Crotyl Chloride Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439227 | Date : Jan, 2026 | Pages : 243 | Region : Global | Publisher : MRU

Crotyl Chloride Market Size

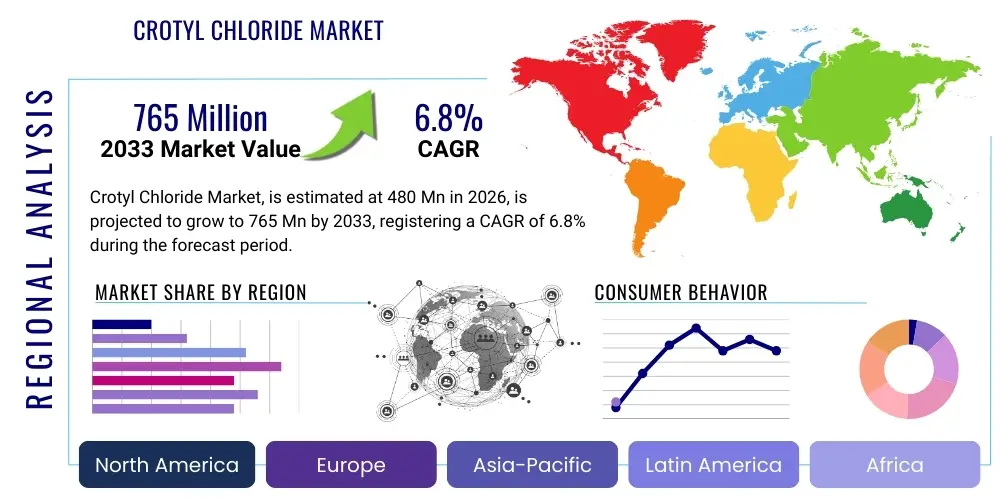

The Crotyl Chloride Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 480 million in 2026 and is projected to reach USD 765 million by the end of the forecast period in 2033.

Crotyl Chloride Market introduction

The Crotyl Chloride market is a specialized segment within the broader chemical industry, primarily driven by its indispensable role as a versatile intermediate in organic synthesis. Crotyl chloride, chemically known as 1-chlorobut-2-ene, is an unsaturated organochlorine compound widely utilized for introducing a crotyl group into various organic molecules. Its unique reactivity, stemming from the presence of both an allyl halide structure and a double bond, makes it a valuable building block for a diverse range of complex chemicals. This compound exists as cis and trans isomers, both of which find specific applications, though trans-crotyl chloride is often preferred due to its greater stability and ease of handling in industrial processes.

Major applications of Crotyl Chloride span across several critical sectors, most notably in the pharmaceutical, agrochemical, and specialty chemical industries. In pharmaceuticals, it serves as a key intermediate for synthesizing active pharmaceutical ingredients (APIs), including various drug molecules with specific therapeutic properties. The agrochemical sector leverages Crotyl Chloride for the production of herbicides, insecticides, and fungicides, contributing to improved crop protection and agricultural productivity. Beyond these, its utility extends to the synthesis of flavor and fragrance compounds, polymers, and other fine chemicals, where precise structural modification and reactivity are paramount. The benefits of using Crotyl Chloride include its efficiency in facilitating chemical reactions, its ability to form diverse derivatives, and its role in creating value-added products with enhanced functionalities.

The market is predominantly driven by the expanding demand for advanced pharmaceuticals, the continuous innovation in agrochemical formulations to address global food security challenges, and the sustained growth of the specialty chemicals industry. The increasing complexity of chemical synthesis required for novel materials and advanced drug discovery further fuels the adoption of Crotyl Chloride. Moreover, the robust research and development activities aimed at exploring new applications and optimizing existing synthetic routes are expected to provide significant impetus to market expansion. Manufacturers are continuously investing in process improvements to enhance purity, yield, and sustainability in Crotyl Chloride production, ensuring its continued relevance in a dynamic chemical landscape.

Crotyl Chloride Market Executive Summary

The Crotyl Chloride market is experiencing steady growth, propelled by the increasing demand from downstream industries such as pharmaceuticals, agrochemicals, and specialty chemicals. Business trends indicate a focus on process optimization, supply chain resilience, and the development of higher-purity grades to meet stringent regulatory requirements, particularly in the pharmaceutical sector. Key players are investing in R&D to explore novel synthetic routes and expand the application scope of Crotyl Chloride, aiming to capture emerging opportunities in new chemical entities and advanced materials. Consolidation and strategic partnerships among manufacturers and distributors are also observed, aimed at strengthening market presence and improving global supply capabilities. The market's stability is underpinned by its critical role as an essential chemical intermediate, making it less susceptible to short-term economic fluctuations compared to end-consumer markets.

Regional trends highlight Asia Pacific as the largest and fastest-growing market for Crotyl Chloride, driven by the rapid expansion of its chemical manufacturing base, increasing pharmaceutical production, and significant agricultural activities in countries like China and India. North America and Europe represent mature markets with a strong emphasis on high-purity applications, innovation, and adherence to strict environmental regulations, leading to demand for advanced manufacturing processes. Latin America and the Middle East & Africa are emerging markets, showing promising growth owing to increasing investments in industrialization, agricultural modernization, and the establishment of new pharmaceutical manufacturing facilities. Each region presents unique opportunities and challenges, influencing market dynamics and strategic priorities for global suppliers.

Segmentation trends reveal that the pharmaceutical segment commands a significant share, attributed to the ongoing research into new drug molecules and the increasing production of generics. The agrochemical segment is also a substantial contributor, driven by the need for effective crop protection solutions. In terms of purity, high-purity Crotyl Chloride is witnessing accelerated demand, especially for sensitive applications in life sciences and electronics, where impurities can compromise product integrity. The market is also segmented by isomer type, with trans-crotyl chloride often dominating due to its stability. Furthermore, end-use industry segmentation indicates a broad range of applications, from polymers and resins to flavors and fragrances, underscoring the compound's versatility and critical role across various industrial verticals. These segmentation insights guide manufacturers in tailoring their product offerings and market strategies effectively.

AI Impact Analysis on Crotyl Chloride Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Crotyl Chloride market primarily revolve around several key themes: how AI can optimize chemical synthesis processes, improve efficiency in manufacturing, enhance quality control, and accelerate discovery of new applications. Users are keen to understand if AI can reduce production costs, minimize waste, and predict market demand more accurately. Concerns often surface about the investment required for AI implementation, the availability of skilled personnel, and the ethical implications of autonomous systems in chemical production. There's an expectation that AI could revolutionize aspects of R&D and supply chain management, leading to more sustainable and responsive market operations. The overall sentiment suggests a strong interest in leveraging AI for competitive advantage, while also acknowledging potential challenges and the need for careful strategic integration.

The application of AI in the Crotyl Chloride market holds the potential to significantly transform various operational facets, from laboratory-scale research to large-scale industrial production. In the realm of chemical synthesis, AI-driven algorithms can analyze vast datasets of reaction parameters, catalysts, and reagents to predict optimal reaction conditions, thereby improving yields and reducing reaction times. This predictive capability can minimize the need for extensive empirical experimentation, accelerating the development of new synthetic routes for Crotyl Chloride and its derivatives. Furthermore, AI can assist in the design of novel molecules that incorporate the crotyl group, leading to the discovery of new applications in advanced materials or pharmaceuticals, broadening the market's addressable opportunities.

Beyond synthesis and discovery, AI's impact extends to enhancing operational efficiency and quality assurance within Crotyl Chloride manufacturing facilities. Predictive maintenance systems, powered by AI, can monitor equipment performance in real-time, anticipate potential failures, and schedule maintenance proactively, thereby reducing downtime and optimizing production throughput. AI-driven vision systems and sensors can provide continuous quality control, detecting impurities or deviations from specifications with higher accuracy and speed than traditional methods, ensuring a consistent high-purity product. Moreover, AI can optimize supply chain logistics by predicting demand fluctuations, managing inventory levels, and streamlining distribution networks, leading to reduced operational costs and improved market responsiveness for Crotyl Chloride producers. The integration of AI tools promises a future of more intelligent, efficient, and sustainable chemical manufacturing.

- AI-driven optimization of reaction parameters for enhanced Crotyl Chloride yield and selectivity.

- Predictive maintenance for manufacturing equipment, reducing downtime and operational costs.

- Advanced quality control through AI-powered sensors and analytics, ensuring product purity.

- Accelerated discovery of novel applications and derivatives through computational chemistry and AI.

- Optimized supply chain and logistics, improving inventory management and demand forecasting.

- Enhanced process safety through real-time monitoring and anomaly detection.

- Automation of routine laboratory tasks and data analysis in R&D.

DRO & Impact Forces Of Crotyl Chloride Market

The Crotyl Chloride market is influenced by a dynamic interplay of drivers, restraints, and opportunities, shaping its growth trajectory and competitive landscape. A primary driver is the escalating demand from the pharmaceutical industry, where Crotyl Chloride serves as a crucial intermediate for synthesizing various active pharmaceutical ingredients (APIs) and advanced drug candidates. The global increase in healthcare expenditure, coupled with the rising prevalence of chronic diseases and the continuous innovation in drug discovery, fuels a sustained need for specialized chemical building blocks like Crotyl Chloride. Similarly, the agrochemical sector's persistent demand for effective herbicides, insecticides, and fungicides to bolster food security and crop yield acts as another significant market driver. The versatility of Crotyl Chloride in forming a diverse range of chemical compounds positions it as an essential component in developing new and improved agrochemical formulations. Furthermore, the growth of the specialty chemicals industry, which relies on Crotyl Chloride for synthesizing polymers, fragrances, and other fine chemicals, further contributes to its market expansion. Technological advancements in synthesis methods, leading to improved purity and cost-effectiveness, also play a pivotal role in driving market adoption.

Despite these robust drivers, the Crotyl Chloride market faces several restraints that could impede its growth. Stringent environmental regulations and increasing public concern regarding hazardous chemicals pose significant challenges for manufacturers, leading to higher compliance costs and potential restrictions on production and waste disposal. The volatility of raw material prices, particularly for precursors like crotonaldehyde and hydrogen chloride, can impact production costs and subsequently affect the profitability of market players. Additionally, the availability of substitute chemicals or alternative synthetic routes, though often less efficient or more costly, could present a long-term restraint. The high capital investment required for establishing and maintaining manufacturing facilities that meet safety and environmental standards also acts as a barrier to entry for new players, limiting market competition and potentially slowing innovation. Furthermore, the handling and storage of Crotyl Chloride, due to its hazardous nature, necessitate specialized infrastructure and adherence to strict safety protocols, adding to operational complexities.

Opportunities within the Crotyl Chloride market are substantial and primarily lie in the continuous innovation and expansion of its application spectrum. The emergence of new drug development pipelines, especially in areas like oncology, immunology, and rare diseases, presents fresh avenues for Crotyl Chloride derivatives. Research into sustainable and green chemistry approaches for its production could unlock new market segments by addressing environmental concerns and reducing manufacturing footprints. The growing demand for high-performance polymers and advanced materials, where Crotyl Chloride can act as a crucial monomer or initiator, offers another significant opportunity. Moreover, increasing investments in agricultural research and development to create more targeted and environmentally friendly agrochemicals will continue to generate demand. The ongoing globalization of the chemical industry, coupled with the rising industrialization in developing economies, opens new geographical markets for Crotyl Chloride suppliers. Strategic collaborations between manufacturers and end-users to co-develop tailored solutions and explore novel applications will be key to capitalizing on these opportunities and ensuring sustained market growth.

Segmentation Analysis

The Crotyl Chloride market is meticulously segmented to provide a granular understanding of its diverse applications, product types, and end-user industries, offering valuable insights for market participants. This segmentation helps in identifying specific growth pockets, tailoring product offerings, and formulating targeted market strategies. The primary segmentation criteria typically include purity levels, isomer type, and crucially, end-use industry. Purity is a critical factor, especially for sensitive applications, driving the distinction between technical grade and high-purity variants. Isomer type differentiates between cis and trans forms, with trans-crotyl chloride often being more industrially relevant due to its stability. However, the most impactful segmentation is by end-use industry, reflecting the varied demand dynamics from pharmaceutical, agrochemical, and other specialty chemical sectors, each with unique requirements and growth drivers.

Analyzing the market through these segments reveals distinct trends. For instance, the demand for high-purity Crotyl Chloride is consistently rising from the pharmaceutical and advanced materials sectors, where even trace impurities can compromise product integrity and efficacy. This pushes manufacturers to invest in advanced purification technologies and stringent quality control measures. In terms of isomer type, while both cis and trans isomers have niche applications, trans-crotyl chloride generally holds a larger market share due to its greater stability and more favorable reaction kinetics in many industrial processes. However, specialized syntheses might specifically require the cis isomer for particular stereochemical outcomes, indicating a nuanced demand across applications. Understanding these nuances within each segment is crucial for companies to position their products effectively and cater to specific customer needs. The ongoing research into new synthesis methods also impacts segment dynamics, potentially leading to more cost-effective production of specific isomers or higher purity grades, thereby influencing market share and competitive advantage.

The end-use industry segmentation provides the most comprehensive view of market consumption patterns. The pharmaceutical industry remains a dominant consumer, driven by the increasing global demand for new drug molecules and generic pharmaceutical production. Crotyl Chloride's role as a versatile building block for various Active Pharmaceutical Ingredients (APIs) ensures its continued relevance in this sector. Similarly, the agrochemical industry represents another substantial end-user, utilizing Crotyl Chloride in the synthesis of a wide array of pesticides, herbicides, and fungicides essential for modern agriculture. The specialty chemicals sector, encompassing applications in flavors and fragrances, polymers, and other fine chemicals, also contributes significantly to market demand. These diverse applications underscore Crotyl Chloride's fundamental importance as a chemical intermediate, with market growth closely tied to the expansion and innovation within these key industries. As these industries evolve, so too will the specific requirements and demand patterns for Crotyl Chloride, necessitating continuous market monitoring and adaptation.

- By Purity

- Technical Grade

- High Purity Grade

- By Isomer Type

- Cis-Crotyl Chloride

- Trans-Crotyl Chloride

- Mixed Isomers

- By Application

- Pharmaceutical Intermediates

- Agrochemical Intermediates

- Flavor and Fragrance Synthesis

- Polymer and Resin Modifiers

- Specialty Chemical Synthesis

- Others

- By End-Use Industry

- Pharmaceuticals

- Agrochemicals

- Chemical Manufacturing

- Cosmetics & Personal Care

- Food & Beverages (Flavor Industry)

- Research & Development

- Others

Value Chain Analysis For Crotyl Chloride Market

The value chain for the Crotyl Chloride market encompasses a series of interconnected stages, beginning from the procurement of raw materials and extending through manufacturing, distribution, and ultimately to the end-use industries. At the upstream analysis stage, the primary raw materials involved in the synthesis of Crotyl Chloride typically include crotonaldehyde, which serves as the fundamental organic precursor, and hydrogen chloride (HCl) or other chlorinating agents. Suppliers of these raw materials play a critical role, and their pricing, quality, and supply consistency directly impact the production costs and operational stability of Crotyl Chloride manufacturers. Access to reliable and cost-effective sources for these basic chemicals is a key factor in maintaining competitive advantage, highlighting the importance of robust supplier relationships and strategic sourcing. Fluctuations in the global prices of these commodities can ripple throughout the entire value chain, affecting profitability margins at subsequent stages.

Moving downstream, the manufacturing process transforms these raw materials into Crotyl Chloride through various chemical reactions, often involving catalysts and specific reaction conditions to achieve desired purity and isomer ratios. This stage is capital-intensive and requires specialized chemical engineering expertise, stringent safety protocols, and adherence to environmental regulations. Post-synthesis, further processing steps like purification, distillation, and quality control are essential to produce different grades of Crotyl Chloride, such as technical grade and high-purity grade, each catering to specific application requirements. The efficiency and technological sophistication of the manufacturing facilities directly influence product quality, production costs, and market competitiveness. Innovation in process technology, such as developing greener synthesis methods or more efficient separation techniques, can lead to significant improvements in the value chain by reducing waste and enhancing sustainability.

The distribution channel plays a crucial role in connecting manufacturers with end-users. This typically involves a combination of direct and indirect distribution strategies. Direct sales are often utilized for large-volume customers or those with specialized requirements, allowing manufacturers to maintain closer relationships and offer tailored technical support. Indirect distribution involves a network of distributors, wholesalers, and chemical suppliers who manage inventory, logistics, and sales to a broader base of smaller and medium-sized customers across various regions. These intermediaries provide essential services such as warehousing, transportation, and regulatory compliance assistance, especially for hazardous chemicals like Crotyl Chloride. The effectiveness of the distribution network is paramount for timely delivery, minimizing supply chain disruptions, and ensuring market accessibility. A well-optimized distribution channel can significantly enhance market reach and customer satisfaction, contributing to the overall success of Crotyl Chloride producers in a globally competitive environment.

Crotyl Chloride Market Potential Customers

The potential customers for Crotyl Chloride are predominantly within the industrial chemical sector, spanning across various end-use industries that require it as a crucial chemical intermediate or building block. The largest segment of end-users are pharmaceutical companies, ranging from multinational corporations involved in drug discovery and development to generic drug manufacturers. These companies utilize Crotyl Chloride for the synthesis of Active Pharmaceutical Ingredients (APIs), including anti-cancer drugs, anti-inflammatory agents, and central nervous system medications, where the crotyl group is essential for the molecule's efficacy or structural integrity. As the pharmaceutical industry continues its quest for new therapeutic compounds and more efficient production methods, the demand for high-purity Crotyl Chloride remains robust and is expected to grow further, driven by global healthcare needs and an aging population.

Another significant customer base resides within the agrochemical industry, encompassing manufacturers of pesticides, herbicides, and fungicides. Companies specializing in crop protection products depend on Crotyl Chloride to synthesize active ingredients that enhance agricultural productivity and protect crops from pests and diseases. With the global population increasing and demand for food security rising, the agrochemical sector is under continuous pressure to develop more effective and environmentally friendly solutions, which often necessitates the use of versatile intermediates like Crotyl Chloride. These customers are typically large-scale chemical producers who integrate Crotyl Chloride into their complex multi-step synthesis pathways, prioritizing consistent quality, reliable supply, and competitive pricing from their suppliers.

Beyond pharmaceuticals and agrochemicals, the specialty chemicals industry represents a broad and diverse group of potential customers. This includes manufacturers of flavors and fragrances, who use Crotyl Chloride to create specific aromatic compounds for the food and beverage, cosmetic, and personal care industries. Polymer and resin manufacturers also represent potential customers, as Crotyl Chloride can be used as a monomer or modifier to impart unique properties to various polymer structures. Additionally, research and development institutions, universities, and fine chemical companies engaged in custom synthesis for various industrial applications also procure Crotyl Chloride in smaller quantities for their specific projects. These diverse customer segments underscore the wide-ranging utility of Crotyl Chloride as a fundamental chemical building block, making its market dynamics intertwined with the growth and innovation across multiple industrial verticals.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 480 Million |

| Market Forecast in 2033 | USD 765 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Merck KGaA, TCI Chemicals (India) Pvt. Ltd., Tokyo Chemical Industry Co., Ltd. (TCI), Santa Cruz Biotechnology, Inc., Parchem fine & specialty chemicals, Chem-Impex International Inc., Penta Manufacturing Company, Inc., Angene International Limited, Alfa Aesar (Thermo Fisher Scientific), AK Scientific, Inc., Acros Organics (Thermo Fisher Scientific), LGC Standards, Sisco Research Laboratories Pvt. Ltd., Clearsynth Labs Limited, Haihang Industry Co., Ltd., Zibo Hailan Chemical Co., Ltd., J&K Scientific, Inc., Apollo Scientific Ltd., VWR International, LLC (Avantor), Combi-Blocks, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Crotyl Chloride Market Key Technology Landscape

The key technology landscape for the Crotyl Chloride market is characterized by a continuous evolution of synthesis methods, purification techniques, and process optimization strategies aimed at improving efficiency, purity, and sustainability. Traditionally, Crotyl Chloride is synthesized through the chlorination of crotonaldehyde or related precursors, often employing specific chlorinating agents like thionyl chloride or phosphorus trichloride, followed by isomerization and purification steps. Recent technological advancements focus on refining these processes to achieve higher yields, better selectivity towards desired isomers (cis or trans), and reduced formation of undesirable byproducts. This involves the development of novel catalytic systems that can facilitate reactions under milder conditions, thereby enhancing safety and reducing energy consumption. Continuous flow chemistry, for instance, is gaining traction as a promising technology that allows for better control over reaction parameters, leading to more consistent product quality and higher throughput compared to traditional batch processes.

Furthermore, the demand for high-purity Crotyl Chloride, particularly from the pharmaceutical and advanced materials sectors, drives innovation in purification technologies. Techniques such as advanced distillation, preparative chromatography, and solvent extraction are continuously being optimized to achieve ultra-high purity grades with minimal impurities. These sophisticated purification processes are critical for ensuring that Crotyl Chloride meets the stringent quality requirements for sensitive applications, where even trace contaminants can affect the performance or safety of the final product. Research into membrane-based separation techniques and crystallization processes is also exploring new avenues to enhance purification efficiency and reduce the environmental footprint associated with traditional methods. The ability to produce specific cis or trans isomers with high purity is another technological focus, as the stereochemistry of Crotyl Chloride can significantly impact its reactivity and the properties of its derivatives in various synthesis pathways.

Beyond synthesis and purification, the technological landscape also encompasses advancements in process analytical technology (PAT) and automation. PAT tools, including in-line and at-line spectroscopic techniques (e.g., FTIR, Raman spectroscopy), provide real-time monitoring of reaction progress, intermediate formation, and product quality. This enables manufacturers to make immediate adjustments to process parameters, thereby ensuring consistency, reducing batch rejection rates, and optimizing resource utilization. Automation and advanced control systems are being integrated into manufacturing facilities to minimize human intervention, enhance safety, and improve overall operational efficiency. The adoption of digital twin technology and artificial intelligence (AI) for process modeling and optimization is also emerging, allowing for predictive analytics and more intelligent decision-making throughout the production lifecycle of Crotyl Chloride. These technological advancements collectively contribute to a more efficient, sustainable, and responsive Crotyl Chloride market, supporting its critical role in various downstream industries.

Regional Highlights

- North America: A mature market characterized by a strong pharmaceutical industry and robust R&D activities. Demand for high-purity Crotyl Chloride is significant, driven by stringent regulatory standards and innovation in drug discovery and specialty chemicals. Companies here focus on high-value applications and advanced manufacturing processes.

- Europe: Similar to North America, Europe is a key market for high-grade Crotyl Chloride, with a well-established chemical and pharmaceutical industry. Strict environmental regulations propel research into sustainable production methods and green chemistry applications. Germany, Switzerland, and the UK are prominent contributors to market demand.

- Asia Pacific (APAC): The largest and fastest-growing market, propelled by rapid industrialization, expanding chemical manufacturing bases, and significant growth in the pharmaceutical and agrochemical sectors, particularly in China and India. Lower production costs and increasing domestic demand contribute to its dominance.

- Latin America: An emerging market exhibiting promising growth due to increasing investments in industrial development, agricultural expansion, and a burgeoning pharmaceutical sector. Brazil and Mexico are key countries, focusing on both domestic production and import of Crotyl Chloride for their growing industries.

- Middle East and Africa (MEA): This region is an emerging market with gradual growth, driven by increasing industrialization, diversification efforts in national economies, and developing healthcare infrastructure. Investments in chemical production capabilities and a growing need for agrochemicals in agricultural economies are contributing factors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Crotyl Chloride Market.- Merck KGaA

- TCI Chemicals (India) Pvt. Ltd.

- Tokyo Chemical Industry Co., Ltd. (TCI)

- Santa Cruz Biotechnology, Inc.

- Parchem fine & specialty chemicals

- Chem-Impex International Inc.

- Penta Manufacturing Company, Inc.

- Angene International Limited

- Alfa Aesar (Thermo Fisher Scientific)

- AK Scientific, Inc.

- Acros Organics (Thermo Fisher Scientific)

- LGC Standards

- Sisco Research Laboratories Pvt. Ltd.

- Clearsynth Labs Limited

- Haihang Industry Co., Ltd.

- Zibo Hailan Chemical Co., Ltd.

- J&K Scientific, Inc.

- Apollo Scientific Ltd.

- VWR International, LLC (Avantor)

- Combi-Blocks, Inc.

Frequently Asked Questions

Analyze common user questions about the Crotyl Chloride market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Crotyl Chloride primarily used for?

Crotyl Chloride is primarily used as a versatile chemical intermediate in organic synthesis, most notably in the pharmaceutical industry for Active Pharmaceutical Ingredient (API) synthesis, and in the agrochemical sector for producing herbicides, insecticides, and fungicides. It also finds applications in specialty chemicals, flavors, and fragrances.

What are the key drivers of the Crotyl Chloride market growth?

The market growth is majorly driven by the increasing demand from the pharmaceutical industry for new drug development, the expanding agrochemical sector needing effective crop protection, and the continuous growth of the specialty chemicals industry, all relying on Crotyl Chloride as a critical building block.

Which regions are leading in Crotyl Chloride consumption?

Asia Pacific, particularly China and India, currently dominates the Crotyl Chloride market due to rapid industrialization and significant growth in chemical, pharmaceutical, and agrochemical manufacturing. North America and Europe also represent mature markets with high demand for specialty applications.

What are the main challenges facing the Crotyl Chloride market?

Key challenges include stringent environmental regulations concerning hazardous chemicals, volatility in raw material prices impacting production costs, and the availability of alternative chemicals or synthesis routes, which can restrain market expansion and increase operational complexities.

How does Crotyl Chloride's purity affect its market value?

Purity is a critical factor, especially for applications in pharmaceuticals and advanced materials. High-purity Crotyl Chloride commands a premium price due to the rigorous purification processes required and its indispensable role in sensitive syntheses where even trace impurities can compromise product quality and efficacy.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager