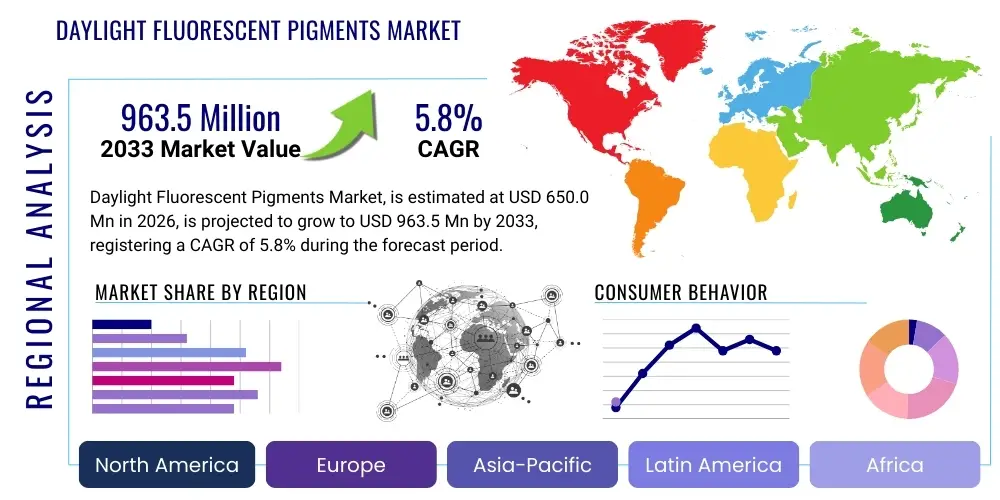

Daylight Fluorescent Pigments Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438969 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Daylight Fluorescent Pigments Market Size

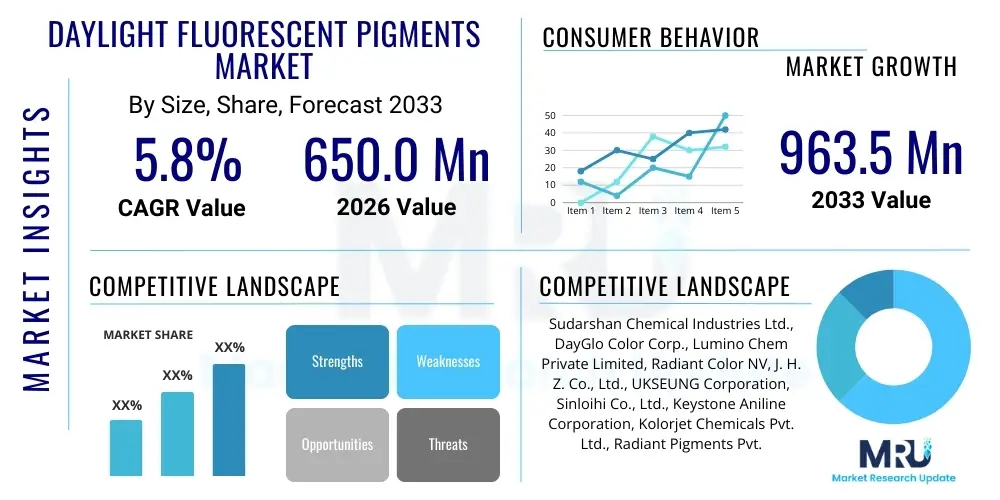

The Daylight Fluorescent Pigments Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 650.0 million in 2026 and is projected to reach USD 963.5 million by the end of the forecast period in 2033.

Daylight Fluorescent Pigments Market introduction

The Daylight Fluorescent Pigments Market encompasses the production and distribution of specialized pigments that exhibit intense coloration under ambient light and, crucially, possess the characteristic of luminescence when exposed to ultraviolet (UV) or short-wavelength visible light. These organic, synthetic pigments absorb light energy and re-emit it almost instantaneously at longer wavelengths, leading to their distinctively brilliant and eye-catching appearance. The unique visual intensity of these pigments makes them invaluable in applications where high visibility, differentiation, and aesthetic impact are paramount. They are distinct from traditional, non-fluorescent pigments due to their superior chroma and brightness, often appearing 3 to 4 times more intense than their conventional counterparts.

Daylight fluorescent pigments are utilized across a wide spectrum of industries, driven by their performance characteristics in demanding environments. Major applications include safety signage, high-visibility clothing (PPE), textiles, printing inks, paints and coatings, plastics, and cosmetic formulations. In the safety sector, they are crucial for ensuring compliance with visibility standards in construction, traffic management, and emergency services. Furthermore, the robust growth of the packaging and consumer goods sectors, particularly in branding and decorative printing, heavily relies on these pigments to achieve standout visual differentiation on crowded retail shelves. The inherent complexity in formulating and stabilizing these pigments ensures that manufacturers with specialized processing capabilities maintain a competitive edge in quality and performance.

The primary driving factors for market expansion include stringent global safety regulations mandating the use of high-visibility materials, increasing infrastructure development requiring durable road markings and safety barriers, and the relentless demand from the fashion and textile industries for vivid, distinctive color palettes. Additionally, continuous advancements in pigment encapsulation technology and particle size reduction are enhancing the durability, lightfastness, and applicability of these pigments across new substrate types, further broadening their market penetration. The shift towards solvent-free and eco-friendly formulations, responding to global regulatory pressures concerning volatile organic compounds (VOCs), also acts as a key market propellant, pushing innovation toward water-based and compliant pigment systems.

Daylight Fluorescent Pigments Market Executive Summary

The Daylight Fluorescent Pigments Market is undergoing robust expansion, driven primarily by evolving safety standards and significant industrial demand across Asia Pacific (APAC) economies. Current business trends indicate a strong move towards environmentally sustainable products, particularly water-based and low-VOC pigment systems, positioning manufacturers who invest in green chemistry research for substantial growth. Furthermore, the consolidation of key players focusing on vertical integration to control raw material quality and supply chain resilience is a defining characteristic of the competitive landscape. Innovation in product stability, especially increasing resistance to fading (lightfastness) and heat resistance for specialized polymer processing, is critical for sustained market relevance, reflecting a maturing market focused on high-performance formulations.

Regionally, APAC stands out as the undisputed leader in both consumption and production capacity, spearheaded by rapid industrialization, burgeoning construction activities, and the massive manufacturing bases in China and India. North America and Europe, while demonstrating slower growth, maintain significant market share through high-value applications in high-end plastics, specialized printing, and mandated safety equipment. The market dynamics in these developed regions are heavily influenced by regulatory compliance and the demand for premium, long-lasting fluorescent materials. Latin America and the Middle East and Africa (MEA) are emerging as high-potential markets, particularly in coatings, textiles, and domestic consumer packaging applications, facilitated by ongoing economic diversification and infrastructure investments.

Segment trends reveal that the solvent-based segment, while historically dominant, is gradually ceding ground to the water-based formulations due to environmental and regulatory pressures. By application, the coatings and paints segment, driven by protective and decorative uses in automotive and architectural sectors, and the plastics segment, critical for injection molding and extrusion processes in safety and toy manufacturing, are exhibiting the strongest growth trajectory. Crucially, the polyamides product type continues to lead due to its excellent pigment load capacity and superior dispersion qualities, making it suitable for demanding plastic compounding and masterbatch production.

AI Impact Analysis on Daylight Fluorescent Pigments Market

User queries regarding the impact of Artificial Intelligence (AI) on the Daylight Fluorescent Pigments Market primarily revolve around three key areas: optimizing color formulation, enhancing quality control and predictive maintenance in manufacturing, and streamlining complex supply chain logistics. Users are keen to understand how AI-driven predictive analytics can accelerate the development cycle of new fluorescent compounds, minimizing trial-and-error in achieving specific chroma and brightness targets, especially when developing novel, highly stable organic dyes. A major concern is the efficiency of quality assurance—specifically, how machine learning (ML) models can be trained on spectral data to instantly detect inconsistencies in batch production, ensuring optimal pigment particle size distribution and flawless dispersion properties critical for end-use performance. Furthermore, there is anticipation concerning AI's role in forecasting demand volatility across diverse regional applications, optimizing inventory levels of complex raw materials like specialized polymers and optical brighteners.

- AI-Driven Formulation Optimization: Machine learning models accelerate the discovery and synthesis of novel fluorescent molecules with improved lightfastness and heat resistance.

- Predictive Quality Control (QC): Computer vision and ML algorithms analyze batch spectral data in real-time, instantly identifying deviations in color intensity, particle size, and dispersion characteristics.

- Supply Chain Resilience: AI predictive analytics forecast fluctuations in demand from key end-use industries (e.g., safety, textiles), optimizing inventory management and minimizing lead times for specialized chemical precursors.

- Manufacturing Efficiency: Implementing AI for predictive maintenance reduces equipment downtime in high-temperature processing units crucial for pigment synthesis and encapsulation.

- Customized Color Matching: AI platforms enable precise, rapid color matching and adjustment for clients requiring highly specific fluorescent shades for branding and product differentiation.

DRO & Impact Forces Of Daylight Fluorescent Pigments Market

The market trajectory for Daylight Fluorescent Pigments is determined by a balance of strong regulatory push for safety, technical constraints related to pigment stability, and promising expansion into high-growth sectors like digital textile printing. Drivers, notably the global proliferation of stringent worker safety regulations (e.g., ANSI, ISO standards for high-visibility apparel) and the increasing demand for enhanced branding aesthetics in consumer goods, provide a constant stimulus for market growth. Restraints primarily involve the inherent technical challenge of achieving high lightfastness (resistance to UV degradation) and high heat stability, crucial for applications in outdoor signage and high-temperature polymer processing. Opportunities arise from technological breakthroughs in encapsulated pigments, offering superior environmental resistance, and the rapidly expanding market for high-security printing and anti-counterfeiting measures where fluorescent properties are essential markers. These forces collectively shape the competitive landscape, emphasizing innovation in performance characteristics over cost reduction alone.

Segmentation Analysis

The Daylight Fluorescent Pigments Market is comprehensively segmented based on its structural composition, form factor, dispersion medium, and primary application areas, allowing for precise market tracking and strategic targeting. Analyzing these segments is essential for understanding shifting demand patterns driven by regulatory changes (e.g., the move away from solvent-based systems) and technological advancements (e.g., pigments suitable for digital printing). The major structural divisions include Thermoplastic, Polyamide, Urea-Formaldehyde, and others, each catering to specific processing requirements in plastics and coatings. Form and physical state segmentation often distinguishes powder, paste, and liquid dispersions, dictating handling and integration methods into final products. Furthermore, the application analysis, spanning Plastics, Paints & Coatings, Inks, Textiles, Paper, and Cosmetics, reveals where end-user demand is strongest, reflecting the criticality of visibility and color intensity across diverse industrial fields.

- By Type (Chemical Structure):

- Polyamide (Leading segment due to stability and dispersion)

- Urea-Formaldehyde (Cost-effective but facing regulatory scrutiny)

- Thermoplastic

- Others (e.g., Melamine-Formaldehyde)

- By Dispersion Medium:

- Solvent-Based Pigments (Traditional, high intensity)

- Water-Based Pigments (Rapidly growing, eco-friendly)

- By Form:

- Powder

- Paste/Dispersion

- Liquid Concentrate

- By Application:

- Plastics (Masterbatches, Injection Molding)

- Paints & Coatings (Architectural, Automotive, Road Marking)

- Inks (Printing, Packaging, Security)

- Textiles (Safety Apparel, Fashion)

- Paper (Security, Highlighters)

- Cosmetics (Nail Polish, Makeup)

Value Chain Analysis For Daylight Fluorescent Pigments Market

The value chain for Daylight Fluorescent Pigments is intricate, beginning with the highly technical synthesis of chemical precursors and extending through specialized manufacturing processes to final application in diverse end-use products. Upstream activities involve the procurement and synthesis of foundational organic dyes, resins (such as polyamides or urea-formaldehyde), and specialized additives required for pigment encapsulation and stabilization. This stage is characterized by high technical expertise and stringent control over chemical purity, as the quality of these raw materials directly dictates the final pigment's color yield and stability. Key upstream suppliers include petrochemical companies and specialty chemical manufacturers providing intermediates like rhodamines, coumarins, and naphthalimides—the core chromophores responsible for fluorescence.

Midstream processing focuses on the complex manufacturing steps: polymerizing the resin around the fluorescent dye (encapsulation), milling the resulting compound to achieve optimal particle size distribution (PSD), and surface treatment to ensure compatibility with various dispersion media (water or solvent). This manufacturing stage is capital-intensive, requiring specialized high-shear mixers, high-energy milling equipment, and precise control systems. Quality control at this stage is paramount, focusing on lightfastness testing, heat stability assessment, and ensuring uniform color strength across batches. Companies that excel in proprietary micro-encapsulation techniques gain a significant competitive advantage in offering performance-grade pigments.

Downstream analysis highlights the robust distribution channels utilized to reach a highly diversified customer base. Direct sales channels are often employed for large industrial users, such as major automotive paint manufacturers or specialized masterbatch producers, enabling technical support and customized formulations. Indirect channels, involving regional distributors, specialty chemical wholesalers, and agents, cater to small-to-medium enterprises (SMEs) across the printing ink, textile, and small-batch plastics markets. The final consumption stage is highly fragmented, necessitating close collaboration between pigment manufacturers and formulators (e.g., ink manufacturers) to ensure successful integration and optimal performance in the end application.

Daylight Fluorescent Pigments Market Potential Customers

Potential customers for Daylight Fluorescent Pigments span a broad industrial spectrum, unified by the requirement for superior visual impact and high visibility. The primary buyers are large-scale manufacturers and formulators operating in regulated sectors where safety and compliance are mandatory. These include masterbatch producers who incorporate pigments into polymer pellets for plastic manufacturing (toys, packaging, safety equipment) and large ink producers specializing in security printing, flexible packaging, and digital textile inks. Secondly, paint and coatings manufacturers, particularly those focusing on road marking, architectural coatings, and specialized protective coatings for industrial machinery, represent significant consumer clusters due to the necessity for high-contrast visibility and durable coloration in external environments. The procurement decision for these institutional buyers is heavily weighted towards pigment performance attributes, such as dispersion quality, lightfastness, and regulatory compliance (e.g., REACH, FDA approvals).

Another rapidly growing segment of potential customers includes specialized textile manufacturers involved in producing high-visibility apparel (HI-VIS), utilized extensively in construction, mining, transportation, and emergency services. These buyers require pigments that can withstand rigorous washing, UV exposure, and the high temperatures associated with textile dyeing and finishing processes without losing fluorescence intensity. Furthermore, the consumer goods sector, including manufacturers of highlighters, stationery, toys, and cosmetics, drives demand for aesthetically driven, non-functional applications, where brilliant, eye-catching color is key to market differentiation. In this segment, factors such as non-toxicity, ease of use in formulation, and broad color availability are the primary purchasing criteria. Therefore, suppliers must offer a diversified portfolio that meets both highly technical performance needs and aesthetic consumer demands.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 650.0 million |

| Market Forecast in 2033 | USD 963.5 million |

| Growth Rate | CAGR 5.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Sudarshan Chemical Industries Ltd., DayGlo Color Corp., Lumino Chem Private Limited, Radiant Color NV, J. H. Z. Co., Ltd., UKSEUNG Corporation, Sinloihi Co., Ltd., Keystone Aniline Corporation, Kolorjet Chemicals Pvt. Ltd., Radiant Pigments Pvt. Ltd., VICHEM, China Chemical Company, Apollo Colors Inc., Aron Universal, Shanghai Caisheng Industrial Co., Ltd., Brilliant Pigment Co., Ltd., Organic Dyes and Pigments (ODAP), Toyo Ink Group, Lanxess AG, BASF SE |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Daylight Fluorescent Pigments Market Key Technology Landscape

The technological landscape of the Daylight Fluorescent Pigments Market is primarily defined by advancements in micro-encapsulation, particle size reduction, and the shift towards environmentally sound carrier systems. Micro-encapsulation technology is perhaps the most critical innovation, involving the coating of the fluorescent organic dye within a durable, clear resin shell, typically polyamide or melamine. This protective barrier significantly enhances the pigment's stability against environmental factors such as UV light, heat degradation during processing (e.g., plastic extrusion), and chemical attack from solvents or aqueous media. Advanced encapsulation methods are crucial for unlocking higher performance levels, enabling fluorescent pigments to be used reliably in durable outdoor applications, which was historically a significant limitation for these dyes.

Another significant technological focus is on optimizing particle size distribution (PSD) and developing high-performance water-based dispersions. Achieving an ultra-fine, narrow PSD is essential for applications demanding high gloss, smooth film formation, and compatibility with sophisticated printing technologies like inkjet and digital textile printing. Manufacturers are utilizing advanced milling techniques, such as high-energy bead milling and jet milling, coupled with specialized surface treatments (wetting and dispersing agents) to produce stable liquid concentrates and pastes that offer superior color strength and clarity without settling or agglomeration. This fine particle technology directly supports the market transition towards water-based pigment systems, addressing stringent environmental regulations regarding volatile organic compounds (VOCs) and solvent usage.

Furthermore, research efforts are concentrated on developing novel, metal-free fluorescent chromophores that offer improved heat resistance and compliance with stricter global chemical inventories (like TSCA or REACH). This involves synthesizing new organic dyes that are inherently more stable, reducing reliance on traditional, sometimes less stable, rhodamine or coumarin structures. The integration of advanced testing methodologies, including accelerated weathering chambers and high-throughput screening for thermal stability, ensures that newly developed pigments meet the high-performance demands of high-temperature polymer processing and long-term outdoor exposure applications, thereby expanding the potential scope and market size for these high-visibility materials.

Regional Highlights

Geographically, the Daylight Fluorescent Pigments Market exhibits distinct growth and consumption patterns influenced by regional regulatory environments, industrialization rates, and infrastructure development projects. Asia Pacific (APAC) dominates the global market, both in terms of production volume and consumption, driven by its expansive manufacturing base, particularly in plastics, textiles, and printing inks in countries like China, India, and South Korea. Rapid urbanization, large-scale infrastructural investments (e.g., roads, construction safety), and the massive consumer electronics and toy manufacturing sectors necessitate huge volumes of highly visible, colored materials. Furthermore, lower manufacturing costs and increasing domestic demand for premium safety wear contribute significantly to APAC's leading position.

North America and Europe represent mature markets characterized by stringent safety regulations and a high focus on high-performance, quality-certified pigments. In these regions, growth is primarily driven by replacement demand, adoption of specialized, high-end applications (e.g., automotive coatings, security printing, and certified safety apparel meeting ANSI/EN standards), and the accelerated transition towards eco-friendly water-based formulations. European markets, in particular, are influenced heavily by REACH regulations, pushing manufacturers to innovate toward compliant and non-toxic pigment chemistries. Demand in these regions is stable, focusing on value rather than volume, emphasizing enhanced durability, lightfastness, and compatibility with advanced polymer systems.

Latin America (LATAM) and the Middle East and Africa (MEA) are emerging regions poised for rapid market penetration. Growth in LATAM is stimulated by expanding construction sectors and increased safety awareness in mining and oil & gas operations, demanding safety signage and hi-vis protective gear. MEA markets, fueled by diversification efforts, large infrastructure projects (like Saudi Arabia’s Vision 2030), and the growing textiles and packaging industries, are showing increased appetite for daylight fluorescent materials. While starting from a smaller base, these regions offer untapped potential, contingent upon stabilized economic conditions and streamlined distribution networks for specialty chemicals.

- Asia Pacific (APAC): Leading market share due to vast manufacturing capacity, rapid industrial expansion, high demand from plastics and textile industries, and burgeoning infrastructure projects in China and India.

- North America: Mature market focusing on high-value safety applications, stringent regulatory compliance (ANSI standards), and adoption of technologically advanced, durable pigment formulations.

- Europe: Driven by strict environmental regulations (REACH), demand for water-based, low-VOC pigments, and strong usage in security printing and high-end automotive and architectural coatings.

- Latin America (LATAM): Emerging growth fueled by expansion in construction, mining sectors, and increasing adherence to regional safety protocols.

- Middle East and Africa (MEA): High growth potential driven by large-scale government infrastructure investments, oil and gas safety requirements, and growing domestic consumer packaging industries.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Daylight Fluorescent Pigments Market.- Sudarshan Chemical Industries Ltd.

- DayGlo Color Corp.

- Lumino Chem Private Limited

- Radiant Color NV

- J. H. Z. Co., Ltd.

- UKSEUNG Corporation

- Sinloihi Co., Ltd.

- Keystone Aniline Corporation

- Kolorjet Chemicals Pvt. Ltd.

- Radiant Pigments Pvt. Ltd.

- VICHEM

- China Chemical Company

- Apollo Colors Inc.

- Aron Universal

- Shanghai Caisheng Industrial Co., Ltd.

- Brilliant Pigment Co., Ltd.

- Organic Dyes and Pigments (ODAP)

- Toyo Ink Group

- Lanxess AG

- BASF SE

Frequently Asked Questions

Analyze common user questions about the Daylight Fluorescent Pigments market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between standard and daylight fluorescent pigments?

Daylight fluorescent pigments exhibit significantly higher chroma and brilliance compared to standard pigments because they absorb both visible light and short-wavelength light (UV/blue) and re-emit it as visible light, effectively multiplying the perceived brightness. This characteristic is crucial for applications requiring maximum visibility, such as safety apparel and signage.

Which application segment drives the highest demand for daylight fluorescent pigments globally?

The Plastics and Coatings segments collectively drive the highest volume demand. Plastics, particularly for masterbatches used in safety equipment and consumer goods, require high heat-stable fluorescent pigments. Coatings, especially for road marking and architectural uses, demand durable and weather-resistant formulations.

What are the main technical challenges associated with fluorescent pigments?

The primary technical challenge is poor lightfastness (susceptibility to fading upon prolonged UV exposure) and low heat stability. Manufacturers address this through advanced micro-encapsulation techniques, shielding the dye core with a protective polymer resin to enhance outdoor durability and thermal resistance during high-temperature processing.

How are environmental regulations impacting the formulation of fluorescent pigments?

Strict environmental regulations, particularly in Europe and North America, are accelerating the market shift away from traditional solvent-based pigments towards eco-friendly water-based and low-VOC (Volatile Organic Compound) formulations. This requires significant R&D investment in developing high-performance aqueous dispersions and compliant chemistries.

Which region is expected to show the fastest growth rate in the Daylight Fluorescent Pigments Market?

Asia Pacific (APAC) is projected to exhibit the fastest growth rate due to rapid industrialization, large-scale infrastructure investment, increasing domestic regulatory emphasis on worker safety, and the massive presence of textile and consumer goods manufacturing bases in countries like India and China.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager