Cryogenic Personal Protect Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439122 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Cryogenic Personal Protect Equipment Market Size

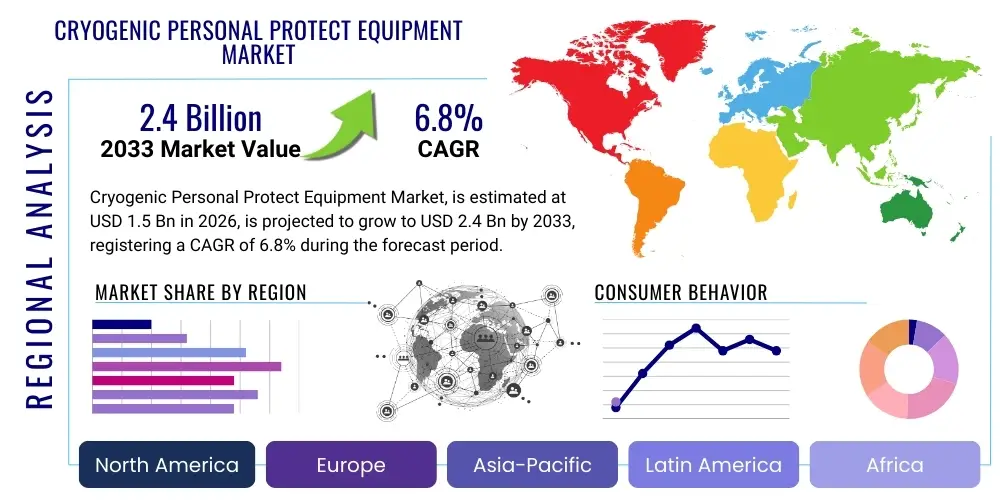

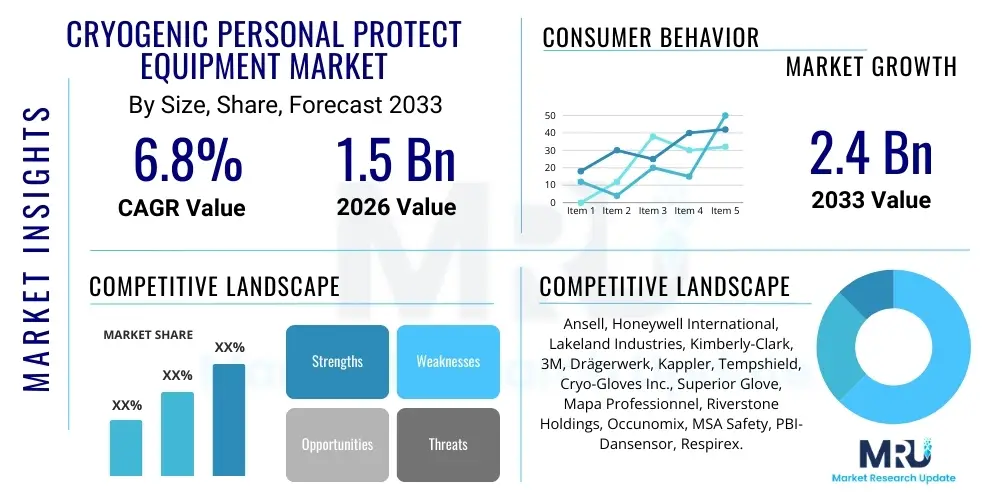

The Cryogenic Personal Protect Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.4 Billion by the end of the forecast period in 2033.

Cryogenic Personal Protect Equipment Market introduction

The Cryogenic Personal Protect Equipment (PPE) Market encompasses specialized gear and garments designed to safeguard personnel working with extreme cold materials, typically below -150°C, such as liquid nitrogen (LN2), liquid helium, liquid oxygen, and other ultra-low temperature gases. This protective equipment is engineered using advanced insulation technologies and materials that prevent thermal transfer, skin burns, and tissue damage caused by direct contact or exposure to cryogenic liquids and vapors. The fundamental product description includes insulated gloves, aprons, face shields, suits, and footwear, all rigorously tested to meet global safety standards, particularly focusing on preventing splash injuries and sustained contact risk in highly volatile environments.

Major applications of cryogenic PPE span critical industrial and scientific sectors where superconductivity, materials preservation, and high-tech manufacturing processes are common. Key end-use sectors include healthcare and biotechnology, where cryogenic storage is essential for preserving biological samples, vaccines, and cell therapies. Additionally, the industrial gas industry, aerospace research (dealing with cryogenic fuels), and specialized chemical processing facilities are significant consumers. The inherent benefits of utilizing certified cryogenic PPE include regulatory compliance, significant reduction in workplace thermal injuries, enhanced worker confidence, and maintenance of operational continuity in hazardous cold environments, thereby promoting a safer working atmosphere across various high-risk industries.

The primary driving factors propelling the expansion of this market are stringent occupational safety regulations globally, particularly those mandated by bodies like OSHA and the European Agency for Safety and Health at Work (EU-OSHA), which require employers to furnish appropriate protection against temperature extremes. Furthermore, the rapid growth of the biopharmaceutical sector, necessitating large-scale cryogenic sample storage for drug discovery and cell therapy manufacturing, significantly contributes to demand. Technological advancements in lightweight, high-performance insulating materials, offering increased dexterity and comfort without compromising safety, are also critical determinants fostering market growth and broader adoption rates across emerging industrial applications.

Cryogenic Personal Protect Equipment Market Executive Summary

The Cryogenic Personal Protect Equipment Market is characterized by stable demand driven fundamentally by increasing safety awareness and the escalating requirements of the biotechnology and industrial gas sectors. Current business trends indicate a strong move toward integrating smart technologies, such as temperature sensors and monitoring capabilities, into traditional PPE designs to offer real-time risk assessment and proactive safety alerts. Key manufacturers are focusing heavily on material science innovations, particularly developing multi-layered, highly flexible composites that offer superior thermal protection alongside improved ergonomic factors. Mergers and acquisitions remain pivotal strategies for market players aiming to consolidate regional presence and acquire specialized technology portfolios, leading to moderate consolidation and fierce competition in product differentiation and compliance adherence.

Regionally, North America maintains market dominance due to its robust healthcare infrastructure, expansive aerospace industry, and stringent regulatory frameworks mandating the use of specialized PPE in cold chain logistics and research. Asia Pacific is projected to exhibit the fastest growth, primarily fueled by the rapid industrialization of nations like China and India, coupled with massive investments in domestic bioprocessing and industrial gas production facilities. European countries demonstrate mature market conditions, where demand is stable and innovation is often centered around achieving sustainability goals alongside high safety standards, particularly within the advanced manufacturing and energy sectors requiring specialized cryogenic handling protocols.

Segment trends reveal that the Gloves segment continues to dominate the market share, given that hands are the most frequently exposed body part during cryogenic material handling, driving consistent innovation in dexterity and insulation features. The Material segment is shifting towards high-performance composite fabrics over traditional leather, offering lighter weight and better vapor permeability, essential for prolonged use. In terms of end-use, the Healthcare and Biopharma segment is registering the highest growth rate, directly correlated with the global expansion of regenerative medicine, biobanking, and large-scale vaccine cold storage requirements. This sector requires ultra-high purity materials and verifiable certification, driving premium pricing and specialized product development within the cryogenic PPE supply chain.

AI Impact Analysis on Cryogenic Personal Protect Equipment Market

User questions related to AI's impact on Cryogenic PPE frequently revolve around how AI can enhance safety prediction, optimize equipment use, and revolutionize manufacturing processes. Users are concerned about whether AI-driven maintenance scheduling can extend the lifespan of high-cost PPE and how machine learning algorithms might interpret data from integrated smart sensors to prevent accidents before they occur. There is strong user expectation regarding AI’s role in material science R&D, specifically in accelerating the discovery and testing of novel, lightweight, and superior insulating materials. Furthermore, users question the implementation complexity and cost of AI integration into existing cold chain safety protocols and the subsequent need for specialized training to manage these advanced, data-driven protective systems, highlighting a desire for predictive safety mechanisms rather than reactive measures in ultra-low temperature environments.

- AI algorithms can be used in predictive maintenance models to determine optimal replacement schedules for high-cost cryogenic suits and gloves based on usage patterns and sensor data, extending equipment lifespan and ensuring peak protection efficacy.

- Integration of Machine Learning (ML) with sensor technology embedded in PPE allows for real-time monitoring of thermal exposure and structural integrity, providing immediate alerts to both the wearer and safety supervisors regarding potential material failure or dangerous thermal conditions.

- AI-driven simulation and material science optimization accelerate the development of next-generation composite fabrics, reducing the time required to test new insulating layers against extreme cold and thermal shock hazards.

- Computer vision systems powered by AI can monitor compliance on factory floors and research labs, automatically identifying instances where personnel are handling cryogenic liquids without correctly wearing mandated PPE, thus significantly reducing human error risks.

- AI enhances training simulations and virtual reality environments, allowing workers to practice complex cryogenic handling procedures in a risk-free digital space, optimizing reaction times and adherence to safety protocols when using specialized equipment.

- Data analytics generated by AI systems provide deep insights into accident patterns, allowing companies to refine standard operating procedures (SOPs) and customize PPE requirements based on specific workplace hazards and historical incident data, optimizing inventory management and safety investment.

DRO & Impact Forces Of Cryogenic Personal Protect Equipment Market

The Cryogenic PPE market dynamics are strongly influenced by stringent regulatory compliance (Driver) in industries handling hazardous substances, offset by high material and manufacturing costs (Restraint) associated with specialized insulation technologies. Opportunities emerge from the burgeoning fields of regenerative medicine and cryo-electron microscopy, demanding specialized, high-dexterity equipment. The core impact forces driving market acceptance include the imperative to mitigate catastrophic thermal injuries, the constant threat of regulatory penalties for non-compliance, and the increasing global investment in cold chain logistics, particularly for sensitive biological products. These forces collectively mandate the adoption of certified and high-quality protective solutions across all relevant sectors.

Key drivers include the global expansion of Liquid Natural Gas (LNG) infrastructure and the industrial gases sector, requiring robust PPE for handling large volumes of liquefied gases under extreme pressure and temperature. The escalating focus on occupational health and safety standards worldwide, particularly in developed economies, acts as a primary catalyst, compelling end-users to upgrade existing protective gear inventories. Furthermore, the increasing complexity of scientific research, especially in physics and materials science requiring ultra-low temperatures, necessitates innovative and custom-designed cryogenic protective solutions that offer superior protection without inhibiting detailed manipulation tasks.

Restraints primarily encompass the significant initial investment required for specialized cryogenic PPE, which can pose a barrier to adoption for smaller research facilities or industrial operations with limited budgets. Challenges related to comfort and ergonomics, particularly the inherent bulkiness and reduced dexterity associated with highly insulated gloves and suits, can lead to worker non-compliance or reduced operational efficiency. Moreover, the lack of standardized global testing protocols for all types of cryogenic exposure (vapor vs. liquid splash) across different temperature ranges complicates product certification and comparison, creating confusion in procurement decisions. Opportunities are abundant in developing cost-effective, multi-use, and modular PPE systems that can adapt to various operational temperatures and hazard levels. The rapid digitalization of supply chains also presents an opportunity to improve the distribution and customization of specialized protective equipment globally, addressing niche market requirements efficiently.

Segmentation Analysis

The Cryogenic Personal Protect Equipment market is highly segmented based on the type of protective gear required, the materials used for insulation, and the specific end-use industry utilizing the equipment. Understanding these segments is crucial for manufacturers to tailor their R&D efforts and marketing strategies, focusing on meeting the precise regulatory and functional demands of specialized applications, such as high-dexterity handling in cleanroom environments versus heavy-duty industrial maintenance tasks. The segmentation reflects the varying degrees of protection and ergonomic attributes necessary when handling extremely low-temperature substances, ensuring targeted product development remains aligned with diverse user needs across the cold chain logistics and scientific research spectrum.

The segmentation structure highlights the critical need for differentiation, particularly between components like gloves, which offer immediate and necessary protection for the hands—the most commonly exposed area—and full-body suits, required for environments with a high risk of catastrophic liquid splash or prolonged exposure, such as bulk liquid transfer operations. Material segmentation, covering composites, specialized leather, and proprietary synthetic fabrics, dictates the equipment's thermal performance, flexibility, and cost. This granular approach allows the market to effectively serve complex industries ranging from high-purity pharmaceutical manufacturing to robust oil and gas operations, each having unique safety requirements and environmental constraints that influence purchasing decisions regarding cryogenic protective gear.

- By Type:

- Gloves and Mitts

- Aprons and Body Protection

- Face Shields and Eye Protection

- Footwear (Boots)

- Headgear and Helmets

- Full Cryogenic Suits

- By Material:

- Advanced Composite Fabrics (e.g., Waterproof Insulated Nylon/Polyolefin blends)

- Specialized Cryo-Leather

- Gore-Tex and Proprietary Membrane Materials

- Fiberglass Insulation

- By End-Use Industry:

- Healthcare and Biopharma (Biobanking, IVF, Cell Therapy)

- Energy and Chemical (LNG, Industrial Gas Production, Refineries)

- Food and Beverage (Cryogenic Freezing and Preservation)

- Aerospace and Defense

- Research and Development (R&D Labs, University Research)

- Electronics and Manufacturing

Value Chain Analysis For Cryogenic Personal Protect Equipment Market

The value chain for Cryogenic Personal Protect Equipment begins with the upstream suppliers responsible for sourcing and refining specialized raw materials, primarily high-performance insulating fibers, proprietary composite fabrics, and specialized synthetic polymers engineered for extreme cold resistance. These materials require specialized chemical treatment to maintain flexibility and integrity at temperatures below -150°C. Key upstream activities involve intensive R&D to develop lightweight materials that adhere to stringent thermal performance standards while ensuring non-toxicity and durability. Manufacturers then process these specialized inputs, focusing on multi-layer construction, ergonomic design, and integrating protective features such as quick-release mechanisms and vapor barriers, all under strict quality control processes to achieve necessary certifications like CE or ANSI standards.

Midstream activities involve the primary manufacturing processes, including cutting, stitching, and assembly of the various PPE components (gloves, suits, aprons). Quality assurance and rigorous testing, especially hydrostatic testing for waterproof integrity and thermal mapping, are crucial at this stage. Distribution channels form the link between manufacturers and end-users, predominantly relying on indirect distribution through specialized industrial safety distributors and medical supply resellers who possess the technical knowledge to advise on correct product selection and usage. Direct sales are often utilized for large government or industrial contracts involving custom-designed, high-volume orders, ensuring streamlined communication regarding specifications and adherence to complex procurement regulations.

The downstream segment involves the end-use industries, including healthcare facilities, industrial gas producers, and research laboratories. End-users’ procurement decisions are heavily influenced by product lifespan, compliance documentation, and post-sales service, including training on proper donning, doffing, and decontamination procedures. Effective customer relationship management and technical support are vital for retaining customers, as improper use or maintenance can severely compromise the protective capabilities of the equipment. The lifecycle ends with disposal or recycling, where specialized synthetic materials require specific environmental handling protocols, completing the comprehensive value chain from raw material sourcing to end-of-life management.

Cryogenic Personal Protect Equipment Market Potential Customers

Potential customers for Cryogenic Personal Protect Equipment represent a diverse group of industries united by the necessity of handling, storing, or transporting ultra-low temperature media, primarily liquid nitrogen, LNG, and other noble gases. The primary buyers fall into sectors where human intervention is required in proximity to cryogenic systems, encompassing laboratory technicians, biobank managers, industrial maintenance crews, aerospace engineers, and specialized logistics personnel involved in the cold chain. These end-users prioritize verifiable safety credentials, ease of movement (dexterity), and long-term durability when making purchasing decisions, often requiring bulk orders of replaceable items such as gloves and aprons, alongside longer-lifecycle purchases like full suits and specialized boots for higher-risk operations.

Within the highly specialized Healthcare and Biopharma segment, the main purchasers are biobanking facilities, fertility clinics, research institutions conducting cell and gene therapy trials, and large pharmaceutical companies managing vaccine cold storage. These customers demand non-shedding, cleanroom-compatible PPE that offers maximum protection against extreme temperature exposure while maintaining low particle contamination levels necessary for sterile environments. Conversely, in the Energy and Industrial Gas sector (e.g., LNG production and transport), the buyers are typically large utilities and chemical plant operators who require heavy-duty, robust equipment capable of withstanding industrial wear and potential high-pressure liquid splashes, prioritizing ruggedness and certified resistance to hydrocarbon exposure alongside thermal protection.

The sustained demand from the scientific community, particularly high-energy physics labs and university research centers, also positions them as crucial potential customers. These buyers often require custom-sized gloves and face shields for intricate manipulation tasks involving superconducting magnets or complex cryogenic cooling loops. Their purchase cycles are frequently tied to research grant cycles or large capital expenditure projects. Overall, the common thread among all potential customers is the non-negotiable requirement for compliance with specific regional and international safety standards, making product certification and proven performance history critical factors in securing procurement contracts across the global market landscape.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.4 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ansell, Honeywell International, Lakeland Industries, Kimberly-Clark, 3M, Drägerwerk, Kappler, Tempshield, Cryo-Gloves Inc., Superior Glove, Mapa Professionnel, Riverstone Holdings, Occunomix, MSA Safety, PBI-Dansensor, Respirex. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cryogenic Personal Protect Equipment Market Key Technology Landscape

The technology landscape in the Cryogenic Personal Protect Equipment market is rapidly evolving, driven by the need for enhanced thermal performance combined with improved user comfort and dexterity. A critical technology involves the use of multi-layered composite materials, specifically engineered to create a combination of insulating layers (often proprietary synthetic fibers or aerogels) and a highly effective vapor barrier layer. This construction is essential because it not only provides protection against direct liquid contact but, more importantly, shields against the rapid cooling effect of cryogenic vapors, which can cause severe burns. The technological innovation focuses on minimizing the thickness of these layers without compromising the thermal protection value (TpV), aiming to increase the tactile sensitivity and flexibility of products like gloves, which are crucial for precise laboratory work.

Another significant technological advancement is the integration of high-tech textile manufacturing processes, such as seamless knitting technology, which reduces potential failure points inherent in traditional stitched seams, especially important in creating a robust vapor seal. Manufacturers are also increasingly adopting Phase Change Materials (PCMs) in localized areas of the PPE, which are non-cryogenic but assist in managing body temperature and reducing the risk of heat stress, a common issue when personnel wear heavily insulated, non-breathable garments for extended periods. This combination of superior insulation against external cold and internal thermal regulation represents a crucial technological refinement aimed at boosting worker endurance and compliance in challenging cryogenic environments.

Furthermore, the market is beginning to witness the deployment of smart PPE technologies, incorporating flexible micro-sensors and RFID tags into gloves and suits. These technologies allow for continuous environmental monitoring, tracking the internal temperature, moisture levels, and potentially alerting the user or supervisor if the material integrity is compromised due to over-exposure or damage. While still nascent, this smart integration leverages IoT principles to move safety protocols from passive protection to active, data-driven risk management. This technological push is particularly relevant for high-value applications in nuclear physics and aerospace, where early detection of equipment failure can prevent catastrophic safety incidents and protect multi-million dollar assets, solidifying technology as a key differentiator in high-specification PPE procurement.

Regional Highlights

- North America: North America holds the largest market share in the Cryogenic PPE market, primarily due to the established and highly regulated industrial landscape, particularly in the United States and Canada. The region benefits from substantial investments in pharmaceutical R&D, advanced manufacturing, and a mature aerospace sector that consistently uses cryogenic propellants and cooling systems. Regulatory bodies such as OSHA enforce strict standards regarding workplace safety, driving mandatory adoption and replacement cycles for certified protective gear. The prevalence of leading biotechnology companies and expansive biobanking facilities, critical for gene therapy and personalized medicine, ensures sustained, high-value demand for premium, specialized cryogenic gloves and suits.

- Europe: Europe represents a mature market characterized by stringent EU safety directives (e.g., European Norms, EN standards) governing PPE used in ultra-cold environments. Key market drivers include the region's strong industrial gas production capacity and significant activity in advanced materials research and particle physics (such as CERN). Germany, France, and the UK are major contributors, demonstrating stable demand driven by mandatory compliance and a strong emphasis on ergonomic and sustainable PPE solutions. The market exhibits slow but consistent growth, focusing on technological upgrades and materials science innovation to comply with evolving environmental and safety mandates concerning chemical resistance alongside thermal performance.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market globally, fueled by rapid industrialization, burgeoning pharmaceutical manufacturing capabilities, and massive infrastructure development in energy (LNG terminals and cold chain expansion). Countries like China, India, Japan, and South Korea are heavily investing in large-scale biobanks and domestic industrial gas production, creating vast new opportunities for cryogenic PPE suppliers. The challenge in APAC remains balancing the rapid adoption of international safety standards with cost-effectiveness, leading to robust demand for mid-range, yet certified, protective equipment required across rapidly expanding industrial centers and growing healthcare sectors.

- Latin America (LATAM): The LATAM market is characterized by moderate growth, primarily centered around industrial gas distribution, limited aerospace activities, and nascent biopharma sectors in countries like Brazil and Mexico. Market growth is often volatile and highly dependent on commodity prices and foreign direct investment into industrial projects. Demand drivers include the increasing regulation of the chemical and oil and gas industries, pushing for adherence to basic international safety standards. The market focuses largely on essential items such as gloves and basic aprons, with less adoption of high-end specialized suits compared to North America or Europe.

- Middle East and Africa (MEA): The MEA region's demand is heavily concentrated in the Middle Eastern oil and gas sector, particularly related to the handling and storage of LNG and industrial gases required for chemical processing. Market expansion is correlated with large-scale energy infrastructure projects. The demand in Africa is predominantly localized in South Africa and specific North African industrial hubs. Regulatory compliance is often complex and varies widely by country, but large international operators typically enforce high global standards, driving procurement of high-quality cryogenic PPE for major industrial operations and expatriate-led projects, prioritizing resilience in demanding climatic conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cryogenic Personal Protect Equipment Market.- Ansell

- Honeywell International Inc.

- Lakeland Industries Inc.

- Kimberly-Clark Corporation

- 3M Company

- Drägerwerk AG & Co. KGaA

- Kappler, Inc.

- Tempshield, Inc.

- Cryo-Gloves Inc.

- Superior Glove Works Ltd.

- Mapa Professionnel (A subsidiary of Newell Brands)

- Riverstone Holdings LLC (Owner of various PPE brands)

- Occunomix International LLC

- MSA Safety Incorporated

- PBI-Dansensor A/S

- Respirex International Limited

- Tingley Rubber Corporation

- PIP Global Holdings (Protective Industrial Products)

- Showa Group

- VWR International (Part of Avantor)

Frequently Asked Questions

Analyze common user questions about the Cryogenic Personal Protect Equipment market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of cryogenic PPE and what are the key materials used?

The primary function of cryogenic Personal Protect Equipment is to shield users from thermal burns and tissue damage caused by exposure to ultra-low temperature liquids or vapors (typically below -150°C), such as liquid nitrogen. Key materials used include specialized multi-layered composite fabrics, high-performance waterproof insulation like polyolefin blends, and durable leather designed to prevent thermal conduction and liquid splash penetration.

Which end-use industry drives the highest demand for cryogenic PPE?

The Healthcare and Biopharma industry currently drives the highest growth and specialized demand for cryogenic PPE. This is due to the exponential growth in biobanking, cell and gene therapy research, and large-scale vaccine cold chain logistics, which necessitate rigorous safety protocols for handling vast quantities of biological samples stored in liquid nitrogen.

What are the main regulatory standards governing the certification of cryogenic gloves?

The main regulatory standards governing cryogenic PPE certification include the European Norms (EN 511 for protection against cold) and ANSI/ISEA standards in North America. These standards dictate specific testing requirements for contact cold, convective cold, and most critically, resistance to liquid penetration and thermal insulation performance under extreme low-temperature conditions.

How does AI impact the future development of cryogenic protective gear?

AI impacts the future development by enhancing predictive maintenance, optimizing material composition through machine learning simulations to improve thermal efficiency and flexibility, and integrating smart sensors into PPE for real-time monitoring of thermal stress and potential equipment failure, thereby shifting safety focus towards proactive risk management.

What is the largest restraint to market growth for high-end cryogenic safety suits?

The largest restraint to market growth for high-end cryogenic safety suits is the high initial cost associated with specialized, multi-layered insulating materials and complex manufacturing processes required to meet stringent safety certifications. Additionally, the inherent bulkiness can sometimes lead to reduced user dexterity and compliance issues, particularly in precision handling tasks.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager