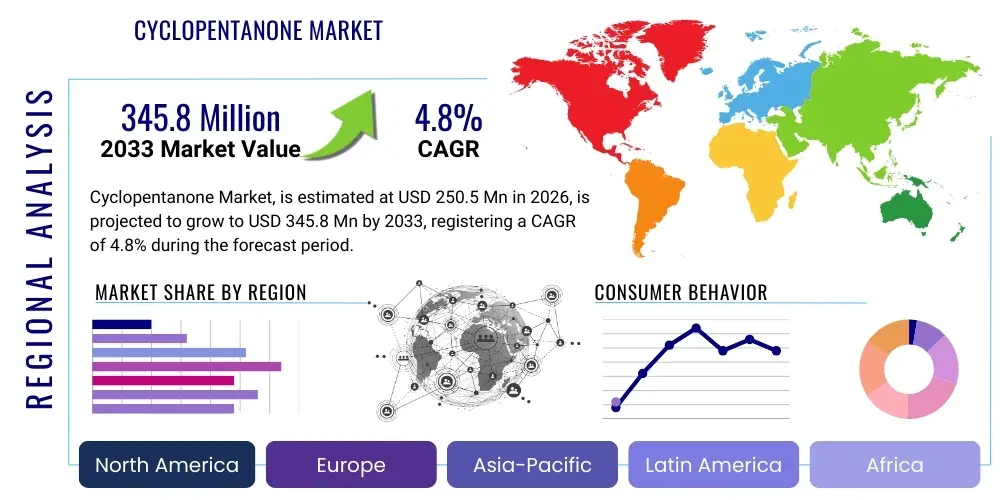

Cyclopentanone Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437153 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Cyclopentanone Market Size

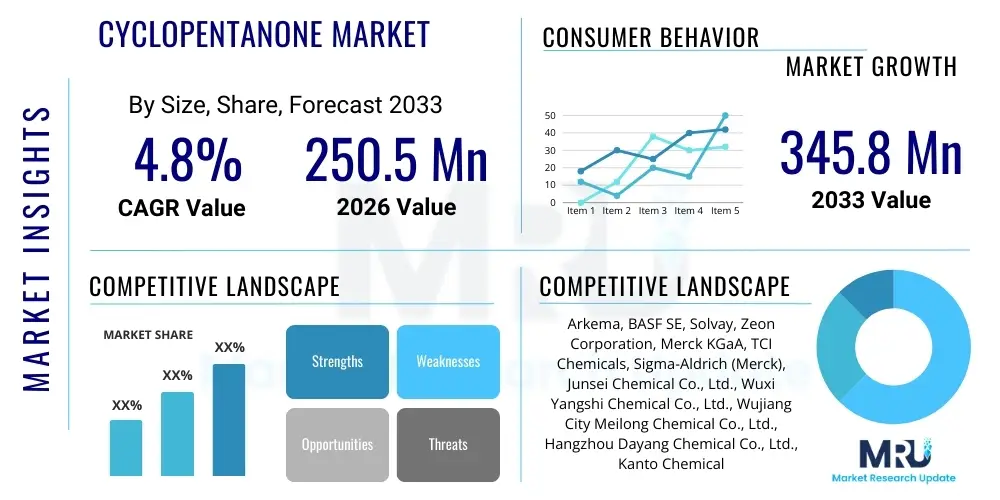

The Cyclopentanone Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 250.5 Million in 2026 and is projected to reach USD 345.8 Million by the end of the forecast period in 2033.

The consistent growth trajectory of the Cyclopentanone market is fundamentally driven by its indispensable role as a critical intermediate in various high-value chemical syntheses, particularly within the fragrance, pharmaceutical, and specialty polymer industries. Cyclopentanone, a cyclic ketone, serves as a versatile building block, enabling the creation of complex molecules used in high-performance applications. The demand surge for fine chemicals and custom synthesis solutions across Asia Pacific, coupled with robust regulatory frameworks standardizing chemical purity in Europe and North America, provides significant momentum for market expansion. Furthermore, continuous innovations in manufacturing processes, such as catalyzed oxidation techniques, are enhancing yield and reducing production costs, making Cyclopentanone more accessible for large-scale industrial use, thereby supporting the projected market valuation increase.

The market expansion is also underpinned by shifting consumer preferences towards sustainable and exotic fragrances, many of which utilize Cyclopentanone derivatives like Jasmone and methyl dihydrojasmonate. As disposable incomes rise in developing economies, the consumption of premium cosmetic and personal care products incorporating these complex fragrance profiles escalates, directly translating into higher demand for the Cyclopentanone intermediate. Stakeholders are heavily investing in capacity expansion and backward integration strategies to secure raw material supply, especially derived from adipic acid or related processes. This structural strengthening of the supply chain, combined with the material's increasing utility in agrochemical formulations as a solvent or reaction precursor, solidifies the market's anticipated growth from its 2026 valuation towards the projected 2033 benchmark.

Cyclopentanone Market introduction

Cyclopentanone is a saturated cyclic ketone characterized by a five-membered ring structure, serving primarily as a key chemical intermediate known for its distinctive odor and high reactivity. This clear, colorless liquid is pivotal in the synthesis of a broad spectrum of derivatives, most notably those utilized in the production of high-grade fragrances, pharmaceuticals, and agricultural chemicals. Its high solvency power and specific chemical structure make it invaluable for creating sophisticated compounds such as prostaglandins, jasmonates (vital components in perfumery), and specialized resins and polymers requiring controlled cross-linking. The inherent stability and functional characteristics of Cyclopentanone ensure its persistent demand across diverse industrial sectors requiring precision chemical synthesis.

Major applications of Cyclopentanone extend across several high-growth domains. In the fragrance industry, it is a precursor to jasmonates, imparting essential floral and jasmine notes to perfumes, soaps, and detergents. The pharmaceutical sector leverages Cyclopentanone in the synthesis of complex active pharmaceutical ingredients (APIs) and drug intermediates, particularly those targeting inflammatory or cardiovascular conditions. Furthermore, it plays a critical role in the agrochemical industry, acting as a solvent and intermediate in the manufacturing of specific herbicides and insecticides, enhancing product efficacy and stability. The versatility afforded by its chemical structure—allowing for facile condensation, alkylation, and reduction reactions—is a key benefit driving its adoption over alternative solvents or precursors.

The market for Cyclopentanone is significantly driven by the accelerating demand for premium personal care products and the rapid expansion of the generic and specialty drug manufacturing base globally, particularly in Asia. The main benefits of using Cyclopentanone include its high purity commercially available and its effectiveness as a precursor for highly specialized, high-value molecules. Driving factors include technological advancements in catalytic production methods that improve yield and sustainability, coupled with the rising consumption of performance polymers and coatings where Cyclopentanone derivatives act as essential cross-linking or modifying agents. Increased regulatory scrutiny demanding high purity intermediates in critical applications further reinforces the market position of certified Cyclopentanone suppliers.

Cyclopentanone Market Executive Summary

The Cyclopentanone market is navigating a dynamic landscape characterized by robust growth in specialty chemical applications, particularly within the Asian industrial hubs. Key business trends indicate a strong focus on green chemistry approaches, with manufacturers exploring bio-based or more environmentally benign synthesis routes to align with global sustainability mandates and reduce reliance on petrochemical feedstocks. Pricing stability remains a crucial factor, influenced heavily by the fluctuating costs of precursor chemicals like adipic acid and the efficiency gains achieved through advanced oxidation catalysis. Strategic alliances between upstream chemical producers and downstream fragrance/API manufacturers are becoming prevalent, aiming to streamline supply chain logistics and ensure consistent quality, signaling a maturation of the global competitive environment.

Regional trends reveal Asia Pacific (APAC) as the primary engine of growth, underpinned by its dominance in global fragrance and pharmaceutical manufacturing capacity, notably in China and India. These countries offer favorable manufacturing conditions and expanding domestic consumption bases for finished goods derived from Cyclopentanone. North America and Europe, while representing established markets, emphasize innovation, focusing on ultra-high-purity grades required for specialized electronics and advanced polymer applications, and maintaining stringent regulatory oversight. This geographical disparity in demand profile—volume-driven in APAC versus value-driven in the West—dictates tailored marketing and production strategies for key market players, influencing investment in regional production facilities and distribution networks to optimize delivery times and cost efficiencies.

Segmentation trends highlight the increasing significance of the Pharmaceutical Grade segment, which commands a premium price due to the stringent purity requirements and regulatory compliance needed for drug synthesis. Furthermore, the application segment focused on fragrance and flavor production continues its established dominance, driven by consistent consumer demand for scented products worldwide. Within technology, the shift away from older, less efficient methods toward highly selective catalytic processes is a defining trend. This technological pivot aims to minimize waste, enhance reaction selectivity, and ultimately reduce the overall environmental footprint associated with Cyclopentanone production, impacting long-term operational costs and segment profitability across the board.

AI Impact Analysis on Cyclopentanone Market

User inquiries regarding AI's influence in the Cyclopentanone domain commonly revolve around questions concerning process optimization, predictive demand forecasting, and accelerated new product discovery (especially novel fragrance molecules). Users are keen to understand how AI-driven reaction modeling can enhance synthesis efficiency, reduce waste streams, and improve product yield in real-time manufacturing environments. Key concerns include the upfront investment required for integrating AI systems into existing chemical plants and the necessary skills gap to manage these sophisticated digital tools. Expectations are high regarding AI's potential to significantly shorten the R&D cycle for pharmaceutical intermediates derived from Cyclopentanone, allowing companies to quickly prototype and scale production of complex molecules with high specificity, thereby offering a strategic competitive advantage in this specialized chemical sector.

- AI-driven optimization of catalytic processes leading to increased Cyclopentanone yield and reduced energy consumption.

- Predictive maintenance analytics applied to synthesis reactors, minimizing unplanned downtime and maximizing asset utilization.

- Enhanced R&D through machine learning models for predicting the biological activity and stability of novel Cyclopentanone-derived compounds (e.g., APIs or agrochemicals).

- Supply chain management optimization using AI for dynamic demand forecasting and optimizing inventory levels of raw materials like adipic acid.

- Automated quality control (AQC) systems utilizing computer vision and spectral analysis for ensuring stringent purity standards, especially for pharmaceutical grades.

- AI modeling to accelerate the discovery of new fragrance molecules utilizing Cyclopentanone precursors, significantly shortening the time-to-market for consumer products.

- Simulation of environmental impact and regulatory compliance checking for new production sites, enhancing sustainable manufacturing practices.

DRO & Impact Forces Of Cyclopentanone Market

The dynamics of the Cyclopentanone market are governed by a complex interplay of driving forces, inherent restraints, and emerging opportunities, collectively shaping the market's projected trajectory. The primary driver is the pervasive and non-substitutable role of Cyclopentanone as a fundamental building block in the high-growth fragrance, flavor, and specialty pharmaceutical industries. This constant need for high-purity intermediates ensures sustained market demand. Concurrently, the increasing stringency of environmental regulations, particularly regarding VOC emissions and waste disposal, acts as a significant restraint, compelling manufacturers to invest heavily in expensive, cleaner production technologies like advanced catalytic methods. The major opportunity lies in the rapid technological advancement and commercialization of bio-based Cyclopentanone derived from renewable sources, which promises to mitigate supply chain risks associated with fossil fuel-derived precursors and appeal to environmentally conscious downstream industries. These factors create strong impact forces across the supply chain, affecting raw material sourcing, capital expenditure, and end-user adoption patterns globally.

Impact forces stemming from geopolitical instability and raw material price volatility present ongoing challenges. Cyclopentanone production relies heavily on precursors such as adipic acid, which itself is subject to fluctuating petrochemical prices. Any disruption in the supply chain of these precursors directly impacts the profitability and stability of Cyclopentanone manufacturers. However, counterbalancing this restraint is the strong opportunity arising from market diversification. Emerging applications in electronics and high-performance material coatings are creating new revenue streams, reducing the market's dependence on traditional end-use sectors like fragrances. Successful market penetration in these niche, high-value applications requires adherence to extremely high purity specifications, driving process innovation and rewarding technologically advanced producers.

Furthermore, the competitive landscape in Asian markets exerts considerable downward pressure on pricing, acting as a constant restraint on profit margins for global players. To mitigate this, companies are focused on optimizing production scale and leveraging economies of scale. The strategic opportunity resides in intellectual property protection for novel synthesis routes and proprietary catalyst systems, which can provide a significant competitive moat against generic manufacturers. Moreover, the long-term impact force of increasing global health consciousness drives steady demand for high-quality pharmaceutical intermediates, securing the future growth potential of the pharmaceutical grade Cyclopentanone segment, despite the challenging regulatory compliance burdens imposed by bodies like the FDA and EMA.

Segmentation Analysis

The Cyclopentanone market is comprehensively segmented based on Purity Level, Application, and Manufacturing Process, reflecting the diverse requirements of end-user industries and the technological heterogeneity in production. Purity Level segmentation, typically categorized into Industrial Grade, Fragrance Grade, and Pharmaceutical Grade, is paramount as it dictates the end-use suitability and corresponding market price. The pharmaceutical segment demands the highest purity (typically >99.9%), imposing rigorous quality control and manufacturing standards, while industrial grades are utilized in bulk applications such as solvent recovery and general chemical synthesis. Understanding these purity requirements is critical for manufacturers to tailor production processes and meet stringent customer specifications across various high-value sectors.

Application segmentation clearly defines the primary demand vectors, with Fragrances and Flavors consistently holding the largest market share due to the widespread use of Cyclopentanone derivatives (like Jasmone) in consumer products globally. The Pharmaceutical segment, though smaller in volume, holds significant value due to the high costs associated with API synthesis. Agrochemicals utilize Cyclopentanone for solvent and intermediate purposes in pesticide and herbicide formulations. The Polymers and Resins segment, while niche, is growing steadily as specialized coatings and engineering plastics increasingly rely on Cyclopentanone as a modifier or solvent, providing specialized performance characteristics like enhanced durability or specific reaction kinetics.

The segmentation by Manufacturing Process is highly relevant from a technological and environmental perspective. Traditional methods, such as the synthesis from adipic acid, are volume-intensive but face scrutiny due to byproduct formation. Newer, Catalytic Oxidation routes are gaining traction due to higher efficiency, better selectivity, and reduced waste generation, aligning with sustainability objectives. Producers are strategically aligning their investment based on these segments, prioritizing high-pmargin, specialized segments (like Pharma Grade) with technologically advanced processes to ensure regulatory compliance and maximize return on investment, while maintaining capacity for bulk industrial demands via optimized conventional routes.

- By Purity Level:

- Industrial Grade

- Fragrance Grade

- Pharmaceutical Grade

- High Purity Grade (for Electronics)

- By Application:

- Fragrances and Flavors

- Pharmaceuticals

- Agrochemicals

- Polymers and Resins

- Chemical Intermediates and Solvents

- By Manufacturing Process:

- Adipic Acid Route

- Cyclohexanol Oxidation

- Cyclopentene Oxidation

- Catalytic Hydrogenation/Dehydrogenation

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East & Africa (MEA)

Value Chain Analysis For Cyclopentanone Market

The Cyclopentanone value chain commences with the upstream analysis, focusing on the sourcing and processing of core raw materials, predominantly adipic acid or cyclohexanol, which are themselves petrochemical derivatives. The stability and cost efficiency of this initial stage are crucial, as raw material costs typically constitute the largest component of the final product price. Key players in the upstream segment include major petrochemical giants who supply these precursors. Efficient procurement, long-term supply contracts, and hedging against price volatility are essential strategies for manufacturers to maintain competitive cost structures in the conversion of these bulk chemicals into high-purity Cyclopentanone intermediates, ensuring a reliable base for the entire downstream structure.

The midstream stage involves the synthesis and purification of Cyclopentanone. This step is characterized by significant capital investment in reaction equipment and advanced purification technologies, such as fractional distillation and chromatography, essential for meeting the stringent purity requirements of fragrance and pharmaceutical applications. Manufacturers must optimize their processes, often employing proprietary catalyst systems and reaction conditions, to maximize yield and minimize energy consumption. The ability to produce multiple grades (Industrial, Fragrance, Pharma) from the same facility dictates the operational flexibility and profitability of the midstream players, focusing on process safety and quality assurance systems compliant with global standards like ISO and cGMP.

Downstream analysis involves the distribution channel and the utilization of the final product by end-user industries. Cyclopentanone reaches its ultimate buyers through two primary channels: direct sales and indirect distribution networks. Direct sales are common for large-volume industrial purchasers and pharmaceutical companies requiring custom specifications and technical support. Indirect channels, involving specialized chemical distributors, cater to smaller manufacturers, research labs, and regional fragrance houses, providing inventory management and localized logistics support. The efficiency of this distribution network, including cold chain logistics for certain high-purity grades, directly impacts the shelf life and accessibility of Cyclopentanone across international markets, emphasizing the role of specialized chemical logistics providers.

Cyclopentanone Market Potential Customers

The primary potential customers and end-users of Cyclopentanone are concentrated within three high-value manufacturing sectors: the fragrance and flavor industry, the pharmaceutical manufacturing sector, and agrochemical producers. Fragrance houses and cosmetic conglomerates are massive consumers, utilizing Cyclopentanone to synthesize key aroma chemicals like methyl dihydrojasmonate, which provides foundational notes for modern perfumes, body lotions, and cleaning agents. These buyers demand consistency in quality (Fragrance Grade) and large volume capacity from their suppliers. The growth in the global luxury goods and personal care market directly translates into increasing procurement volumes from this segment, making them the market's largest revenue drivers.

The pharmaceutical industry represents the second most critical customer segment. Potential buyers include generic drug manufacturers and large biotech firms that use high-purity Cyclopentanone as a reaction solvent or intermediate in the complex, multi-step synthesis of Active Pharmaceutical Ingredients (APIs), particularly prostaglandins, which are sensitive chemical compounds. These customers require ultra-high purity (>99.9%) and impeccable documentation supporting regulatory compliance (e.g., Certificates of Analysis, Batch Records) as mandated by global health authorities. Agrochemical companies, producing pesticides, herbicides, and specialized fertilizers, also form a crucial customer base, relying on Cyclopentanone as an effective solvent and precursor for synthesizing specific biological agents used to enhance crop yield and protection globally.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 250.5 Million |

| Market Forecast in 2033 | USD 345.8 Million |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Arkema, BASF SE, Solvay, Zeon Corporation, Merck KGaA, TCI Chemicals, Sigma-Aldrich (Merck), Junsei Chemical Co., Ltd., Wuxi Yangshi Chemical Co., Ltd., Wujiang City Meilong Chemical Co., Ltd., Hangzhou Dayang Chemical Co., Ltd., Kanto Chemical Co., Inc., Tokyo Chemical Industry Co., Ltd., Shanghai Chemex International Co., Ltd., Jiangsu Aoxin Chemical Co., Ltd., Capot Chemical Co., Ltd., Lier Chemical Co., Ltd., Jining Sanli Chemical Co., Ltd., Hebei Jinchang Chemical Co., Ltd., Wuhan Newradar Chemical Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cyclopentanone Market Key Technology Landscape

The key technology landscape for Cyclopentanone production is currently dominated by two primary methodologies: the conventional route utilizing adipic acid or related derivatives, and emerging, more sustainable catalytic processes. The conventional method, while mature and capable of high volume output, often involves multiple steps and can result in significant byproduct generation, leading to higher purification costs and environmental concerns related to waste streams. Manufacturers employing this technology are heavily focused on optimizing reaction parameters, such as temperature and pressure control, to maximize selectivity and minimize the formation of undesired cyclic byproducts, thereby incrementally improving overall process efficiency and reducing the cost of industrial grade material.

A significant technological shift is observed in the adoption of advanced catalytic oxidation and dehydrogenation techniques, particularly those utilizing transition metal catalysts (e.g., palladium or ruthenium complexes). These modern processes aim for higher atomic efficiency, enabling the direct conversion of precursors like cyclopentene or cyclohexanol with significantly greater selectivity and fewer environmentally harmful steps. This technological advancement is critical for producing the ultra-high-purity Cyclopentanone required by the pharmaceutical and specialized electronics industries, where trace impurities can compromise product integrity. Investment in proprietary catalyst development, often enabled by computational chemistry and AI modeling, is central to gaining a competitive edge, allowing producers to achieve lower energy consumption and better compliance with global green chemistry initiatives.

Furthermore, the technology landscape is being influenced by the nascent development of bio-based synthesis routes, positioning Cyclopentanone within the circular economy framework. Researchers are actively exploring fermentation processes or chemo-catalytic conversion of biomass-derived feedstocks, such as furfural, to produce Cyclopentanone. While currently less cost-competitive than petrochemical routes for bulk production, these bio-technologies represent a critical future pathway. They address the long-term volatility and supply security issues associated with petrochemical reliance. The commercialization challenge lies in scaling these bio-routes efficiently while achieving the requisite purity levels, a focus area for major chemical corporations aiming to diversify their product portfolio with sustainable alternatives and respond to increasing consumer and regulatory pressure for bio-sourced intermediates.

Regional Highlights

- Asia Pacific (APAC): APAC stands as the undisputed epicenter of Cyclopentanone demand and consumption, fueled by the presence of large-scale manufacturing hubs in China, India, and Southeast Asia. The region’s dominance is primarily attributed to its burgeoning fragrance and flavor manufacturing industry, catering to both massive domestic populations and acting as a global exporter of finished consumer goods. Furthermore, the rapid expansion of generic pharmaceutical production and significant investment in new chemical industrial parks facilitate high volume consumption of Cyclopentanone as a key intermediate. The competitive advantage here lies in cost-effective manufacturing and economies of scale, although regulatory oversight regarding environmental discharge is progressively tightening, pushing local manufacturers toward cleaner technologies.

- North America: The North American market is characterized by high demand for pharmaceutical-grade and specialized high-purity Cyclopentanone. This region focuses less on bulk industrial grade production and more on high-value applications, supporting advanced research and development in specialty polymers, electronics, and sophisticated drug synthesis. Stringent quality standards imposed by the FDA and the environmental protection agency (EPA) necessitate the use of premium-priced, high-specification materials, driving manufacturers to maintain impeccable supply chain transparency and product purity. Innovation in sustainable synthesis and the development of new, niche applications are the key strategic focus areas for players operating within the U.S. and Canadian markets.

- Europe: The European Cyclopentanone market is highly regulated, emphasizing sustainability, safety, and traceability under comprehensive frameworks such as REACH. Demand is stable and substantial, particularly within the sophisticated European fragrance houses (France, Germany) and the well-established pharmaceutical sector. European manufacturers are leaders in adopting advanced, eco-friendly synthesis technologies to minimize carbon footprint and waste. High labor and operational costs mean the region is focused on producing high-margin, ultra-pure specialty chemicals rather than competing on volume with Asian counterparts. Strategic investments are centered on maintaining technological leadership and securing stable supply chains from environmentally compliant sources.

- Latin America (LATAM) & Middle East and Africa (MEA): LATAM and MEA represent emerging but high-potential markets. Growth in LATAM is driven by expanding local cosmetic and personal care manufacturing, particularly in Brazil and Mexico, creating increasing demand for fragrance precursors. MEA’s market growth is linked to regional industrial diversification initiatives, primarily in Saudi Arabia and the UAE, involving the setup of new chemical processing facilities and increasing investment in local pharmaceutical and agricultural sectors. While currently reliant on imports, increasing local production capacity in these regions is anticipated over the forecast period, supported by favorable government policies aiming for self-sufficiency in key chemical inputs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cyclopentanone Market.- Arkema

- BASF SE

- Solvay

- Zeon Corporation

- Merck KGaA

- TCI Chemicals

- Sigma-Aldrich (Merck)

- Junsei Chemical Co., Ltd.

- Wuxi Yangshi Chemical Co., Ltd.

- Wujiang City Meilong Chemical Co., Ltd.

- Hangzhou Dayang Chemical Co., Ltd.

- Kanto Chemical Co., Inc.

- Tokyo Chemical Industry Co., Ltd.

- Shanghai Chemex International Co., Ltd.

- Jiangsu Aoxin Chemical Co., Ltd.

- Capot Chemical Co., Ltd.

- Lier Chemical Co., Ltd.

- Jining Sanli Chemical Co., Ltd.

- Hebei Jinchang Chemical Co., Ltd.

- Wuhan Newradar Chemical Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Cyclopentanone market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Cyclopentanone primarily used for in the industry?

Cyclopentanone is primarily utilized as a versatile chemical intermediate, most prominently in the synthesis of specialized fragrance and flavor components, such as jasmonates, which are crucial for the cosmetic and personal care industries. It is also an essential precursor in the production of high-value pharmaceutical intermediates (APIs) and certain agrochemicals.

Which geographical region leads the global demand for Cyclopentanone?

The Asia Pacific (APAC) region currently leads the global demand for Cyclopentanone, driven by the substantial growth of its manufacturing sectors, particularly in fine chemicals, generic pharmaceuticals, and high-volume fragrance production in countries like China and India. This regional dominance is supported by favorable manufacturing economies of scale.

What are the key purity grades of Cyclopentanone available in the market?

Cyclopentanone is commercialized in several purity grades, catering to different industrial needs. The key grades include Industrial Grade (used as a solvent or bulk intermediate), Fragrance Grade (requiring high odor purity), and the highly regulated Pharmaceutical Grade, which mandates the highest purity standards (often >99.9%) for drug synthesis applications.

How is the market influenced by raw material price volatility?

The market is significantly influenced by the price volatility of its primary raw material, adipic acid, which is derived from petrochemical sources. Fluctuations in crude oil prices directly impact the cost structure of Cyclopentanone production, acting as a crucial restraint that affects profitability and requires manufacturers to adopt efficient procurement and hedging strategies.

What technological advancements are shaping the future production of Cyclopentanone?

Future production is increasingly shaped by the adoption of cleaner, more efficient catalytic processes, utilizing advanced transition metal catalysts to enhance yield and selectivity, thereby reducing waste. Additionally, research into bio-based synthesis routes from renewable feedstocks is a critical emerging technology aimed at improving sustainability and reducing reliance on petrochemicals.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Cyclopentanone Market Statistics 2025 Analysis By Application (Fragrance, Pharmaceuticals, Electronics, Rubber, Others), By Type (Electronic grade, Industrial grade, Pharmaceutical grade), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Cyclopentanone Market Statistics 2025 Analysis By Application (Fragrance, Pharmaceuticals, Electronics, Rubber), By Type (Electronic grade, Industrial grade, Pharmaceutical grade), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager