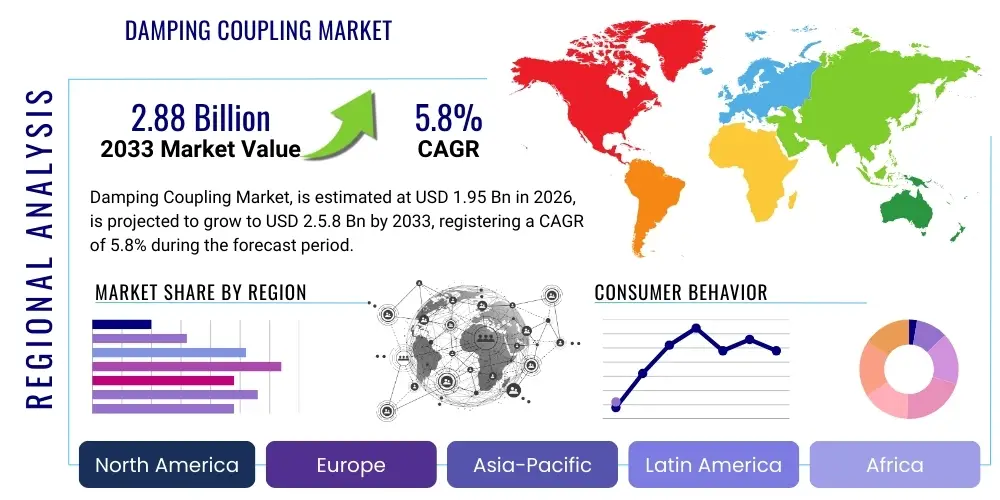

Damping Coupling Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438825 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Damping Coupling Market Size

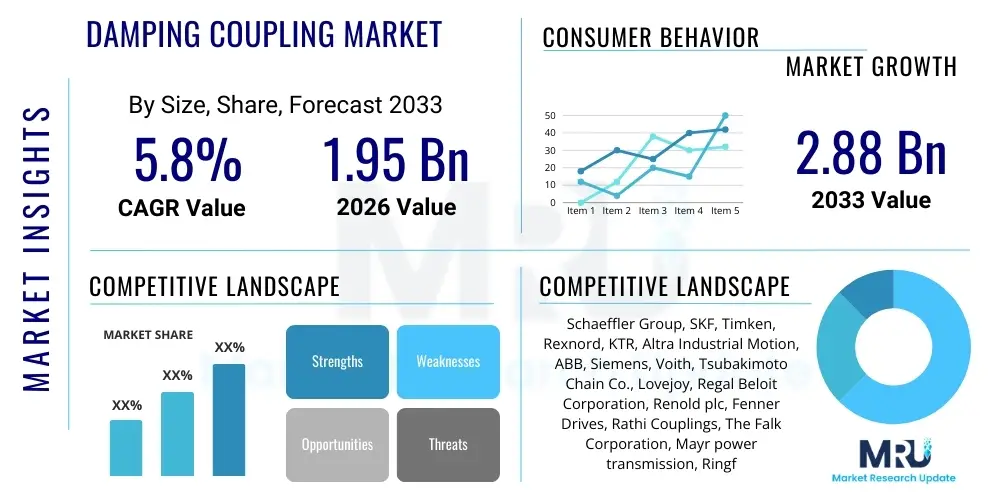

The Damping Coupling Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.95 Billion in 2026 and is projected to reach USD 2.88 Billion by the end of the forecast period in 2033.

Damping Coupling Market introduction

The Damping Coupling Market encompasses mechanical components engineered specifically to connect two rotating shafts while simultaneously absorbing or mitigating operational shock loads, vibrations, and compensating for unavoidable shaft misalignment. These couplings are crucial in high-performance mechanical drive systems where the transmission of torque must be smooth and protected from dynamic disturbances that could lead to premature equipment failure or degraded operational precision. The fundamental design often incorporates viscoelastic materials or specialized geometries, such as fluid or viscous elements, which dissipate kinetic energy, thereby safeguarding expensive machinery and extending service life.

Major applications for damping couplings span across diverse heavy industries, including power generation, oil and gas extraction, material handling, and sophisticated manufacturing processes like CNC machining and robotics. The inherent benefit of utilizing damping couplings is the drastic reduction in operational noise and stress on surrounding components, particularly bearings and seals, which are highly susceptible to fatigue from continuous torsional oscillation. Furthermore, in systems requiring high rotational fidelity, such as aerospace and defense, these components maintain power transmission stability even under severe transient conditions.

The primary driving factors propelling the growth of this market include the increasing global emphasis on predictive maintenance strategies, demanding components that enhance system reliability, and the rapid industrialization in emerging economies, leading to higher installations of heavy machinery. Regulatory pressures in sectors like automotive and aerospace, enforcing stricter standards for noise and vibration reduction, also necessitate the adoption of advanced damping solutions. Moreover, the continuous development of high-performance elastomeric and composite materials is improving the capacity and lifespan of modern damping couplings.

Damping Coupling Market Executive Summary

The global Damping Coupling Market is characterized by robust business trends driven primarily by the shift towards Industry 4.0, which mandates increased machinery uptime and precision control. Key industry participants are focusing heavily on developing smart couplings integrated with sensors for condition monitoring, enabling real-time diagnostics regarding misalignment, temperature, and vibration levels. This technological integration transforms the coupling from a passive component into an active part of the predictive maintenance ecosystem. Furthermore, merger and acquisition activities are prominent, as large industrial conglomerates seek to consolidate technology portfolios and expand geographical reach, particularly into high-growth manufacturing hubs in Asia Pacific.

Regionally, Asia Pacific (APAC) stands out as the highest-growth market, primarily fueled by massive infrastructure investments, expansion of the manufacturing base in China and India, and rising demand in the automotive sector for noise, vibration, and harshness (NVH) reduction technologies. North America and Europe, while mature, maintain strong market shares driven by stringent regulatory frameworks concerning industrial safety and environmental noise, coupled with significant demand for high-end, customized damping solutions in aerospace and defense. These developed regions lead in the adoption of advanced materials and digitalized monitoring solutions.

Segment trends reveal that the industrial machinery sector, including compressors, pumps, and conveyors, remains the largest application segment due to the sheer volume of installations requiring vibration control. In terms of product type, viscous and fluid couplings are experiencing accelerated growth, particularly in high-torque, fluctuating load applications like heavy mining equipment and oil and gas drilling, owing to their superior capability to dissipate high levels of shock energy. Material innovation, especially the utilization of specialized polymers and high-damping elastomers, is driving the performance enhancements across all major segments, allowing couplings to operate reliably under extreme temperature and chemical exposure.

AI Impact Analysis on Damping Coupling Market

Common user questions regarding AI's impact on damping couplings often revolve around how artificial intelligence can optimize coupling design parameters, predict component failure before critical incidents, and automate maintenance schedules based on operational data analysis. Users are particularly interested in whether AI-driven diagnostics can accurately isolate coupling-specific issues versus problems originating from adjacent machinery. The central themes emerging from this user analysis include the expectation of AI enhancing the longevity and efficiency of rotating equipment, the need for standardized data protocols for sensor integration, and the concern over the necessary investment in digital infrastructure to support real-time data processing for maintenance optimization.

AI's primary influence is moving Damping Coupling maintenance from scheduled or reactive to fully predictive models. By analyzing vast datasets generated by integrated sensors (monitoring vibration, torsional stiffness, and temperature), AI algorithms can detect subtle anomalies indicative of impending failure, such as slight changes in viscoelastic behavior or minor increases in misalignment stress. This capability allows operators to intervene precisely when required, minimizing downtime and maximizing the useful life of the coupling and connected equipment, thereby offering substantial operational savings.

Furthermore, AI and machine learning (ML) are being utilized in the design phase itself. ML models can simulate thousands of material combinations and geometry variations against real-world operational profiles (e.g., varying load cycles, temperature extremes) faster and more accurately than traditional finite element analysis (FEA). This drastically shortens the product development cycle for highly customized damping couplings required in specialized high-speed or extreme-environment applications, leading to optimally designed products that intrinsically offer superior damping characteristics and reliability.

- AI-powered Predictive Maintenance: Utilization of ML algorithms to analyze real-time vibration data, predicting coupling failure hours or weeks in advance, optimizing maintenance schedules.

- Optimized Design and Simulation: Use of generative design and ML models to determine ideal material compositions and coupling geometries for specific operational environments.

- Condition Monitoring Integration: AI systems interpret data from embedded sensors (temperature, strain gauges) to assess the remaining useful life (RUL) of the damping element.

- Automated Fault Diagnosis: Distinguishing between coupling degradation and other system faults (e.g., motor imbalance, bearing wear) using advanced pattern recognition.

- Enhanced Inventory Management: Predictive analytics forecast component wear rates across an asset base, allowing manufacturers and end-users to optimize spare parts inventory levels globally.

DRO & Impact Forces Of Damping Coupling Market

The Damping Coupling Market is significantly influenced by several interconnected factors summarized by the Drivers, Restraints, and Opportunities (DRO) framework, which define the scope and intensity of its growth trajectory. The fundamental market drivers stem from the global push for higher industrial efficiency, demanding machinery that can handle increased speeds and torque without compromising reliability. This is further magnified by strict industrial safety regulations, particularly in hazardous environments like petrochemical processing and mining, which mandate vibration control systems to prevent catastrophic failures. The overall impact force driving the market is the irreversible need for asset protection and operational longevity across critical infrastructure.

However, the market faces critical restraints, primarily centered around the high initial cost associated with advanced, customized damping solutions, particularly those utilizing specialized composite materials or integrated sensor technology. Additionally, a lack of standardized testing protocols across various industries for measuring damping performance and material degradation creates complexity for end-users when selecting appropriate couplings. The perceived complexity of installing and aligning high-precision couplings, requiring specialized technical expertise, also acts as a barrier, particularly for smaller operational units.

The opportunities within the sector are vast, driven by technological breakthroughs in material science and digitalization. The rise of hybrid damping couplings, combining the best aspects of fluid and elastomer technologies, opens new market potential in sectors previously reliant on traditional rigid or purely flexible couplings. Furthermore, the burgeoning demand for renewable energy infrastructure, such as large wind turbines and tidal power generators, provides a fertile ground for high-torque, extreme-environment damping solutions. The integration of the Internet of Things (IoT) for remote condition monitoring represents the strongest opportunity for manufacturers to transition from selling components to providing value-added predictive maintenance services, securing long-term revenue streams.

Segmentation Analysis

The Damping Coupling Market segmentation provides a granular view of component demand across various industrial ecosystems, categorized primarily by type, material, application, and end-use. Analyzing these segments is crucial for understanding regional market dynamics and identifying specific niches where technological innovation yields the highest competitive advantage. The diversity in applications, ranging from highly sensitive precision machinery to robust heavy industrial equipment, necessitates a corresponding array of specialized coupling designs, driving the complexity and depth of the market structure.

Segmentation based on Type—such as Fluid, Viscous, Torsional, and Elastomeric Damping Couplings—highlights differing capabilities in torque transmission and shock absorption. For instance, fluid couplings dominate in applications requiring soft start characteristics and continuous shock load dissipation, whereas elastomeric couplings are preferred for their cost-effectiveness and excellent misalignment compensation in medium-duty machinery. The growing sophistication of end-user demands ensures that coupling manufacturers must maintain a comprehensive product portfolio tailored to precise operational requirements regarding temperature, speed, and chemical resistance.

- By Type:

- Fluid Damping Couplings

- Viscous Damping Couplings

- Torsional Damping Couplings

- Elastomeric Damping Couplings (e.g., Rubber, Polyurethane)

- By Material:

- High-Damping Elastomers

- Steel and Cast Iron

- Composites (e.g., Carbon Fiber)

- Plastics and Polymers

- By Application:

- Pumps and Compressors

- Material Handling Equipment (Conveyors, Cranes)

- Industrial Machinery (Machine Tools, Automation Systems)

- Power Generation (Turbines, Generators)

- Oil & Gas Equipment (Drilling, Offshore Platforms)

- Automotive and Transportation

- By End-Use Industry:

- Manufacturing

- Mining and Metals

- Chemical and Petrochemical

- Water and Wastewater Treatment

- Aerospace and Defense

Value Chain Analysis For Damping Coupling Market

The value chain for the Damping Coupling Market begins with the upstream sourcing of specialized raw materials, primarily high-grade steels, advanced composites, and engineered elastomers, which are critical for determining the coupling's performance characteristics. Key suppliers in this stage include specialty chemical companies and precision metal foundries. The quality and stability of these raw material inputs directly influence the manufacturing efficiency and the final product's ability to withstand extreme operating conditions, emphasizing the strong negotiating power of high-quality material providers in this niche market.

The core manufacturing and assembly stage involves precision machining, molding, and balancing operations, where manufacturers transform raw materials into complex, dimensionally accurate coupling components. This stage includes significant investment in R&D for material science integration and advanced testing facilities to ensure products meet international standards for torque capacity and vibration dampening. Distribution follows, encompassing a mix of direct and indirect channels; direct sales are preferred for large, highly customized industrial projects, ensuring technical expertise is readily available during installation and commissioning.

The downstream segment involves interaction with various distribution channels, including specialized industrial distributors, component resellers, and direct supply relationships with major original equipment manufacturers (OEMs). OEMs, particularly in the heavy machinery and automotive sectors, represent a substantial stable market. The final stage involves installation, maintenance, and aftermarket services. Aftermarket services, including replacement parts and condition monitoring solutions, are increasingly important revenue generators, driven by the longevity requirements of industrial assets. Indirect channels often handle standardized, smaller-volume replacement orders, while highly complex damping systems require specialized field service teams from the original manufacturer.

Damping Coupling Market Potential Customers

Potential customers, or end-users, of damping couplings span the entire spectrum of heavy and light industrial operations where power transmission and mechanical integrity are critical. The primary buyers are capital equipment manufacturers (OEMs) who integrate these couplings into their final products, such as industrial gearbox producers, pump manufacturers, and makers of large compressors used in petrochemical facilities. These OEMs seek high-reliability components that minimize warranty claims and enhance the overall performance ratings of their machinery.

Another significant customer base comprises large process industries that operate continuous production lines, including mining, oil and gas, and chemical processing plants. For these customers, the operational cost of unplanned downtime is prohibitively high. They purchase couplings for maintenance, repair, and overhaul (MRO) activities and prioritize products that offer superior lifespan and are compatible with existing condition monitoring systems. Specific purchasing criteria focus on Mean Time Between Failures (MTBF) and ease of replacement.

Furthermore, specialized sectors like aerospace, defense, and power generation represent high-value customers. These buyers require customized, highly engineered damping solutions that meet extremely rigorous specifications for weight, rotational speed, and shock resistance, often purchasing directly from manufacturers that possess specialized certifications and testing capabilities. The core motivation for all these customers is asset protection, efficiency maximization, and compliance with increasingly demanding operational safety standards.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.95 Billion |

| Market Forecast in 2033 | USD 2.88 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Schaeffler Group, SKF, Timken, Rexnord, KTR, Altra Industrial Motion, ABB, Siemens, Voith, Tsubakimoto Chain Co., Lovejoy, Regal Beloit Corporation, Renold plc, Fenner Drives, Rathi Couplings, The Falk Corporation, Mayr power transmission, Ringfeder Power Transmission, Ameridrives International, Zero-Max Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Damping Coupling Market Key Technology Landscape

The technology landscape of the Damping Coupling Market is rapidly evolving, moving beyond traditional mechanical designs toward integrated, smart solutions. A significant trend is the development of advanced material science, particularly in specialized elastomers and polymers that offer superior vibration absorption capacity across wider temperature and chemical exposure ranges. These new generation materials exhibit optimized hysteresis properties, allowing them to dissipate kinetic energy more effectively without rapid structural degradation, thereby significantly improving the Mean Time Between Failures (MTBF) of the coupling components and ensuring operational reliability in demanding environments like subsea oil & gas operations or high-temperature power plants.

Furthermore, the digitalization of coupling technology is a major technological thrust, centered around the integration of smart sensors and IoT connectivity. Modern damping couplings are increasingly fitted with miniature sensors (e.g., accelerometers, proximity sensors, and temperature probes) that continuously monitor key operational parameters. This collected data is processed locally or transmitted wirelessly to centralized diagnostic platforms, enabling sophisticated condition monitoring and predictive maintenance strategies. This shift transforms the coupling from a simple mechanical component into a critical data node within the industrial internet of things (IIoT) ecosystem, providing crucial insights into overall machinery health.

Another area of critical innovation is the refinement of fluid and viscous damping technologies. Manufacturers are developing adaptive fluid couplings that can automatically adjust their stiffness and damping coefficients in response to changing load conditions and rotational speeds. This adaptability ensures optimal performance across a wide operating envelope, minimizing energy loss and maximizing shock absorption capability. Advances in finite element analysis (FEA) and computational fluid dynamics (CFD) are simultaneously enabling engineers to design lighter, more efficient coupling structures that maintain high-torque capacity while reducing rotational inertia, which is crucial for high-speed industrial applications.

Regional Highlights

The Damping Coupling Market demonstrates distinct growth profiles and demand characteristics across the major global regions, reflecting variances in industrial maturity, regulatory environment, and capital investment cycles.

- Asia Pacific (APAC): APAC is the engine of market growth, driven by rapid urbanization, massive infrastructure development, and the expansion of manufacturing bases in China, India, and Southeast Asian nations. High demand originates from the automotive sector for NVH (Noise, Vibration, and Harshness) reduction components and from the massive installed base of industrial machinery and power generation facilities. India and China are key revenue contributors, prioritizing cost-effective yet reliable elastomeric and fluid couplings for heavy-duty applications.

- North America: Characterized by high technological adoption and a focus on premium, engineered solutions. The market is mature but stable, fueled by strong demand from the aerospace, defense, and high-precision manufacturing industries. There is a high propensity for investing in smart couplings with integrated monitoring systems (IIoT compatibility) to minimize labor costs associated with manual inspections and comply with strict operational safety standards.

- Europe: The European market is robust, particularly in Germany, Italy, and the UK, driven by stringent environmental regulations and a focus on energy efficiency. Demand is concentrated in specialized segments, including advanced robotics, renewable energy (offshore wind turbines), and high-speed rail transportation, necessitating sophisticated torsional and viscous damping couplings known for superior precision and longevity.

- Latin America (LATAM): Growth in LATAM is closely linked to fluctuations in the commodity markets, particularly mining and oil and gas. Brazil and Mexico are primary markets where demand is driven by the replacement cycle for heavy mining machinery and petroleum extraction equipment, focusing on durable, heavy-duty couplings that can withstand corrosive and harsh environments.

- Middle East and Africa (MEA): This region's demand is dominated by the massive oil and gas and petrochemical sectors. Investments in new refineries and pipeline infrastructure necessitate high-specification, explosion-proof damping couplings. Government initiatives aimed at diversifying economies also spur demand in emerging manufacturing and logistics hubs, though political instability and reliance on commodity prices remain influencing factors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Damping Coupling Market.- Schaeffler Group

- SKF

- Timken Company

- Rexnord Corporation

- KTR Systems GmbH

- Altra Industrial Motion Corp.

- ABB Ltd.

- Siemens AG

- Voith Turbo GmbH & Co. KG

- Tsubakimoto Chain Co.

- Lovejoy Inc.

- Regal Beloit Corporation

- Renold plc

- Fenner Drives (part of Michelin)

- Rathi Couplings

- The Falk Corporation (part of Rexnord)

- Mayr power transmission

- Ringfeder Power Transmission

- Ameridrives International

- Zero-Max Inc.

Frequently Asked Questions

Analyze common user questions about the Damping Coupling market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a damping coupling in industrial applications?

The primary function is to transmit torque between two shafts while simultaneously mitigating or absorbing operational vibrations, torsional oscillations, and shock loads. This minimizes stress on connected equipment like bearings and gears, significantly extending the system's lifespan and improving operational stability.

How does AI impact the maintenance of damping couplings?

AI enables predictive maintenance by analyzing real-time data from integrated sensors (vibration, temperature). Machine learning algorithms identify subtle patterns indicative of impending component failure, allowing operators to schedule precise interventions and avoid costly, unplanned downtime.

Which type of damping coupling is most suitable for high-torque applications with frequent shock loads?

Viscous or fluid damping couplings are generally most suitable for high-torque applications characterized by frequent, fluctuating shock loads, such as in mining or oil and gas equipment. They use fluid dynamics to smoothly dissipate kinetic energy, offering superior shock absorption capabilities compared to pure elastomeric types.

What major factors are restraining the growth of the damping coupling market?

Key restraints include the high initial cost associated with advanced, custom-engineered damping solutions and the technical complexity involved in precise installation and alignment, which requires specialized expertise and calibration tools.

Which geographical region is expected to exhibit the fastest growth in the Damping Coupling Market?

Asia Pacific (APAC) is projected to exhibit the fastest growth rate, driven by accelerated industrialization, massive infrastructure development projects, and increasing capital investments across the manufacturing, automotive, and power generation sectors in countries like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager