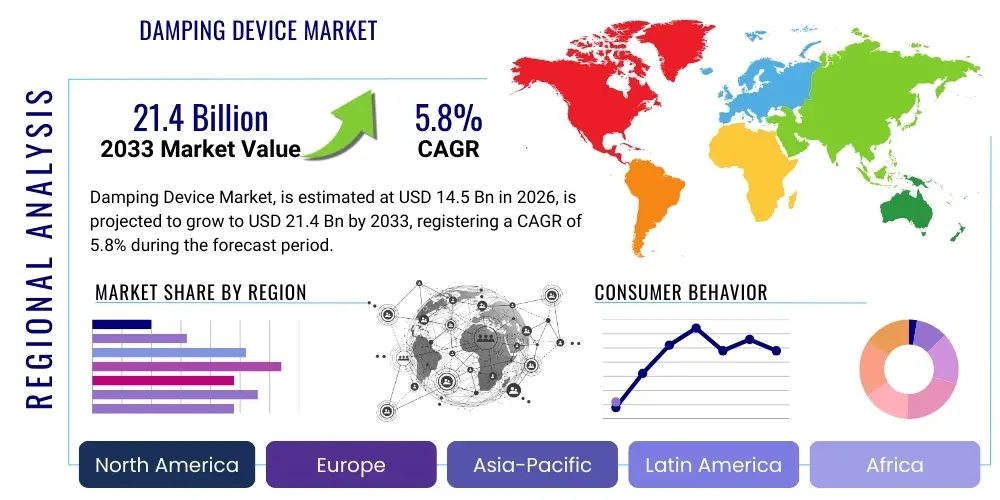

Damping Device Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436176 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Damping Device Market Size

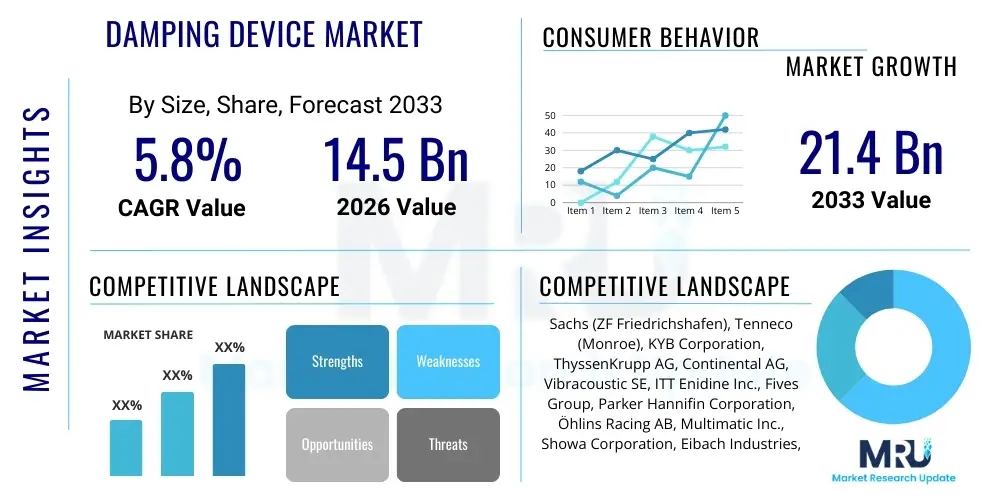

The Damping Device Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 14.5 Billion in 2026 and is projected to reach USD 21.4 Billion by the end of the forecast period in 2033.

Damping Device Market introduction

The Damping Device Market encompasses a broad range of mechanical components designed to absorb and dissipate kinetic energy, primarily used to reduce unwanted oscillations, vibrations, and structural movement within complex systems. These devices are critical for ensuring system reliability, enhancing operational comfort, and protecting structural integrity across various industries. Key products include hydraulic dampers, viscous dampers, pneumatic dampers, and specialized friction and magneto-rheological (MR) damping systems. The primary function involves converting kinetic energy into heat, which is then safely dissipated, thereby preventing destructive resonance and fatigue failures in machinery and civil structures. The fundamental principle driving demand is the increasing necessity for precision, stability, and longevity in modern engineering applications, particularly those exposed to dynamic loads or seismic activity. Given the continuous pursuit of higher performance and safety standards, the integration of advanced damping technologies is becoming a non-negotiable requirement for manufacturers globally.

Major applications of damping devices span diverse sectors, most notably in the automotive industry where they are integral components of suspension systems, improving vehicle handling, safety, and passenger comfort. In civil engineering, massive dampers are deployed in skyscrapers, bridges, and critical infrastructure to mitigate the effects of wind load and earthquakes, ensuring structural resilience and preventing catastrophic failure. Furthermore, industrial machinery, including robotics, packaging equipment, and heavy manufacturing presses, utilize damping devices to increase operational speed, reduce noise, and prolong the lifespan of sensitive components by minimizing shock loads and excessive vibration. The versatility and customization capability of these devices—ranging from miniature rotational dampers used in consumer electronics to massive tuned mass dampers in high-rise buildings—underscore their pervasive influence on modern technology and engineering practices.

The market is currently being driven by several macro-environmental factors, including rapid urbanization, which necessitates the construction of taller and more resilient buildings, and the global surge in automotive production, particularly in emerging economies where road infrastructure is often challenging. Moreover, stringent regulatory mandates concerning occupant safety and equipment longevity across various jurisdictions are compelling industries to adopt high-performance damping solutions. Benefits derived from deploying these technologies include superior shock absorption, improved equipment uptime, enhanced structural stability against external forces, and overall reduction in operational noise levels. These tangible advantages are fueling the continuous investment in research and development aimed at creating smarter, more efficient, and maintenance-free damping systems that utilize advanced materials and control algorithms.

Damping Device Market Executive Summary

The Damping Device Market is characterized by robust expansion, primarily propelled by escalating infrastructural development worldwide and the burgeoning demand for enhanced vehicle safety and comfort systems. Current business trends indicate a significant shift towards smart and adaptive damping solutions, such as semi-active and active systems utilizing magneto-rheological fluids or electronically controlled valves, allowing for instantaneous adjustment to changing load conditions or road surfaces. This technological evolution is fostering higher average selling prices and driving growth in the premium segment. Furthermore, manufacturers are focusing on miniaturization and lightweight materials, crucial for applications in aerospace and high-speed rail, where weight reduction directly translates to energy efficiency gains. Competitive intensity remains high, with established players leveraging deep R&D capabilities to offer specialized products compliant with increasingly strict performance standards across major application sectors.

Regionally, the Asia Pacific (APAC) market is exhibiting the highest growth rate, primarily attributed to massive investments in infrastructure projects, including high-speed railways, residential complexes, and commercial skyscrapers, particularly in China and India. The burgeoning automotive manufacturing base in countries like South Korea, Japan, and India further solidifies APAC's dominant position in consumption and production volume. North America and Europe, while mature, remain crucial centers for innovation, focusing heavily on replacing aging infrastructure with resilient, damped structures and integrating sophisticated damping systems into electric vehicle (EV) platforms. These established markets are defined by high regulatory scrutiny and a strong preference for high-durability, long-lifecycle products, favoring specialized hydraulic and viscous damping technologies designed for extreme environmental conditions.

Segment-wise, the market sees hydraulic dampers maintaining the largest market share due to their proven reliability, high load-bearing capacity, and cost-effectiveness, making them indispensable in heavy machinery and construction. However, the fastest growth is observed in the segment of specialized dampers, particularly those based on magneto-rheological (MR) technology, driven by their ability to offer real-time variable damping capabilities critical for high-performance applications like Formula 1 racing or advanced seismic protection systems. In terms of application, the automotive segment consistently leads, but the civil engineering and infrastructure protection segment is experiencing a significant acceleration in adoption, especially in earthquake-prone zones, reflecting the heightened global awareness regarding resilience engineering and disaster mitigation planning.

AI Impact Analysis on Damping Device Market

User inquiries regarding AI's impact on the Damping Device Market predominantly revolve around three core themes: predictive maintenance efficiency, optimization of damping system design, and the development of truly smart, autonomous control systems. Users frequently ask if AI can eliminate unscheduled downtime by forecasting damper failures based on real-time vibration data, and how machine learning algorithms are utilized to tailor dynamic responses, moving beyond traditional semi-active controls. A major concern is the practicality and cost-effectiveness of integrating complex AI hardware and software into existing industrial and automotive damping mechanisms. Overall, the expectation is that AI will transform damping from a reactive mechanical process into a predictive, fully integrated component of a larger system, enhancing overall structural health monitoring (SHM) and operational reliability across demanding environments like smart factories and next-generation transportation networks.

The integration of Artificial Intelligence fundamentally alters the operational paradigm of damping devices, shifting the focus from fixed performance curves to adaptive, real-time response mechanisms. AI algorithms, particularly those utilizing deep learning, can process vast quantities of sensor data (accelerometers, displacement sensors, temperature readings) instantaneously. This capability allows the damping device’s control unit to predict impending road conditions, wind load fluctuations, or structural stresses milliseconds before they fully materialize, enabling proactive adjustment of the damping force. This predictive capability significantly optimizes performance, maximizes energy absorption efficiency, and drastically reduces the wear and tear on the system, thereby extending the service life of the components and reducing maintenance intervals, which is a major cost saving for large infrastructure owners.

Furthermore, AI is increasingly being applied during the design and simulation phase of new damping systems. Generative design techniques powered by machine learning allow engineers to explore thousands of optimized design iterations, testing parameters like fluid viscosity, valve geometry, and material elasticity against hundreds of simulated load scenarios that would be impossible or too time-consuming using conventional methods. This accelerates product development cycles and leads to the creation of lighter, more efficient, and highly customized damping solutions tailored precisely to specific application requirements, such as optimizing the stiffness-to-weight ratio for aerospace landing gear or tailoring seismic dampers for a specific geological hazard zone. The market anticipates that AI-driven quality control will also improve manufacturing precision, ensuring every unit adheres strictly to highly complex performance specifications.

- AI-driven predictive maintenance optimizes service schedules, reducing unplanned equipment downtime in critical infrastructure.

- Machine Learning (ML) algorithms enable sophisticated real-time adjustment of semi-active and active damping forces based on environmental input.

- AI enhances structural health monitoring (SHM) systems by correlating vibration signatures with long-term structural integrity data.

- Generative design accelerates the development of optimized, lightweight, and customized damper geometries and material compositions.

- AI facilitates advanced fault detection and diagnostics within complex electromechanical damping systems, improving reliability.

DRO & Impact Forces Of Damping Device Market

The Damping Device Market is significantly influenced by a dynamic interplay of Drivers (D), Restraints (R), and Opportunities (O), shaped by underlying Impact Forces. A key driver is the globally increasing emphasis on structural safety and resilience, particularly in seismically active regions and areas prone to extreme weather events, which mandates the use of robust seismic isolation and vibration control technologies in civil construction. This is compounded by the rapid expansion of the automotive sector, focusing on manufacturing vehicles with superior ride comfort and handling stability, achieved through advanced suspension damping systems. However, market growth faces restraints, primarily related to the relatively high initial capital expenditure required for installing sophisticated active and semi-active damping systems, particularly in older infrastructure, and the complexity associated with the specialized maintenance and integration of MR fluid technologies. The market is simultaneously presented with significant opportunities arising from the development of IoT-enabled smart dampers capable of remote monitoring and diagnostics, and the untapped potential in emerging markets in Southeast Asia and Latin America, which are rapidly modernizing their transportation and building infrastructure.

The industry is currently subject to high impact forces stemming from regulatory pressure and technological evolution. Global standardization bodies are continuously raising the bar for safety and performance in construction and automotive manufacturing, forcing companies to invest heavily in advanced R&D to meet these stringent requirements. Furthermore, competitive rivalry is fierce, pushing prices down in the high-volume standard damper segments while simultaneously fostering intense innovation in niche, high-margin areas like aerospace and specialized machinery. Supplier power remains moderate, as key components like specialized hydraulic fluids, precision seals, and sensor technology are often sourced from specialized vendors, but manufacturers maintain control through proprietary design and assembly techniques. Buyer power is segmented; while large Automotive OEMs exert strong influence over pricing, specialized civil engineering firms often prioritize performance and compliance over cost, balancing the impact forces.

Market dynamics suggest that the primary opportunity lies in the digitalization of damping solutions. Developing integrated hardware and software packages that provide holistic structural health monitoring, utilizing cloud connectivity and edge computing, offers a significant value-add beyond simple mechanical energy dissipation. Furthermore, sustainability considerations are becoming a major force; the development of eco-friendly damping fluids and the use of lighter, recyclable materials in damper construction present long-term strategic advantages. The market must navigate the restraint imposed by skilled labor shortages required for the installation and maintenance of complex electronic damping systems, necessitating focused training and automation solutions to mitigate this operational challenge and fully capitalize on the identified opportunities for digitalization and expansion into new infrastructure segments.

Segmentation Analysis

The Damping Device Market is comprehensively segmented based on Type, Application, and End-User, reflecting the diverse requirements and technological variations across industries. Segmentation by Type distinguishes between traditional passive systems, which rely on mechanical components and fluid properties, and modern active or semi-active systems, which incorporate electronic controls and external energy sources for real-time adjustments. Application segmentation identifies the primary sectors utilizing these devices, with infrastructure/civil engineering, automotive, and industrial machinery being the most prominent consumers. This granular segmentation allows market participants to tailor their offerings, marketing strategies, and R&D investments toward segments exhibiting the highest growth potential or requiring specialized technical expertise, thereby maximizing market penetration and achieving optimized resource allocation within a highly competitive landscape.

- By Type:

- Hydraulic Dampers (Largest Share)

- Viscous Dampers

- Pneumatic Dampers

- Friction Dampers

- Magneto-Rheological (MR) Dampers (Fastest Growth)

- Active Damping Systems

- Passive Damping Systems

- Semi-Active Damping Systems

- By Application:

- Automotive (Suspension, Engine Mounts, Cabin Control)

- Civil Engineering and Infrastructure (Bridges, Skyscrapers, Dams, Seismic Isolation)

- Industrial Machinery (Robotics, Conveyors, Packaging Equipment, Machine Tools)

- Aerospace and Defense (Landing Gear, Ejection Seats, Flight Control Surfaces)

- Railway (Bogie Suspension, Inter-car Dampers)

- Consumer Electronics and Appliances

- By End-User:

- Original Equipment Manufacturers (OEMs)

- Aftermarket and Maintenance, Repair, and Operations (MRO)

- Construction and Engineering Firms

- Government and Public Sector

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, U.K., France, Italy)

- Asia Pacific (China, Japan, India, South Korea)

- Latin America (Brazil, Argentina)

- Middle East and Africa (MEA) (GCC Countries, South Africa)

Value Chain Analysis For Damping Device Market

The value chain for the Damping Device Market begins with the sourcing of specialized raw materials, including high-grade steel and aluminum alloys for casings and rods, specific polymers and elastomers for seals, and specialized damping fluids (hydraulic oils, silicone oils, or MR fluids). The upstream segment is dominated by chemical and metallurgical suppliers who must adhere to rigorous quality control standards to ensure the durability and performance characteristics of the final damping unit. The efficiency and pricing of these upstream components significantly influence the final product cost and manufacturing lead times. Manufacturers then focus on precision machining, assembly, and rigorous testing, incorporating proprietary designs for piston valves and fluid channels, which represents the core value addition stage involving high levels of intellectual property and technical expertise, ensuring the damper meets the precise force-velocity curve specified by the client, particularly for highly sensitive applications like seismic protection or Formula 1 suspension.

The distribution channel is multifaceted, relying heavily on both direct and indirect networks depending on the customer segment. For large Original Equipment Manufacturers (OEMs), particularly in the automotive and aerospace sectors, direct sales and long-term supply contracts are the prevalent model, fostering tight integration between the damper manufacturer and the end-product assembler for design collaboration and quality assurance. Conversely, the aftermarket segment and specialized MRO buyers are serviced through indirect channels, including specialized industrial distributors, automotive parts wholesalers, and engineering supply houses. This two-pronged approach ensures that manufacturers can efficiently handle high-volume OEM contracts while maintaining broad accessibility for replacement parts and smaller, specialized orders, crucial for maximizing market reach and minimizing inventory costs across the supply chain.

Downstream analysis highlights the critical role of installers and system integrators, especially in civil engineering where specialized construction firms are responsible for the complex installation and calibration of large-scale seismic and wind dampers in high-rise buildings and bridges. The performance validation at this stage is crucial, often requiring sophisticated monitoring systems to confirm operational efficiency post-installation. The aftermarket and maintenance services also contribute substantial value, ensuring the longevity and continued high performance of deployed damping systems. The profitability across the value chain is largely concentrated in the manufacturing and design stage, particularly for companies holding patents on advanced damping technologies like MR fluid systems or adaptive valve mechanisms, which command higher margins due to their superior performance characteristics and technological exclusivity.

Damping Device Market Potential Customers

The primary customers for damping devices are Original Equipment Manufacturers (OEMs) across critical industries, ranging from global automotive giants to specialized aerospace and heavy machinery manufacturers. Automotive OEMs constitute the largest segment, requiring vast quantities of hydraulic and gas dampers for suspension systems in passenger vehicles, commercial trucks, and two-wheelers. These customers prioritize mass-production capabilities, cost-efficiency, and strict adherence to global safety and performance standards (e.g., ISO, FMVSS). Their purchasing decisions are often based on long-term supplier relationships, technological collaboration, and the ability of the damper to enhance vehicle attributes like ride quality and dynamic handling, directly impacting the final consumer appeal of their product lineups. Securing these large OEM contracts guarantees stable, high-volume revenue streams for damper manufacturers over extended periods.

Another significant customer base resides within the Civil Engineering and Construction sector, specifically major infrastructure developers and specialized engineering procurement and construction (EPC) firms focused on high-value, high-risk projects. These customers require highly specialized, large-scale damping solutions such as Tuned Mass Dampers (TMDs) and seismic isolation bearings for mitigating forces in bridges, skyscrapers, nuclear facilities, and critical governmental buildings. Unlike automotive OEMs, these buyers prioritize absolute reliability, high durability (often requiring a 50+ year operational lifespan), and compliance with rigorous local seismic codes and structural engineering specifications. Decisions in this segment are less price-sensitive and more focused on technical consultancy, validated performance data, and the proven track record of the supplier in handling complex structural challenges, often necessitating customized engineering solutions rather than off-the-shelf products.

Industrial machinery and robotics manufacturers form a rapidly growing cohort of potential customers. Companies producing automated production lines, CNC machinery, high-speed printers, and sensitive measuring equipment require precision miniature and high-cycle-rate dampers to absorb energy generated during rapid motion cycles, protect sensors, and ensure positional accuracy. These end-users demand dampers that offer extremely repeatable performance with low heat generation and minimal maintenance requirements, essential for sustaining high throughput and quality control in factory automation environments. Additionally, the Maintenance, Repair, and Operations (MRO) segment, consisting of various service providers and fleet operators, represents a continuous demand for replacement parts, particularly standard hydraulic and friction dampers that wear out during the normal operational life cycle of vehicles and industrial equipment, ensuring a steady, though cyclical, revenue flow for the aftermarket service providers within the value chain.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 14.5 Billion |

| Market Forecast in 2033 | USD 21.4 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sachs (ZF Friedrichshafen), Tenneco (Monroe), KYB Corporation, ThyssenKrupp AG, Continental AG, Vibracoustic SE, ITT Enidine Inc., Fives Group, Parker Hannifin Corporation, Öhlins Racing AB, Multimatic Inc., Showa Corporation, Eibach Industries, S&S Cycle, Mando Corporation, Trelleborg AB, ACE Controls Inc., Taylor Devices Inc., Nippon Power Systems, and Alstom SA |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Damping Device Market Key Technology Landscape

The technological landscape of the Damping Device Market is rapidly evolving, driven primarily by the need for higher performance, reduced maintenance, and greater adaptability to dynamic operating conditions. The most significant technological advancements are centered around the development and refinement of semi-active and active damping systems. Semi-active technologies, such as those utilizing Magneto-Rheological (MR) fluids, allow for instantaneous changes in fluid viscosity and, consequently, damping force when an electromagnetic field is applied. This capability enables systems to respond dynamically to input from sensors monitoring road surfaces or structural oscillations, offering a superior blend of control and comfort compared to traditional passive systems. Further innovation in these systems focuses on miniaturizing sensors, improving power efficiency of the control units, and developing more stable and less temperature-sensitive MR fluids that extend operational ranges and reliability, which is crucial for safety-critical applications like advanced automotive suspension or large-scale seismic vibration absorbers.

Another crucial technological frontier involves material science advancements and manufacturing precision. The shift towards lightweighting, particularly in the automotive and aerospace industries, compels manufacturers to utilize advanced materials like high-strength aluminum alloys and carbon fiber composites for damper housings and piston rods, reducing unsprung mass without compromising structural integrity or heat dissipation capabilities. Simultaneously, advanced manufacturing techniques, including precision honing and surface treatments for internal components, are essential to minimize friction losses, enhance sealing efficiency, and ensure extremely consistent performance characteristics across large production runs. The convergence of superior materials with sophisticated computational fluid dynamics (CFD) modeling during the design phase allows for the creation of hydraulic valve systems that offer finely tuned damping curves, improving energy absorption capacity while maintaining smooth operation under extreme high-cycle conditions, a critical requirement for modern industrial automation systems.

Furthermore, the integration of smart technologies is defining the next generation of damping devices. Key technological developments include embedded sensors (IoT capabilities) for continuous structural health monitoring (SHM), allowing for real-time remote diagnostics and predictive maintenance scheduling. These smart dampers are not merely mechanical components but sophisticated nodes within a larger control network. For instance, in seismic applications, interconnected dampers can communicate with a central control system to coordinate their responses, optimizing overall structural stability during an earthquake. The increasing sophistication of the electronic control units (ECUs) and the algorithms running on them—many of which now incorporate machine learning—are central to this trend, pushing the boundaries of what is possible in real-time vibration and shock mitigation across civil, industrial, and transportation engineering domains, ensuring resilience and operational uptime across highly regulated environments globally.

Regional Highlights

Regional dynamics play a crucial role in shaping the Damping Device Market, with distinct growth drivers and technological adoption patterns observed across major geographies. The analysis below highlights key regional characteristics, emphasizing the areas of highest growth potential and technological maturity.

- Asia Pacific (APAC): APAC represents the largest and fastest-growing market globally, driven primarily by massive investments in public infrastructure and the booming automotive manufacturing sector. Countries like China, India, and Southeast Asian nations are undergoing rapid urbanization, necessitating extensive construction of high-rise buildings and modern transportation networks, including high-speed rail, where sophisticated seismic and vibration control technologies are mandatory. The significant growth in middle-class disposable income is fueling higher demand for passenger vehicles equipped with advanced suspension systems, further boosting the consumption of hydraulic and semi-active dampers. This region is also becoming a major global manufacturing hub for standard and specialized damping devices, benefiting from lower production costs and vast domestic demand, making it a critical focus area for global market players seeking long-term volume expansion.

- North America: North America is characterized by high technological maturity and significant expenditure on advanced R&D. The demand here is largely concentrated in high-performance segments, including aerospace, defense, and specialized high-end automotive manufacturing. The region is also heavily invested in upgrading and maintaining aging infrastructure, driving the demand for specialized, high-durability viscous and hydraulic dampers for bridges and complex architectural structures. A strong regulatory environment, coupled with the early adoption of active and semi-active technologies, positions North America as a leader in terms of value contribution per unit, focusing on integration with structural health monitoring systems and predictive maintenance protocols.

- Europe: Europe holds a strong position, driven by stringent vehicle safety and environmental regulations, pushing automotive manufacturers towards implementing advanced, lightweight damping systems that contribute to fuel efficiency and superior occupant safety. Germany, France, and the UK are key contributors, particularly in the high-end vehicle and precision industrial machinery segments. The European market also shows a significant focus on railway applications, demanding high-reliability primary and secondary suspension dampers for extensive high-speed rail networks. Regulatory requirements concerning noise reduction and vibration isolation in industrial settings further solidify the sustained demand for high-quality, long-life damping solutions across the continent.

- Latin America (LATAM): The LATAM market is experiencing steady growth, fueled by infrastructure revitalization projects and expanding local automotive assembly operations, particularly in Brazil and Mexico. While cost sensitivity remains higher than in developed markets, the increasing incidence of infrastructure damage due to seismic activity or unstable ground conditions is slowly shifting priorities toward investing in basic seismic and structural vibration control technologies. Demand is predominantly for reliable, cost-effective hydraulic and passive viscous dampers suitable for local operational environments.

- Middle East and Africa (MEA): The MEA region is witnessing growth driven by mega-construction projects, especially in the GCC states (UAE, Saudi Arabia, Qatar) where high-profile skyscrapers and complex architectural designs require world-class wind and seismic damping solutions. Oil and gas infrastructure maintenance also creates consistent demand for specialized heavy-duty industrial dampers used in pipelines, drilling equipment, and refineries to manage high loads and corrosive environments. Africa’s increasing urbanization and infrastructure development, albeit from a lower base, offer long-term potential for standard damping solutions in both construction and affordable automotive segments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Damping Device Market.- Sachs (ZF Friedrichshafen)

- Tenneco (Monroe)

- KYB Corporation

- ThyssenKrupp AG

- Continental AG

- Vibracoustic SE

- ITT Enidine Inc.

- Fives Group

- Parker Hannifin Corporation

- Öhlins Racing AB

- Multimatic Inc.

- Showa Corporation

- Eibach Industries

- S&S Cycle

- Mando Corporation

- Trelleborg AB

- ACE Controls Inc.

- Taylor Devices Inc.

- Nippon Power Systems

- Alstom SA

Frequently Asked Questions

Analyze common user questions about the Damping Device market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between passive, semi-active, and active damping systems?

Passive systems use fixed mechanical resistance and fluid properties without external control. Semi-active systems, like MR dampers, can adjust their damping force in real-time based on external sensor input but do not add energy. Active systems use external power sources to generate precise forces, effectively acting against vibrations, offering the highest level of control and performance.

Which application segment holds the largest share in the Damping Device Market?

The automotive industry currently holds the largest market share, driven by the massive volume requirement for vehicle suspension systems, engine mounts, and seating isolation devices necessary to ensure vehicle safety, performance, and overall ride comfort across all vehicle classes globally.

How is the Damping Device Market impacted by advancements in civil engineering?

Civil engineering advancements are driving demand for specialized, large-scale damping devices, particularly seismic dampers and tuned mass dampers (TMDs), crucial for protecting high-rise structures, long-span bridges, and critical infrastructure against wind loads and earthquake forces, ensuring structural resilience and longevity.

What are Magneto-Rheological (MR) dampers and why are they considered high growth?

MR dampers use a fluid whose viscosity instantly changes when exposed to an electromagnetic field. They are high growth because they provide semi-active control with millisecond response times, offering a cost-effective and reliable alternative to fully active systems for high-performance automotive and precision industrial applications requiring variable damping characteristics.

Which geographic region is projected to exhibit the fastest growth in the Damping Device Market?

The Asia Pacific (APAC) region is projected to exhibit the fastest market growth, primarily due to large-scale infrastructure investments, rapid urbanization, and the corresponding growth in automotive and manufacturing sectors across countries such as China, India, and various developing economies in Southeast Asia.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager