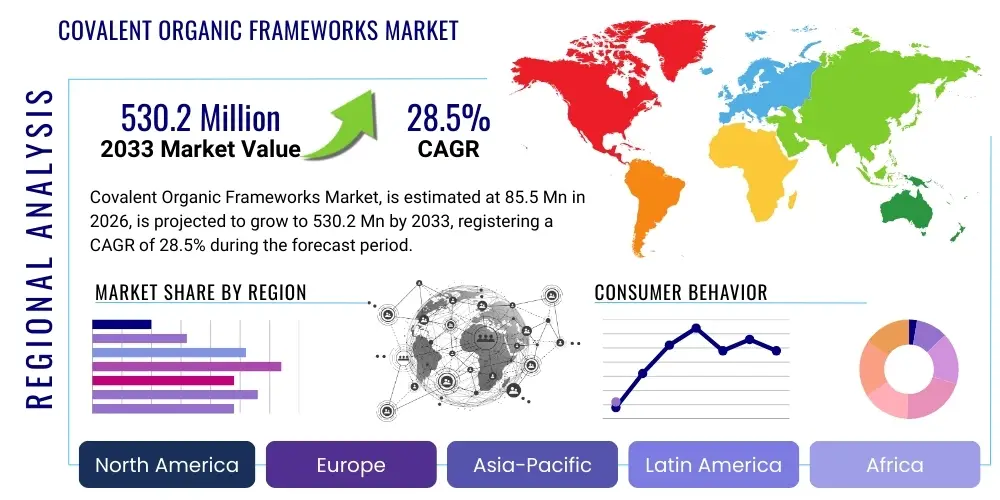

Covalent Organic Frameworks Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440606 | Date : Jan, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Covalent Organic Frameworks Market Size

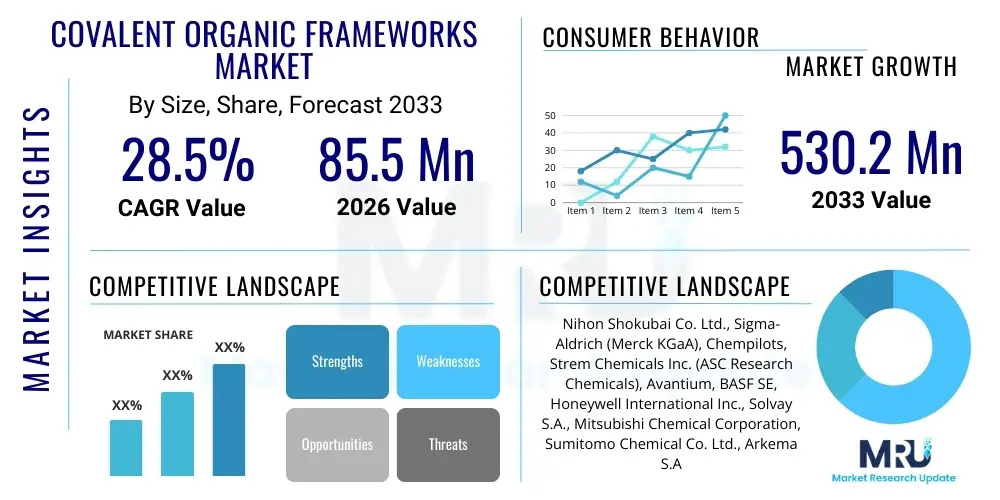

The Covalent Organic Frameworks Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 28.5% between 2026 and 2033. The market is estimated at USD 85.5 Million in 2026 and is projected to reach USD 530.2 Million by the end of the forecast period in 2033.

Covalent Organic Frameworks Market introduction

Covalent Organic Frameworks (COFs) represent a groundbreaking class of crystalline porous materials meticulously constructed from organic building blocks linked by strong, irreversible covalent bonds. These materials offer exceptional structural predictability and chemical tunability, enabling the creation of one-dimensional (1D), two-dimensional (2D), or three-dimensional (3D) porous architectures with precisely defined pore sizes and functionalities. Their unique properties, including ultra-high surface area, high porosity, excellent thermal and chemical stability, and customizable pore environments, make them highly attractive for a diverse array of advanced applications across various industries. The intrinsic flexibility in their design allows for the incorporation of specific functional groups, leading to tailored interactions with guest molecules and significantly enhancing their performance in specialized tasks.

Major applications for Covalent Organic Frameworks span critical sectors, driven by their superior performance characteristics. In gas storage and separation, COFs are highly valued for their ability to efficiently capture and store gases like hydrogen (H2), methane (CH4), and carbon dioxide (CO2), offering solutions for clean energy and environmental management. Their precise and tunable pore structures also enable highly selective gas separations, crucial for industrial processes. In catalysis, COFs serve as robust and reusable heterogeneous catalysts, providing well-defined active sites within their porous network, which can enhance reaction rates and selectivity, making them vital for sustainable chemical synthesis. Furthermore, their application extends to energy storage, where their high surface area and conductive properties can improve the performance of supercapacitors and batteries, and to drug delivery systems, where their porous structures can encapsulate and controllably release therapeutic agents, offering advancements in pharmaceutical applications. The intrinsic benefits of COFs, such as their low density, chemical diversity, and structural robustness, underscore their potential to revolutionize material science and engineering, providing a sustainable alternative to traditional materials.

The market for Covalent Organic Frameworks is primarily driven by an escalating global demand for advanced materials capable of addressing pressing challenges in energy, environment, and healthcare. The increasing need for efficient and selective gas storage and separation technologies, particularly in the context of carbon capture and clean energy initiatives, acts as a significant catalyst for market growth. Similarly, the growing imperative for sustainable and efficient catalytic processes in the chemical industry fuels the adoption of COF-based catalysts. Furthermore, continuous advancements in synthetic methodologies, coupled with a deeper understanding of structure-property relationships, are expanding the range of COF materials available and improving their commercial viability. Research and development investments from both academic institutions and industrial players are accelerating the discovery of novel COF structures and their applications, thereby broadening the market landscape. These factors collectively position COFs as a transformative technology with substantial growth potential.

Covalent Organic Frameworks Market Executive Summary

The Covalent Organic Frameworks market is experiencing robust growth, primarily fueled by significant advancements in materials science and an increasing demand for high-performance porous materials across diverse industries. Business trends indicate a strong focus on research and development, with numerous academic and industrial collaborations aimed at optimizing COF synthesis, improving scalability, and exploring novel applications. Key players are investing heavily in intellectual property, securing patents for proprietary COF structures and manufacturing processes to gain a competitive edge. There is also an emerging trend towards developing composite materials that integrate COFs with other polymers or inorganic materials to enhance mechanical properties or introduce synergistic functionalities, broadening their applicability in complex systems. Furthermore, market strategies are increasingly emphasizing cost-effective and environmentally friendly synthesis methods, addressing concerns about sustainability and industrial adoption. The shift towards application-specific COF designs is another notable trend, moving from general-purpose materials to highly tailored solutions for specific industrial challenges, thereby driving market specialization and innovation.

Regionally, the market is characterized by varying levels of maturity and growth drivers. North America and Europe are leading the market in terms of research and development, backed by substantial government funding for advanced materials science and a strong presence of key academic and industrial research institutions. These regions are also early adopters of COF technologies in niche applications such as specialized catalysis and advanced separation membranes, owing to stringent environmental regulations and a high demand for innovative solutions in the energy sector. The Asia Pacific region, particularly countries like China, Japan, and South Korea, is emerging as a significant growth hub. This growth is driven by increasing industrialization, rising investments in manufacturing capabilities, and a burgeoning electronics and automotive sector seeking lightweight and high-performance materials. Additionally, governments in APAC are actively promoting material science research through various initiatives, creating a fertile ground for COF market expansion. Latin America, the Middle East, and Africa are still in nascent stages, with growth expected to accelerate as awareness increases and industrial infrastructure develops, particularly in areas requiring advanced gas processing and environmental solutions.

From a segmentation perspective, the market's growth is predominantly observed in the gas storage & separation and catalysis segments, which are currently the most mature application areas for COFs. The demand for efficient carbon capture technologies and the need for high-performance catalysts in fine chemical synthesis are major contributors to this growth. The energy storage segment is poised for significant expansion, driven by advancements in battery technology and supercapacitors where COFs offer potential for enhanced charge density and cycling stability. The drug delivery and sensing segments, while smaller, are exhibiting rapid growth due fueled by ongoing biomedical research demonstrating the unique capabilities of COFs for targeted drug release and highly sensitive detection of biomolecules and environmental pollutants. The underlying structural classifications, such as 2D COFs and 3D COFs, are also seeing varied adoption rates, with 2D COFs often preferred for membrane applications due to their layered structure and 3D COFs gaining traction in bulk applications requiring high volumetric capacity. The diversification of end-use industries, including chemical & petrochemical, pharmaceutical, energy, and environmental sectors, further underscores the broad applicability and growth potential of Covalent Organic Frameworks.

AI Impact Analysis on Covalent Organic Frameworks Market

Users frequently inquire about how Artificial Intelligence (AI) can accelerate the discovery and optimization of Covalent Organic Frameworks (COFs), improve their synthesis and characterization, and ultimately drive their commercialization. Key themes revolve around leveraging AI for predictive material design, overcoming synthesis challenges, automating experimental processes, and analyzing complex data to uncover structure-property relationships. Users are keen to understand AI's role in shortening the discovery cycle, reducing trial-and-error experimentation, and identifying novel COF structures with enhanced performance for specific applications. Concerns often center on the need for robust, high-quality datasets to train AI models effectively and the interpretability of AI-generated insights, especially in complex chemical systems. Expectations are high regarding AI's potential to unlock previously unexplorable COF chemistries and to make COF synthesis more scalable and reproducible, paving the way for widespread industrial adoption and new market opportunities.

- Accelerated Materials Discovery: AI algorithms, particularly machine learning models, can rapidly screen vast virtual libraries of potential COF structures, predicting their properties (e.g., porosity, gas adsorption capacity, catalytic activity) based on their molecular building blocks and topological designs. This significantly reduces the time and cost associated with experimental synthesis and characterization of unsuitable candidates, focusing research efforts on the most promising COF architectures.

- Predictive Synthesis Pathways: AI can analyze extensive reaction data to predict optimal synthetic conditions (e.g., solvent, temperature, time, catalyst) for novel COFs, helping to overcome common challenges in reproducibility and scalability. By identifying key parameters influencing yield and crystallinity, AI tools can guide chemists towards more efficient and reliable synthesis protocols, thereby accelerating the transition from laboratory-scale production to industrial manufacturing.

- Performance Optimization: Through iterative learning, AI models can fine-tune the design of COFs for specific applications, such as maximizing CO2 capture efficiency or enhancing catalytic turnover rates. By establishing robust correlations between structural features (pore size, functional groups) and functional performance, AI enables targeted modifications to improve material efficacy beyond conventional trial-and-error approaches, leading to superior product development.

- Automated Characterization and Data Analysis: AI can automate the interpretation of complex experimental data from techniques like X-ray diffraction (XRD), transmission electron microscopy (TEM), and gas adsorption isotherms. This automation speeds up the characterization process, reduces human error, and allows for the rapid identification of new trends or anomalies in material properties. Furthermore, AI can integrate data from multiple sources to provide a holistic understanding of COF performance and stability.

- Identification of Structure-Property Relationships: Advanced AI and deep learning techniques can uncover subtle, non-obvious relationships between the molecular structure of COFs and their macroscopic properties. This deeper mechanistic understanding is crucial for rational design principles, enabling researchers to predict how changes in building blocks or linkage chemistry will affect overall performance, thereby fostering innovation and patentable breakthroughs in COF design.

- Enhanced Quality Control and Process Monitoring: In manufacturing settings, AI can be deployed to monitor COF synthesis in real-time, detecting deviations from optimal conditions and predicting potential quality issues. This allows for proactive adjustments, ensuring consistent product quality and reducing waste, which is critical for the industrial scalability and commercialization of COF materials.

- Custom Material Design for Niche Applications: AI can facilitate the rapid design of highly specialized COFs tailored to unique application requirements, such as biosensors for specific biomarkers or membranes for challenging industrial separations. By quickly exploring the vast chemical space, AI enables the creation of bespoke materials that meet the exact performance criteria of emerging niche markets, unlocking new commercial avenues.

- Intellectual Property Strategy and Landscape Analysis: AI tools can analyze existing patent landscapes and scientific literature to identify white spaces for new COF inventions and predict future research trends. This strategic insight helps companies prioritize R&D investments, develop robust IP strategies, and maintain a competitive edge in the rapidly evolving COF market by guiding the creation of novel and protectable materials.

DRO & Impact Forces Of Covalent Organic Frameworks Market

The Covalent Organic Frameworks (COFs) market is profoundly shaped by a dynamic interplay of driving forces, inherent restraints, and burgeoning opportunities that collectively determine its trajectory and impact the competitive landscape. Key drivers include the escalating demand for highly efficient gas storage and separation technologies, particularly in response to global environmental concerns such as carbon emissions reduction and the pursuit of clean energy solutions. The burgeoning need for advanced heterogeneous catalysts in sustainable chemical synthesis, offering benefits like recyclability and enhanced selectivity, further propels market expansion. Moreover, continuous innovation in materials science, coupled with significant research and development investments, is broadening the application spectrum of COFs, making them attractive for diverse high-tech industries. These drivers create a robust foundation for sustained growth, encouraging new entrants and fostering technological advancements that enhance COF performance and reduce production costs.

However, the market also faces considerable restraints that temper its growth potential. The high synthesis cost associated with producing COFs at an industrial scale remains a significant barrier, particularly due to expensive organic precursors and energy-intensive reaction conditions. Scalability challenges, including difficulties in achieving consistent product quality and morphology across large batches, pose another hurdle, limiting widespread commercial adoption. Furthermore, the nascent stage of industrial production, coupled with limited understanding of long-term stability in harsh operational environments, contributes to a perception of risk among potential end-users. Reproducibility issues in COF synthesis, where slight variations in reaction conditions can lead to vastly different material properties, complicate standardization and quality control. These restraints necessitate substantial R&D to develop more cost-effective, scalable, and robust synthesis methods, as well as comprehensive characterization protocols to instill greater confidence in their industrial viability.

Despite these challenges, the Covalent Organic Frameworks market is abundant with compelling opportunities. The expansion into novel application areas such as advanced biomedical devices, including sophisticated drug delivery systems and high-precision biosensors, promises significant future growth. Environmental remediation, through highly efficient contaminant adsorption and degradation, presents another lucrative avenue, addressing critical global challenges related to water and air pollution. The development of next-generation energy storage solutions, leveraging COFs for enhanced battery and supercapacitor performance, also represents a substantial market opportunity. Furthermore, the integration of COFs into advanced electronics, particularly for flexible devices and transparent conductors, could unlock new high-value markets. Strategic collaborations between academia and industry, coupled with increasing governmental support for advanced materials research, are facilitating the translation of laboratory discoveries into commercial products, positioning COFs to capture a larger share of the advanced materials market. The collective influence of these DRO & Impact Forces defines a dynamic and evolving market landscape for Covalent Organic Frameworks, driven by innovation but constrained by commercialization hurdles.

Segmentation Analysis

The Covalent Organic Frameworks (COFs) market is intricately segmented to reflect the diverse structural types, wide-ranging applications, and varied end-use industries that leverage these advanced porous materials. This segmentation provides a granular understanding of market dynamics, growth drivers, and competitive landscapes across different niches. By classifying COFs based on their inherent characteristics and their functional utility, stakeholders can identify key growth areas, evaluate market penetration strategies, and tailor product development to specific industrial demands. The primary segmentations include differentiation by COF type, highlighting the distinct structural architectures; by application, detailing the functional roles COFs play; and by end-use industry, identifying the sectors that integrate these materials into their processes or products. This comprehensive breakdown is crucial for strategic planning and market forecasting in this rapidly evolving field of material science.

- By Type

- 2D COFs (Two-Dimensional Covalent Organic Frameworks)

- 3D COFs (Three-Dimensional Covalent Organic Frameworks)

- Hybrid COFs (Combination of 2D and 3D features, or integrated with other materials)

- By Application

- Gas Storage & Separation (e.g., H2, CO2, CH4 capture, noble gas separation)

- Catalysis (e.g., Heterogeneous catalysis, photocatalysis, organocatalysis)

- Energy Storage (e.g., Supercapacitors, batteries, fuel cells)

- Drug Delivery & Biomedical (e.g., Targeted drug release, bioimaging, biosensors)

- Sensing (e.g., Chemical sensing, environmental monitoring, explosives detection)

- Membrane Technology (e.g., Water purification, gas separation membranes)

- Electronics & Optoelectronics (e.g., Conductive materials, light-emitting devices)

- Others (e.g., Adsorption, environmental remediation)

- By End-Use Industry

- Chemical & Petrochemical Industry

- Pharmaceutical & Biotechnology

- Energy & Power

- Environmental & Water Treatment

- Automotive & Aerospace

- Electronics & Semiconductor

- Healthcare & Medical Devices

- Research & Development Institutes

- Defense & Security

- Others

Value Chain Analysis For Covalent Organic Frameworks Market

The value chain for the Covalent Organic Frameworks (COFs) market is a complex ecosystem, beginning with the sourcing of raw materials and culminating in the end-use applications. Upstream analysis focuses on the suppliers of fundamental chemical precursors, which are the molecular building blocks necessary for COF synthesis. This segment involves manufacturers of high-purity organic monomers, linkers, and catalysts, whose quality directly impacts the structural integrity and performance of the resultant COFs. Key challenges at this stage include ensuring a consistent supply of specialized and often expensive chemical reagents, managing intellectual property related to proprietary precursors, and maintaining stringent quality control standards. Innovation in precursor synthesis, aiming for more cost-effective and sustainable routes, is crucial for optimizing the overall efficiency of the COF production process. The diversity and availability of these raw materials significantly influence the variety and scalability of COFs that can be produced, making this upstream segment a critical determinant of market growth.

Midstream activities involve the actual synthesis, functionalization, and preliminary characterization of COFs. This stage encompasses R&D institutions, specialized chemical companies, and advanced materials manufacturers that possess the expertise in various synthetic methodologies, such as solvothermal, hydrothermal, or mechanochemical approaches. These entities are responsible for developing scalable and reproducible synthesis protocols, ensuring the formation of COFs with desired pore sizes, topologies, and functionalities. Post-synthesis modifications, such as grafting additional functional groups or incorporating guest molecules, also fall within this stage to tailor COFs for specific applications. Comprehensive quality assurance and advanced characterization techniques (e.g., XRD, BET, TEM, TGA) are essential here to validate the structural integrity, porosity, and stability of the synthesized materials. The efficiency and cost-effectiveness of these midstream processes are paramount for transitioning COFs from laboratory curiosities to commercially viable products, requiring continuous investment in process optimization and automation.

Downstream analysis covers the distribution channels and end-use integration of COFs. Once produced, COFs are distributed through various channels, including direct sales from manufacturers to specialized industrial users, or through chemical distributors that cater to a broader market, including research laboratories and smaller enterprises. Direct channels are often preferred for highly specialized applications requiring technical support and customization, while indirect channels provide wider market access. The ultimate end-users are diverse industries such as chemical & petrochemical, pharmaceutical, energy, environmental, and electronics, where COFs are integrated into products like gas separation membranes, catalytic reactors, drug delivery systems, or energy storage devices. Successful integration requires extensive collaboration between COF producers and end-users to optimize material properties for specific operational conditions and performance requirements. The market penetration of COFs heavily relies on demonstrating clear economic and performance advantages over existing solutions, emphasizing their unique benefits in efficiency, selectivity, and sustainability across these varied distribution and application landscapes.

Covalent Organic Frameworks Market Potential Customers

The Covalent Organic Frameworks market targets a diverse array of potential customers, primarily comprised of industries and research institutions seeking advanced materials with highly specific and tunable properties. Chemical and petrochemical companies represent a significant segment, driven by the need for more efficient and selective processes in catalysis, gas separation, and adsorption for purification. These industries are constantly seeking innovative solutions to reduce energy consumption, minimize waste, and enhance the yield of chemical reactions, making COFs highly attractive for their robust catalytic performance and precise molecular sieving capabilities. For instance, in gas processing, COFs can offer superior separation of valuable hydrocarbons or the removal of impurities, thereby improving product purity and operational efficiency. Their potential to catalyze reactions with high selectivity and stability also provides a pathway to more sustainable and cost-effective chemical manufacturing, appealing directly to process engineers and R&D departments in this sector.

Another crucial segment comprises pharmaceutical and biotechnology companies, which are increasingly exploring COFs for sophisticated applications in drug delivery, diagnostics, and bioseparation. The tunable pore sizes and biocompatibility of certain COFs make them ideal candidates for encapsulating therapeutic agents, enabling controlled release profiles and targeted delivery to specific cells or tissues, thereby reducing side effects and improving treatment efficacy. Furthermore, their high surface area and modifiable interiors allow for the selective capture and sensing of biomolecules, opening doors for advanced diagnostic tools and purification processes for complex biological mixtures. Researchers in these fields are continually looking for novel platforms that can enhance drug stability, improve bioavailability, and facilitate personalized medicine approaches. The demand for innovative materials that can overcome the limitations of traditional drug carriers and diagnostic tools positions COFs as a high-potential solution for the pharmaceutical and biotechnology sectors.

The energy and environmental sectors also represent a substantial customer base for COFs. Energy companies are keen on utilizing COFs for efficient hydrogen storage in fuel cell vehicles, carbon capture technologies in power plants, and methane storage for natural gas vehicles, all aimed at fostering clean energy solutions and reducing greenhouse gas emissions. Their exceptionally high porosity and affinity for specific gases provide a compelling advantage over conventional storage and separation materials. Similarly, environmental agencies and water treatment companies are investigating COFs for advanced water purification, contaminant removal, and air filtration due to their high adsorption capacities and chemical stability. For example, COFs can effectively remove heavy metals, organic pollutants, and microplastics from water, offering sustainable solutions for addressing global water scarcity and pollution challenges. The growing emphasis on sustainability, coupled with stringent environmental regulations, creates a strong market pull for COF-based technologies in these critical industries, attracting innovation and investment from both public and private entities focused on environmental stewardship and energy efficiency.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 85.5 Million |

| Market Forecast in 2033 | USD 530.2 Million |

| Growth Rate | 28.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Nihon Shokubai Co. Ltd., Sigma-Aldrich (Merck KGaA), Chempilots, Strem Chemicals Inc. (ASC Research Chemicals), Avantium, BASF SE, Honeywell International Inc., Solvay S.A., Mitsubishi Chemical Corporation, Sumitomo Chemical Co. Ltd., Arkema S.A., Sinopec Corp., Evonik Industries AG, LG Chem, ExxonMobil Chemical Company, Dow Chemical Company, Tosoh Corporation, Covestro AG, Daicel Corporation, SAES Getters S.p.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Covalent Organic Frameworks Market Key Technology Landscape

The technological landscape of the Covalent Organic Frameworks (COFs) market is dynamic and rapidly evolving, primarily driven by innovations in synthetic methodologies, advanced characterization techniques, and computational modeling. The most prevalent synthesis technologies include solvothermal and hydrothermal methods, where organic building blocks react in solution under elevated temperatures and pressures to form crystalline COF structures. These methods allow for precise control over crystallinity and pore morphology but often face challenges related to scalability and solvent usage. Other emerging synthetic routes, such as mechanochemistry, which involves grinding solids to induce reactions, offer solvent-free or reduced-solvent alternatives, aligning with green chemistry principles and potentially simplifying industrial scale-up. Microwave-assisted synthesis and template-directed growth are also gaining traction for their ability to reduce reaction times and achieve specific structural control, pushing the boundaries of what is possible in COF fabrication.

Beyond synthesis, advanced characterization technologies are indispensable for validating the structure and properties of COFs. X-ray diffraction (XRD) techniques, including powder XRD and single-crystal XRD, are fundamental for confirming crystallinity and elucidating the periodic structures of COFs, providing critical insights into their pore arrangement and connectivity. Transmission Electron Microscopy (TEM) and Scanning Electron Microscopy (SEM) offer high-resolution imaging of COF morphology, crystal size, and defect analysis, which are crucial for understanding their performance characteristics. Gas adsorption techniques, such as Brunauer-Emmett-Teller (BET) and pore size distribution analyses, quantify the surface area and porosity, directly relating to their gas storage and separation capabilities. Furthermore, spectroscopic methods like Nuclear Magnetic Resonance (NMR), Infrared (IR), and Raman spectroscopy are employed to confirm the covalent linkages and functional group integrity, ensuring the chemical composition matches the intended design. Thermal analysis techniques, such as Thermogravimetric Analysis (TGA), are also vital for assessing the thermal stability of COFs under various conditions, an essential factor for industrial applications.

The role of computational modeling and simulation technologies is increasingly critical in accelerating the discovery and optimization of COFs. Density Functional Theory (DFT) calculations are extensively used to predict the electronic structure, stability, and reactivity of COF building blocks and final frameworks, guiding experimental synthesis efforts. Molecular dynamics (MD) simulations allow researchers to model gas adsorption and diffusion within COF pores, providing insights into their separation performance and transport mechanisms. Grand Canonical Monte Carlo (GCMC) simulations are commonly employed to predict gas uptake capacities under different pressures and temperatures, complementing experimental gas adsorption data. More recently, machine learning and artificial intelligence (AI) algorithms are being integrated into the COF research workflow to predict structure-property relationships, screen virtual COF libraries for optimal performance, and even suggest novel synthetic pathways. These computational tools significantly reduce the need for extensive trial-and-error experimentation, enabling faster development cycles and the rational design of COFs with tailored properties for specific applications, thereby driving the technological frontier of the market.

Regional Highlights

- North America: This region is a leading innovator in the Covalent Organic Frameworks market, characterized by extensive research and development activities in academic institutions and government-funded laboratories. The United States and Canada are at the forefront, benefiting from substantial investments in advanced materials science and nanotechnology. Early adoption of COF technologies is observed in high-value applications, particularly in defense, aerospace, and specialized chemical processing, driven by stringent environmental regulations and a strong emphasis on energy efficiency and carbon capture technologies. The presence of major chemical and energy companies, coupled with robust venture capital funding for advanced materials startups, fosters a dynamic ecosystem for COF commercialization.

- Europe: Europe represents another significant hub for COF research and application, with strong contributions from countries like Germany, the UK, France, and Switzerland. The region benefits from a long history of excellence in chemistry and materials science, supported by powerful research infrastructure and collaborative funding initiatives from the European Union. Key drivers include a focus on sustainable chemistry, green energy solutions, and advanced medical applications. European chemical and pharmaceutical giants are actively exploring COF integration into their product lines, particularly for catalysis, drug delivery, and environmental remediation, demonstrating a clear strategic intent towards innovative material adoption.

- Asia Pacific (APAC): The APAC region is projected to exhibit the fastest growth in the Covalent Organic Frameworks market, primarily driven by rapid industrialization, increasing investments in R&D, and growing demand from manufacturing sectors in China, Japan, South Korea, and India. Governments across these countries are actively promoting material science research through various incentives and partnerships. The burgeoning electronics, automotive, and energy sectors in APAC are keen to adopt COFs for applications such as advanced battery components, lightweight composites, and efficient gas purification systems. The region's large manufacturing base offers significant opportunities for scaling up COF production and integration into commercial products.

- Latin America: While still an emerging market for Covalent Organic Frameworks, Latin America is showing nascent interest, particularly in countries like Brazil and Mexico. Growth in this region is driven by increasing awareness of advanced materials, coupled with a growing focus on sustainable resource management and energy efficiency. Applications in environmental remediation, particularly water purification and industrial effluent treatment, along with potential in the petrochemical sector for improved separation processes, are expected to drive initial adoption. Strategic partnerships with international research bodies and technology transfer initiatives will be crucial for accelerating market development in this region.

- Middle East and Africa (MEA): The MEA region is at an early stage of COF market development but holds considerable long-term potential, especially in Gulf Cooperation Council (GCC) countries. The region's vast oil and gas industries are significant potential end-users for COFs in gas separation, natural gas purification, and CO2 capture technologies. Investments in diversifying economies away from traditional hydrocarbons and towards high-tech industries, coupled with efforts in water scarcity solutions through advanced desalination and purification, could fuel future adoption. Academic institutions are beginning to establish research programs in advanced materials, laying the groundwork for future market expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Covalent Organic Frameworks Market.- Nihon Shokubai Co. Ltd.

- Sigma-Aldrich (Merck KGaA)

- Chempilots

- Strem Chemicals Inc. (ASC Research Chemicals)

- Avantium

- BASF SE

- Honeywell International Inc.

- Solvay S.A.

- Mitsubishi Chemical Corporation

- Sumitomo Chemical Co. Ltd.

- Arkema S.A.

- Sinopec Corp.

- Evonik Industries AG

- LG Chem

- ExxonMobil Chemical Company

- Dow Chemical Company

- Tosoh Corporation

- Covestro AG

- Daicel Corporation

- SAES Getters S.p.A.

- MOF Technologies

- NuMat Technologies Inc.

- Novaphene

- Porous Materials, Inc.

- Micromeritics Instrument Corp.

- Tokyo Chemical Industry Co., Ltd. (TCI)

- Frontier Scientific, Inc.

- Alfa Aesar (Thermo Fisher Scientific)

- Merck Performance Materials

- Applied Materials Inc.

Frequently Asked Questions

Analyze common user questions about the Covalent Organic Frameworks market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are Covalent Organic Frameworks (COFs) and their primary advantages?

Covalent Organic Frameworks (COFs) are a class of crystalline porous polymers constructed from organic building blocks linked by strong covalent bonds. Their primary advantages include exceptional porosity, ultra-high surface area, tunable pore sizes, chemical and thermal stability, and the ability to incorporate diverse functionalities. These properties make COFs highly versatile for applications requiring precise molecular recognition, separation, or catalysis, offering superior performance compared to many traditional porous materials.

What are the main applications driving the Covalent Organic Frameworks market?

The main applications driving the COFs market are gas storage and separation (e.g., CO2 capture, H2 storage), catalysis (e.g., heterogeneous, photocatalysis), energy storage (e.g., supercapacitors, batteries), and drug delivery. Emerging applications also include sensing, membrane technology for water purification, and components in advanced electronics. The demand for efficient, selective, and sustainable solutions in these sectors is a key growth catalyst for COF adoption.

What are the key challenges hindering the widespread adoption of COFs?

Key challenges for widespread COF adoption include high synthesis costs due to expensive precursors and complex procedures, scalability issues in achieving reproducible and consistent material properties at industrial volumes, and the nascent stage of long-term stability data in various operational environments. Additionally, the limited industrial production capacity and the need for more standardized characterization protocols pose significant hurdles to their commercialization.

How is Artificial Intelligence (AI) impacting the development of Covalent Organic Frameworks?

AI is significantly impacting COF development by accelerating materials discovery through predictive modeling, optimizing synthesis pathways for improved reproducibility, and enhancing performance for specific applications. AI also aids in automating complex characterization data analysis and identifying new structure-property relationships, thereby reducing research cycles and facilitating the rational design of novel COF materials. This accelerates the transition from lab to industry by streamlining development and quality control.

Which regions are leading the market for Covalent Organic Frameworks, and what drives their growth?

North America and Europe currently lead the COFs market due to significant investments in R&D, strong academic-industrial collaborations, and stringent environmental regulations driving demand for advanced materials. The Asia Pacific region, particularly China and South Korea, is experiencing the fastest growth, driven by rapid industrialization, government support for material science, and increasing demand from manufacturing, electronics, and energy sectors seeking high-performance solutions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager