Corrosive Storage Cabinets Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439210 | Date : Jan, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Corrosive Storage Cabinets Market Size

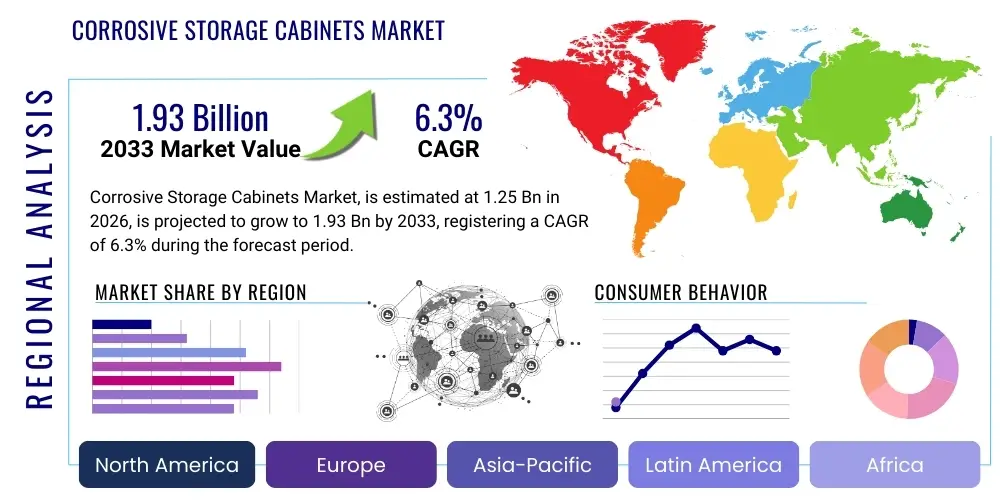

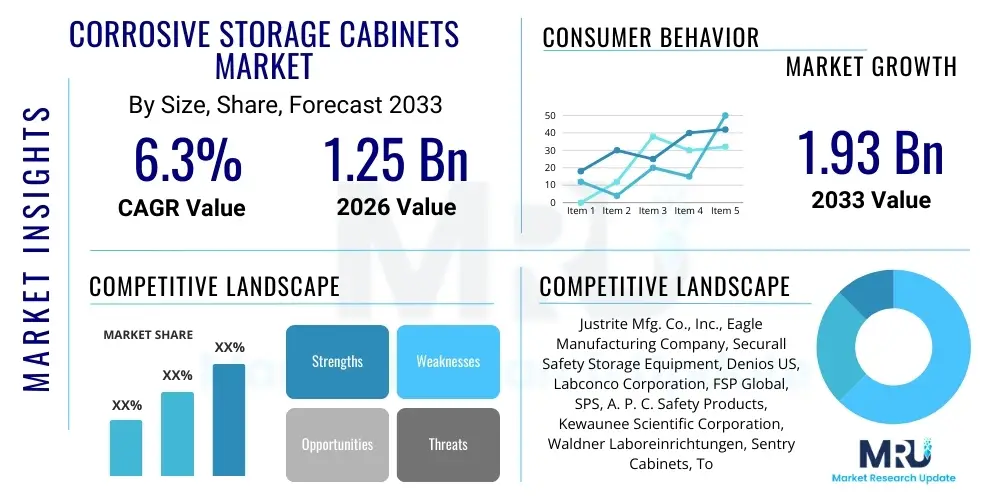

The Corrosive Storage Cabinets Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.3% between 2026 and 2033. The market is estimated at USD 1.25 billion in 2026 and is projected to reach USD 1.93 billion by the end of the forecast period in 2033.

Corrosive Storage Cabinets Market introduction

The Corrosive Storage Cabinets Market encompasses the design, manufacturing, and distribution of specialized enclosures engineered to safely store hazardous corrosive chemicals. These cabinets are crucial safety equipment, designed to protect personnel and facilities from the inherent risks associated with storing acids, bases, and other corrosive substances. Constructed from materials resistant to chemical attack, such as high-density polyethylene (HDPE) or specially coated steel, they are equipped with features like spill containment sumps, self-latching doors, and often, ventilation ports to manage fumes.

Major applications span across diverse sectors including chemical manufacturing, pharmaceuticals, research and development laboratories, educational institutions, healthcare facilities, and various industrial settings where corrosive materials are routinely handled. The primary benefit of these cabinets lies in their ability to minimize the risk of chemical spills, fires, and explosions, thereby ensuring compliance with stringent safety regulations such set by OSHA (Occupational Safety and Health Administration), NFPA (National Fire Protection Association), and local authorities. These safety provisions not only protect human life but also safeguard valuable infrastructure and sensitive equipment from corrosive damage.

Driving factors for market growth include escalating safety regulations worldwide, a rising emphasis on workplace safety culture, growth in chemical and pharmaceutical industries necessitating more storage solutions, and increasing awareness regarding the proper handling and storage of hazardous materials. Continuous innovation in materials science and cabinet design further contributes to market expansion by offering enhanced protection, durability, and compliance features, making these essential investments for any entity working with corrosive agents.

Corrosive Storage Cabinets Market Executive Summary

The global Corrosive Storage Cabinets Market is experiencing steady growth driven by a confluence of regulatory mandates, expanding industrial chemical usage, and a heightened focus on occupational safety. Business trends indicate a shift towards modular and customizable cabinet solutions, allowing end-users to tailor storage capacity and features to specific operational needs and space constraints. Manufacturers are also increasingly integrating advanced material technologies to enhance chemical resistance and longevity, while smart monitoring features are emerging to provide real-time safety data.

Regional trends reveal robust demand in North America and Europe, propelled by mature safety cultures and stringent regulatory frameworks. The Asia Pacific region is demonstrating significant growth potential, fueled by rapid industrialization, particularly in chemical manufacturing, pharmaceuticals, and electronics, leading to increased adoption of safety storage solutions. Latin America and the Middle East & Africa also present emerging opportunities as these regions progressively align with international safety standards and expand their industrial infrastructure. Competitive strategies often involve product differentiation through certification, material innovation, and comprehensive after-sales support.

Segment trends highlight the dominance of steel cabinets due to their robustness and fire resistance, though polyethylene cabinets are gaining traction for highly corrosive acids given their superior chemical inertness. The market is also segmented by capacity, end-use industry, and compliance standards, with the pharmaceutical and chemical sectors remaining primary consumers. There is a growing demand for FM Approved and OSHA-compliant cabinets, indicating a strong market preference for certified solutions that meet the highest safety benchmarks. This segmentation underscores the diverse needs within the market, prompting manufacturers to offer a broad portfolio of specialized products.

AI Impact Analysis on Corrosive Storage Cabinets Market

User inquiries regarding AI's influence on the Corrosive Storage Cabinets Market often center on how artificial intelligence can enhance safety, improve compliance, and optimize inventory management of corrosive materials. Common questions explore the integration of AI-powered sensors for leak detection, predictive maintenance of storage infrastructure, and automated compliance auditing. Users are keen to understand if AI can reduce human error in hazardous environments, streamline regulatory reporting, and offer proactive insights into potential safety breaches, thereby transforming traditional, often manual, safety protocols into more intelligent and preventative systems within facilities handling dangerous substances.

- AI-powered sensor integration for real-time corrosive leak detection and environmental monitoring within cabinets.

- Predictive maintenance analytics for cabinet integrity, ventilation systems, and sealing mechanisms, anticipating failures before they occur.

- Automated inventory management of corrosive chemicals, optimizing stock levels and tracking shelf-life or usage patterns.

- AI-driven compliance auditing and reporting, flagging deviations from safety protocols or regulatory standards.

- Integration with facility management systems for emergency response automation and improved safety coordination.

- Smart ventilation control systems that adapt to detected fume levels, enhancing air quality and energy efficiency.

- Data analytics on incident trends related to corrosive storage, informing better cabinet design and safety training.

- Augmented reality (AR) tools, potentially AI-enhanced, for maintenance and inspection guidance of complex cabinet systems.

DRO & Impact Forces Of Corrosive Storage Cabinets Market

The Corrosive Storage Cabinets Market is significantly shaped by a dynamic interplay of Drivers, Restraints, and Opportunities, collectively forming the key Impact Forces. Robust drivers include increasingly stringent global health and safety regulations, such as those imposed by OSHA, EPA, and REACH, which mandate secure storage for hazardous materials. The continuous expansion of industries heavily reliant on corrosive chemicals, including pharmaceuticals, petrochemicals, electronics, and research & development, further fuels demand for compliant storage solutions. Moreover, a heightened corporate focus on risk mitigation and employee well-being globally compels organizations to invest in superior safety infrastructure.

Conversely, the market faces several restraints. The substantial initial investment cost associated with purchasing high-quality, certified corrosive storage cabinets can be a barrier, particularly for small and medium-sized enterprises (SMEs) with limited capital. A lack of awareness or understanding regarding specific regulatory requirements in some developing regions can also hinder adoption rates. Additionally, the need for specialized maintenance and periodic inspection of these cabinets, coupled with the proper disposal of outdated units, adds to the operational costs and complexity for end-users, potentially slowing market penetration in cost-sensitive segments.

Opportunities within this market are abundant and promising. The growing trend towards smart laboratory solutions and connected industrial facilities opens avenues for integrating IoT and AI into corrosive storage cabinets, offering features like real-time monitoring, automated alerts, and predictive maintenance. Development of new, more resistant, and sustainable materials for cabinet construction presents a chance for product innovation and differentiation. Furthermore, expanding into emerging markets with developing industrial sectors and evolving safety standards offers significant growth potential for manufacturers capable of providing cost-effective and compliant solutions tailored to local needs. Customized solutions and modular designs catering to specific application requirements also represent lucrative opportunities for market players.

Segmentation Analysis

The Corrosive Storage Cabinets Market is meticulously segmented across various dimensions to cater to the diverse needs of different industries and applications. These segmentations provide a granular view of the market, enabling manufacturers to develop targeted products and strategies while helping end-users select the most appropriate storage solutions for their specific corrosive material handling requirements. Understanding these segments is crucial for analyzing market dynamics, competitive landscapes, and future growth trajectories, reflecting the industry's commitment to specialized safety solutions.

- By Material Type

- Steel Corrosive Storage Cabinets

- Polyethylene (HDPE) Corrosive Storage Cabinets

- Wood/Laminate Corrosive Storage Cabinets (with specific liners)

- Fiberglass Reinforced Plastic (FRP) Cabinets

- Others (e.g., Stainless Steel for specific applications)

- By Capacity

- Small Capacity (e.g., < 15 gallons)

- Medium Capacity (e.g., 15-30 gallons)

- Large Capacity (e.g., > 30 gallons)

- By Door Type

- Manual Closing Doors

- Self-Closing Doors

- Sliding Doors

- By End-Use Industry

- Chemical & Petrochemical Industry

- Pharmaceutical & Biotechnology Industry

- Research & Academic Institutions (Laboratories)

- Healthcare Industry

- Manufacturing & Industrial (e.g., Automotive, Electronics)

- Water & Wastewater Treatment

- Food & Beverage Processing

- Government & Defense

- Others

- By Compliance & Certification

- FM Approved Cabinets

- OSHA Compliant Cabinets

- NFPA Compliant Cabinets

- UL Listed Cabinets

- Local/Regional Specific Standards

- By Application

- Acid Storage

- Base Storage

- General Corrosive Storage

Value Chain Analysis For Corrosive Storage Cabinets Market

The value chain for the Corrosive Storage Cabinets Market begins with upstream analysis, involving the procurement of raw materials such as various grades of steel (e.g., galvanized, epoxy-coated), high-density polyethylene resins, stainless steel, and specialized plastics. This also includes sourcing components like hinges, latches, ventilation ports, spill sumps, and safety labels. Key suppliers in this stage are chemical companies providing polymer resins, metal manufacturers, and component fabricators. The quality and cost of these raw materials directly impact the final product's performance, durability, and market competitiveness, necessitating strong relationships with reliable and certified suppliers.

Further along the value chain, the manufacturing process involves precision cutting, forming, welding, and coating for metal cabinets, or molding and fabrication for plastic cabinets. Assembly, quality control, and adherence to specific safety standards (like FM, OSHA, NFPA) are critical at this stage. After manufacturing, products move through distribution channels, which can be direct or indirect. Direct channels involve manufacturers selling directly to large industrial clients, government entities, or through their own e-commerce platforms. This offers greater control over sales and customer relationships but requires significant logistical capabilities.

Indirect distribution involves leveraging a network of distributors, wholesalers, safety equipment suppliers, laboratory supply companies, and specialized resellers. These intermediaries often have established relationships with end-users, offer localized support, and provide value-added services such as installation, maintenance, and compliance consultation. Downstream activities involve reaching the end-users in various industries such as chemical, pharmaceutical, research, and manufacturing, where the cabinets are installed and utilized. Post-sales services, including warranty, maintenance, and regulatory updates, form the final, crucial part of the value chain, ensuring customer satisfaction and repeat business.

Corrosive Storage Cabinets Market Potential Customers

The primary end-users or buyers of corrosive storage cabinets are entities across diverse industries that handle, store, or process corrosive chemicals on a regular basis. These range from large-scale industrial operations to smaller research facilities, all requiring robust and compliant solutions for hazardous material management. Their common need is to ensure workplace safety, protect assets, and adhere to stringent environmental and occupational health regulations, making these cabinets an indispensable part of their operational infrastructure. Understanding the varied requirements of these customer segments is crucial for manufacturers to tailor product offerings and marketing strategies effectively, addressing specific capacity, material, and compliance needs.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.93 Billion |

| Growth Rate | 6.3% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Justrite Mfg. Co., Inc., Eagle Manufacturing Company, Securall Safety Storage Equipment, Denios US, Labconco Corporation, FSP Global, SPS, A. P. C. Safety Products, Kewaunee Scientific Corporation, Waldner Laboreinrichtungen, Sentry Cabinets, Total Protection Supplies, Safety Storage Systems, National Safety Inc., Terra Universal Inc., Plas-Labs, PolyScience, Biocision, Fisher Scientific (part of Thermo Fisher Scientific), InterFocus |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Corrosive Storage Cabinets Market Key Technology Landscape

The technology landscape for the Corrosive Storage Cabinets market is primarily driven by advancements in materials science, manufacturing processes, and integrated safety features. Core technologies involve the development and application of highly resistant materials such as specialized steels with advanced epoxy or powder coatings that offer superior protection against a wide range of corrosive chemicals. For applications requiring extreme chemical inertness, high-density polyethylene (HDPE) resins and fiberglass reinforced plastics (FRP) are crucial, utilizing sophisticated molding and fabrication techniques to ensure seamless construction and leak-proof designs. These material innovations directly translate into enhanced cabinet longevity, reduced risk of material degradation, and improved overall safety performance.

Beyond materials, manufacturing technologies focus on precision engineering to ensure structural integrity, secure sealing mechanisms, and robust ventilation systems. This includes advanced welding techniques for steel cabinets, ensuring strong, impermeable joints, and rotational molding for plastic cabinets to create seamless, monolithic structures. The integration of self-closing and self-latching door mechanisms relies on reliable mechanical and hydraulic damping systems, critical for preventing accidental door openings and ensuring immediate containment in an emergency. Furthermore, the design incorporates features like integrated spill containment sumps, often molded as part of the cabinet structure, to safely collect any accidental leaks or spills, a fundamental aspect of corrosive material safety.

Emerging technologies are also making their way into the market, enhancing the "intelligence" of these safety critical assets. This includes the incorporation of sensor technologies for real-time monitoring of internal conditions such as temperature, humidity, and the detection of corrosive vapor leaks. These sensors can be integrated with building management systems or cloud-based platforms to provide automated alerts and data analytics, moving towards predictive maintenance and proactive safety management. The potential for IoT (Internet of Things) connectivity and AI (Artificial Intelligence) for smart inventory tracking, compliance auditing, and optimized environmental control within the cabinets represents the next frontier in the technological evolution of corrosive storage solutions, offering unprecedented levels of safety, efficiency, and regulatory adherence.

Regional Highlights

- North America: A mature market characterized by stringent regulatory frameworks from OSHA, EPA, and NFPA, driving high demand for certified corrosive storage solutions. The presence of a large chemical industry, pharmaceutical companies, and extensive research institutions ensures consistent market growth. The U.S. and Canada lead in adopting advanced safety practices and investing in high-quality, compliant storage equipment.

- Europe: Dominated by robust safety standards such as REACH and COSHH, fostering a strong demand for high-performance and environmentally compliant corrosive storage cabinets. Germany, the UK, France, and Italy are key contributors, driven by well-established chemical, pharmaceutical, and automotive industries. Focus on sustainability and worker protection continuously pushes for innovative and durable solutions.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid industrialization, expanding manufacturing bases (especially in chemicals, electronics, and pharmaceuticals), and increasing awareness of occupational safety. Countries like China, India, Japan, and South Korea are witnessing significant investments in safety infrastructure. While regulations are evolving, the adoption of international standards is a key driver for market expansion.

- Latin America: An emerging market with growing industrial sectors and evolving regulatory landscapes. Brazil and Mexico are leading the region, driven by investments in petrochemicals, mining, and manufacturing. Increased foreign direct investment and a gradual shift towards international safety benchmarks are stimulating demand for reliable corrosive storage solutions.

- Middle East and Africa (MEA): This region presents significant opportunities, particularly in countries with burgeoning oil & gas, petrochemical, and industrial manufacturing sectors. Economic diversification initiatives and increasing infrastructure development projects are creating a need for robust safety equipment. Adoption is gradual but driven by large-scale industrial projects and efforts to align with global safety practices.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Corrosive Storage Cabinets Market.- Justrite Mfg. Co., Inc.

- Eagle Manufacturing Company

- Securall Safety Storage Equipment

- Denios US

- Labconco Corporation

- FSP Global

- SPS

- A. P. C. Safety Products

- Kewaunee Scientific Corporation

- Waldner Laboreinrichtungen

- Sentry Cabinets

- Total Protection Supplies

- Safety Storage Systems

- National Safety Inc.

- Terra Universal Inc.

- Plas-Labs

- PolyScience

- Biocision

- Fisher Scientific (part of Thermo Fisher Scientific)

- InterFocus

Frequently Asked Questions

Analyze common user questions about the Corrosive Storage Cabinets market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are corrosive storage cabinets and why are they essential?

Corrosive storage cabinets are specialized, chemically resistant enclosures designed for the safe storage of acids, bases, and other hazardous corrosive substances. They are essential to prevent spills, contain fumes, protect personnel from chemical exposure, and ensure compliance with safety regulations like OSHA and NFPA, thereby minimizing workplace accidents and property damage.

What materials are corrosive storage cabinets typically made from?

Common materials include high-density polyethylene (HDPE) for strong chemical resistance against a broad range of corrosives, and specially coated steel (e.g., epoxy or powder-coated galvanized steel) for durability and fire resistance, sometimes with polyethylene liners for added protection. Fiberglass Reinforced Plastic (FRP) is also used for specific highly corrosive applications.

What key features should I look for when selecting a corrosive storage cabinet?

Key features include FM Approved or other certified compliance (OSHA, NFPA), chemical-resistant construction material, self-closing/self-latching doors, integrated spill containment sumps to collect leaks, corrosion-resistant hinges and hardware, and often, ventilation ports for fume management. Capacity and suitable shelving are also critical considerations.

How do corrosive storage cabinets comply with safety regulations?

Compliance is achieved through specific design, material selection, and construction that meets standards set by regulatory bodies such as OSHA (Occupational Safety and Health Administration) for general workplace safety, NFPA (National Fire Protection Association) for fire safety, and often FM Approvals for product performance verification. These standards dictate requirements for construction, labeling, and hazardous material containment.

Can corrosive storage cabinets be customized for specific laboratory or industrial needs?

Yes, many manufacturers offer customization options for corrosive storage cabinets. This can include varying capacities, specific material choices for unique chemical resistance requirements, additional shelving configurations, custom dimensions to fit particular spaces, integration with ventilation systems, and advanced monitoring features, allowing precise tailoring to a facility's operational demands and safety protocols.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager