Custom Casting Services Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439728 | Date : Jan, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Custom Casting Services Market Size

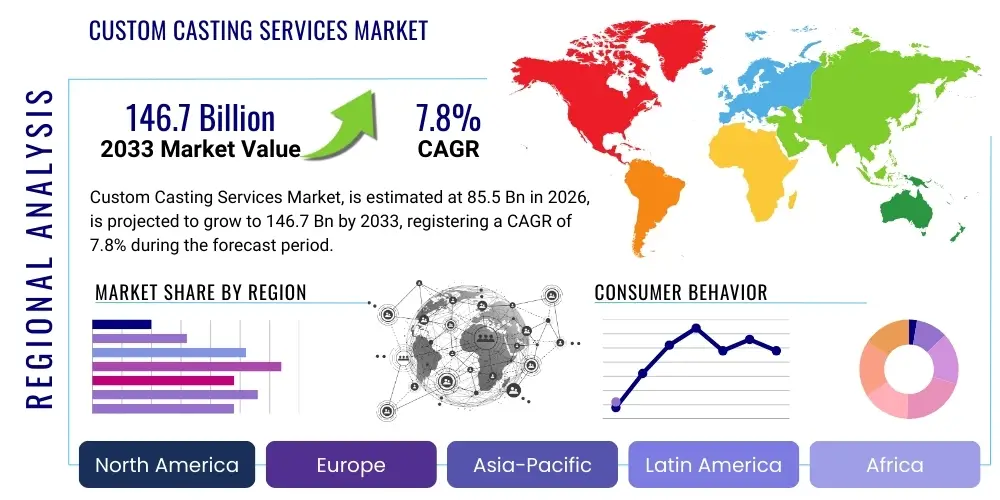

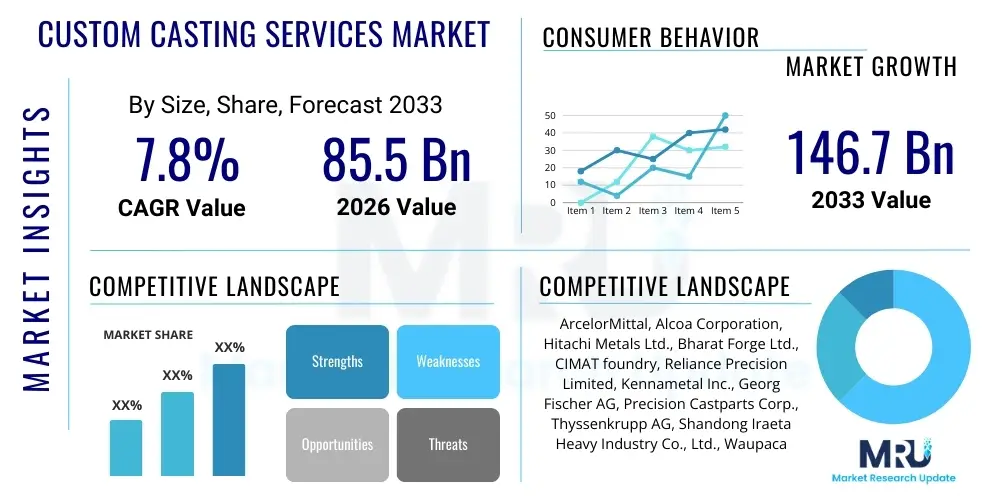

The Custom Casting Services Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 85.5 billion in 2026 and is projected to reach USD 146.7 billion by the end of the forecast period in 2033.

Custom Casting Services Market introduction

The Custom Casting Services Market encompasses specialized manufacturing processes where molten metal is poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. These services are tailored to client specifications, offering unique designs, specific material compositions, and precise tolerances for diverse industrial applications. Custom casting is critical for producing complex geometries and large components that would be difficult or impossible to fabricate by other methods, ensuring optimal performance and cost-efficiency for specific production volumes.

Major applications span across the automotive, aerospace, defense, industrial machinery, medical, construction, and energy sectors, providing custom parts ranging from engine blocks and turbine components to surgical implants and structural elements. The primary benefits of leveraging custom casting services include superior structural integrity, dimensional accuracy, material versatility, and the ability to achieve intricate designs that meet stringent performance requirements. This flexibility allows industries to innovate and optimize product functionality while managing production costs effectively.

Driving factors for market growth include the increasing demand for lightweight, high-strength components in advanced manufacturing, the expansion of industrial infrastructure globally, and the continuous need for customized parts to support complex machinery and equipment. Furthermore, technological advancements in casting processes, materials science, and simulation software are enhancing the efficiency and capabilities of custom casting providers, allowing for greater design freedom and improved product quality.

Custom Casting Services Market Executive Summary

The Custom Casting Services Market is experiencing robust growth driven by several key business trends, including the increasing adoption of digitalization and automation in foundry operations, a rising demand for specialized alloys, and a greater emphasis on supply chain resilience and localized production. Companies are investing in advanced manufacturing technologies, such as simulation software and robotics, to enhance precision, reduce lead times, and optimize material usage. The trend towards lightweighting in industries like automotive and aerospace continues to spur innovation in custom casting, particularly for aluminum and magnesium alloys, alongside high-strength steel and superalloys.

Regionally, the Asia Pacific market is poised for significant expansion, fueled by rapid industrialization, infrastructure development, and a burgeoning manufacturing sector, particularly in countries like China and India. North America and Europe maintain strong positions due to established industrial bases, a focus on technological innovation, and a steady demand from high-value sectors such as aerospace and medical. Emerging economies in Latin America and the Middle East & Africa are also contributing to market growth, driven by investments in energy, construction, and general manufacturing, creating new opportunities for custom casting providers.

Segment-wise, the market is seeing strong performance across various process types, with investment casting and die casting gaining traction for high-precision and intricate parts, while sand casting remains vital for larger, more complex components. Material demand is diversifying, with ferrous metals maintaining their foundational role and non-ferrous metals like aluminum seeing accelerated growth due to their lightweight properties. The automotive and industrial machinery end-use sectors consistently represent significant portions of the market, though the aerospace and medical sectors are exhibiting strong growth dueable to their critical need for highly customized and certified components.

AI Impact Analysis on Custom Casting Services Market

Users frequently inquire about the transformative potential of Artificial Intelligence in the custom casting services market, specifically how AI can enhance efficiency, precision, and material utilization. Common questions revolve around AI's role in design optimization, predicting casting defects, automating quality control, and improving supply chain management. Stakeholders are keen to understand if AI can significantly reduce production costs, minimize waste, and accelerate time-to-market for complex custom parts, thereby addressing traditional challenges such as material variability and process inconsistencies.

The key themes emerging from user concerns and expectations include the desire for intelligent systems that can learn from vast datasets of casting parameters and outcomes to provide predictive insights, thereby preventing costly errors before they occur. There is a strong expectation that AI will streamline the entire casting lifecycle, from initial design validation through final inspection, making custom casting more accessible, efficient, and reliable. Users are also interested in how AI might democratize advanced casting techniques, allowing for more intricate and novel designs to be realized with greater consistency and less trial-and-error.

Overall, the market anticipates that AI will be a critical enabler for smart foundries, leading to a significant paradigm shift in how custom casting services are designed, manufactured, and delivered. This includes not only direct operational improvements but also broader implications for competitive advantage, workforce upskilling, and the strategic planning of production capacities. The integration of AI is expected to move custom casting from a largely experience-driven craft to a data-driven science, opening new avenues for innovation and precision engineering.

- AI-driven generative design tools optimize part geometry for casting, reducing material usage and improving structural integrity.

- Predictive analytics algorithms identify potential casting defects like porosity or shrinkage cavities during the design and simulation phases, minimizing rework.

- Machine learning models analyze real-time sensor data from casting processes to automatically adjust parameters for optimal quality and consistency.

- AI-powered visual inspection systems automate quality control, detecting surface imperfections and internal flaws with higher accuracy and speed than manual methods.

- Robotics and automation, guided by AI, enhance precision in mold handling, pouring, and finishing operations, leading to increased productivity and worker safety.

- Supply chain optimization through AI improves raw material procurement, inventory management, and logistics, reducing lead times and operational costs.

- Digital twin technology, often supported by AI, creates virtual replicas of casting operations for real-time monitoring, predictive maintenance, and process optimization.

- AI assists in material selection by analyzing performance requirements against vast material databases, recommending optimal alloys for specific custom applications.

DRO & Impact Forces Of Custom Casting Services Market

The Custom Casting Services Market is propelled by several potent drivers, primarily the escalating global demand for lightweight and complex components across critical industries such as automotive, aerospace, and industrial machinery, which necessitates highly precise and customized solutions. The continuous advancements in casting technologies, including improvements in material science and process automation, further enhance the capabilities of custom casting, allowing for the creation of intricate geometries and superior material properties. Moreover, the increasing focus on product differentiation and performance optimization by manufacturers drives the adoption of custom casting to achieve unique designs and functional benefits not readily available through standard manufacturing processes. The robust growth in infrastructure development and industrial expansion in emerging economies also contributes significantly to the market's upward trajectory, creating a consistent need for bespoke cast parts.

However, the market faces significant restraints that temper its growth. High capital investment required for setting up and upgrading casting foundries, particularly for advanced processes, poses a substantial barrier to entry and expansion. Stringent environmental regulations related to emissions, waste disposal, and energy consumption compel foundries to invest heavily in compliance, increasing operational costs. The volatility in raw material prices, especially for metals like aluminum, steel, and specialty alloys, introduces cost uncertainties and impacts profitability. Furthermore, a persistent shortage of skilled labor proficient in advanced casting techniques and foundry management presents challenges for maintaining quality and efficiency.

Opportunities for growth are abundant within the custom casting services market, particularly through the integration of additive manufacturing techniques for producing molds and cores, which significantly reduces lead times and allows for even more complex designs. The expanding industrial base in emerging economies offers lucrative markets for custom casting providers, as these regions increasingly demand high-quality manufactured goods and infrastructure. The development and adoption of smart casting processes, incorporating IoT, AI, and data analytics for real-time monitoring and control, represent a key opportunity to enhance efficiency and quality. Additionally, a growing emphasis on sustainable manufacturing practices, including the use of recycled materials and energy-efficient processes, provides avenues for market players to innovate and differentiate their offerings, aligning with global environmental objectives.

Impact forces such as rapid technological innovation, global economic fluctuations, evolving regulatory landscapes, and potential disruptions in global supply chains exert considerable influence on the custom casting market. Technological advancements, including digital simulation and automation, fundamentally reshape production capabilities and competitiveness. Economic cycles dictate industrial investment and consumer demand, directly affecting order volumes for cast components. Changes in trade policies, environmental standards, and labor laws create compliance challenges and opportunities for market participants. Geopolitical events and natural disasters can disrupt raw material supply and logistics, necessitating agile and resilient supply chain strategies. These forces collectively shape the operational environment and strategic direction for custom casting service providers.

Segmentation Analysis

The Custom Casting Services Market is comprehensively segmented to provide granular insights into its diverse operational landscape and application areas. This segmentation helps to understand the market dynamics across different processing techniques, material types, and end-use industries, offering a clear picture of demand patterns and technological preferences. The market's complexity necessitates a multi-faceted approach to categorization, reflecting the specialized nature of custom casting.

Understanding these segments allows market players to identify niche opportunities, tailor their offerings to specific client needs, and strategically position themselves within the competitive landscape. Each segment is characterized by unique technical requirements, material properties, and market drivers, contributing distinctly to the overall market growth. The detailed breakdown covers the entire spectrum of custom casting, from traditional methods to advanced manufacturing techniques.

- By Process

- Sand Casting

- Die Casting

- Investment Casting (Lost Wax Casting)

- Permanent Mold Casting (Gravity Die Casting)

- Centrifugal Casting

- Shell Mold Casting

- Lost Foam Casting

- Plaster Mold Casting

- By Material

- Ferrous Metals

- Cast Iron (Gray, Ductile, Malleable)

- Steel (Carbon, Alloy, Stainless)

- Non-Ferrous Metals

- Aluminum Alloys

- Magnesium Alloys

- Copper Alloys (Brass, Bronze)

- Zinc Alloys

- Nickel Alloys

- Titanium Alloys

- Other Non-Ferrous Alloys

- Ferrous Metals

- By End-Use Industry

- Automotive

- Aerospace & Defense

- Industrial Machinery & Equipment

- Medical & Healthcare

- Energy (Oil & Gas, Power Generation)

- Construction

- Marine

- Agriculture

- Railways

- Electronics

- Others (e.g., consumer goods, art)

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Custom Casting Services Market

The value chain for the Custom Casting Services Market begins with the sourcing of raw materials, primarily metals like iron, steel, aluminum, and various alloys, from mining companies and metal suppliers. This upstream segment is crucial as the quality and cost of raw materials directly impact the final product. Material suppliers often work closely with foundries to ensure consistent quality and timely delivery, sometimes offering specialized alloys tailored to specific casting requirements.

Moving downstream, the core of the value chain involves the custom casting manufacturers themselves, who receive design specifications from clients, create molds or patterns, melt the raw materials, cast the molten metal, and then perform initial finishing operations such as fettling and shot blasting. Many casting manufacturers also offer value-added services like machining, heat treatment, surface finishing, and assembly, integrating these into their offerings to provide a complete solution to their customers. This integration helps streamline the manufacturing process for the end-user, reducing the need for multiple vendors.

Distribution channels for custom casting services can be direct or indirect. Direct channels involve manufacturers selling directly to end-user industries (e.g., an automotive OEM directly contracting with a foundry for engine blocks). This is common for high-volume or highly specialized custom parts where close collaboration is essential. Indirect channels may involve intermediaries such as industrial distributors, engineering firms, or supply chain aggregators who consolidate orders from multiple smaller clients and outsource them to various foundries. The choice of channel often depends on the complexity of the part, order volume, geographic reach, and the nature of the client relationship, with a growing trend towards direct engagement for highly customized and critical components to ensure quality control and communication.

Custom Casting Services Market Potential Customers

The Custom Casting Services Market caters to a diverse range of end-users and buyers across numerous industrial sectors, all of whom require specialized metal components that cannot be met by off-the-shelf solutions. A primary segment of potential customers includes Original Equipment Manufacturers (OEMs) in the automotive industry, demanding custom engine blocks, transmission cases, brake components, and structural parts designed for specific vehicle models, often emphasizing lightweighting and durability. These OEMs require precision and reliability to meet stringent safety and performance standards, making custom casting an indispensable part of their supply chain.

Another significant customer base comprises manufacturers in the aerospace and defense sectors, where custom casting is vital for producing critical components for aircraft engines, airframes, and weaponry. These applications demand exceptional material strength, resistance to extreme temperatures, and dimensional accuracy, often utilizing superalloys and advanced ferrous metals. Medical device companies also represent a growing segment, requiring biocompatible and highly precise custom cast components for surgical instruments, implants, and diagnostic equipment, where material purity and intricate designs are paramount for patient safety and device functionality.

Furthermore, industrial machinery and equipment manufacturers across various sub-sectors, including construction, agriculture, mining, and power generation, are key buyers. They rely on custom casting for large, complex components such as gearboxes, pump housings, turbine components, and heavy-duty structural parts that must withstand harsh operating conditions and provide long-term reliability. The energy sector, encompassing oil and gas exploration, refining, and renewable energy, also frequently sources custom cast valves, fittings, and specialized equipment designed to operate under high pressure and corrosive environments, underscoring the broad applicability and critical importance of custom casting services.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 85.5 billion |

| Market Forecast in 2033 | USD 146.7 billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ArcelorMittal, Alcoa Corporation, Hitachi Metals Ltd., Bharat Forge Ltd., CIMAT foundry, Reliance Precision Limited, Kennametal Inc., Georg Fischer AG, Precision Castparts Corp., Thyssenkrupp AG, Shandong Iraeta Heavy Industry Co., Ltd., Waupaca Foundry Inc., AFS Corporate Member, Bradken Limited, Doncasters Group, Fonderie de Gentilly (FDG), Kubota Corporation, Magna International Inc., MetalTek International, ME Elecmetal |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Custom Casting Services Market Key Technology Landscape

The Custom Casting Services Market is continuously evolving with significant advancements in its technology landscape, driven by the need for greater precision, efficiency, and material versatility. Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software form the foundational backbone, enabling engineers to create intricate part geometries and design complex molds with high accuracy. These digital tools are increasingly integrated with simulation software, such as Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD), which allow for the virtual testing of casting processes to predict metal flow, solidification patterns, and potential defects, thereby optimizing mold design and process parameters before physical production begins.

The adoption of 3D printing technology has become a game-changer, particularly for creating complex sand molds, cores, and wax patterns for investment casting. This additive manufacturing approach eliminates the need for traditional tooling, significantly reducing lead times and allowing for the rapid prototyping and production of highly customized parts with intricate internal structures. Automated molding lines and robotic systems are also becoming more prevalent in foundries, enhancing consistency, reducing manual labor, improving worker safety, and increasing overall production throughput, particularly for repetitive and hazardous tasks like pouring molten metal and mold handling.

Furthermore, advanced inspection techniques, including industrial computed tomography (CT scanning), ultrasonic testing, and advanced optical metrology, are employed for non-destructive evaluation of custom cast parts, ensuring dimensional accuracy and internal integrity. Sensor integration and Internet of Things (IoT) devices are increasingly being deployed throughout the casting process to gather real-time data on temperature, pressure, and other critical parameters. This data, when analyzed with artificial intelligence (AI) and machine learning (ML) algorithms, facilitates predictive maintenance, process optimization, and proactive quality control, moving the custom casting industry towards a more intelligent and digitally integrated manufacturing paradigm.

Regional Highlights

- North America: This region holds a significant share in the Custom Casting Services Market, driven by robust demand from the automotive, aerospace, and defense industries. The presence of major OEMs and a strong focus on advanced manufacturing technologies, including automation and digital foundries, contribute to its market dominance. Investments in lightweight materials and complex component development are key growth drivers, particularly in the United States and Canada.

- Europe: Europe is a mature market for custom casting services, characterized by a strong emphasis on precision engineering, high-quality standards, and environmental regulations. Countries like Germany, the UK, and France lead in industrial machinery, automotive, and medical device manufacturing, requiring highly specialized cast components. The region is also at the forefront of adopting sustainable casting practices and advanced simulation technologies.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region in the Custom Casting Services Market, fueled by rapid industrialization, infrastructure development, and a booming manufacturing sector in countries such as China, India, Japan, and South Korea. The region benefits from lower labor costs, increasing foreign investment, and a growing domestic demand for vehicles, industrial equipment, and consumer goods, making it a global manufacturing hub.

- Latin America: The market in Latin America is experiencing steady growth, primarily driven by the automotive industry in countries like Mexico and Brazil, along with increasing investments in infrastructure and mining. While still developing, the region offers potential for expansion as industrialization progresses and local demand for customized components rises, attracting international players seeking new market opportunities.

- Middle East and Africa (MEA): MEA represents an emerging market for custom casting services, with growth primarily influenced by significant investments in oil and gas infrastructure, power generation, and construction projects, particularly in countries within the GCC (Gulf Cooperation Council). As these economies diversify and industrialize, the demand for specialized cast parts for heavy machinery and energy applications is expected to increase, offering long-term growth prospects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Custom Casting Services Market.- ArcelorMittal

- Alcoa Corporation

- Hitachi Metals Ltd.

- Bharat Forge Ltd.

- CIMAT foundry

- Reliance Precision Limited

- Kennametal Inc.

- Georg Fischer AG

- Precision Castparts Corp.

- Thyssenkrupp AG

- Shandong Iraeta Heavy Industry Co., Ltd.

- Waupaca Foundry Inc.

- AFS Corporate Member

- Bradken Limited

- Doncasters Group

- Fonderie de Gentilly (FDG)

- Kubota Corporation

- Magna International Inc.

- MetalTek International

- ME Elecmetal

Frequently Asked Questions

What is custom casting and how does it differ from standard casting?

Custom casting involves manufacturing metal parts to specific, unique design specifications provided by a client, often requiring specialized molds, alloys, and processes for intricate geometries, specific material properties, or particular performance criteria. Standard casting, conversely, typically refers to producing common, off-the-shelf components using pre-existing molds and standard material grades for broader applications.

Which industries benefit most from custom casting services?

Industries that benefit most include automotive for engine components and chassis parts, aerospace and defense for lightweight and high-strength structural elements, medical for precision implants and instruments, and industrial machinery for durable and complex equipment components. These sectors require parts with strict tolerances, unique designs, and specialized material performance that only custom casting can reliably provide.

What are the primary materials used in custom casting?

The primary materials used in custom casting broadly fall into ferrous and non-ferrous categories. Ferrous metals include various grades of cast iron (e.g., ductile, gray) and steel (e.g., carbon, stainless, alloy steel). Non-ferrous metals encompass aluminum alloys, magnesium alloys, copper alloys (brass, bronze), zinc alloys, nickel alloys, and titanium alloys, chosen based on specific application requirements for strength, weight, corrosion resistance, or thermal properties.

What technological advancements are driving the custom casting market?

Key technological advancements include the widespread adoption of CAD/CAM and advanced simulation software for design and process optimization, 3D printing for rapid prototyping of molds and patterns, automation and robotics for improved efficiency and safety, and the integration of IoT and AI for real-time monitoring, predictive maintenance, and quality control. These innovations enhance precision, reduce lead times, and enable more complex designs.

What are the environmental considerations in custom casting and how are they addressed?

Environmental considerations include energy consumption, waste generation (e.g., sand, slag, metal scraps), air emissions, and water usage. The industry addresses these through various strategies such as investing in energy-efficient furnaces, implementing advanced filtration systems to reduce emissions, recycling foundry sand and metal scraps, and optimizing water usage with closed-loop systems. There is also a growing focus on sustainable manufacturing practices and green foundry initiatives.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager