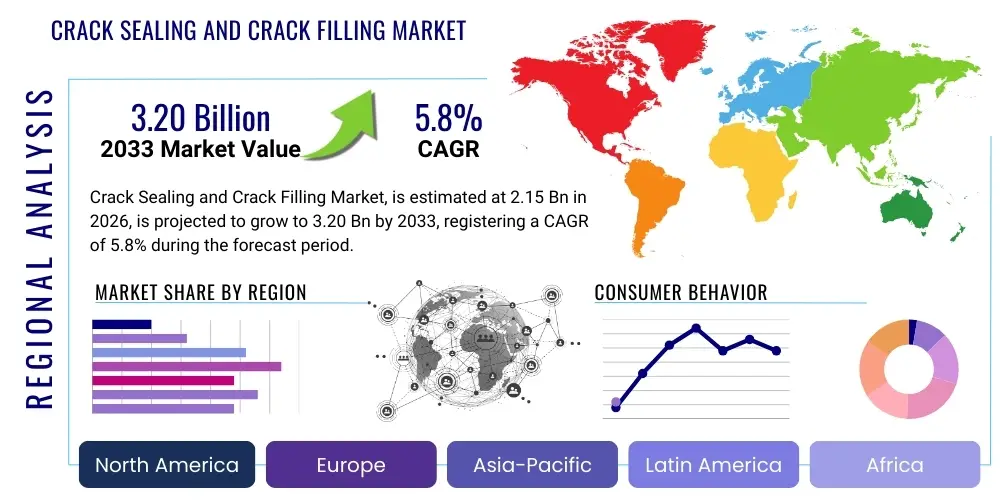

Crack Sealing and Crack Filling Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440182 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Crack Sealing and Crack Filling Market Size

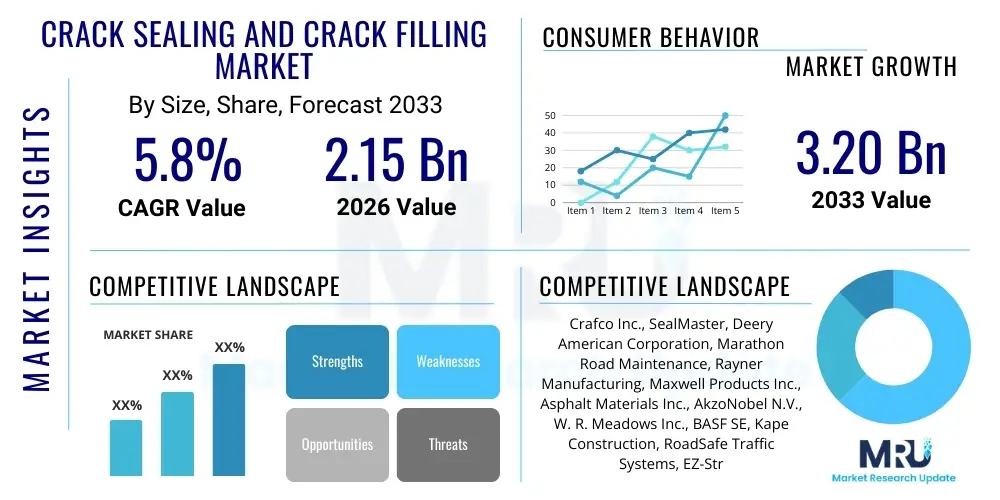

The Crack Sealing and Crack Filling Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 2.15 billion in 2026 and is projected to reach USD 3.20 billion by the end of the forecast period in 2033.

Crack Sealing and Crack Filling Market introduction

The Crack Sealing and Crack Filling Market encompasses the materials, equipment, and services utilized for repairing cracks in pavement surfaces such as roads, highways, airports, bridges, and parking lots. This crucial maintenance activity prevents water penetration into the sub-base, which can lead to further structural degradation, potholes, and ultimately, premature pavement failure. Crack sealing typically involves placing an adhesive sealant into active cracks to prevent moisture and incompressible material ingress, while crack filling uses a less flexible material to fill non-moving cracks and restore the pavement surface. The primary objective is to extend the lifespan of pavement infrastructure, enhance safety, and reduce the need for more costly rehabilitation or reconstruction efforts. These methods are vital components of comprehensive pavement management strategies, offering cost-effective solutions for preserving existing assets.

Products in this market include various types of sealants and fillers, such as hot-applied rubberized asphalt sealants, cold-applied emulsion-based fillers, and specialized polymer-modified materials designed for specific environmental conditions and traffic loads. Major applications span across public infrastructure projects managed by government agencies, commercial properties like shopping centers and industrial parks, and private residential driveways. The benefits are multifold: preventing water damage, inhibiting freeze-thaw cycles from expanding cracks, reducing aggregate raveling, improving ride quality, and significantly extending the service life of pavements. The market is primarily driven by the global aging infrastructure, increasing traffic volumes necessitating durable road networks, and a growing emphasis on preventive maintenance strategies by public and private entities seeking to optimize asset longevity and minimize life-cycle costs. Additionally, climate change and extreme weather events often accelerate pavement deterioration, further bolstering demand for effective crack repair solutions.

Crack Sealing and Crack Filling Market Executive Summary

The Crack Sealing and Crack Filling Market is experiencing robust growth, primarily fueled by global investments in infrastructure maintenance and the urgent need to address deteriorating pavement conditions. Key business trends indicate a shift towards more sustainable and high-performance materials, alongside the adoption of advanced application technologies that enhance efficiency and longevity of repairs. Companies are increasingly focusing on offering integrated solutions, combining specialized materials with efficient equipment and expert services to provide comprehensive pavement preservation programs. This holistic approach helps clients manage their assets more effectively, reducing long-term costs and minimizing operational disruptions. Furthermore, the market is seeing increased collaboration between material suppliers, equipment manufacturers, and service providers to innovate and develop products that can withstand diverse climatic challenges and heavy traffic loads, driving incremental demand and market expansion.

Regional trends highlight significant growth in North America and Europe, driven by well-established infrastructure maintenance programs and substantial government spending on road networks. The Asia Pacific region is emerging as a high-growth market, propelled by rapid urbanization, extensive new infrastructure development, and increasing awareness regarding the economic benefits of proactive pavement management in countries like China and India. Latin America, the Middle East, and Africa are also showing promising potential, as these regions progressively invest in improving their transportation infrastructure. Segment trends reveal a strong demand for hot-applied rubberized asphalt sealants due to their superior performance and durability, particularly in high-stress environments. The application segment sees continued dominance from roads and highways, though airport runways and large commercial parking lots represent significant and growing niche markets. The adoption of automated and semi-automated equipment is also a notable trend, aimed at improving application speed, consistency, and worker safety across various project scales.

AI Impact Analysis on Crack Sealing and Crack Filling Market

Users frequently inquire about how artificial intelligence can revolutionize the traditionally labor-intensive and experience-driven field of crack sealing and crack filling. Common questions revolve around AI's ability to enhance crack detection accuracy, optimize repair schedules, and automate the application process, thereby reducing costs and improving efficiency. There is significant interest in predictive analytics for pavement deterioration, leveraging AI to forecast maintenance needs before critical failures occur. Concerns often include the initial investment costs of AI-integrated systems, the need for skilled personnel to operate and interpret AI data, and the seamless integration of AI solutions with existing infrastructure management systems. Expectations are high for AI to deliver more precise, proactive, and sustainable pavement maintenance practices, leading to longer-lasting repairs and optimized resource allocation. Users anticipate AI will not only identify cracks but also categorize their severity, recommend the most suitable repair method, and even guide robotic application systems, transforming the entire lifecycle management of pavements.

- AI-powered image recognition and drone technology enable highly accurate and rapid crack detection and classification, providing detailed insights into pavement distress.

- Predictive analytics driven by machine learning algorithms forecast pavement deterioration rates, optimizing maintenance schedules and shifting from reactive to proactive repair strategies.

- Robotics and autonomous vehicles, guided by AI, can automate the crack sealing and filling process, improving application consistency, speed, and worker safety while reducing manual labor requirements.

- AI assists in optimizing material usage by precisely calculating the required sealant or filler volume based on crack dimensions and severity, minimizing waste and enhancing cost-efficiency.

- Data aggregation and analysis platforms, leveraging AI, provide comprehensive pavement condition assessments, aiding infrastructure managers in making informed decisions about budget allocation and repair priorities.

DRO & Impact Forces Of Crack Sealing and Crack Filling Market

The Crack Sealing and Crack Filling market is significantly influenced by a dynamic interplay of drivers, restraints, opportunities, and various impact forces that shape its trajectory. A primary driver is the pervasive aging infrastructure across developed nations, where vast networks of roads, bridges, and runways are reaching or exceeding their intended design life. This necessitates continuous maintenance and repair to ensure safety and functionality. Coupled with this, escalating traffic volumes globally place immense stress on pavement surfaces, accelerating deterioration and increasing the frequency of crack formation. Governments worldwide are also committing substantial investments to infrastructure upgrades and preservation programs, recognizing the economic benefits of well-maintained transportation systems, which further propels market growth. The increasing adoption of preventive maintenance strategies over costly full-scale reconstruction is another key driver, as crack sealing and filling are highly cost-effective solutions for extending pavement life.

However, the market faces several notable restraints. The initial capital investment for specialized crack sealing and filling equipment can be substantial, posing a barrier for smaller contractors or municipalities with limited budgets. Moreover, the industry grapples with a persistent shortage of skilled labor, particularly for manual application methods and the operation of sophisticated machinery, which can impact project timelines and quality. Environmental regulations regarding material composition and emissions from hot-applied products present compliance challenges, pushing manufacturers towards developing more eco-friendly solutions, which often come at a higher cost. The seasonal nature of pavement maintenance work in many regions, dictated by weather conditions, introduces variability in demand and operational planning, creating periods of intense activity followed by slowdowns.

Opportunities for market expansion are abundant, especially with the continuous innovation in material science leading to the development of higher-performance, longer-lasting, and environmentally sustainable sealants and fillers. These advanced materials offer enhanced adhesion, flexibility, and resistance to extreme temperatures and UV radiation, extending the efficacy of repairs. The growing trend towards smart cities and digital infrastructure management creates avenues for integrating advanced technologies like AI-powered crack detection, drone-based inspection, and automated robotic application systems, which promise to revolutionize efficiency and accuracy. Furthermore, expansion into emerging economies with rapidly developing infrastructure provides untapped growth potential, as these regions prioritize building and maintaining modern transportation networks. The increasing emphasis on sustainable infrastructure practices and circular economy principles also opens doors for new product developments and service models in the crack sealing and filling domain, focusing on recycled content and reduced environmental footprint.

Segmentation Analysis

The Crack Sealing and Crack Filling Market is comprehensively segmented to provide a detailed understanding of its various facets, enabling targeted market strategies and analysis. These segments are primarily based on the type of product, the specific application areas, the end-user demographics, the material composition used in the repairs, and the application method employed. Each segmentation offers unique insights into market dynamics, demand patterns, and technological preferences across different operational contexts. This granular approach helps stakeholders identify niche markets, understand competitive landscapes, and tailor their offerings to meet specific client requirements. For instance, the distinction between product types like sealants and fillers highlights the varied performance characteristics demanded by different crack severities and pavement types, while end-user segmentation reveals the dominant purchasing authorities and their respective procurement processes and quality expectations.

- By Product Type

- Crack Sealants

- Crack Fillers

- By Application

- Roads and Highways

- Airports

- Bridges

- Parking Lots

- Residential Driveways

- Others (e.g., Industrial Pavements, Recreational Paths)

- By End-User

- Government/Public Agencies (Federal, State, Municipal)

- Commercial & Industrial (Retail, Logistics, Manufacturing, Ports)

- Residential

- Infrastructure Developers

- By Material Type

- Asphalt-Based (Rubberized Asphalt, Polymer-Modified Asphalt)

- Concrete-Based (Epoxy, Polyurethane, Silicone)

- Polymer-Modified Emulsions

- Fiber-Reinforced Materials

- By Application Method

- Hot-Applied

- Cold-Applied

- Spray-Applied

- Pour-and-Seal

Value Chain Analysis For Crack Sealing and Crack Filling Market

The value chain for the Crack Sealing and Crack Filling Market begins with the upstream raw material suppliers, who provide essential components such as asphalt binders, polymers, rubber modifiers, aggregates, and various chemical additives. These suppliers are critical as the quality and availability of their materials directly influence the performance and cost of the final crack sealing and filling products. Following this, manufacturers convert these raw materials into specialized sealants, fillers, and related equipment. This stage involves significant R&D to develop innovative formulations that meet stringent performance standards, environmental regulations, and application requirements, ensuring durability, flexibility, and longevity in diverse climatic conditions. The manufacturing process itself involves blending, heating, and packaging these materials, as well as fabricating the specialized machinery used for application. Efficiency in sourcing and manufacturing directly impacts the competitiveness of the final products in the market, with a strong focus on supply chain resilience and cost optimization.

The downstream analysis of the value chain focuses on the distribution, application, and end-use of crack sealing and filling products and services. Products are distributed through various channels, including direct sales from manufacturers to large contractors or public agencies, and indirect sales through a network of distributors, wholesalers, and specialized construction material suppliers. These intermediaries often provide local inventory, technical support, and logistical services, playing a crucial role in market penetration and accessibility. The application phase is typically carried out by specialized pavement maintenance contractors, road construction companies, or in-house public works departments. These entities possess the necessary equipment, trained personnel, and expertise to execute crack sealing and filling projects effectively, adhering to specific project specifications and quality standards. The ultimate end-users are the owners and operators of pavement infrastructure, including government transportation departments, municipal bodies, airport authorities, commercial property managers, and individual homeowners. Their demand for durable and cost-effective pavement preservation drives the entire value chain.

Distribution channels in this market are diverse, reflecting the varied scale and nature of projects. Direct sales are common for large-scale governmental contracts or substantial commercial projects where manufacturers can offer bulk pricing and direct technical support. This direct model fosters strong relationships between suppliers and major clients. Indirect channels involve a robust network of regional distributors and retailers who serve smaller contractors, local municipalities, and individual consumers. These distributors often stock a range of products from multiple manufacturers, providing convenience and accessibility. The distinction between direct and indirect distribution significantly impacts market reach and customer engagement, with indirect channels proving vital for fragmented segments. Effective management of these distribution networks, including inventory optimization, logistics, and technical training for sales staff, is paramount for ensuring timely product availability and customer satisfaction across the entire market spectrum.

Crack Sealing and Crack Filling Market Potential Customers

Potential customers for the Crack Sealing and Crack Filling Market primarily comprise a broad spectrum of entities responsible for the construction, maintenance, and preservation of paved surfaces across various sectors. These end-users are driven by the necessity to maintain safe, functional, and aesthetically pleasing infrastructure while optimizing their long-term asset management costs. Public sector entities, particularly federal, state, and municipal transportation departments, constitute a significant portion of the customer base. They are responsible for vast networks of roads, highways, and bridges, necessitating continuous crack repair as a core component of their pavement management programs. Their procurement processes often involve competitive bidding for large-scale projects, with emphasis on material performance, contractor experience, and adherence to regulatory standards. Maintaining public infrastructure is a non-negotiable mandate, making these governmental bodies perennial and substantial buyers of crack sealing and filling products and services.

Beyond public infrastructure, the commercial and industrial sectors represent a rapidly growing segment of potential customers. This includes owners and operators of large commercial properties such as shopping centers, retail parks, industrial complexes, logistics hubs, and manufacturing facilities, all of which feature extensive parking lots and access roads. These customers prioritize minimizing operational disruptions, enhancing curb appeal, and ensuring the safety of employees and visitors. Similarly, airport authorities require specialized crack repair solutions for runways and taxiways, where the integrity of pavement is critical for aircraft safety. Ports and railway yards also fall into this category, requiring durable repairs for heavy-duty pavements. Residential customers, although typically purchasing on a smaller scale, contribute to the market through demand for driveway maintenance and repair, often served by local contractors or through DIY retail channels. Infrastructure developers, involved in new construction projects, also engage in crack sealing to address initial structural imperfections or as part of long-term warranty maintenance programs, ensuring the longevity of newly built assets before they are handed over for operation.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.15 billion |

| Market Forecast in 2033 | USD 3.20 billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Crafco Inc., SealMaster, Deery American Corporation, Marathon Road Maintenance, Rayner Manufacturing, Maxwell Products Inc., Asphalt Materials Inc., AkzoNobel N.V., W. R. Meadows Inc., BASF SE, Kape Construction, RoadSafe Traffic Systems, EZ-Street Asphalt, Garon Products Inc., Reimers Electra Steam, VSS International Inc., McAsphalt Industries Limited, Neyra Industries Inc., GemSeal Pavement Products, Asphalt Systems Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Crack Sealing and Crack Filling Market Key Technology Landscape

The Crack Sealing and Crack Filling market is increasingly reliant on a sophisticated array of technologies to enhance efficiency, durability, and cost-effectiveness of pavement repairs. Core to this landscape are advanced material formulations. Innovations in polymer-modified asphalt sealants and fillers have significantly improved their flexibility, adhesion, and resistance to extreme temperatures, UV radiation, and fuel spills. These next-generation materials offer extended service life, reducing the frequency of repairs. Beyond asphalt-based products, there's a growing development of high-performance epoxy, polyurethane, and silicone-based sealants tailored for concrete pavements, offering superior bond strength and chemical resistance. Furthermore, fiber-reinforced materials are gaining traction, providing enhanced tensile strength and crack propagation resistance. The integration of nanotechnology into sealant formulations is an emerging trend, promising self-healing properties or improved material durability at a molecular level.

Complementing material advancements, the technology landscape also features significant developments in application equipment and digital tools. Automated and semi-automated crack sealing machines are becoming more prevalent, equipped with features like precision heating systems for hot-applied materials, computerized control of material flow, and ergonomic designs for operator comfort and safety. These machines improve application consistency, speed up project completion, and reduce labor intensity compared to traditional manual methods. Specialized equipment such as routing machines, hot air lances, and infrared heaters are used for precise crack preparation, ensuring optimal sealant adhesion and longevity. On the digital front, GPS-enabled mapping systems are utilized for accurate crack location and tracking, aiding in planning and post-repair assessment. Moreover, drone-based aerial imaging combined with AI-powered analytics is revolutionizing crack detection and severity assessment, allowing for highly efficient and comprehensive pavement condition surveys. Ground-penetrating radar (GPR) and LiDAR technologies offer non-destructive evaluation of subsurface conditions, providing crucial data for determining the root causes of cracking and optimizing repair strategies.

Regional Highlights

- North America: This region dominates the crack sealing and crack filling market, driven by extensive and aging road networks, high traffic volumes, and substantial government spending on infrastructure maintenance. Countries like the United States and Canada have well-established pavement management programs that heavily rely on proactive crack repair to extend asset life. The demand is also bolstered by technological adoption and a focus on high-performance, durable materials for diverse climatic conditions, from extreme winters to hot summers.

- Europe: Europe represents another mature market with significant demand for crack sealing and filling solutions. Countries such as Germany, the UK, France, and Italy face similar challenges with aging infrastructure and high traffic density. Strict regulatory frameworks regarding pavement quality and safety, coupled with strong governmental emphasis on sustainable infrastructure and life-cycle cost analysis, fuel market growth. Innovations in eco-friendly materials and automated application technologies are key trends here.

- Asia Pacific (APAC): The APAC region is projected to exhibit the fastest growth, primarily due to rapid urbanization, massive infrastructure development projects, and increasing disposable incomes leading to higher vehicle ownership. Countries like China, India, Japan, and Australia are investing heavily in expanding and maintaining their transportation networks. While the focus has historically been on new construction, there is a growing recognition of the importance of preventive maintenance, boosting the demand for crack repair solutions.

- Latin America: This region presents a growing market, with countries like Brazil, Mexico, and Argentina progressively investing in improving their road infrastructure. Economic development and increasing trade activities necessitate better transportation links, driving the need for pavement maintenance. Market growth is often influenced by government initiatives to modernize infrastructure and improve connectivity, though budget constraints can sometimes be a limiting factor, leading to a focus on cost-effective repair methods.

- Middle East and Africa (MEA): The MEA region is characterized by substantial investments in infrastructure expansion, particularly in the GCC countries, alongside efforts to improve existing networks in parts of Africa. Harsh desert climates and extreme temperatures in the Middle East necessitate specialized crack sealing materials capable of withstanding severe environmental stresses. Growth in Africa is more localized and dependent on specific country-level infrastructure projects and foreign investments, with a rising emphasis on sustainable and resilient road construction and maintenance.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Crack Sealing and Crack Filling Market.- Crafco Inc.

- SealMaster

- Deery American Corporation

- Marathon Road Maintenance

- Rayner Manufacturing

- Maxwell Products Inc.

- Asphalt Materials Inc.

- AkzoNobel N.V.

- W. R. Meadows Inc.

- BASF SE

- Kape Construction

- RoadSafe Traffic Systems

- EZ-Street Asphalt

- Garon Products Inc.

- Reimers Electra Steam

- VSS International Inc.

- McAsphalt Industries Limited

- Neyra Industries Inc.

- GemSeal Pavement Products

- Asphalt Systems Inc.

Frequently Asked Questions

Analyze common user questions about the Crack Sealing and Crack Filling market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between crack sealing and crack filling?

Crack sealing uses flexible, rubberized materials inserted into active cracks to prevent water infiltration and seal moving joints, extending pavement life. Crack filling uses less flexible materials to fill non-moving cracks, restoring the surface profile and preventing debris accumulation.

How long do crack sealing and crack filling treatments typically last?

The longevity of treatments varies based on material quality, application method, climate, traffic volume, and crack severity, but typically ranges from 3 to 7 years for crack sealing and 1 to 3 years for crack filling under optimal conditions.

What are the main benefits of proactive crack repair for pavements?

Proactive crack repair prevents water damage, inhibits freeze-thaw cycles, reduces aggregate loss, improves pavement safety and ride quality, and significantly extends the overall service life of roads and other paved surfaces, leading to substantial cost savings compared to full rehabilitation.

Are there environmentally friendly options available for crack sealing and filling materials?

Yes, the market is seeing increased development of eco-friendly solutions, including cold-applied emulsions with lower VOC content, bio-based sealants, and materials incorporating recycled content, aligning with sustainable infrastructure practices.

How is technology impacting the efficiency and accuracy of crack repair?

Technology is revolutionizing crack repair through AI-powered detection (drones, image recognition), predictive maintenance analytics, and automated application equipment (robotic sealers), leading to more precise, faster, and safer repair processes and optimized resource allocation.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager