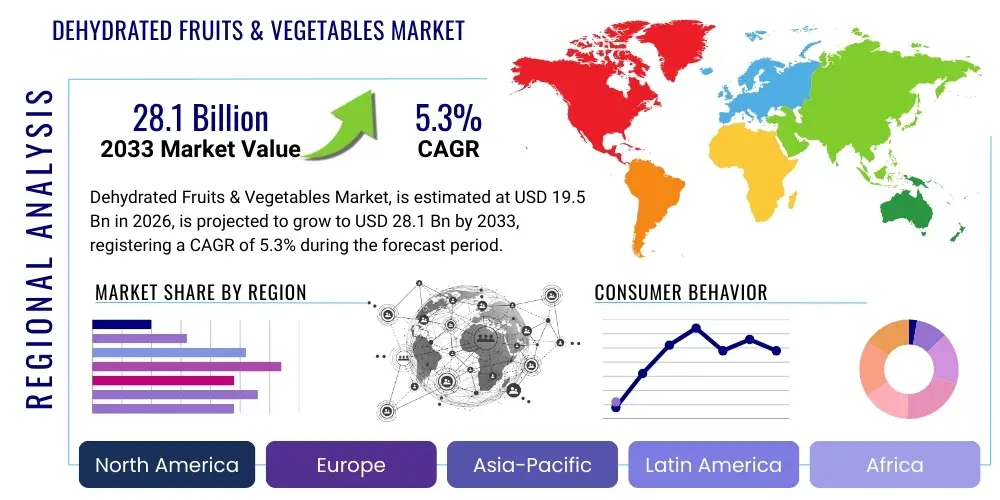

Dehydrated Fruits & Vegetables Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438206 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Dehydrated Fruits & Vegetables Market Size

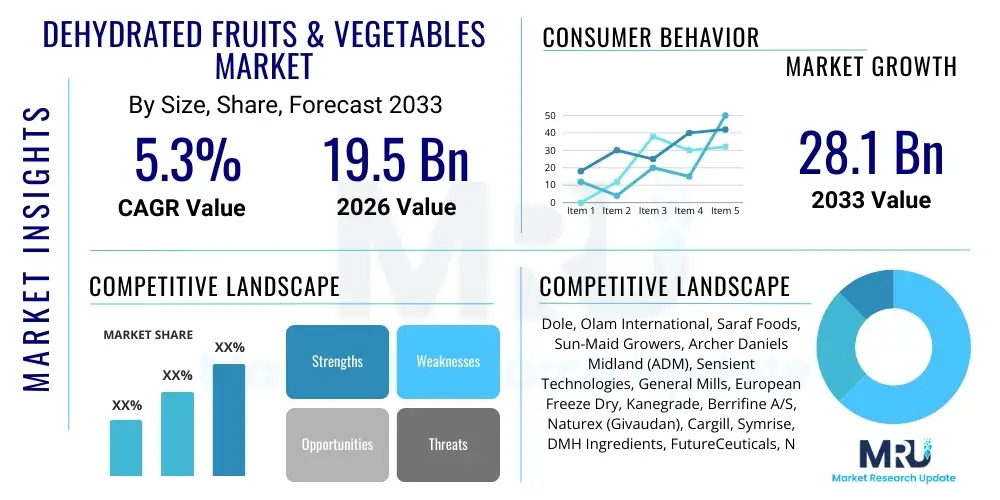

The Dehydrated Fruits & Vegetables Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.3% between 2026 and 2033. The market is estimated at $19.5 Billion in 2026 and is projected to reach $28.1 Billion by the end of the forecast period in 2033.

Dehydrated Fruits & Vegetables Market introduction

The Dehydrated Fruits & Vegetables market encompasses the processing and preservation of fresh produce through moisture removal techniques, significantly extending shelf life and reducing volume/weight for easier transport and storage. This preservation method ensures the retention of essential nutritional compounds, flavors, and colors, making the final products highly desirable across various industrial applications. Key dehydration technologies include sun drying, spray drying, freeze drying (lyophilization), vacuum drying, and air drying, with the choice of method often dictated by the specific type of produce, desired texture, and cost constraints. The resulting products—ranging from powders and flakes to whole pieces—serve as critical ingredients or standalone snack items, addressing the growing global demand for non-perishable food solutions.

Major applications of dehydrated products span the entire food and beverage ecosystem, including Ready-to-Eat (RTE) meals, breakfast cereals, snack foods, bakery products, confectionery, and specialized dietary supplements. The fundamental benefits of these products include enhanced food safety, year-round availability independent of harvest seasons, and substantial reduction in waste associated with spoilage. Moreover, the concentrated flavor profile of dehydrated ingredients often allows for reduced required quantities in formulations, appealing to industrial food manufacturers seeking efficiency and robust sensory characteristics in their end products. This versatility makes the market resilient to economic fluctuations, driving consistent demand from both established and emerging food processors worldwide.

The market expansion is principally driven by rapid urbanization and the corresponding shift toward convenient, time-saving food solutions. Consumers in developed and developing nations are increasingly seeking snacks and meal components that are perceived as healthier alternatives to processed foods, favoring dehydrated options due to their clean label potential and high fiber content. Furthermore, the global expansion of the prepared food industry, coupled with logistical advantages offered by lightweight, stable ingredients, cements the foundational growth trajectory of the dehydrated fruits and vegetables sector. Continuous innovation in drying technology, aimed at improving nutrient retention and reducing energy costs, further accelerates market adoption across functional food and nutraceutical domains.

Dehydrated Fruits & Vegetables Market Executive Summary

The global Dehydrated Fruits & Vegetables market is characterized by robust growth, primarily fueled by evolving consumer preferences favoring convenience, extended shelf life, and functional nutrition. Current business trends indicate a strong move toward advanced drying techniques, particularly freeze-drying and vacuum microwave drying, which minimize nutrient degradation and preserve vibrant sensory attributes, allowing manufacturers to command premium pricing. Furthermore, ingredient traceability and sustainability have become central competitive differentiators; leading players are investing heavily in secure, transparent supply chains, often engaging directly with agricultural cooperatives to ensure consistent quality and ethical sourcing. Strategic mergers and acquisitions are commonplace, aimed at securing raw material supply and expanding geographical reach, particularly into high-growth Asian markets.

Regional trends highlight the Asia Pacific (APAC) as the fastest-growing market, driven by massive population density, increasing middle-class disposable income, and the widespread use of dehydrated products in traditional and packaged food preparations. North America and Europe, while mature, remain dominant in terms of technological adoption and demand for premium, organic, and clean-label dehydrated snacks. European markets, in particular, show a strong inclination towards non-GMO and certified organic dehydrated products used extensively in baby food and health supplements. The regulatory landscape, especially concerning maximum residue limits (MRLs) for pesticides, continues to influence product specifications and trade flows between these major regions, requiring strict quality control measures from market participants.

Segment trends reveal that the application segment is dominated by the snack and functional food categories, reflecting the consumer shift away from traditional chips and highly processed treats toward fruit-based alternatives. Within the technology segment, freeze-drying is experiencing accelerated growth, despite its higher cost, due to its ability to maximize nutritional integrity—a critical factor for the nutraceutical and high-end infant food sectors. Vegetable dehydration, particularly for use in instant soups, ready meals, and specialized spice blends, is also expanding significantly, demonstrating the market’s reliance on these processed ingredients for industrial scale efficiency and product consistency.

AI Impact Analysis on Dehydrated Fruits & Vegetables Market

User queries regarding the impact of Artificial Intelligence (AI) on the dehydrated food sector typically revolve around optimizing resource utilization, ensuring product quality consistency, and enhancing supply chain resilience. Users are keen to understand how AI can reduce energy consumption during energy-intensive drying processes, predict potential equipment failures, and automate meticulous sorting and grading tasks previously reliant on manual labor. A significant area of concern and interest is the integration of machine learning for forecasting raw material availability and pricing fluctuations, given the high perishability and seasonality inherent in fruit and vegetable sourcing. Essentially, users expect AI to transition the industry from reactive quality control to proactive process optimization and predictive supply chain management.

AI’s influence is manifesting most profoundly in upstream processing, where computer vision systems coupled with deep learning are now capable of analyzing surface defects, color consistency, and size variations in fresh produce prior to dehydration at speeds unattainable by humans. This not only enhances sorting accuracy but drastically reduces waste before processing begins. Furthermore, in the dehydration chamber itself, AI-driven sensor networks monitor real-time moisture content, temperature gradients, and airflow, using predictive models to dynamically adjust parameters. This optimization minimizes drying time while ensuring uniform quality across batches, leading directly to reduced energy costs and improved throughput, thereby addressing crucial operational efficiency concerns raised by manufacturers.

Downstream, AI is redefining market segmentation and demand forecasting. Machine learning algorithms analyze vast datasets encompassing consumer purchasing patterns, seasonal food trends, and social media sentiment to provide highly accurate projections for specific dehydrated products (e.g., kale chips versus dried mango slices) in targeted geographies. This predictive capability enables manufacturers to align production schedules precisely with anticipated market demand, minimizing inventory holding costs and maximizing shelf-stocking efficiency in retail environments, thereby creating a more responsive and capital-efficient operational model across the entire value chain.

- Implementation of AI-driven computer vision for automated quality inspection and grading of raw materials, minimizing input waste.

- Optimization of drying parameters (temperature, humidity, airflow) using machine learning models to reduce energy consumption by up to 15-20%.

- Predictive maintenance analytics for drying equipment and associated machinery, minimizing unplanned downtime and extending asset lifespan.

- Enhanced supply chain transparency and logistics optimization using AI to track product origin, processing history, and distribution routes.

- Accurate demand forecasting and inventory management using deep learning algorithms analyzing consumer behavior and macroeconomic indicators.

- Development of personalized functional food ingredients by cross-referencing nutritional profiles and consumer health data via AI platforms.

DRO & Impact Forces Of Dehydrated Fruits & Vegetables Market

The market dynamics for Dehydrated Fruits & Vegetables are shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), underpinned by significant competitive impact forces. The primary drivers revolve around the inherent benefits of the products, specifically the extended shelf life and the resulting minimization of food waste, which aligns powerfully with global sustainability goals and consumer expectations. Furthermore, the strong consumer trend toward healthy snacking and the perception of dehydrated products as minimally processed and nutrient-dense alternatives continues to propel demand across established markets like North America and Western Europe, ensuring sustained volume growth. The convenience factor—dehydrated products require minimal or no preparation—is especially critical in driving adoption among urban populations with fast-paced lifestyles.

Conversely, significant restraints hinder accelerated market expansion. The high initial capital expenditure required for advanced drying technologies, particularly freeze-drying equipment, poses a substantial barrier to entry for smaller manufacturers. Furthermore, the drying process can sometimes lead to undesirable sensory changes, such as browning or texture degradation, especially in heat-intensive methods, which can negatively impact consumer acceptance of certain products. The fluctuating and often volatile prices of fresh produce, influenced by unpredictable climatic events and seasonal variability, also impact profitability, creating input cost instability that manufacturers must constantly mitigate through hedging and strategic sourcing contracts. These cost and quality trade-offs necessitate continuous R&D investment to overcome technical limitations.

Opportunities for growth are vast, particularly within emerging markets where cold chain infrastructure is nascent or unreliable, making shelf-stable ingredients highly valuable for food security. The burgeoning demand for natural food coloring agents and flavoring powders, derived from dehydrated produce, presents a lucrative pathway into the industrial ingredient sector, especially as synthetic alternatives face increasing regulatory scrutiny. The market is also heavily influenced by Porter’s Five Forces. The Threat of Substitutes is moderately high, primarily from canned or frozen alternatives, yet dehydrated products offer unique benefits (lightweight, highly concentrated flavor) that solidify their position. The Bargaining Power of Buyers (large industrial food companies) is significant, demanding stringent quality specifications and competitive pricing, while the Bargaining Power of Suppliers (farmers) is mitigated by global sourcing capabilities but remains high for specialized or organic produce.

Segmentation Analysis

The Dehydrated Fruits & Vegetables market is comprehensively segmented based on Type, Technology, Form, and Application, providing a granular view of market dynamics and specialized consumer demands. This multi-dimensional segmentation allows stakeholders to target specific niches, ranging from industrial ingredient suppliers utilizing bulk powders to specialized retail companies focusing on high-value, freeze-dried snacking segments. Technological advancements continue to reshape these segments, with the Type and Technology variables being primary drivers of overall market value and nutrient retention capabilities.

- By Type: Fruits (Apples, Berries, Bananas, Mangoes, Grapes, Others), Vegetables (Potatoes, Carrots, Onions, Peas, Tomatoes, Others).

- By Technology: Air Drying, Freeze Drying (Lyophilization), Spray Drying, Vacuum Drying, Microwave Drying, Osmotic Dehydration.

- By Form: Powder & Granules, Flakes, Slices & Shreds, Whole/Pieces.

- By Application: Snack & RTE Products, Bakery & Confectionery, Soups & Sauces, Breakfast Cereals, Beverages, Nutraceuticals & Dietary Supplements, Pet Food.

Value Chain Analysis For Dehydrated Fruits & Vegetables Market

The value chain for the Dehydrated Fruits & Vegetables market begins intensely in the upstream segment with the sourcing of raw materials. This stage involves direct engagement with farmers or agricultural cooperatives, emphasizing quality control (pesticide levels, ripeness, size) and logistics for rapid transport to processing facilities to prevent spoilage. Key upstream analysis focuses on establishing resilient contractual agreements and investment in pre-processing infrastructure, suchably grading, washing, and peeling, which determine the yield and final quality of the dehydrated product. Efficiency here directly impacts the cost structure and sustainability credentials of the finished goods.

The core processing stage, or midstream segment, involves the high-tech dehydration methods. This stage represents the highest capital investment due to the specialized machinery required for air drying, freeze drying, or vacuum drying. Value is added through moisture removal, which concentrates flavor and extends stability. This stage is critical for maintaining nutrient integrity, texture, and color. Continuous process optimization, including utilizing renewable energy sources and implementing advanced process control systems, is essential for maintaining competitive advantage and meeting increasingly stringent quality certifications required by downstream industrial buyers.

The downstream segment focuses on distribution and end-market access. Distribution channels are bifurcated: Direct channels involve B2B sales of bulk ingredients (powders, flakes) directly to large industrial food manufacturers (e.g., soup or cereal companies) who incorporate the product into their formulations. Indirect channels involve repackaging finished goods (e.g., snack packs of dried fruits) for B2C retail sale through supermarkets, convenience stores, and rapidly growing e-commerce platforms. Marketing strategies in the indirect channel emphasize product functionality, convenience, and clean-label narratives to appeal directly to the consumer, solidifying the final link in the value delivery chain and maximizing profit margins.

Dehydrated Fruits & Vegetables Market Potential Customers

The primary consumers and end-users of dehydrated fruits and vegetables are diverse, extending far beyond the typical retail snack consumer into sophisticated industrial applications where consistency and shelf stability are paramount. The largest segment of buyers comprises the Food Processing Industry, which relies on dehydrated ingredients for formulating a massive range of products, including instant soups, ready-to-eat meals, baking mixes, sauces, and seasoning blends. These manufacturers seek high-volume, cost-effective ingredients that provide flavor, texture, and nutritional enhancement without the logistical challenges associated with fresh or frozen produce, making supply chain reliability a critical factor for purchase decisions.

Another significant customer base lies within the Nutraceuticals and Dietary Supplements sector. Given the concentrated nutrient profiles achieved through methods like freeze-drying, these companies purchase fruit and vegetable powders for inclusion in tablets, capsules, functional beverages, and protein shakes. This segment prioritizes ingredients with verified bioavailability and high concentrations of specific phytochemicals or vitamins, driving demand for premium, organically certified, and scientifically documented dehydrated products. The demand here is highly sensitive to claims regarding health benefits, necessitating rigorous testing and quality assurance from suppliers.

Furthermore, specialized institutional buyers, including military and emergency relief organizations, represent a steady demand stream. These entities require highly calorie-dense, lightweight, and extremely long shelf-life food solutions for MREs (Meals Ready-to-Eat) and humanitarian aid packages. The requirements for these buyers are centered on robust packaging, guaranteed stability under extreme conditions, and adherence to specific regulatory standards regarding calorie count and nutritional balance, differentiating their purchasing criteria from typical industrial food clients.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $19.5 Billion |

| Market Forecast in 2033 | $28.1 Billion |

| Growth Rate | 5.3% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Dole, Olam International, Saraf Foods, Sun-Maid Growers, Archer Daniels Midland (ADM), Sensient Technologies, General Mills, European Freeze Dry, Kanegrade, Berrifine A/S, Naturex (Givaudan), Cargill, Symrise, DMH Ingredients, FutureCeuticals, Nuts.com, Paradise Fruits, Kiril Mischeff, Chaucer Foods. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dehydrated Fruits & Vegetables Market Key Technology Landscape

The technological landscape of the Dehydrated Fruits & Vegetables market is undergoing continuous refinement, driven by the core need to minimize energy consumption while maximizing the retention of volatile flavor compounds and heat-sensitive nutrients. Traditional hot air drying remains the most cost-effective and widely used method, particularly for high-volume, lower-value commodities, but its major drawback is the potential for significant nutrient and color loss due to prolonged exposure to high temperatures. Consequently, manufacturers are increasingly migrating towards hybrid drying systems, which combine methods like air drying with microwave heating or vacuum conditions to shorten processing times and improve product quality metrics.

Freeze drying (lyophilization) stands out as the premium technology, offering unparalleled quality retention, especially concerning texture and nutritional profile, by sublimating ice directly from the frozen state under vacuum. Although freeze-drying is highly energy-intensive and capital-expensive, the resultant products command high market prices, making it the preferred method for high-value applications such as nutraceuticals, premium specialty snacks, and infant food. Parallel innovations include Osmotic Dehydration, where produce is partially dehydrated using a hypertonic sugar solution prior to final drying, significantly reducing the energy load required for the subsequent thermal drying step and resulting in a product with a unique chewy texture.

Emerging and niche technologies, such as Refractance Window Drying (RWD) and Superheated Steam Drying (SSD), are gaining commercial traction. RWD utilizes infrared energy transmitted through water to rapidly dry thin layers of puree, offering high energy efficiency and better quality than conventional air drying, particularly suitable for powdered ingredients. The key focus of all ongoing technological research is the development of scalable, continuous drying systems that can process large volumes of seasonal produce quickly and economically while maintaining stringent quality specifications mandated by global food safety regulations. Adoption of these technologies is geographically staggered, with North America and Europe leading investment in advanced, low-temperature systems.

Regional Highlights

The global market exhibits distinct regional growth patterns, largely dictated by dietary habits, economic development, and technological infrastructure availability. North America dominates the market share in terms of value, primarily due to the high per capita consumption of packaged snacks, cereals, and functional foods. The U.S. consumer base is highly receptive to health-oriented, clean-label products, driving robust demand for premium dehydrated options, particularly freeze-dried berries and vegetable chips. Technological sophistication and the presence of major food processing conglomerates further solidify the region's position as a technological and consumption leader.

Asia Pacific (APAC) represents the fastest-growing region, poised for exponential expansion over the forecast period. This growth is underpinned by rapidly expanding economies, increasing disposable incomes, and the massive shift towards packaged and convenience foods among the urban middle class in countries like China and India. Dehydrated vegetables are integral to traditional Asian cuisine preparations (e.g., instant noodles, spice mixes), ensuring sustained B2B demand. Furthermore, improvements in cold chain infrastructure are enabling better raw material management, supporting increased localized production capabilities.

Europe maintains a strong market presence, characterized by stringent food quality standards and high demand for organic and non-GMO certified dehydrated ingredients. Western European consumers, particularly in Germany and the UK, prioritize sustainability and traceability, influencing manufacturers to adopt advanced, energy-efficient drying techniques. Latin America and the Middle East & Africa (MEA) are emerging regions, where market growth is stimulated by population growth and increasing awareness of food security challenges, making long-shelf-life dehydrated staples highly attractive, especially in remote or climate-vulnerable areas.

- North America (U.S., Canada): Dominant market for premium, healthy dehydrated snacks and high-tech processing implementation; strong regulatory oversight driving quality standards.

- Europe (Germany, U.K., France): Focus on organic, traceable, and sustainably sourced ingredients; high penetration of freeze-dried products in infant food and health supplements.

- Asia Pacific (China, India, Japan): Highest growth rate driven by urbanization, expanding packaged food industry, and essential use of dehydrated ingredients in staples and instant meals.

- Latin America (Brazil, Mexico): Growing market fueled by industrial adoption in baking and confectionery; increased investment in localized processing capacity.

- Middle East & Africa (South Africa, GCC): Emphasis on shelf-stable solutions for import resilience and food aid programs; potential for sun-drying commercialization.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dehydrated Fruits & Vegetables Market.- Dole

- Olam International

- Saraf Foods

- Sun-Maid Growers

- Archer Daniels Midland (ADM)

- Sensient Technologies

- General Mills

- European Freeze Dry

- Kanegrade

- Berrifine A/S

- Naturex (Givaudan)

- Cargill

- Symrise

- DMH Ingredients

- FutureCeuticals

- Nuts.com

- Paradise Fruits

- Kiril Mischeff

- Chaucer Foods

- International Dehydrated Foods (IDF)

Frequently Asked Questions

Analyze common user questions about the Dehydrated Fruits & Vegetables market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the growth of the Dehydrated Fruits & Vegetables Market?

The primary driver is the accelerating consumer demand for convenient, healthy snacking options and minimally processed ingredients that offer extended shelf life, significantly reducing household food waste and supporting busy, modern lifestyles across urbanized populations globally.

Which dehydration technology offers the highest nutritional retention?

Freeze drying (lyophilization) offers the highest nutritional and sensory retention because it operates at extremely low temperatures and under vacuum, minimizing the thermal degradation of heat-sensitive vitamins, colors, and volatile aromatic compounds, although it remains the most expensive method.

How does the Dehydrated Fruits & Vegetables market contribute to supply chain sustainability?

By converting highly perishable fresh produce into shelf-stable, lightweight ingredients, the market significantly reduces pre-consumer spoilage, decreases transport emissions due to lower product weight, and enables year-round utilization of seasonal crops, enhancing overall food supply chain resilience.

Which application segment holds the largest share in the market?

The Snacks and Ready-to-Eat (RTE) Products segment currently holds the largest market share, driven by the shift away from traditional fried snacks towards perceived healthier, fiber-rich fruit and vegetable alternatives, which are highly popular in Western and increasingly in Asian markets.

What challenges do manufacturers face regarding raw material sourcing?

Manufacturers face significant challenges including the volatile pricing of fresh produce due to climate change impacts, ensuring consistent quality and ripeness across large batches, and meeting strict global residue limits (MRLs), necessitating robust global sourcing strategies and meticulous quality verification systems.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager