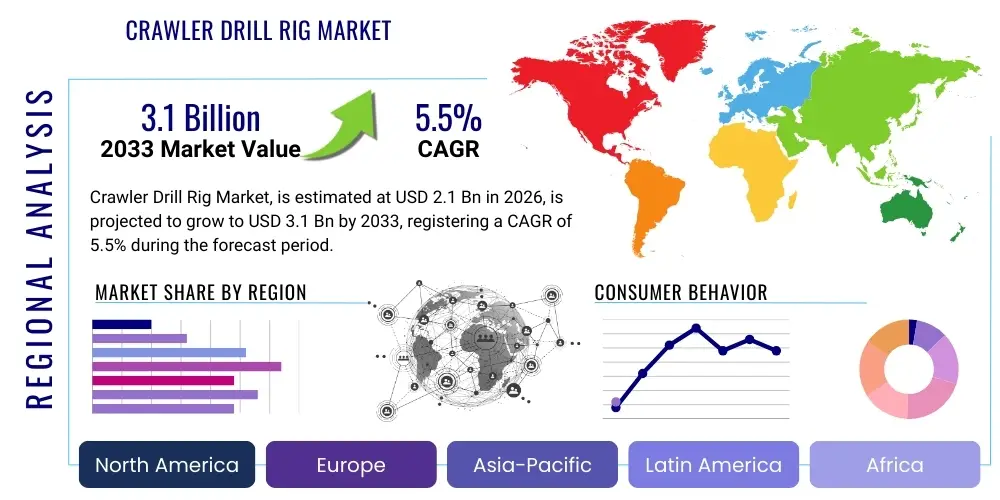

Crawler Drill Rig Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437615 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Crawler Drill Rig Market Size

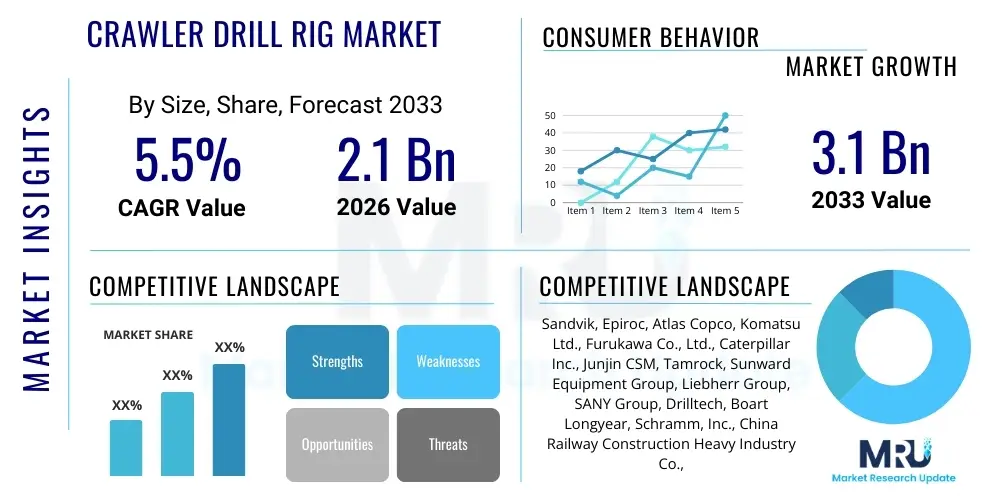

The Crawler Drill Rig Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.5% between 2026 and 2033. This robust growth trajectory is underpinned by sustained global investment in infrastructure development, increased mining activities driven by the demand for essential minerals, and technological advancements focusing on automation and efficiency in drilling operations. The crawler drill rig sector, integral to foundation construction, quarrying, and exploration, is capitalizing on the global recovery in capital expenditure across heavy industries.

The market is estimated at USD 2.1 Billion in 2026 and is projected to reach USD 3.1 Billion by the end of the forecast period in 2033. This valuation reflects the increasing adoption of high-capacity and technologically advanced drill rigs, particularly those incorporating features like remote operation, advanced navigation systems, and enhanced energy efficiency. Emerging economies, particularly in the Asia Pacific region, are major contributors to this growth due to rapid urbanization and large-scale public works projects requiring deep hole and precision drilling capabilities. The competitive landscape remains focused on innovation to reduce operational costs and maximize drilling accuracy in complex geological conditions.

Crawler Drill Rig Market introduction

The Crawler Drill Rig Market encompasses the manufacturing, distribution, and utilization of self-propelled, track-mounted drilling equipment designed for heavy-duty applications requiring stability and mobility across challenging terrain. These versatile machines, which include hydraulic, pneumatic, and electric variants, are primarily utilized for blast hole drilling, foundation drilling, geotechnical sampling, and anchoring operations in construction, mining, and quarrying sectors. The core function of a crawler drill rig is to efficiently penetrate hard rock and soil formations, preparing the ground for extraction activities or structural installations. Their track-based mobility provides significant advantages over wheeled alternatives, allowing access to remote or uneven sites frequently encountered in large infrastructure projects and open-pit mining operations.

Product differentiation in this market centers on power efficiency, drilling depth capabilities, and automation features. Modern crawler drill rigs offer enhanced safety through cabin designs that minimize operator fatigue and exposure to hazards, coupled with telematics systems that optimize maintenance schedules and operational performance tracking. Major applications span critical sectors, including civil engineering for dam construction and tunneling, mineral extraction for coal, iron ore, and precious metals, and construction activities like highway development and high-rise building foundations. The inherent benefits include high drilling precision, superior maneuverability in rugged environments, reduced setup time, and the capacity to handle large-diameter and deep drilling requirements necessary for modern large-scale projects. These attributes collectively position the crawler drill rig as an indispensable asset in the global heavy machinery landscape, supporting fundamental economic growth drivers.

Key driving factors accelerating market expansion include stringent government regulations mandating safer and more precise drilling techniques, the global commodity supercycle pushing mining companies toward new exploration and expansion projects, and massive public and private investment into urban infrastructure overhaul and modernization worldwide. Furthermore, the rising adoption of renewable energy infrastructure, such as large-scale wind and solar farms which require extensive foundation work, significantly contributes to the demand for specialized crawler drilling equipment. Manufacturers are continuously responding to these drivers by engineering machines that offer higher penetration rates and better fuel economy, ensuring compliance with evolving emission standards and client demands for sustainable operational practices.

Crawler Drill Rig Market Executive Summary

The Crawler Drill Rig Market is characterized by robust resilience driven by non-cyclical demand from the global mining sector and accelerating infrastructure development across emerging economies. Current business trends indicate a definitive shift toward integrating digital technologies, including IoT and advanced sensors, into drilling mechanisms to enable predictive maintenance and real-time operational optimization. Strategic alliances and mergers among key original equipment manufacturers (OEMs) are common, aimed at consolidating technological expertise and expanding geographical footprints, particularly into high-growth regions like Southeast Asia and Africa. Furthermore, sustainability has become a critical performance metric, compelling OEMs to innovate hybrid or fully electric crawler rigs that reduce carbon emissions and comply with increasingly stringent environmental regulatory frameworks, positioning specialized equipment providers for significant long-term growth.

Regionally, the Asia Pacific (APAC) stands as the principal engine of market expansion, propelled by unprecedented levels of investment in rail networks, power generation facilities, and residential infrastructure, particularly in China, India, and Indonesia. North America and Europe maintain a strong market presence, characterized by high adoption rates of premium, automated rigs used for complex civil engineering tasks and specialized resource extraction, driven by modernization and replacement cycles of older fleets. The Middle East and Africa (MEA) region show substantial potential, fueled by massive government-led hydrocarbon and construction projects, though growth can be sensitive to oil price volatility and geopolitical stability. Regional competitiveness often depends on establishing strong local distribution and service networks capable of handling the operational demands of heavy machinery in varied climatic conditions.

Segment trends reveal that the hydraulic crawler drill rig segment dominates the market due to its superior power-to-weight ratio, accuracy, and operational flexibility across diverse applications, ranging from small-scale quarrying to deep tunneling. Within applications, the mining sector remains the single largest revenue generator, demanding high-pressure, robust rigs for blast hole preparation, a crucial step in ore extraction. However, the construction and infrastructure segment is forecasted to exhibit the highest CAGR, spurred by global urbanization megatrends and the necessity for foundational drilling in densely populated areas. The demand for rigs capable of deep foundation work and micro-piling is intensifying, leading to specialized product development within the medium and heavy rig capacity categories, addressing diverse requirements from small contractors to major multinational construction firms.

AI Impact Analysis on Crawler Drill Rig Market

Common user questions regarding AI’s influence on the Crawler Drill Rig Market primarily revolve around operational efficiency, safety enhancements, and job displacement concerns. Users frequently inquire about the practical implementation of AI for optimizing drilling parameters (e.g., feed pressure, rotation speed) based on real-time geological data, and the feasibility of achieving fully autonomous drilling cycles. A key concern centers on predictive maintenance algorithms: how accurately can AI forecast component failures in high-stress environments, thereby minimizing costly downtime? Furthermore, users are keen to understand how AI-driven remote monitoring and diagnostics enhance safety protocols by minimizing human exposure to hazardous areas. These inquiries collectively highlight a keen interest in leveraging AI not just for efficiency gains, but also as a fundamental tool for risk management and workforce optimization within drilling operations.

The integration of Artificial Intelligence and Machine Learning (ML) algorithms is rapidly transforming the operational dynamics of crawler drill rigs, transitioning them from manual machinery to highly sophisticated, smart systems. AI algorithms process massive datasets collected from onboard sensors—including vibration analysis, pressure gauges, and GPS—to determine optimal drilling patterns and identify geological anomalies instantaneously. This real-time decision-making capability significantly reduces deviations, improves blast optimization in mining, and minimizes wear and tear on drill bits and components. For example, AI can adjust the percussion frequency based on rock density changes detected milliseconds earlier, resulting in higher penetration rates and reduced energy consumption, directly translating to lower operational expenditure for end-users.

Beyond efficiency, AI is central to enhancing operational safety and resource management. Autonomous rigs, guided by sophisticated vision systems and spatial mapping algorithms, can execute predefined drilling plans with minimal human intervention, effectively removing operators from the most dangerous aspects of the job site. Furthermore, AI-powered fleet management solutions optimize scheduling, fuel consumption, and logistical routes for multiple rigs operating simultaneously across large mining or construction sites. This comprehensive data synthesis allows drilling contractors to move toward a truly integrated smart site environment, where all heavy machinery communicates and collaborates to achieve project goals faster and more safely, substantially improving project predictability and reducing insurance liabilities.

- AI-driven Predictive Maintenance (PdM): Algorithms analyze vibration and temperature data to forecast component failure (e.g., hydraulic pump or engine stress), maximizing uptime.

- Autonomous Drilling Cycles: ML models enable rigs to automatically sequence hole drilling, tramming, and rod changing based on predefined geological maps and real-time feedback.

- Real-time Parameter Optimization: AI adjusts feed force, torque, and flushing pressure based on observed rock characteristics, boosting penetration rate by up to 15%.

- Enhanced Operator Safety: Remote control and teleoperation capabilities are improved by AI stabilizing latency and providing enhanced virtual reality interfaces for precision.

- Resource and Fuel Efficiency: Optimization models minimize engine idling and optimize power delivery for specific drilling tasks, leading to significant fuel savings and reduced emissions.

- Geological Mapping and Targeting: AI fuses seismic data, drone imagery, and drilling logs to refine geological models and ensure high accuracy in resource targeting.

DRO & Impact Forces Of Crawler Drill Rig Market

The market dynamics for crawler drill rigs are fundamentally shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), all subject to significant impact forces stemming from global economic health and regulatory shifts. Key drivers include aggressive worldwide infrastructure spending, particularly in developing nations, coupled with the persistent demand for base and precious metals necessitating expanded mining operations. The industry benefits from technological drivers, such as the increasing maturity of automation, which promises safer, more precise, and cost-effective drilling. Conversely, major restraints include the high initial capital investment required for modern, large-capacity rigs, fluctuations in commodity prices that directly influence mining company expenditure, and the chronic shortage of skilled labor capable of operating and maintaining increasingly sophisticated machinery. These forces collectively dictate the procurement cycles and investment strategies of major end-users, affecting market stability and growth velocity.

Opportunities for market stakeholders lie primarily in three areas: geographical expansion into underserved regions like Africa and Latin America, product diversification into specialized low-emission equipment (e.g., battery-electric rigs) addressing urban construction demands, and aftermarket services modernization. The transition toward electric and hybrid models represents a significant long-term opportunity as environmental, social, and governance (ESG) criteria become mandatory for investment decisions in both mining and construction. Furthermore, the burgeoning demand for critical minerals required for the global energy transition (e.g., copper, lithium) necessitates the deployment of advanced drilling technology in often remote and challenging environments. Manufacturers that successfully deploy robust, interoperable drilling solutions paired with comprehensive digital service contracts are best positioned to capture premium market share and sustain margin expansion throughout the forecast period.

Impact forces significantly affecting the market include rapidly evolving international trade tariffs, which complicate the global supply chain for components and final machinery, and global interest rate hikes, which increase the cost of capital expenditure for drilling contractors. Environmental regulatory tightening, particularly concerning noise pollution and diesel engine emissions (Tier 4 Final/Stage V standards), compels immediate R&D investment but simultaneously drives market consolidation toward compliant, technologically superior products. Geopolitical risks, especially in resource-rich regions, can abruptly halt projects and disrupt market forecasts. Therefore, market participants must employ sophisticated risk mitigation strategies, including localized manufacturing and agile supply chain management, to navigate these powerful external variables and maintain operational continuity across diverse global operational theaters.

Segmentation Analysis

The Crawler Drill Rig Market segmentation provides granular insights into specific product capabilities and application-driven demand patterns. The market is primarily segmented by Type (Surface Drill Rigs, Underground Drill Rigs), Application (Mining, Construction & Infrastructure, Quarrying), and Drilling Method (Rotary Drilling, DTH Drilling, Top Hammer Drilling). This detailed classification is essential for manufacturers to tailor product development, sales strategies, and service offerings to meet the precise requirements of diverse end-user industries. Surface rigs, designed for open-pit operations and large-scale construction, generally prioritize mobility and high-capacity drilling depth, whereas underground rigs focus on compact design, low-profile operation, and exhaust emission management within confined spaces.

The application segment analysis highlights the dominant role of the mining industry, which demands robust rigs capable of continuous operation in harsh environments for blasthole drilling, a prerequisite for efficient extraction processes. However, the construction and infrastructure segment, encompassing vital sectors like tunneling, highway development, and foundation setting, represents the highest growth potential, driven by global urbanization and government infrastructure stimulus packages. Within the technology/method segmentation, Down-the-Hole (DTH) drilling rigs are favored for hard rock applications due to their high penetration rate and accuracy, while Top Hammer drilling remains prevalent in quarrying and smaller construction sites where versatility and lower investment costs are prioritized.

Understanding these segments allows market participants to identify lucrative niches, such as the growing demand for highly specialized rigs for unconventional resource extraction or for geotechnical investigations requiring exceptional precision. The trend is moving toward modular designs that allow rigs to be quickly reconfigured for different drilling methods or applications, enhancing the utilization rates for contractors. Furthermore, the segmentation by operational capacity (light, medium, heavy rigs) directly correlates with project scale and depth requirements, enabling precise competitive positioning and addressing the varied capital constraints of small local contractors versus large multinational corporations.

- Type:

- Surface Drill Rigs

- Underground Drill Rigs

- Application:

- Mining (Open-pit and Underground)

- Construction & Infrastructure (Roads, Tunnels, Foundations)

- Quarrying

- Water Well and Geothermal Drilling

- Drilling Method:

- Down-the-Hole (DTH) Drilling

- Top Hammer Drilling

- Rotary Drilling

- Capacity/Size:

- Light Rigs (up to 3-inch hole diameter)

- Medium Rigs (4-6 inch hole diameter)

- Heavy Rigs (above 6-inch hole diameter)

Value Chain Analysis For Crawler Drill Rig Market

The value chain of the Crawler Drill Rig Market is intricate, starting from the procurement of raw materials and specialized components and extending through manufacturing, assembly, distribution, and critical post-sale services. The upstream segment involves securing high-grade steel alloys, sophisticated hydraulic components (pumps, cylinders, motors), advanced engine systems (meeting strict emission standards), and complex electronic control units. Key challenges in the upstream include maintaining quality control over globally sourced, specialized parts and managing supply chain volatility, which has been exacerbated by recent macroeconomic disruptions. Successful upstream management requires strategic partnerships with highly reliable component suppliers, ensuring consistent quality and availability, crucial for maintaining manufacturing throughput and delivering reliable final products to the demanding end-user industries.

The midstream stage is defined by the manufacturing and assembly process, where Original Equipment Manufacturers (OEMs) leverage precision engineering to integrate components into the final robust crawler chassis and drilling mast structure. This stage is capital-intensive and requires substantial R&D expenditure focused on optimizing drilling performance, improving fuel efficiency, and incorporating advanced safety features. Distribution channels form a critical link between manufacturing and the end-user. Direct sales models are often employed for large fleet purchases and complex, customized rigs, allowing OEMs to maintain control over pricing and customer relationships. Conversely, indirect channels, utilizing exclusive dealers and regional distributors, are essential for covering vast geographic areas, especially in emerging markets where local knowledge and established service infrastructure are vital for market penetration.

The downstream activities involve sales, commissioning, and the crucial aftermarket services segment, including maintenance, repairs, spare parts supply, and operator training. The aftermarket segment is highly profitable and provides a stable revenue stream, often exceeding the margins generated from initial equipment sales. Customer loyalty in the heavy machinery sector is strongly influenced by the efficiency and availability of service support; thus, investment in localized service centers, comprehensive digital diagnostics, and rapid spare parts logistics is paramount. The long operational life of crawler drill rigs means that effective downstream support—including comprehensive warranties and performance guarantees—is a major competitive differentiator, ensuring sustained operational efficiency for mining and construction clients who operate under strict deadlines and severe operational pressure.

Crawler Drill Rig Market Potential Customers

The primary customers for Crawler Drill Rigs are entities engaged in large-scale excavation, resource extraction, and foundational engineering, characterized by high capital expenditure and a necessity for durable, high-performance machinery. The most significant customer base resides within the global mining industry, including multinational corporations specializing in extracting commodities like copper, iron ore, gold, and coal, who require continuous, reliable blast hole drilling for efficient overburden removal and ore body fragmentation. These clients operate 24/7 and prioritize rig capacity, automation features, and the manufacturer's ability to provide timely, comprehensive service support in remote locations. Their procurement decisions are heavily influenced by global commodity price forecasts and the projected lifespan and efficiency metrics (e.g., liters per meter drilled) of the equipment being evaluated.

Another major customer segment is the Construction and Infrastructure sector, including large civil engineering firms, specialized tunneling contractors, and geotechnical companies. These clients procure rigs for specific applications such as setting deep foundations for bridges, high-rise buildings, and wind turbines, as well as for ground reinforcement and slope stabilization projects. Unlike the mining sector, construction customers often require rigs with greater versatility, capable of handling varying geological conditions and constrained site access, emphasizing precision, low noise emission, and regulatory compliance, particularly in urban environments. The demand from this segment is strongly correlated with national and regional government spending on public works projects and private sector investment in commercial real estate development and energy infrastructure.

Secondary but significant potential customers include quarrying operators, who require rigs for aggregate production essential for construction materials, and specialized water well drilling and geothermal energy contractors. Quarrying operators focus on reliability and cost-effectiveness for medium-depth hole production in defined rock types. Geothermal and water well drillers, on the other hand, require highly specialized rigs capable of extreme depths and managing high temperatures and pressures. These varied customer profiles necessitate a segmented sales approach where marketing emphasizes performance specifications relevant to the customer's core operational needs, whether that is sheer tonnage output for mining or environmental compliance and accuracy for urban construction.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.1 Billion |

| Market Forecast in 2033 | USD 3.1 Billion |

| Growth Rate | 5.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sandvik, Epiroc, Atlas Copco, Komatsu Ltd., Furukawa Co., Ltd., Caterpillar Inc., Junjin CSM, Tamrock, Sunward Equipment Group, Liebherr Group, SANY Group, Drilltech, Boart Longyear, Schramm, Inc., China Railway Construction Heavy Industry Co., Ltd. (CRCHI), Doofor Oy, Nanchang Kama, Sinosteel, Hindustan Engineering. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Crawler Drill Rig Market Key Technology Landscape

The current technology landscape in the Crawler Drill Rig Market is defined by a significant push toward digitalization, automation, and sustainable power solutions, fundamentally altering how drilling operations are executed and managed. Telematics and IoT integration are standard features, enabling continuous remote monitoring of vital parameters such as engine health, fuel consumption, and drilling penetration rates. These systems provide centralized fleet management capabilities, allowing contractors and mining companies to maximize asset utilization, schedule preventive maintenance based on actual usage data, and reduce the risk of catastrophic failures. Advanced sensor technology, including inertial navigation systems and high-precision GPS (RTK GPS), ensures highly accurate hole positioning, which is crucial for optimized blasting patterns and minimizing rework in large-scale projects, driving efficiency gains unprecedented in previous generations of equipment.

A crucial technological advancement is the widespread adoption of automation platforms. Semi-autonomous and fully autonomous drilling systems, particularly prevalent in the open-pit mining sector, allow a single operator to manage multiple rigs from a centralized, protected control room. These systems use sophisticated algorithms for automated drill planning, tramming between holes, and automated rod handling and changing, dramatically improving operational consistency and reducing safety risks associated with human interaction near heavy moving parts. Furthermore, drill rigs are increasingly equipped with advanced drilling tools, including high-performance drill bits, hammers, and specialized casing systems designed to improve drilling efficiency in highly fractured or heterogeneous rock formations. These tool enhancements, often manufactured from proprietary composite materials, extend tool life and reduce consumable costs, appealing directly to the end-users' focus on reducing total cost of ownership (TCO).

Sustainability-driven technology is also a major theme, particularly the development of electric and hybrid crawler drill rigs. Driven by stricter environmental regulations and corporate commitments to net-zero emissions, OEMs are investing heavily in battery technology and electric power trains that reduce or eliminate diesel consumption and associated emissions and noise pollution. Electric rigs are particularly attractive for underground mining operations and urban construction sites where air quality and noise constraints are paramount. Additionally, smart hydraulics and energy recovery systems are being integrated to optimize power distribution and minimize energy waste, ensuring that even conventional diesel-powered rigs are substantially more fuel-efficient than their predecessors, balancing the demand for high power with the imperative for environmental responsibility.

Regional Highlights

The regional dynamics of the Crawler Drill Rig Market reflect disparities in infrastructure maturity, regulatory environments, and the concentration of natural resources. The global market is highly decentralized, yet each major region exhibits unique demand characteristics and competitive landscapes. North America and Europe, characterized by mature, high-cost labor markets and strict environmental regulations, drive demand for high-end, automated, and energy-efficient crawler rigs. Replacement cycles in these regions are often faster, favoring rigs equipped with advanced telematics and remote diagnostics capabilities, often justifying the higher initial capital expenditure through superior operational efficiency and adherence to Tier 4 Final/Stage V emission standards.

Asia Pacific (APAC) stands out as the highest-growth region, commanding the largest market share globally, primarily fueled by massive infrastructure investment programs in countries such as China, India, and Indonesia. The sheer volume of demand for construction materials and mineral resources in APAC necessitates the widespread deployment of crawler drill rigs for quarrying, foundation work, and expanding mining operations. Price sensitivity remains a factor in this region, leading to strong competition between global OEMs and local manufacturers who offer cost-competitive, sometimes lower-specification, machinery. The rapid pace of urbanization and industrialization across Southeast Asia is expected to maintain this region's dominance throughout the forecast period, shifting the global manufacturing focus eastward.

Latin America (LATAM) and the Middle East and Africa (MEA) represent critical emerging markets driven primarily by resource extraction (copper, iron ore, and oil & gas infrastructure) and large-scale government construction megaprojects. LATAM's market growth is intimately linked to the highly volatile global metals market, driving demand for powerful rigs capable of handling the challenging geological conditions of the Andes mountains. The MEA region, particularly the GCC countries, sees significant demand related to foundation drilling for futuristic urban developments and deep-hole drilling for oil and gas infrastructure expansion. Challenges in these regions include the necessity for ruggedized equipment capable of operating in extreme heat and the demand for robust aftermarket support due to vast operational distances and logistical complexities.

- Asia Pacific (APAC): Dominant market share and highest growth rate; fueled by large-scale infrastructure projects (e.g., Belt and Road Initiative) and aggressive mining expansion in Australia and Southeast Asia. Key countries: China, India, Australia.

- North America: Strong focus on technology adoption, automation, and premium equipment for specialized civil engineering and complex mining (e.g., gold and copper). Demand driven by strict safety standards.

- Europe: Characterized by stringent environmental mandates (Stage V emissions); high adoption of electric and hybrid rigs, particularly for urban tunneling and foundational work. Market driven by modernization and fleet replacement.

- Latin America (LATAM): Growth tied heavily to commodity prices, especially copper and iron ore mining in Chile, Brazil, and Peru. Demand for robust, high-performance blast hole rigs.

- Middle East and Africa (MEA): Significant market potential due to massive foundational drilling requirements for megaprojects (e.g., Saudi Vision 2030) and burgeoning mining exploration in South and West Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Crawler Drill Rig Market, focusing on product portfolio, geographical reach, innovation pipeline, and strategic market positioning.- Sandvik

- Epiroc

- Atlas Copco

- Komatsu Ltd.

- Furukawa Co., Ltd.

- Caterpillar Inc.

- Junjin CSM

- Tamrock

- Sunward Equipment Group

- Liebherr Group

- SANY Group

- Drilltech

- Boart Longyear

- Schramm, Inc.

- China Railway Construction Heavy Industry Co., Ltd. (CRCHI)

- Doofor Oy

- Nanchang Kama

- Sinosteel

- Hindustan Engineering

- TEI Rock Drills

Frequently Asked Questions

Analyze common user questions about the Crawler Drill Rig market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary factors driving the demand for advanced hydraulic crawler drill rigs?

The primary drivers are escalating global infrastructure spending, particularly on tunneling and deep foundation projects, coupled with the mining sector’s necessity for high-precision, automated drilling to optimize blasting yields and comply with stricter safety regulations. Advanced hydraulic rigs offer superior power efficiency and accuracy, reducing operational costs per meter drilled.

How is the implementation of electric crawler drill rigs impacting the construction and mining sectors?

Electric crawler drill rigs are fundamentally impacting the industry by offering zero direct emissions and significantly reduced noise pollution, making them essential for underground mining and urban construction projects subject to stringent environmental and noise restrictions. This shift reduces reliance on diesel fuel, lowers maintenance requirements, and aligns with global corporate sustainability goals.

Which regional market holds the largest growth potential for crawler drill rig manufacturers?

The Asia Pacific (APAC) region, specifically emerging economies like India, Indonesia, and China, presents the highest growth potential. This is attributed to rapid urbanization, massive government investment in infrastructure (roads, railways, power), and sustained demand for mineral resources, driving the need for both large-capacity and highly efficient drilling equipment.

What role does telematics and IoT play in optimizing the efficiency of modern crawler drill rigs?

Telematics and IoT integration enable real-time remote monitoring of rig performance, geo-positioning, fuel consumption, and component health. This data is utilized for predictive maintenance scheduling, optimizing operational parameters based on geological feedback, and enhancing overall fleet management, significantly minimizing unplanned downtime and maximizing asset utilization.

What is the difference between DTH (Down-the-Hole) and Top Hammer drilling methods in crawler rigs?

DTH drilling utilizes a hammer mechanism located directly behind the drill bit, efficiently transferring maximum impact energy directly to the rock face, making it ideal for deep holes and hard rock formations. Top Hammer drilling uses a hammer located on the surface (outside the hole) which transmits impact energy down the drill string. Top Hammer is generally preferred for smaller diameter holes, quarrying, and applications requiring greater hole accuracy over medium depths.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager