Customized Air Motors Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434542 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Customized Air Motors Market Size

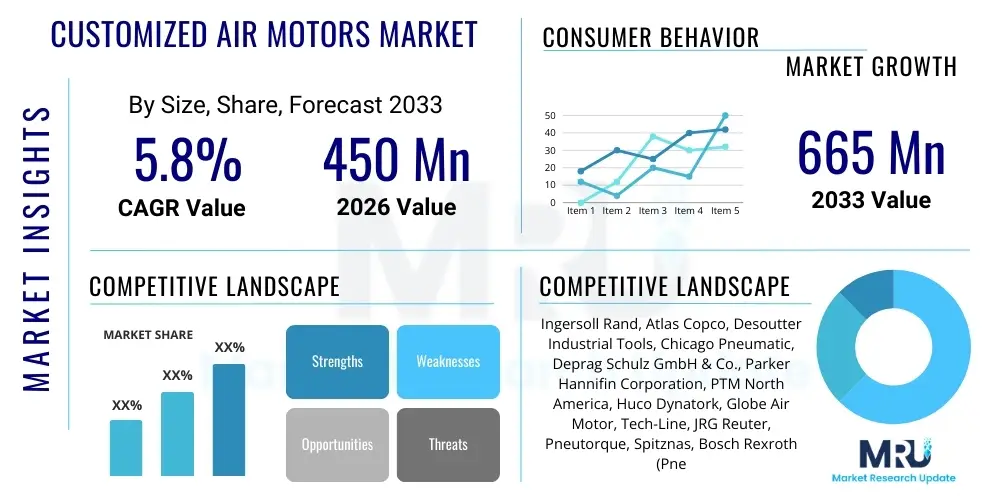

The Customized Air Motors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 665 Million by the end of the forecast period in 2033.

Customized Air Motors Market introduction

The Customized Air Motors Market encompasses the design, manufacture, and distribution of pneumatic motors specifically engineered or modified to meet unique operational parameters and application requirements that standard, off-the-shelf air motors cannot satisfy. These customizations typically involve alterations in materials (e.g., stainless steel for corrosive environments), output power characteristics (torque, speed), mounting configurations, size constraints, and integration of specialized control systems. Air motors, or pneumatic motors, are prized in industries where electric motors pose safety risks due to flammable atmospheres, such as mining, petrochemicals, and painting facilities, owing to their inherent non-sparking nature.

Customized air motors serve a crucial function in highly specialized industrial processes, offering solutions for extreme conditions, including high temperatures, chemical exposure, or submerged operations, which demand exceptional reliability and durability. Key applications span across automated machinery, mixing equipment, material handling systems, tooling, and specialized medical devices where lightweight design and high power density are essential. The market growth is fundamentally driven by the increasing need for explosion-proof equipment in hazardous locations (HazLoc) and the continuous trend toward high-precision automation requiring unique performance envelopes.

The primary benefits of customized air motors include enhanced safety in volatile environments, superior power-to-weight ratio compared to electric counterparts, infinite variable speed control, and stall resistance without overheating or damage. Driving factors include stringent industrial safety regulations, technological advancements in material science enabling lighter and more robust motor components, and the growing demand for highly efficient, compact power sources within robotics and advanced manufacturing sectors seeking optimal operational performance tailored precisely to their workflows.

Customized Air Motors Market Executive Summary

The global Customized Air Motors Market exhibits robust growth, primarily propelled by the stringent implementation of safety standards in industries characterized by hazardous conditions, such as chemicals, oil & gas, and pharmaceuticals. Business trends indicate a significant pivot towards rapid prototyping and additive manufacturing techniques, allowing manufacturers to drastically reduce lead times for complex customized designs, thereby enhancing market responsiveness. There is a strong emphasis on developing motors that offer improved air efficiency and reduced noise levels, addressing long-standing operational drawbacks associated with traditional pneumatic technology, while focusing on integration capabilities with advanced digital control systems.

Regional trends highlight Asia Pacific (APAC) as the fastest-growing market, driven by rapid industrialization, burgeoning investments in automotive manufacturing and infrastructure development, particularly in countries like China and India, where the demand for specialized automated tooling is escalating. North America and Europe maintain dominance in terms of market value, underpinned by established aerospace and defense sectors, stringent workplace safety regulations (ATEX/IECEx compliance), and a high adoption rate of advanced, high-performance machinery requiring tailored pneumatic power solutions for specialized tasks.

Segment trends reveal that the Vane Motor segment, due to its simplicity, cost-effectiveness, and ease of customization, holds the largest market share by type, while the application segment is dominated by material handling and mixing equipment requiring high torque output. Furthermore, the customization based on material type, specifically the use of advanced composites and non-corrosive stainless steel, is witnessing accelerated growth as end-users prioritize longevity and maintenance reduction in harsh operating environments. The market structure remains moderately fragmented, with specialized niche manufacturers competing fiercely through innovation in design software and rapid customer service capabilities.

AI Impact Analysis on Customized Air Motors Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Customized Air Motors Market frequently center on how AI can accelerate the complex design and optimization process inherent in customization. Users are primarily concerned with whether AI can predict motor performance under novel operational constraints, how it can optimize internal geometries for maximum pneumatic efficiency, and the potential for AI-driven predictive maintenance models to extend motor lifespan in remote or hostile environments. Key themes revolve around leveraging machine learning algorithms to reduce physical prototyping cycles and ensuring that the customized designs are inherently more robust and energy-efficient than traditionally engineered solutions.

AI’s influence is transformative, moving customization from a time-consuming, iterative process based on expert experience to a data-driven, accelerated workflow. AI and Generative Design algorithms allow manufacturers to input complex parameters—such as required torque curve, specific operating temperature range, vibration tolerance, and material constraints—and generate thousands of optimized motor designs simultaneously. This significantly compresses the concept-to-production timeline, making highly niche customization economically viable even for smaller batch sizes, thereby broadening the market accessibility for specialized pneumatic solutions.

Furthermore, the integration of smart sensors and IoT capabilities into customized air motors creates vast data streams concerning performance, wear, pressure differential, and temperature profiles. Machine Learning (ML) models analyze this data to identify subtle deviations indicative of impending failure, enabling highly accurate predictive maintenance schedules. This capability is critical for sectors like mining or deep-sea exploration, where unscheduled downtime of specialized, customized equipment results in massive financial losses. AI ensures that the operational longevity and reliability of customized air motors meet the stringent expectations of advanced industrial applications.

- AI-Driven Generative Design: Optimizing internal motor geometry (e.g., vane or piston shape) for peak air efficiency and power output based on precise customer specifications.

- Predictive Performance Modeling: Using ML to simulate motor performance under extreme or novel operating conditions, reducing the need for costly and lengthy physical testing.

- Accelerated Prototyping: Decreasing the time required to finalize customized designs by leveraging simulation tools integrated with AI optimization engines.

- Enhanced Quality Control: Utilizing computer vision and deep learning models during manufacturing to inspect the precision of highly customized components, ensuring compliance with tight tolerances.

- Predictive Maintenance Integration: Deploying ML algorithms analyzing operational data from integrated sensors to forecast component failure and optimize maintenance cycles for maximized uptime.

- Supply Chain Optimization: Using AI to manage the sourcing and inventory of specialized materials and components required for diverse customization projects.

DRO & Impact Forces Of Customized Air Motors Market

The Customized Air Motors Market is governed by a complex interplay of Drivers, Restraints, and Opportunities (DRO), collectively shaping its growth trajectory and competitive landscape. The primary driver is the pervasive demand for explosion-proof (Ex) rated equipment across critical manufacturing sectors, where pneumatic technology offers a safer, intrinsically non-sparking alternative to electric motors, particularly in classified hazardous areas. This necessity, coupled with the desire for high power density in compact, lightweight customized solutions (critical in robotics and portable tooling), fuels market expansion. However, restraints persist, notably the lower overall energy efficiency compared to modern electric servo motors and the substantial ongoing compressed air generation costs, which often necessitate complex infrastructure and energy management strategies for end-users.

Opportunities in this market are intrinsically linked to technological advancement and market diversification. The rising adoption of Industry 4.0 principles, necessitating modular and highly flexible manufacturing setups, creates significant scope for tailored pneumatic actuation systems that can integrate seamlessly with IoT networks. Furthermore, the development of advanced materials, such as specialized ceramics and polymers, allows for motors that are more resistant to corrosion and extreme temperatures, opening lucrative customization opportunities in specialized fields like nuclear power facilities, food and beverage sterilization zones, and deep-sea exploration where standard metal components fail rapidly.

The market impact forces are strongly influenced by regulatory pressure, specifically the enforcement of ATEX, IECEx, and OSHA standards, which compels industries to invest in compliant customized air motor solutions for safety assurance. The high cost of customization and the requirement for specialized engineering expertise act as strong barriers to entry, concentrating market share among established players capable of offering comprehensive design-to-delivery services. The long-term impact force remains the competition from advanced electric motor technologies, which constantly push boundaries in terms of miniaturization and efficiency, requiring continuous innovation in pneumatic motor design to maintain competitive relevance.

Segmentation Analysis

The Customized Air Motors Market is strategically segmented based on factors such as motor type, power output, operating technology, and critical end-use applications, providing a granular view of demand dynamics across various industrial landscapes. Understanding these segments is vital for manufacturers focusing on specific customization niches, such as high-torque requirements for specialized mixers or high-speed demands for precision grinding tools. The segmentation by motor type is critical, as vane motors, piston motors, and turbine motors possess fundamentally different inherent characteristics (e.g., starting torque, speed range, reversibility) that lend themselves to distinct customization pathways based on the application constraints.

Further analysis of segmentation by power output is essential, distinguishing between low-power motors (typically used in small tools or light automation) and high-power motors (deployed in heavy-duty machinery like winches or mixing tanks), where customization complexity and cost scale proportionally. The most defining segmentation driver remains the End-Use Industry, as sectors such as Chemical & Pharmaceutical require extreme non-corrosive material customization, while the Automotive sector focuses on high-precision, rapid-cycling tailored solutions for assembly and quality checks. This diverse demand profile necessitates highly flexible manufacturing processes tailored to specific sectoral needs.

The emphasis on customization means that hybrid segmentation approaches are becoming increasingly common, where a specific motor type (e.g., radial piston) is customized using specialized materials (e.g., titanium) for a niche application (e.g., deep-sea ROVs). This highlights the market's shift away from standard product offerings toward complex, engineered solutions, often bundled with sophisticated control systems and monitoring capabilities designed for specific operational environments and regulatory compliance requirements.

- By Motor Type

- Vane Motors (Rotary Vane)

- Piston Motors (Axial Piston, Radial Piston)

- Turbine Motors

- Diaphragm Motors

- Gear Motors (Limited Customization)

- By Customization Level

- Material Customization (Stainless Steel, Composites, Ceramics)

- Performance Customization (Torque, Speed, Power Envelope)

- Dimensional and Mounting Customization

- Sealing and Lubrication Customization (Oil-Free, Food Grade)

- By Application

- Mixing and Agitation Equipment (High Torque)

- Material Handling (Winches, Hoists)

- Industrial Robotics and Automation

- Specialized Tooling (Grinding, Drilling, Polishing)

- Medical and Pharmaceutical Devices

- Test and Measurement Systems

- By End-Use Industry

- Chemical and Petrochemical

- Oil and Gas (Upstream and Downstream)

- Mining and Construction

- Aerospace and Defense

- Food, Beverage, and Pharmaceutical

- Automotive Manufacturing

Value Chain Analysis For Customized Air Motors Market

The value chain for the Customized Air Motors Market begins with the upstream procurement of specialized raw materials, followed by complex manufacturing and assembly, culminating in customized distribution and intensive after-sales service. Upstream analysis focuses heavily on securing high-quality, specialized raw materials essential for motors operating in extreme conditions, such as high-grade stainless steel (316L or higher), specialized polymers (e.g., PEEK) for vanes and seals, and advanced bearing materials capable of dry running or extreme load handling. Manufacturers often maintain close relationships with specialty material suppliers to ensure compliance with material certifications (e.g., FDA, specific chemical resistance standards) critical for customization projects.

The manufacturing phase is highly specialized, differentiating the customized market from the standard pneumatic motor sector. It involves advanced CNC machining for complex casing geometries, rapid prototyping for initial design verification, and precise assembly requiring highly skilled labor due to tight tolerance requirements inherent in customized high-performance pneumatic systems. Downstream activities involve rigorous quality assurance testing tailored to the unique operational profile requested by the customer, ensuring the motor meets specified torque curves and pneumatic efficiency targets before deployment. This complexity adds significant cost and time compared to mass-produced items.

Distribution channels in the customized air motors market are predominantly direct or utilize highly specialized value-added distributors (VADs) who possess deep technical knowledge and often provide local customization and integration services. Direct sales are preferred for large, complex projects, allowing direct collaboration between the end-user’s engineering team and the manufacturer’s design department. Indirect channels primarily involve Maintenance, Repair, and Overhaul (MRO) specialists and system integrators who incorporate customized motors into larger automation solutions. Effective distribution relies heavily on rapid, localized technical support and engineering consultation, making the channel selection a strategic component of delivering bespoke solutions.

Customized Air Motors Market Potential Customers

Potential customers for Customized Air Motors are predominantly industrial entities operating in environments categorized as hazardous, requiring explosion-proof certification, or those facing unique physical or chemical constraints that necessitate tailored power solutions. The primary end-users are concentrated within the heavy process industries, including the chemical processing sector, which requires motors made from specific corrosion-resistant alloys for agitators and pumps handling aggressive media, and the oil and gas industry, demanding rugged, high-torque piston motors for offshore drilling and refinery operations.

Another significant customer segment is found within the advanced manufacturing and automation sectors, particularly companies developing sophisticated robotics, specialized assembly lines, and high-speed precision tooling. These applications often require customized miniature air motors delivering high power-to-weight ratios and exceptional speed stability, which cannot be achieved with standard pneumatic designs. Furthermore, the Food, Beverage, and Pharmaceutical industries are key buyers, necessitating customization in materials (hygienic stainless steel), sealing technologies, and lubrication (oil-free or food-grade lubricants) to adhere to strict sanitary and validation protocols.

In essence, any organization where safety regulations mandate non-electric actuation, or where physical constraints (size, weight, temperature, submerged operation) exceed the capabilities of off-the-shelf motors, constitutes a high-potential customer. This includes niche customers such as aerospace MRO facilities requiring specialized tools, deep-sea exploration vehicle manufacturers, and military/defense contractors needing highly reliable, ruggedized pneumatic systems for remote operation or challenging fieldwork conditions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 665 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ingersoll Rand, Atlas Copco, Desoutter Industrial Tools, Chicago Pneumatic, Deprag Schulz GmbH & Co., Parker Hannifin Corporation, PTM North America, Huco Dynatork, Globe Air Motor, Tech-Line, JRG Reuter, Pneutorque, Spitznas, Bosch Rexroth (Pneumatic Division), Gast Manufacturing, Rotary Power, PTM Industries, Fuji Industrial Power Tools, Hilti Corporation (Specialized Tools), Air-Mite Devices |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Customized Air Motors Market Key Technology Landscape

The technology landscape in the Customized Air Motors Market is rapidly evolving, moving beyond traditional pneumatic principles through advancements in materials science, computational fluid dynamics (CFD), and precision manufacturing techniques. A key technological focus is enhancing the pneumatic efficiency (reducing air consumption per unit of power output) of customized motors. This involves sophisticated CFD modeling during the design phase to optimize air passage geometries, vane profiles in rotary vane motors, or piston stroke mechanisms in piston motors, ensuring maximum utilization of compressed air energy tailored to the customer's specified operating pressure and flow rate.

Additive manufacturing (3D printing) represents a significant disruptive technology, particularly for creating prototypes and low-volume, highly complex internal components required for unique customization. This allows manufacturers to quickly test novel geometries or integrate complex features, such as integrated manifolds or cooling channels, that would be prohibitively expensive or impossible to produce using conventional subtractive machining. The ability to utilize specialized lightweight or high-temperature polymers and metals via additive techniques directly supports the demand for motors designed for extreme environmental niche applications.

Furthermore, the incorporation of advanced sensor technology and smart features is becoming standard in high-end customized air motors. Modern motors are often equipped with integrated encoders for precise speed and position feedback, as well as sensors monitoring air pressure, temperature, and vibration. This connectivity facilitates integration into industrial IoT platforms and enables the implementation of AI-driven performance optimization and predictive maintenance strategies, providing valuable operational data back to the end-user and enhancing the overall value proposition of the customized solution.

Regional Highlights

Global demand for customized air motors is geographically diverse, reflecting varying industrial safety standards, manufacturing concentrations, and maturity of process industries. Each region presents unique customization challenges and opportunities based on its specific regulatory environment and technological adoption rates.

- North America (NA): This region commands a significant market share, driven by robust industrial sectors including aerospace and defense, and a high concentration of sophisticated manufacturing requiring precision automation. Strict adherence to OSHA regulations, particularly concerning safety in hazardous locations (HazLoc), mandates the use of specialized, non-electric solutions. Demand is high for custom material configurations (e.g., non-magnetic or stainless steel) and highly integrated pneumatic control systems. The prevalence of established oil and gas extraction industries further fuels the need for customized, high-performance motors capable of operating reliably in harsh extraction and refining environments.

- Europe: Europe is a mature market characterized by stringent environmental and safety regulations, notably ATEX (for explosive atmospheres). This framework necessitates bespoke motor solutions engineered for certified explosive safety zones. Key drivers include the robust chemical, pharmaceutical, and automotive sectors, where high levels of automation demand tailored torque and speed profiles. Germany and the UK are primary consumers, focusing heavily on customization for minimizing compressed air consumption and achieving quiet operation, aligning with regional sustainability goals.

- Asia Pacific (APAC): APAC represents the fastest-growing market globally due to accelerated industrialization, large-scale infrastructure projects, and significant foreign direct investment into manufacturing capabilities, particularly in China, Japan, South Korea, and India. While safety standards are rapidly catching up to Western counterparts, the primary driver for customization here is scaling capacity and adapting motors for local environmental extremes (e.g., high humidity or dust). The automotive sector’s expansion and the growing demand for specialized machinery in mining and construction contribute heavily to the need for cost-effective, customized pneumatic solutions.

- Latin America (LATAM): Growth in LATAM is closely linked to the mining, construction, and nascent petrochemical industries. The demand for customized air motors is centered around ruggedized designs capable of withstanding severe physical strain and intermittent maintenance schedules common in remote operating sites. Brazil and Mexico are the largest markets, focusing primarily on robust piston and vane motor customization for material handling and heavy-duty tooling applications where durability is prioritized over highly advanced efficiency metrics.

- Middle East and Africa (MEA): The MEA market is dominated by the massive oil and gas and petrochemical industries, creating a consistent and essential requirement for customized explosion-proof air motors for pumps, mixers, and drilling equipment. Customization in this region heavily emphasizes extreme temperature resilience (high desert heat), corrosion resistance due to marine environments (offshore rigs), and adherence to international safety certifications (IECEx). Investments in diversification projects also introduce demand from specialized construction and water treatment facilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Customized Air Motors Market.- Ingersoll Rand

- Atlas Copco

- Deprag Schulz GmbH & Co.

- Parker Hannifin Corporation

- Globe Air Motor

- Chicago Pneumatic

- Desoutter Industrial Tools

- Gast Manufacturing

- PTM North America

- Huco Dynatork

- Bosch Rexroth (Pneumatic Solutions)

- Tech-Line

- JRG Reuter

- Pneutorque

- Spitznas

- Fuji Industrial Power Tools

- Rotor Tool (Cleco)

- Airmite Devices

- Rotary Power

- Hilti Corporation (Specialized Pneumatic Tools Division)

Frequently Asked Questions

Analyze common user questions about the Customized Air Motors market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary safety advantages of customized air motors over standard electric motors in hazardous environments?

Customized air motors offer intrinsic safety advantages in hazardous locations (HazLoc) because they operate solely on compressed air, eliminating the risk of electrical sparking, overheating, or ignition sources. Customization ensures the motor materials and sealing systems meet specific explosion-proof certifications (like ATEX or IECEx) tailored precisely to the volatile gases or dusts present in the user's operational zone.

How does customization affect the total cost of ownership (TCO) for air motors?

While the initial procurement cost of a customized air motor is significantly higher than a standard unit, the TCO can be lower over the motor's lifespan. Customization ensures optimal performance, minimizes downtime due to failure in harsh conditions, extends service life through tailored materials, and avoids regulatory fines by ensuring strict safety compliance, leading to long-term operational savings.

Which customization features are most requested by the Food and Beverage industry?

The Food and Beverage sector primarily requests material customization, specifically non-corrosive, hygienic materials like 316L stainless steel casings, and oil-free, food-grade lubrication systems (or completely lubrication-free operation). They also require specialized sealing to withstand rigorous wash-down procedures and temperature customization for use in extreme sterilization processes.

Can customized air motors be integrated into modern Industry 4.0 and IoT platforms?

Yes, high-end customized air motors are increasingly designed with integrated smart sensors (pressure, temperature, speed encoders) that transmit operational data via industrial communication protocols (e.g., IO-Link). This connectivity allows for real-time monitoring, AI-driven predictive maintenance, and seamless integration into larger plant-wide Industrial IoT ecosystems for enhanced process control.

What role does additive manufacturing play in the development of customized air motors?

Additive manufacturing (3D printing) enables rapid prototyping of complex internal components and allows for the creation of unique, optimized motor geometries that are dimensionally tailored to tight space constraints or performance requirements. This technology dramatically reduces lead times and manufacturing costs associated with low-volume, highly complex bespoke air motor designs.

This report provides a comprehensive analysis of the Customized Air Motors Market, detailing growth drivers, technological impacts, and critical segmentation insights for strategic decision-making. The demand for highly specialized, safety-compliant, and high-performance pneumatic solutions ensures sustained market expansion through the forecast period, driven by innovation in design and manufacturing processes.

The detailed competitive landscape assessment indicates that market differentiation hinges less on volume production and more on engineering consultative capabilities and the flexibility to incorporate exotic materials and proprietary sealing technologies. Manufacturers capable of rapid iteration using computational fluid dynamics (CFD) tools coupled with robust supply chain management for specialized components are best positioned to capture high-margin customization projects. The evolution of vane motor technology specifically addresses historical restraints by focusing on materials that minimize friction and wear, allowing for extended duty cycles and reduced maintenance overhead, which are crucial customization metrics for sectors like aerospace tooling and specialized chemical pumping. Furthermore, the rising demand for lightweight portable devices in sectors like construction and industrial maintenance necessitates advanced composite materials in customized motor casings to maximize portability while maintaining torque output, a requirement often unique to specific client workflows.

Strategic planning within the Customized Air Motors Market must account for the growing regulatory stringency across mature markets, particularly regarding noise emission and vibration damping. Customization now frequently includes acoustic enclosure design and proprietary balancing mechanisms to meet strict workplace health and safety standards in confined spaces. This regulatory compliance, while a short-term cost driver, acts as a long-term barrier to entry for smaller, less specialized competitors. The transition towards more sophisticated control interfaces, often requiring specialized proportional pneumatic valves tailored to the custom motor’s air consumption profile, further elevates the technical sophistication required of market participants. These control packages are essential for achieving the precise speed control and rapid response times often demanded by modern automation systems using customized pneumatic power sources.

The energy efficiency paradox remains a central challenge; while air motors are intrinsically safe and durable, their overall system efficiency (from compressor inlet to motor shaft output) is generally lower than electric alternatives. Customization efforts are therefore heavily invested in proprietary porting designs, advanced lubrication systems (including oil-free versions that maintain high performance), and specialized coatings that reduce internal friction. Companies that successfully demonstrate verifiable efficiency gains through bespoke design features gain a significant competitive edge, especially in regions with high energy costs. The mining industry, for example, seeks customized radial piston motors that can deliver maximum torque at low speed, necessitating entirely unique mechanical designs optimized for geological exploration equipment and heavy-duty drilling applications where fail-safe operation is paramount.

Future opportunities are strongly aligned with the global push towards automation in diverse sectors. Small, customized air motors are increasingly integrated into collaborative robots (cobots) where lightweight end effectors are essential. The customization here focuses on ultra-compact size, extreme precision in speed control (often requiring sophisticated gearing and feedback systems), and minimal heat generation, which is a natural advantage of pneumatic motors. Additionally, the medical device sector presents unique, high-value opportunities for customized pneumatic motors used in surgical tools and ventilator systems, demanding materials that can withstand autoclaving (high-heat sterilization) and ensuring zero contamination risk, pushing material science boundaries beyond standard industrial grades.

Regional dynamics continue to emphasize tailored solutions. In the APAC region, while volume manufacturing drives much of the market, the surge in high-tech electronics manufacturing demands miniaturized customized motors for precision assembly and handling of delicate components under cleanroom conditions. This necessitates cleanroom-compatible materials and specialized exhaust systems integrated directly into the motor housing. Conversely, the Middle East’s focus on large-scale infrastructure and energy projects requires large, customized turbine and piston motors for high-pressure fluid transfer and power generation backup systems, emphasizing robustness against dust, sand, and chemical exposure, demanding unique material compositions and sealing approaches that resist environmental degradation over decades of service life.

The competitive strategy involves shifting from selling hardware to providing comprehensive engineered solutions. Leading companies offer extensive pre-sales consultation and post-sales maintenance contracts tailored specifically to the custom motor's unique specifications. This service-centric approach creates strong customer loyalty and high switching costs, consolidating market power among established players. Furthermore, intellectual property protection around proprietary customization algorithms, high-efficiency vane materials, and unique noise reduction technologies becomes a critical differentiator in securing specialized contracts. The strategic acquisition of niche material science firms or advanced precision machining centers by major air motor manufacturers is also a visible trend aimed at vertically integrating key customization capabilities, thereby controlling quality and reducing lead times for complex bespoke orders.

Segmentation by power output is increasingly complex due to variable speed requirements. A customer might require a motor capable of delivering high-speed rotation for an initial task and then shifting to a high-torque, low-speed regime for a secondary operation—all within the same compact footprint. This necessitates customizing internal transmission mechanisms, often involving planetary gears or specialized fluid couplings integrated directly into the pneumatic motor design, representing a significant engineering challenge and a high-value customization offering. The complexity of these integrated systems requires manufacturers to maintain highly specialized software tools for simulation and stress analysis, ensuring the custom assembly maintains its rated lifespan under the highly variable duty cycles common in modern flexible manufacturing environments.

Finally, the customization trend is pushing the envelope for extreme environment tolerance. Customers in deep-sea research or high-altitude aerospace applications require motors that are resistant to intense pressure variations, sub-zero temperatures, or corrosive seawater immersion. This requires utilizing advanced composite fiber windings around metal cores, specialized pressure equalization valves integrated into the motor casing, and non-conventional lubrication techniques that function reliably across broad thermal and pressure ranges. The ability to meet these niche, stringent technical demands is what defines success and market leadership within the highly specialized Customized Air Motors Market, differentiating general suppliers from expert solution providers who drive the market forward through innovation tailored to the most challenging industrial requirements. The investment in research and development remains paramount, focusing particularly on improving the pneumatic circuit design to maximize kinetic energy conversion and minimize residual heat generation, a critical factor when dealing with materials sensitive to temperature fluctuations in confined operational spaces.

The ongoing evolution of materials is perhaps the most critical technological factor underpinning market growth. The utilization of advanced polymers, such as PTFE and PEEK, in internal motor components (like vanes, seals, and rotors) is essential for developing oil-free customized motors, fulfilling the stringent cleanroom requirements of the semiconductor and pharmaceutical industries. These materials offer superior wear resistance and low friction coefficients compared to traditional metallic components, ensuring the custom motor maintains peak efficiency and purity standards throughout its operational life. Furthermore, specialized ceramic bearings are increasingly specified in high-temperature applications where conventional steel bearings fail, demanding customization of the motor housing and mounting assembly to accommodate these non-standard components precisely, ensuring thermal stability and vibration isolation essential for high-precision operations.

The regulatory landscape surrounding compliance and certification often dictates the level and type of customization required. For instance, achieving IECEx certification for Zone 0 requires meticulous documentation and design verification, often leading to bespoke motor casings with specific wall thicknesses, specialized grounding mechanisms, and complex sealing arrays to prevent internal component ingress or external gas penetration. Market leaders leverage dedicated regulatory compliance teams and established partnerships with certification bodies to streamline the approval process for unique, customized designs, offering customers a significant value proposition beyond the hardware itself. This high level of regulatory expertise transforms the supplier from a component vendor into a crucial compliance partner for end-users operating in high-risk sectors.

Downstream market dynamics are increasingly influenced by the need for quick repair and field serviceability of customized units. Since these motors are often integral to critical process infrastructure, manufacturers must customize service kits and documentation specific to the unique bill of materials and assembly procedures of each bespoke unit. This necessitates sophisticated database management systems to track every customized motor delivered globally. The provision of specialized, locally trained technicians capable of handling the intricacies of non-standard pneumatic systems is a vital competitive factor, ensuring minimal Mean Time To Repair (MTTR), which is a key performance indicator for potential customers, especially in remote or difficult-to-access sites like offshore oil platforms or remote mining locations.

Segmentation by technology reveals growing demand for customized air motors utilizing integrated gearbox assemblies to achieve extreme torque multiplication while maintaining a minimal physical footprint. Customization in this area involves designing bespoke gear ratios, utilizing specialized aerospace-grade hardened materials for the gears, and integrating specialized lubrication systems that can handle high radial loads unique to the customer’s application, such as specialized robotic arm actuation or heavy-duty drilling feeds. These complex mechanical customizations are far removed from standard motor offerings and represent the pinnacle of engineering expertise within the pneumatic domain.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager