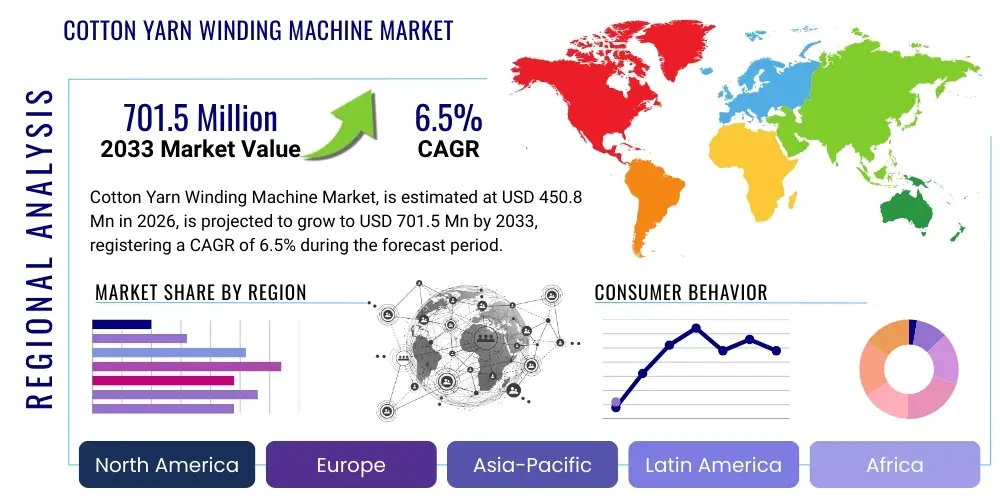

Cotton Yarn Winding Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436722 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Cotton Yarn Winding Machine Market Size

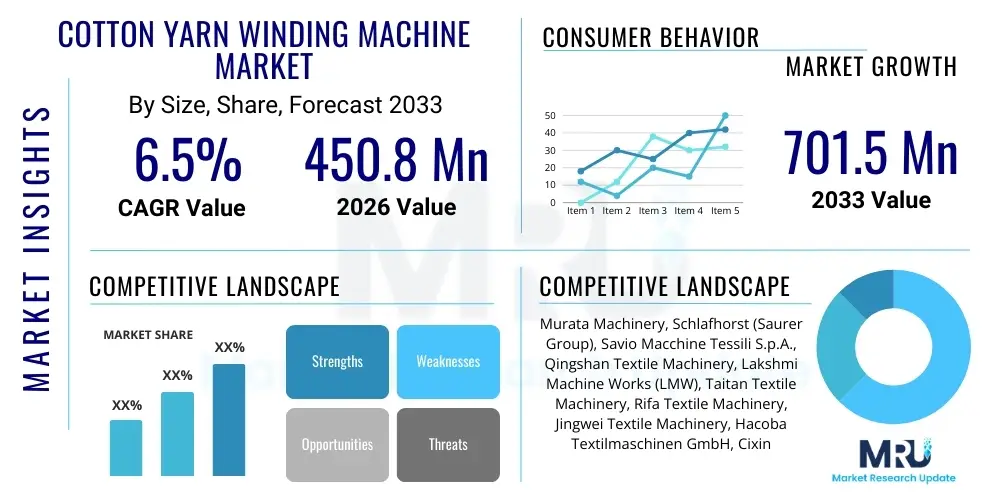

The Cotton Yarn Winding Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 450.8 Million in 2026 and is projected to reach USD 701.5 Million by the end of the forecast period in 2033.

Cotton Yarn Winding Machine Market introduction

The Cotton Yarn Winding Machine Market encompasses machinery specifically designed for the crucial post-spinning process in textile manufacturing, where yarn packages (bobbins) are unwound and subsequently rewound into larger, uniform packages (cones or spools) suitable for weaving, knitting, dyeing, or final retail presentation. These machines are engineered to optimize yarn quality by removing defects such as slubs, foreign materials, and weak points, while simultaneously improving package density and consistency. Modern winding machines integrate advanced tension control systems, electronic clearing mechanisms, and splice technology, significantly boosting efficiency and minimizing yarn breakage rates, which is paramount for high-speed downstream processing. The continuous demand for high-quality, defect-free fabrics across global apparel and home textile industries directly fuels the adoption of sophisticated automated winding solutions.

The primary applications of these sophisticated machines span across various sectors of the textile value chain, including spinning mills, integrated textile manufacturers, and specialized yarn processing units. Key benefits derived from utilizing modern cotton yarn winding machines include enhanced productivity due to higher winding speeds, superior quality assurance through precision electronic clearers, and reduced labor costs through automation features such as automatic package loading and doffing. Furthermore, the ability to create customized package geometries (e.g., precise taper angles and traverse lengths) ensures compatibility with specific knitting and weaving loom requirements, minimizing wastage and maximizing fabric quality outputs. The machinery acts as a critical quality gate between raw yarn production and subsequent fabric formation.

Driving factors for market growth are strongly linked to the expansion of the global textile industry, particularly in developing economies in Asia Pacific, coupled with a fundamental shift towards sustainable and automated manufacturing practices worldwide. Increasing consumer demand for natural fiber textiles, especially high-thread-count cotton fabrics, necessitates investment in high-precision machinery capable of handling fine count yarns without damage. Technological innovations, including the incorporation of sensor technology for real-time monitoring and predictive maintenance, are further accelerating machine replacement cycles in established markets. Additionally, stringent quality standards imposed by major apparel brands push manufacturers to adopt winding technology that guarantees zero defects in the final yarn package.

Cotton Yarn Winding Machine Market Executive Summary

The global Cotton Yarn Winding Machine Market is characterized by intense competition focused primarily on technological differentiation, especially concerning automation levels, winding speed, and integration of quality control features like electronic yarn clearers and sophisticated splicing mechanisms. Business trends indicate a robust demand for automatic winding machines over manual or semi-automatic variants, driven by manufacturers seeking to mitigate rising labor costs and achieve consistent, high-volume production outputs. Key market players are concentrating their research and development efforts on developing energy-efficient models and machines compatible with Industry 4.0 standards, allowing for seamless data exchange and integration into Textile Execution Systems (MES). Furthermore, there is a strategic geographical shift in manufacturing capacity, with machinery suppliers establishing closer ties or local production facilities within major textile hubs like India, China, and Vietnam to capitalize on localized textile mill expansions.

Regional trends reveal Asia Pacific (APAC) as the dominant and fastest-growing region, primarily due to the colossal scale of cotton production and textile manufacturing in countries such as China, India, Pakistan, and Bangladesh. Significant government support and foreign direct investment in establishing vertically integrated textile parks in these nations necessitate continuous investment in high-speed post-spinning machinery. Europe and North America, while mature markets, demonstrate demand primarily focused on high-end replacement cycles, emphasizing advanced technological features, maximum energy efficiency, and low maintenance requirements, often sourcing specialized machinery for technical textiles or niche high-value cotton processing. Latin America and the Middle East & Africa are emerging markets showing gradual adoption of modern machinery, largely influenced by export-oriented garment manufacturing initiatives requiring internationally compliant yarn quality.

Segment trends highlight the dominance of automatic cone winding machines, which are favored for their ability to handle large batches with minimal human intervention, offering superior operational economics. In terms of automation, the market is rapidly migrating towards fully automatic and robotics-assisted winding solutions. The application segment sees substantial growth driven by the knitting sector, which demands extremely precise and knot-free yarn packages to ensure defect-free high-speed operation on modern circular knitting machines. While the traditional weaving segment remains a major consumer, the focus here is shifting towards winding machines capable of preparing large, dimensionally stable packages for advanced air-jet and water-jet looms. Material handling capability, particularly for fine-count long staple cotton yarns, represents a key differentiation point among machinery vendors.

AI Impact Analysis on Cotton Yarn Winding Machine Market

User queries regarding AI in the Cotton Yarn Winding Machine Market predominantly revolve around improving quality assurance, predicting maintenance needs, and optimizing winding parameters for diverse yarn types. Users are keen to understand how AI-driven vision systems can replace or augment traditional electronic yarn clearers for enhanced defect detection, specifically subtle defects difficult for conventional sensors to identify. Concerns also center on the feasibility and return on investment (ROI) of integrating complex AI algorithms into existing machinery infrastructure. Expectations are high regarding AI's potential to establish predictive analytics models, moving maintenance schedules from reactive or fixed periods to condition-based monitoring, thus maximizing machine uptime and overall equipment effectiveness (OEE). Furthermore, textile manufacturers anticipate AI capabilities in automatically adjusting tension settings and winding speeds based on real-time yarn characteristics (e.g., unevenness, hairiness) to ensure consistent package quality across varying environmental conditions and raw material batches.

- AI-driven Predictive Maintenance: Utilizing machine learning algorithms to analyze vibration, temperature, and current consumption data for anticipating component failure, significantly reducing unplanned downtime.

- Enhanced Quality Control: Integration of deep learning-based vision systems for identifying and classifying subtle yarn defects (e.g., foreign fibers, subtle shade variation, minor slubs) beyond the capability of standard electronic clearers.

- Process Optimization: AI models adjusting winding parameters (tension, speed, traverse length) dynamically based on real-time feedback regarding yarn input characteristics and desired package output quality.

- Autonomous Fault Diagnosis: Machine learning assisting operators by immediately pinpointing the cause of operational stoppages or yarn breaks, accelerating troubleshooting and reducing labor dependence.

- Energy Efficiency Optimization: Algorithms optimizing machine operation cycles and power consumption based on production load and ambient conditions, leading to significant energy savings over manual operation settings.

DRO & Impact Forces Of Cotton Yarn Winding Machine Market

The Cotton Yarn Winding Machine Market is primarily driven by the imperative for textile manufacturers to achieve higher productivity and maintain impeccable yarn quality standards required for global export markets. Restraints often include the significant initial capital investment required for high-end automatic machinery and the operational challenge of ensuring skilled labor availability for maintenance and programming of advanced computerized controls. Opportunities lie strongly in developing specialized machinery for technical textiles and exploring sustainable manufacturing solutions, such such as reduced energy consumption and lower waste generation. The primary impact forces shaping the market involve intense competitive pricing strategies among Asian and European manufacturers, coupled with evolving global trade policies affecting textile import/export dynamics, compelling manufacturers to seek maximum operational efficiency to remain cost-competitive.

Major market drivers include the rapid modernization of spinning mills across Asia, necessitated by the need to scale production and meet rising global consumer demand for cotton-based apparel and furnishings. The relentless pursuit of knot-free packages, crucial for increasing the efficiency of high-speed weaving and knitting looms, mandates the adoption of automatic winding machines equipped with sophisticated splicing technology. Moreover, regulatory pressures concerning worker safety and environmental sustainability are indirectly driving the adoption of highly automated systems that reduce human intervention and minimize material waste through precision winding controls. The push towards Industry 4.0 integration also acts as a powerful driver, encouraging mills to invest in internet-enabled machinery for better fleet management and data analytics.

However, the market faces significant restraints. The high cost of fully automated, computerized winding systems often deters small and medium-sized textile enterprises (SMEs) from upgrading their equipment, particularly in regions facing tight credit conditions. Furthermore, the complexity of maintaining and troubleshooting high-tech machinery necessitates specialized technical expertise, which is scarce in many textile manufacturing clusters. Economic volatility and fluctuation in raw cotton prices can also lead to delayed capital expenditure decisions by textile manufacturers. Opportunities are abundant in the field of localized manufacturing and service support within key textile production hubs, alongside the development of modular and scalable winding solutions tailored for specific regional needs or niche applications like organic cotton processing.

The core impact forces involve the technological superiority of established European players setting the benchmark for performance, compelling Asian competitors to rapidly innovate and offer similar functionalities at competitive price points. Global sourcing patterns for textiles heavily influence regional market size; shifts in sourcing from countries due to geopolitical or trade issues (e.g., tariffs, quotas) directly impact local investment in winding machinery. Environmental impact regulations, specifically those concerning noise levels and energy consumption during winding, are becoming critical competitive factors, forcing manufacturers to integrate energy-recovering systems and quieter operational mechanisms. Ultimately, the cost of labor versus the cost of automation remains the primary financial leverage point influencing investment decisions.

Segmentation Analysis

The Cotton Yarn Winding Machine Market is comprehensively segmented based on the degree of automation, the specific type of machine, and the end-use application within the textile industry. Segmentation by automation level (automatic, semi-automatic, manual) highlights the market’s decisive shift toward fully automatic systems which offer superior speed and quality control. Machine type segmentation includes cone winding machines, cop winding machines, and precision winding machines, each catering to different stages of textile preparation. Application segmentation focuses on distinguishing demand drivers across weaving preparation, knitting preparation, and dyeing package preparation, reflecting varied requirements for package dimensions and yarn tension uniformity across these downstream processes.

- By Automation Level:

- Automatic Winding Machines

- Semi-Automatic Winding Machines

- Manual Winding Machines

- By Machine Type:

- Cone Winding Machines

- Cop Winding Machines

- Precision Winding Machines

- Assembly Winding Machines (Doubling)

- By Application:

- Weaving Preparation

- Knitting Preparation

- Dyeing Preparation

- Technical Textiles

- By Yarn Count:

- Fine Count Yarns (Ne 60 and above)

- Medium Count Yarns (Ne 30 to Ne 60)

- Coarse Count Yarns (Below Ne 30)

Value Chain Analysis For Cotton Yarn Winding Machine Market

The value chain for the Cotton Yarn Winding Machine Market begins with the upstream suppliers providing critical raw materials and components, including precision-engineered metals (steel, aluminum), advanced electronic components (sensors, microprocessors, drives), and specialized mechanical parts (spindles, traverse mechanisms, bearings). The quality and reliability of these components, particularly the sensors used in electronic clearers and tension devices, are paramount to the performance of the final machine. Suppliers capable of providing customized, high-tolerance components often partner closely with machinery manufacturers. This upstream segment is characterized by increasing specialization, with key players focusing on developing robust, high-speed electronic control systems and energy-efficient motor technologies necessary for modern winding operations.

The midstream involves the core activities of the winding machine manufacturers, who engage in design, assembly, software integration, testing, and final packaging. European manufacturers often focus on high-end, highly automated, and precision-driven machinery, emphasizing proprietary software and patented mechanical systems. Asian manufacturers, while rapidly closing the technological gap, often focus on high-volume production with competitive pricing. Direct distribution channels are typically employed for major contracts involving large spinning mills or textile groups, allowing for direct negotiation, customized installation, and integrated technical support. Indirect channels, involving agents, distributors, and localized service providers, are utilized to penetrate smaller markets and provide essential after-sales service and spare parts supply across dispersed geographic locations, optimizing localized market reach and support capabilities.

Downstream activities involve the extensive network of end-users, primarily spinning mills, integrated textile plants, and yarn processing units, who utilize the machines to prepare yarn for weaving, knitting, or dyeing. The efficiency of the winding machine directly impacts the profitability and quality of these downstream textile operations. After-sales service, including periodic maintenance, spare parts availability, and technical training, constitutes a significant segment of the value chain, ensuring prolonged machine lifespan and sustained operational efficiency. The feedback loop from these end-users back to the manufacturers regarding machine performance, quality outcomes, and desired automation features is crucial for iterative product development and technological advancement within the competitive market landscape.

Cotton Yarn Winding Machine Market Potential Customers

The primary consumers and buyers of cotton yarn winding machines are large-scale spinning mills globally, particularly those focusing on export-oriented cotton yarn production for the international apparel market. Integrated textile manufacturers, which handle spinning, weaving, and finishing under one roof, represent another significant customer base, often requiring sophisticated winding systems that can integrate seamlessly with their automated downstream processes. Furthermore, specialized yarn dyeing and processing units that prepare packages optimized for consistent dye penetration (soft winding) are key buyers of precision and assembly winding machines. The decision to purchase is heavily influenced by factors such as production scale requirements, desired yarn quality metrics (e.g., knotless guarantee), energy efficiency, and the total cost of ownership (TCO) over the machine's lifecycle.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.8 Million |

| Market Forecast in 2033 | USD 701.5 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Murata Machinery, Schlafhorst (Saurer Group), Savio Macchine Tessili S.p.A., Qingshan Textile Machinery, Lakshmi Machine Works (LMW), Taitan Textile Machinery, Rifa Textile Machinery, Jingwei Textile Machinery, Hacoba Textilmaschinen GmbH, Cixing Group, Tsudakoma Corp., SSM Schärer Schweiter Mettler AG, Zhejiang Rifa Textile Machinery Co., Ltd., Fongs Industries Co., Ltd., Prashant Group, Picanol Group, A.T.E. Enterprises Private Ltd., Kirloskar Pneumatic Co. Ltd., Truetzschler Group, Rieter Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cotton Yarn Winding Machine Market Key Technology Landscape

The technological landscape of the Cotton Yarn Winding Machine Market is heavily defined by advancements in automation, precision mechanics, and digital integration capabilities, collectively moving the industry toward smart manufacturing environments. The core focus remains on increasing winding speeds while maintaining yarn quality and minimizing breaks. This is achieved through sophisticated electronic tension control systems that monitor and adjust yarn tension in milliseconds, ensuring consistent package build-up regardless of variations in the input bobbin. Modern automatic winders utilize servo motor technology for highly accurate traverse mechanisms, replacing traditional mechanical systems and allowing for flexible, programmable package geometries tailored to specific customer needs (e.g., optimal density for high-pressure dyeing or soft winding for preparation).

A major technological differentiator is the sophistication of electronic yarn clearers. Modern clearers integrate capacitive sensors, optical sensors, and advanced signal processing to identify not just common defects (slubs, thick places) but also subtle issues like foreign fibers, synthetic contamination, and minor shade differences which are crucial for maintaining quality in high-end yarns. Furthermore, the evolution from mechanical knotting to pneumatic splicing technology is nearly complete, with high-performance splicers capable of joining yarn ends with minimum strength loss and invisibility in the final fabric. Machine manufacturers are also incorporating specialized feeders and suction systems that manage yarn ends automatically during a break, dramatically reducing operator intervention time and boosting overall machine efficiency (OEE).

The trend towards Industry 4.0 has propelled the development of winding machines equipped with Internet of Things (IoT) connectivity. These machines feature integrated sensors and control units that transmit real-time operational data—such as production metrics, energy consumption, yarn break rates, and individual spindle performance—to centralized monitoring dashboards or cloud platforms. This digital integration facilitates predictive maintenance scheduling, allowing mills to optimize spare parts inventory and reduce unexpected failures. Furthermore, advanced software allows for remote diagnostics and centralized recipe management, ensuring standardized winding parameters across an entire fleet of machines regardless of their physical location, which is critical for global textile enterprises maintaining consistent product quality.

Another area of intense technological focus is energy efficiency. New generation winding machines use high-efficiency direct drive servo motors and optimized aerodynamics to minimize air consumption (particularly critical for pneumatic splicing and suction systems), leading to substantial operational cost reductions. Precision winding technology, which creates packages with extremely uniform density, directly impacts the efficiency of subsequent processes like dyeing, where uneven packages can lead to patchy coloration. The development of multi-function machines capable of handling diverse yarn types—from fine cotton and blends to specialty synthetic fibers—without requiring extensive mechanical adjustments further showcases the market's trajectory towards flexible, high-precision manufacturing solutions.

The integration of human-machine interface (HMI) systems has also seen significant improvement. Modern HMI screens are large, intuitive, touch-sensitive displays that provide operators with detailed, contextual information about machine status, fault location, and production statistics. These interfaces often support multiple languages and incorporate diagnostic tools that simplify complex maintenance procedures, lowering the requirement for highly specialized technicians for routine operation. The convergence of hardware precision, sophisticated sensor technology, and AI-enabled software analytics is the primary driver of competitive advantage, enabling manufacturers to guarantee superior yarn package quality, which is the ultimate goal of the winding process.

Regional Highlights

- Asia Pacific (APAC): APAC is the global epicenter for the Cotton Yarn Winding Machine Market, driven by its massive installed base of spinning capacity, particularly in China, India, and Vietnam. This region is characterized by high volume manufacturing, continuous mill expansion, and a strong push for modernization. India and China are not only significant consumers but also major manufacturers of winding machinery. The regional demand is polarized, with high demand for both economical semi-automatic models for smaller mills and highly advanced automatic machines for large, export-oriented conglomerates seeking peak efficiency and quality compliance. Government initiatives promoting textile park development and technology upgrades further bolster market expansion in Bangladesh and Pakistan.

- Europe: Europe represents a mature market focused primarily on replacement cycles and highly specialized machinery. European textile manufacturers demand the highest level of automation, energy efficiency, and precision winding technology, often for processing high-value, niche cotton products or highly technical cotton blends. Key manufacturers in countries like Italy, Germany, and Switzerland are technology leaders, setting global benchmarks for speed, automation, and electronic clearing quality. The market here is less driven by capacity expansion and more by sustainability requirements and operational excellence optimization.

- North America: Similar to Europe, North America is a replacement market where investment decisions prioritize superior automation, minimal labor requirement, and adherence to stringent quality control standards. The relatively high labor cost environment necessitates the use of fully automatic and integrated winding solutions. Demand is focused on machinery capable of handling specialized cotton types, organic yarns, and technical textile applications, with emphasis placed on data connectivity and predictive maintenance features to maximize machine utilization rates.

- Latin America: This region, including countries like Brazil and Mexico, is experiencing steady growth driven by localized textile production aimed at both domestic consumption and regional exports. Market penetration is gradual, characterized by investments in moderately automated winding machines that balance upfront capital costs with efficiency gains. Machinery suppliers are increasingly offering flexible financing options and comprehensive localized service contracts to stimulate sales and facilitate the transition from older generation equipment.

- Middle East and Africa (MEA): The MEA region shows nascent growth, particularly in countries like Turkey, Egypt, and Saudi Arabia, which are investing heavily in establishing modern, vertically integrated textile facilities. The demand profile is focused on efficient automatic machinery to establish competitive production capabilities quickly. Geopolitical stability and government efforts to diversify economies away from oil revenue, often channeling funds into manufacturing sectors like textiles, are key drivers for winding machine procurement.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cotton Yarn Winding Machine Market.- Murata Machinery, Ltd. (Japan)

- Schlafhorst (Saurer Group) (Germany/Switzerland)

- Savio Macchine Tessili S.p.A. (Italy)

- Lakshmi Machine Works (LMW) (India)

- Taitan Textile Machinery Co., Ltd. (China)

- Qingshan Textile Machinery Co., Ltd. (China)

- Jingwei Textile Machinery Co., Ltd. (China)

- Rifa Textile Machinery Co., Ltd. (China)

- SSM Schärer Schweiter Mettler AG (Switzerland)

- Hacoba Textilmaschinen GmbH & Co. KG (Germany)

- Cixing Group Co., Ltd. (China)

- Tsudakoma Corp. (Japan)

- Zhejiang Rifa Textile Machinery Co., Ltd. (China)

- Fongs Industries Co., Ltd. (China/Hong Kong)

- Picanol Group (Belgium)

- A.T.E. Enterprises Private Ltd. (India)

- Prashant Group (India)

- Kirloskar Pneumatic Co. Ltd. (India)

- Truetzschler Group (Germany)

- Rieter Group (Switzerland)

Frequently Asked Questions

Analyze common user questions about the Cotton Yarn Winding Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the current growth trajectory for automatic cotton yarn winding machines?

The automatic segment is experiencing robust growth, driven by the global imperative for textile manufacturers to reduce labor dependency, increase production efficiency, and ensure consistently high-quality, knotless yarn packages essential for high-speed weaving and knitting operations.

How do electronic yarn clearers contribute to the value proposition of modern winding technology?

Electronic yarn clearers are critical quality control instruments that utilize advanced sensors to detect and eliminate defects (slubs, foreign fibers, thick/thin places) in the yarn during winding, thereby significantly improving the final fabric quality and minimizing machine stoppages in downstream processes.

Which geographical region dominates the consumption of cotton yarn winding machines?

Asia Pacific (APAC) dominates the market consumption, primarily due to the vast spinning capacity and continuous mill expansion projects in major textile manufacturing countries such as China, India, and Bangladesh, driven by global demand for cotton textiles.

What role does Industry 4.0 integration play in new winding machine procurement decisions?

Industry 4.0 features, including IoT connectivity and real-time data analytics, are vital drivers, enabling mills to implement predictive maintenance, optimize energy usage, remotely monitor performance, and seamlessly integrate winding data into centralized textile management systems (MES).

What is the difference between soft winding and standard winding in textile preparation?

Soft winding is a specialized process used specifically for dyeing preparation, creating packages with uniform low density to ensure consistent and deep penetration of dye liquor throughout the yarn package. Standard winding focuses on achieving maximum density and package stability for subsequent weaving or knitting processes.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager