diagnostics. These connectivity advancements are pivotal in supporting the industry's shift towards IIoT architectures, allowing Coriolis meters to deliver not just flow data, but predictive process intelligence directly to cloud-based analytical platforms.

Regional Highlights

The dynamics of the Coriolis Mass Flowmeters market are intrinsically linked to regional industrial maturity, investment cycles in critical infrastructure, and the enforcement of measurement standards.

- North America: This region is defined by technological maturity and high replacement demand, driven by stringent regulatory requirements for custody transfer accuracy in the vast crude oil and natural gas pipeline networks. The focus is heavily on incorporating advanced diagnostics, cybersecurity, and seamless integration of new meters with legacy DCS infrastructure within the mature chemical and refining sectors.

- Europe: Characterized by a strong emphasis on precision and hygienic applications, particularly within the German and Swiss pharmaceutical, chemical, and food processing industries. European demand is bolstered by strict adherence to the Measuring Instruments Directive (MID) for trade applications and the requirement for highly certified meters, favoring sophisticated, straight-tube, hygienic designs.

- Asia Pacific (APAC): Positioned as the primary engine of volume growth globally, driven by immense governmental and private investment in infrastructure, chemical plant construction, and expansion of refining capacity in China, India, and ASEAN nations. Demand in APAC is high for both large-scale industrial projects (greenfield) and smaller, cost-effective meters for general process control in rapidly growing manufacturing bases.

- Middle East & Africa (MEA): Growth is almost exclusively concentrated in the oil and gas sector, centered on major infrastructure projects for crude extraction, refining, and LNG export facilities. High-pressure, high-flow rate Coriolis meters for custody transfer operations remain the dominant product type, with purchasing decisions heavily influenced by accuracy compliance with international petroleum standards.

- Latin America: Market stability is tied closely to commodity price cycles, particularly oil and gas. Adoption is moderate but consistent, focusing on modernizing outdated flow measurement infrastructure in existing refineries and transportation networks, primarily seeking robust meters capable of handling challenging, often unprocessed, hydrocarbon media.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Coriolis Mass Flowmeters Market.- Emerson Electric Co.

- Endress+Hauser Group Services AG

- KROHNE Messtechnik GmbH

- Yokogawa Electric Corporation

- ABB Ltd.

- Schneider Electric SE

- Honeywell International Inc.

- Siemens AG

- Brooks Instrument (ITW)

- Danfoss A/S

- Badger Meter, Inc.

- Vögtlin Instruments GmbH

- GF Piping Systems (Georg Fischer)

- Baker Hughes Company

- Toshiba Infrastructure Systems & Solutions Corporation

- METTLER TOLEDO

- TrigasFI

- Rota Yokogawa

- Faure Herman

- Heinrichs Messtechnik GmbH

Frequently Asked Questions

Analyze common user questions about the Coriolis Mass Flowmeters market and generate a concise list of summarized FAQs reflecting key topics and concerns.Why are Coriolis flowmeters essential for custody transfer and financial transactions?

Coriolis meters provide a measurement of mass, which is a constant quantity, ensuring fair trade regardless of fluctuating fluid temperature, pressure, or density. This certainty of measurement minimizes errors in volumetric conversions, protecting revenue for both the buyer and seller.

Can Coriolis meters accurately measure gas flow, particularly high-pressure natural gas?

Yes, modern Coriolis meters, utilizing advanced DSP and high-frequency oscillation, are highly effective for gas flow, offering exceptional accuracy that is crucial for pipeline operations and flare gas measurement, where traditional meters often struggle with density variations.

What defines a "Hygienic" Coriolis flowmeter, and where are they primarily used?

Hygienic Coriolis flowmeters typically feature straight-tube designs made of highly polished stainless steel (316L) with specific certifications (like 3-A or EHEDG). They are essential in Food & Beverage and Pharmaceutical industries to prevent contamination and ensure effective Clean-in-Place (CIP) procedures.

How do Coriolis meters handle multiphase fluid measurements, such as aerated liquids?

While traditionally challenging, recent technological advances, especially through sophisticated AI-enhanced signal processing, allow modern Coriolis meters to identify and compensate for the presence of entrained gas or air within liquids, providing a much more stable and reliable mass flow reading than older generations.

What is the role of sensor material selection in the purchase of Coriolis flowmeters?

Sensor material is critical for ensuring the meter's longevity and performance. Materials like Hastelloy or Titanium are chosen for highly corrosive chemical applications, preventing erosion and contamination, while high-grade stainless steel is the standard for sanitary and general industrial use.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager