Curved Surface Printer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431734 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Curved Surface Printer Market Size

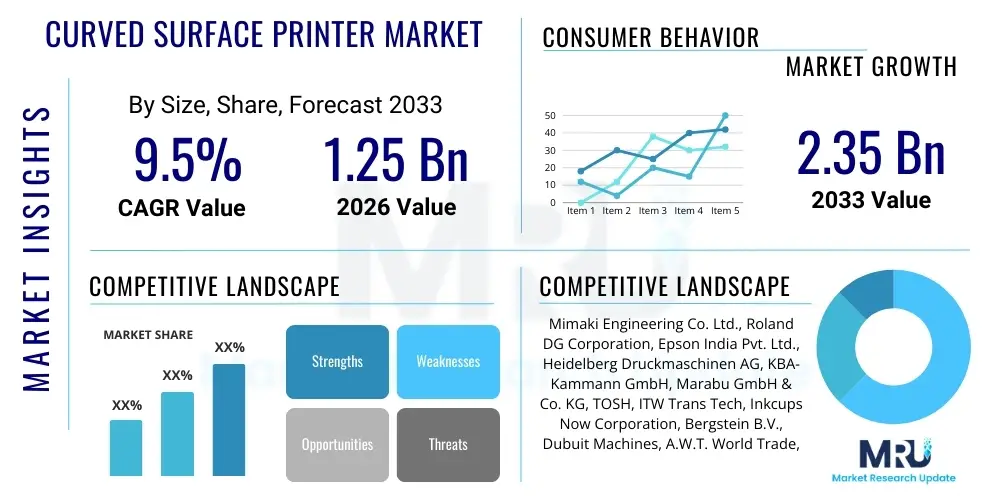

The Curved Surface Printer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2026 and 2033. This robust growth trajectory is underpinned by increasing global demand for customized, ergonomically designed products across sectors like consumer electronics, automotive components, and specialized medical devices. The unique capability of curved surface printing technology to apply high-resolution graphics and functional layers onto non-planar geometries is driving its accelerated adoption over traditional flatbed methods, which often fail to achieve precise registration and uniform deposition on complex substrates.

The market is estimated at $1.25 Billion in 2026, representing a pivotal stage where industrial automation and advanced digital printing technologies converge. Key industry stakeholders are heavily investing in research and development to improve ink adhesion, curing speeds, and sophisticated multi-axis robotic systems required for handling varied three-dimensional shapes. These technological improvements are expanding the market’s penetration into high-volume manufacturing environments, shifting the perception of curved printing from a niche customization tool to an essential industrial process.

The market is projected to reach $2.35 Billion by the end of the forecast period in 2033. This projected expansion reflects the growing necessity for highly aesthetic and functionally printed surfaces, particularly within smart devices and luxury goods where brand differentiation relies heavily on superior surface finishing. Furthermore, the burgeoning demand for printing functional inks, such as conductive traces for 3D molded electronics (3DME), is set to significantly contribute to the market valuation, moving beyond purely decorative applications toward integral component manufacturing.

Curved Surface Printer Market introduction

The Curved Surface Printer Market encompasses advanced printing systems engineered specifically to deposit inks, coatings, or functional materials onto substrates with non-planar, irregular, or complex geometries. Unlike conventional flatbed or screen printing technologies, these systems—including highly specialized digital inkjet, pad printing, and transfer printing adaptations—utilize sophisticated mechanical movements, multi-axis control, and precise curing mechanisms (such as UV or LED) to ensure uniform and accurate application across curves, spheres, and cylinders. This technology is critical for manufacturers requiring seamless aesthetic integration or specific functional properties on finished products, addressing the limitations inherent in two-dimensional printing methods when applied to three-dimensional objects.

Major applications of curved surface printing span a vast industrial landscape, predominantly impacting consumer electronics (e.g., smart watch casings, curved smartphone screens, earbuds), the automotive sector (dashboard components, interior trims, external badges), and beverage/packaging industries (bottles, customized containers). The primary benefits derived from these systems include superior design versatility, the capacity for high-resolution graphics on previously unprintable areas, reduced material waste through precision jetting, and the ability to handle on-demand customization and personalization without requiring expensive tooling changes. These benefits directly align with contemporary manufacturing trends emphasizing product differentiation and short production runs.

Driving factors propelling this market forward include the continuous push for ergonomic design in consumer products, which necessitates printing on complex, user-friendly shapes, and the accelerated adoption of In-Mold Electronics (IME) and 3D Printed Electronics technologies. Furthermore, advancements in digital ink formulations that offer enhanced flexibility, adhesion, and resistance to environmental factors (such as abrasion and UV exposure) are crucial enablers. The increasing focus on sustainability also favors digital curved printing, as it allows for precise material deposition, minimizing excess consumption compared to older analogue methods.

Curved Surface Printer Market Executive Summary

The global Curved Surface Printer Market is characterized by vigorous growth, driven primarily by evolving consumer preferences for personalized and aesthetically intricate products, especially within the Asia Pacific region. Business trends reflect a strong shift towards industrial-grade digital printing solutions, emphasizing robotic integration and advanced machine vision systems to manage the complex registration challenges associated with curved substrates. Key manufacturers are focusing their R&D efforts on enhancing printer speed and incorporating AI-driven quality control mechanisms, thereby enabling high-throughput manufacturing compatible with automotive and electronics supply chain demands. This move toward automation is crucial for maintaining competitive edge and addressing labor shortages in specialized printing operations.

Regionally, the market dynamics are significantly influenced by manufacturing strongholds. Asia Pacific (APAC) currently dominates the market share due to the massive concentration of consumer electronics and automotive manufacturing bases, particularly in China, Japan, and South Korea, which require continuous innovation in surface finishing. North America and Europe, while smaller in volume, represent critical markets for high-value, high-precision applications, including medical device printing and specialized aerospace components. These regions prioritize regulatory compliance and the printing of functional materials, creating opportunities for specialized, low-volume, high-mix service providers.

In terms of segment trends, the digital inkjet segment is forecasted to exhibit the highest CAGR, primarily because of its flexibility, non-contact nature, and capability to handle variable data printing necessary for mass customization. Application segmentation reveals robust growth in the consumer goods and packaging sectors, where the need for brand visibility and intricate labeling on irregular containers drives adoption. Furthermore, the end-user market is seeing increasing penetration in sectors like medical technology, where precise printing of biosensors or identifying marks on syringes and drug delivery devices demands the accuracy provided by curved printing methodologies, signaling a strong move beyond purely aesthetic applications.

AI Impact Analysis on Curved Surface Printer Market

User queries regarding AI in curved surface printing center predominantly on enhanced automation, quality assurance, and predictive maintenance. Common concerns include how AI can manage the complexity of multi-axis movement, minimize setup time, and guarantee consistent print quality across highly variable substrate geometries. Users are highly interested in solutions that utilize machine learning for real-time defect detection, which is crucial as manual inspection of printed curved surfaces is highly prone to human error. The overarching expectation is that AI will transform the printing process from a labor-intensive, calibration-dependent operation into a self-optimizing, fully automated industrial system capable of zero-defect manufacturing, particularly in high-stakes fields like medical and automotive component production.

- AI-driven path optimization: Machine learning algorithms analyze 3D substrate scans to generate the most efficient, non-stop print paths, minimizing nozzle travel time and ensuring ink uniformity across extreme curves.

- Real-time quality control: AI vision systems utilize deep learning to identify microscopic defects, registration errors, and curing inconsistencies instantly, allowing for immediate process adjustments or rejection before material waste accumulates.

- Predictive maintenance: AI models monitor print head performance, ink viscosity, and system component wear, forecasting potential failures and scheduling maintenance proactively to maximize uptime.

- Automated calibration and registration: AI reduces complex, manual setup procedures by automatically registering the print pattern to the substrate's exact geometry and compensating for minor physical misalignments dynamically.

- Enhanced color management: Machine learning optimizes color matching and consistency when transitioning between different substrate materials (e.g., plastic to glass), accounting for varying light refraction properties on curved surfaces.

DRO & Impact Forces Of Curved Surface Printer Market

The market for Curved Surface Printers is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities that collectively shape investment and technological evolution. Key drivers include the overwhelming consumer demand for personalized and uniquely shaped products, which necessitates printing capabilities far beyond flat surfaces. The rapid expansion of 3D printing and 3D molded electronics (3DME) mandates compatible printing methods for integrating functional circuits or conductive pathways onto non-planar structures. Furthermore, increasing automation in manufacturing requires printing systems that can be seamlessly integrated into robotic assembly lines, favoring high-precision, digital solutions.

Restraints primarily revolve around technical complexities and operational costs. The high initial capital investment required for sophisticated multi-axis robotic systems, specialized software for geometric mapping, and advanced curing mechanisms acts as a barrier to entry, particularly for Small and Medium-sized Enterprises (SMEs). Operational challenges involve achieving perfect ink adhesion and consistent image registration on highly varied materials and complex geometries, requiring highly skilled technicians and costly material science R&D. Furthermore, the slow development of highly flexible and durable functional inks specifically formulated for extreme curvature applications limits immediate expansion in certain high-demand functional printing segments.

Opportunities are emerging through technological convergence, particularly in functional printing and advanced material deposition. The rise of bio-printing and microfluidics presents a significant opportunity for curved printers to accurately deposit biological materials or highly precise diagnostic patterns onto specialized medical substrates. Moreover, the focus on sustainable manufacturing is driving demand for non-contact digital printing that minimizes solvent use and material waste. The impact forces indicate that technological advancement (specifically the maturation of digital inkjet and AI integration) is the strongest force pushing the market forward, mitigating the restraint imposed by initial cost through demonstrable efficiency and versatility improvements.

Segmentation Analysis

The Curved Surface Printer Market is meticulously segmented based on Technology, Application, and End-Use Industry, allowing for a detailed examination of market dynamics across varied operational environments. Technological segmentation highlights the competitive landscape between advanced digital methods, such as specialized UV/LED inkjet adapted for 3D surfaces, and sophisticated conventional methods like rotational screen and pad printing. Application segmentation divides the market based on the specific function or outcome of the printing (e.g., decorative printing, functional printing, security printing). End-Use segmentation tracks where the final printed product is utilized, with major categories including Consumer Electronics, Automotive, Packaging, and Medical Devices, reflecting the diverse industrial adoption landscape for these specialized machines.

- By Technology:

- Digital Inkjet Printing (UV, LED, Aqueous)

- Pad Printing (Tampo Printing)

- Screen Printing (Rotary Screen Adaptation)

- Transfer Printing (Heat Transfer/Decal)

- By Application:

- Decorative Printing (Aesthetics and Branding)

- Functional Printing (Conductive Traces, Biosensors)

- Security Printing (Anti-counterfeiting Measures)

- Information Printing (Barcodes, Serial Numbers)

- By End-Use Industry:

- Consumer Electronics

- Automotive

- Packaging and Beverages

- Medical and Pharmaceutical Devices

- Aerospace and Defense

- Industrial Components

Value Chain Analysis For Curved Surface Printer Market

The value chain for the Curved Surface Printer Market begins with upstream suppliers, focusing primarily on the manufacturing of specialized printing equipment components and the formulation of proprietary inks. Upstream analysis involves key suppliers providing high-precision print heads (e.g., piezo-electric or thermal), multi-axis robotic platforms necessary for handling complex geometries, and advanced curing systems (UV lamps, LED arrays). Most critically, the development and supply of application-specific inks—including highly flexible UV-curable inks, conductive pastes, and specialized adhesion promoters for challenging substrates like glass or ceramics—form a substantial portion of the upstream value, demanding significant investment in chemical R&D to ensure compatibility and durability.

Midstream activities are dominated by the Original Equipment Manufacturers (OEMs) who design, assemble, and integrate the complete curved surface printing systems. These manufacturers focus on integrating sophisticated software for 3D substrate mapping and registration, ensuring seamless operation between the mechanical robot arm and the print head firing sequence. Distribution channels are varied, involving both direct sales models for large industrial clients (such as major automotive Tier 1 suppliers or global electronics brands) and indirect channels through regional distributors and specialized system integrators, especially for smaller market participants or customized machine configurations. Integrators often add value by providing specialized training, post-sale maintenance, and adapting standard equipment to unique client manufacturing workflows.

Downstream analysis focuses on the end-use industries, where the value is realized through the final product enhancement. Direct customers include major consumer electronics firms and automotive manufacturers who use the technology in-house for high-volume production. Indirect impact is seen through specialized contract manufacturers and custom printing houses that offer curved surface printing services to a wide array of clients, allowing SMEs access to advanced capabilities without the capital expenditure. The final value captured is highly dependent on the complexity and functionality added to the substrate, with functional printing (e.g., printing conductive circuits) commanding significantly higher value capture compared to purely decorative applications due to the integration of critical product functionality.

Curved Surface Printer Market Potential Customers

The primary customers for Curved Surface Printing technology are large-scale manufacturing enterprises across several key vertical markets that require consistent, high-quality marking or functional deposition on non-standard product forms. End-users in the Consumer Electronics sector, including smartphone, wearable device, and gaming accessory manufacturers, represent a major buying bloc. They leverage curved printing to apply branding, regulatory marks, and sophisticated graphics directly onto ergonomic casings and touch surfaces that are increasingly non-flat, seeking aesthetic superiority and durability in high-touch items.

Another significant group of buyers is found within the Automotive industry, encompassing OEMs and their Tier 1 suppliers. These customers utilize curved printers for decorating and labeling complex interior components, such as dashboards, control buttons, and steering wheel trims, which often feature intricate contours for ergonomic reasons. Crucially, they also use this technology for functional printing, applying sensors or conductive traces onto molded plastic surfaces, demanding printers with extremely high accuracy and adherence to strict regulatory standards for temperature and abrasion resistance inherent in vehicle use.

The third crucial customer segment involves the Medical and Pharmaceutical device manufacturing sector. Buyers here require ultra-precise printing on small, curved objects like syringes, drug delivery pens, implantable devices, and diagnostic tools. The printing must be non-toxic, highly legible, and resistant to sterilization processes (e.g., autoclaving). These customers prioritize validation, traceability, and the ability to print functional biosensors or identification codes with microscopic accuracy on complex curved geometries inherent in specialized medical instruments, making precision and regulatory compliance the foremost purchasing criteria.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.25 Billion |

| Market Forecast in 2033 | $2.35 Billion |

| Growth Rate | 9.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Mimaki Engineering Co. Ltd., Roland DG Corporation, Epson India Pvt. Ltd., Heidelberg Druckmaschinen AG, KBA-Kammann GmbH, Marabu GmbH & Co. KG, TOSH, ITW Trans Tech, Inkcups Now Corporation, Bergstein B.V., Dubuit Machines, A.W.T. World Trade, Engineered Printing Solutions (EPS), Isimat GmbH Siebdruckmaschinen, SPS Technoscreen GmbH, Sisma S.p.A., M&R Companies, Adelco Screen Process Ltd., Thieme GmbH & Co. KG, SMT Max Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Curved Surface Printer Market Key Technology Landscape

The Curved Surface Printer market is defined by several core and evolving technologies necessary to overcome the challenges of non-planar printing, primarily focusing on precision deposition and adhesion. Digital Inkjet technology, particularly utilizing UV-curable and LED-curable inks, represents the most transformative shift. These non-contact methods allow for variable data printing and on-demand customization, requiring highly advanced multi-axis robotic arms or specialized fixtures to manipulate the substrate precisely underneath stationary print heads. The immediate curing capabilities provided by UV or LED light sources are essential for preventing ink run-off and ensuring rapid process times on vertical or steeply curved surfaces, drastically improving throughput in industrial settings.

While digital methods grow, adapted conventional technologies like Pad Printing and Rotary Screen Printing remain vital, especially for specific material types or high-volume, single-design applications. Pad printing (or tampo printing) excels at transferring ink from a cliché plate via a flexible silicone pad onto irregularly shaped surfaces, making it indispensable for small, concave, or convex items like medical components and golf balls. Screen printing has been modernized with rotary and servo-driven control systems, allowing continuous, high-speed printing on cylindrical or conical items such as bottles and tubes, demanding sophisticated software control to maintain screen-to-substrate parallelism throughout the rotation cycle.

Crucially, the enabling technological landscape is heavily focused on integrated software solutions. Modern curved surface printers rely on Computer-Aided Manufacturing (CAM) software to accurately map the substrate's 3D geometry and translate the 2D image data into precise, compensated print paths. Technologies such as advanced sensor systems, high-resolution cameras, and laser profiling are incorporated for meticulous registration verification and real-time adjustment of print coordinates. This integration of hardware and software intelligence is necessary to achieve micron-level accuracy, which is non-negotiable for functional printing applications like conductive traces or fine-line biosensor deposition on medical equipment.

Regional Highlights

- Asia Pacific (APAC): APAC is the dominant market region, primarily driven by the colossal manufacturing bases for consumer electronics (smartphones, wearables) and automotive production in countries like China, South Korea, and Japan. The region benefits from lower manufacturing costs and a robust supply chain capable of high-volume production, making it a critical hub for the adoption of high-speed, automated curved surface printing systems for both decorative branding and functional layer integration.

- North America: This region is characterized by high investment in specialized, high-value applications, particularly in the aerospace, defense, and advanced medical device sectors. North American companies prioritize technological innovation, focusing on the use of curved printers for functional printing (e.g., printing antennas, circuits) and materials research. Demand is driven by strict quality control standards and the need for highly customized, low-volume production runs.

- Europe: Europe maintains a strong market position, especially in industrial manufacturing, luxury packaging, and automotive interiors (Germany, Italy, France). The emphasis is placed on precision engineering, compliance with stringent environmental regulations (driving the adoption of UV/LED and solvent-free digital inks), and sophisticated aesthetics for premium consumer goods. The region serves as a key innovator in integrating curved printing into highly automated Industry 4.0 environments.

- Latin America (LATAM): The LATAM market, while smaller, is growing steadily, propelled by expanding local packaging and beverage industries requiring high-quality labeling on contoured bottles and containers. Economic stabilization and increased foreign investment in regional manufacturing hubs are gradually leading to the adoption of advanced printing machinery, moving away from entirely manual or traditional processes.

- Middle East and Africa (MEA): This region exhibits niche growth, primarily centered in the UAE and Saudi Arabia due to infrastructure development projects and limited consumer goods manufacturing. The demand is concentrated in the packaging industry and oil/gas sectors, requiring durable, traceable marking on curved industrial components, often focusing on reliability and extreme environment durability rather than intricate aesthetics.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Curved Surface Printer Market.- Mimaki Engineering Co. Ltd.

- Roland DG Corporation

- Epson India Pvt. Ltd.

- Heidelberg Druckmaschinen AG

- KBA-Kammann GmbH

- Marabu GmbH & Co. KG

- TOSH

- ITW Trans Tech

- Inkcups Now Corporation

- Bergstein B.V.

- Dubuit Machines

- A.W.T. World Trade

- Engineered Printing Solutions (EPS)

- Isimat GmbH Siebdruckmaschinen

- SPS Technoscreen GmbH

- Sisma S.p.A.

- M&R Companies

- Adelco Screen Process Ltd.

- Thieme GmbH & Co. KG

- SMT Max Inc.

Frequently Asked Questions

Analyze common user questions about the Curved Surface Printer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary technical challenge in curved surface printing?

The primary technical challenge is achieving precise registration and uniform ink deposition (layer thickness) across complex, non-planar geometries, requiring advanced multi-axis control and sophisticated software to dynamically map the surface profile during the printing process.

Which end-use industry drives the highest demand for functional curved printing?

The Consumer Electronics and Medical Device industries drive the highest demand for functional curved printing, specifically for applying conductive traces, biosensors, or internal identification marks onto intricate 3D molded components and small delivery devices.

How does AI improve the efficiency of curved surface printing operations?

AI significantly improves efficiency by automating the complex calibration process, optimizing the print path for minimum waste and speed, and providing real-time quality control through machine vision to instantly detect and correct microscopic defects.

Is digital inkjet or pad printing more common for curved surfaces?

Digital inkjet is rapidly growing due to its versatility and non-contact nature, favored for mass customization and variable data printing on large industrial scales. However, pad printing remains essential for specific small, highly concave/convex objects requiring thick ink layers and high adhesion.

What types of inks are predominantly used in curved surface printing?

UV-curable inks and LED-curable inks are predominant. They offer instant curing upon exposure to UV or LED light, ensuring the ink adheres immediately to the curved substrate without running or smearing, which is crucial for printing on vertical or highly angled surfaces.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager