Dental Handpiece Air Turbines Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434604 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Dental Handpiece Air Turbines Market Size

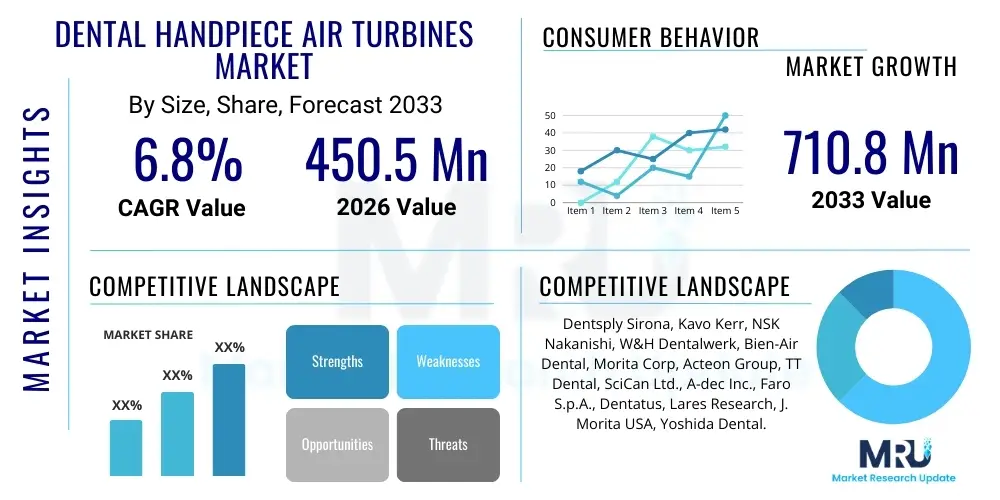

The Dental Handpiece Air Turbines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 710.8 Million by the end of the forecast period in 2033.

The expansion of the global dental tourism industry, coupled with increasing public awareness regarding oral hygiene and the rising prevalence of dental disorders, are the primary propellers of this significant market growth. Furthermore, continuous technological advancements focused on improving the ergonomics, precision, and noise reduction capabilities of air turbine handpieces are enhancing their adoption rate among dental practitioners worldwide. Developing economies, in particular, are witnessing rapid infrastructural development in healthcare, creating new opportunities for market penetration.

Market valuation is directly influenced by the shift toward minimally invasive dental procedures, which require high-speed, precise rotary instruments. Air turbine handpieces, known for their powerful torque and lightweight design, remain the cornerstone of restorative and prophylactic dentistry. The sustained investment in dental education and the adoption of stricter regulatory standards regarding instrument sterilization and performance also contribute significantly to the positive market trajectory through the forecast period.

Dental Handpiece Air Turbines Market introduction

The Dental Handpiece Air Turbines Market encompasses the manufacturing, distribution, and sales of high-speed rotary instruments used primarily in preparatory and restorative dental procedures. These instruments operate by converting compressed air into mechanical energy, driving a turbine to achieve rotational speeds often exceeding 300,000 RPM, essential for rapid and precise cutting of tooth structure, removal of old fillings, and preparation of cavities. Key applications include crown preparation, cavity cutting, endodontic access, and polishing. The major benefits derived from modern air turbines include their cost-effectiveness, high torque output, lightweight design, and the ability to maintain precision at ultra-high speeds, which reduces patient chair time and improves procedural efficiency. Market expansion is chiefly driven by the escalating demand for cosmetic dentistry, increasing disposable incomes in emerging markets, and continuous innovation aimed at integrating superior ceramic bearing technology and enhanced fiber optic illumination into handpiece designs.

The core product within this market segment is the high-speed air turbine handpiece, typically utilizing either ball bearings or advanced ceramic bearings for enhanced longevity and reduced heat generation. These tools are indispensable in clinical environments, offering the necessary speed and control for treating complex dental conditions. While electrically driven handpieces offer consistent torque at lower speeds, air turbines dominate the high-speed segment due to their robust performance and reliability in demanding applications. Their continued prominence is further solidified by factors such as standardized sterilization protocols and the need for reliable, maintenance-friendly equipment in busy dental practices globally.

Driving factors for the market include the growing elderly population, which requires extensive restorative dental care, and government initiatives promoting oral health accessibility. The proliferation of specialized dental clinics and the increasing adoption of advanced materials like zirconia and lithium disilicate, which require powerful and stable cutting instruments, also fuel demand for high-performance air turbines. Furthermore, companies are investing heavily in ergonomic designs to minimize user fatigue and incorporate features like anti-retraction systems to enhance hygiene and patient safety, thereby encouraging regular replacement and upgrade cycles among dental professionals.

Dental Handpiece Air Turbines Market Executive Summary

The global Dental Handpiece Air Turbines Market is characterized by robust business trends focusing on material science innovation, particularly the integration of lightweight titanium housing and durable ceramic bearings to enhance instrument longevity and reduce operational noise. Key industry participants are engaging in strategic mergers and acquisitions and forging strong distribution partnerships to solidify their market presence across high-growth regions. The trend toward developing smart handpieces with embedded sensors for usage tracking and maintenance alerts represents the future direction of product development, ensuring optimal performance and compliance with stringent quality standards. This move towards digitalization in dental instrumentation is reshaping competitive dynamics.

Regionally, North America and Europe maintain leading positions due to high healthcare expenditure, established dental infrastructure, and rapid adoption of cutting-edge dental technology. However, the Asia Pacific (APAC) region is projected to exhibit the fastest growth rate, fueled by expanding healthcare access, a booming population, and increasing foreign direct investment in dental care facilities, particularly in countries like China and India. Regional trends also indicate a rising demand for affordable, yet high-quality, generic handpiece alternatives, especially in Latin America and the Middle East & Africa (MEA), forcing multinational corporations to adapt their pricing and product strategies to cater to diverse economic segments.

Segmentation trends highlight the dominance of ceramic bearing air turbines over traditional ball bearing types due to their superior performance, reduced friction, and increased lifespan, justifying a higher price point. In terms of application, general dentistry continues to be the largest consumer, though specialized segments like cosmetic and reconstructive dentistry are showing accelerated growth due to increasing aesthetic demands. The shift from large hospitals to specialized, private dental clinics as primary end-users is another crucial trend impacting distribution channels and marketing focus within the market.

AI Impact Analysis on Dental Handpiece Air Turbines Market

User queries regarding AI's impact on dental instruments frequently revolve around predictive maintenance, optimization of instrument lifespan, and how digital diagnostics might influence physical tool usage. Users are concerned about whether AI integration will lead to entirely automated procedures, thereby reducing reliance on traditional handpiece skill, and how AI can ensure the consistent, high-precision performance required of air turbines. Key themes include the use of machine learning (ML) for identifying optimal cutting parameters based on patient-specific tooth density and material type, and the expectation that AI will standardize sterilization protocols and maintenance schedules, significantly reducing instrument downtime and operational costs in large clinical settings. The overall user sentiment suggests excitement about predictive analytics but anxiety about potential job displacement or the rising cost associated with incorporating "smart" technology into historically mechanical tools.

While air turbine handpieces remain fundamentally mechanical devices, AI primarily influences their operational ecosystem rather than the direct cutting mechanism. AI algorithms analyze usage patterns, vibration data, and heat profiles collected by embedded sensors, flagging potential mechanical failures (like bearing degradation) before they occur. This transition from reactive repair to proactive, predictive maintenance fundamentally changes the life cycle and management of handpiece inventories in clinics and hospitals, enhancing efficiency and minimizing unexpected interruptions during procedures. This optimized performance ensures that the precision cutting capabilities of the air turbine are utilized effectively throughout its lifespan.

Furthermore, AI-driven diagnostic and planning software assists dentists in defining the exact depth, angle, and duration required for preparation work. Although the handpiece executes the task, AI provides the precise roadmap, potentially reducing operator error and ensuring the air turbine performs within its optimal parameters. This integration elevates the overall standard of restorative dentistry, making high-speed procedures more predictable and standardized across different practitioners, thereby indirectly increasing the reliability and perceived value of high-quality air turbine systems.

- AI enhances predictive maintenance for air turbines, optimizing service cycles and minimizing downtime.

- Machine Learning analyzes sensor data (vibration, heat) to monitor bearing health and operational stress.

- AI-driven diagnostics inform precise cutting parameters, improving procedural consistency and efficiency.

- Digital platforms integrate handpiece usage data for automated inventory management and sterilization compliance tracking.

- Improved procedural efficiency driven by AI planning indirectly supports the demand for high-performance, reliable air turbine technology.

DRO & Impact Forces Of Dental Handpiece Air Turbines Market

The Dental Handpiece Air Turbines Market is significantly propelled by the increasing global prevalence of dental caries and periodontal diseases, necessitating frequent restorative and prophylactic treatments (Drivers). However, the market faces headwinds primarily from the high maintenance costs associated with air turbine systems and the competitive threat posed by electric handpieces, which offer superior low-speed torque control (Restraints). Opportunities abound in untapped emerging markets, particularly through the development of cost-effective and highly ergonomic designs, alongside integrating advanced materials such as titanium and ceramic bearings to boost durability. These factors interact within a dynamic environment where technological obsolescence and stringent regulatory approvals (Impact Forces) continuously shape market entry and product life cycles.

Key drivers include the global expansion of middle-class populations with disposable income to spend on elective and cosmetic dentistry, coupled with substantial improvements in dental coverage provided by insurance providers in developed nations. Moreover, continuous innovation by leading manufacturers to reduce the inherent noise and vibration associated with air turbines is addressing key user discomfort factors, making these instruments more appealing. Conversely, a major restraint is the complex and highly sensitive nature of air turbines, making them susceptible to damage from improper sterilization or lubrication protocols, leading to shorter effective lifespans compared to simpler dental tools and driving up total ownership costs for practitioners.

Significant market opportunities exist in specialized segments like pediatric dentistry and orthodontics, where specific, smaller-scale air turbine designs are required. Furthermore, the push towards integrating illumination (fiber optics or LED) and standardized coupling systems across different brands enhances interoperability, driving replacement purchases. The market is also heavily influenced by regulatory bodies like the FDA and CE, which enforce strict standards for safety and sterilization (Impact Force), ensuring only high-quality, compliant devices reach the market, thereby influencing competitive strategies and product development timelines.

Segmentation Analysis

The Dental Handpiece Air Turbines Market is comprehensively segmented based on product type, application, end-use, and technology. The segmentation reflects the diverse needs of the global dental community, ranging from high-volume general dentistry practices requiring robust, cost-effective high-speed instruments, to specialized clinics demanding precision tools with advanced features like ceramic bearings and integrated fiber optics. High-speed air turbines remain the dominant product type due to their necessity in almost all restorative and crown preparation procedures, while the application segmentation highlights general dentistry as the largest revenue contributor. Technological segmentation is crucial as it dictates performance characteristics, separating traditional ball bearing systems from advanced, quieter, and longer-lasting ceramic bearing platforms.

- By Product Type: High-Speed Handpieces, Low-Speed Handpieces, Attachments, Accessories (e.g., Couplings, Maintenance Systems).

- By Technology: Ball Bearing Handpieces, Ceramic Bearing Handpieces, Gear-driven Air Handpieces.

- By Application: General Dentistry, Cosmetic Dentistry, Orthodontics, Endodontics, Oral Surgery.

- By End-Use: Hospitals, Dental Clinics, Ambulatory Surgical Centers, Research & Academic Institutes.

Value Chain Analysis For Dental Handpiece Air Turbines Market

The value chain for the Dental Handpiece Air Turbines Market begins with the Upstream Analysis, focusing on the sourcing and supply of critical raw materials, primarily specialized metals (titanium, stainless steel) for housing, durable plastics, and high-precision components like ceramic bearings, turbines, and fiber optics. Reliability and quality control at this initial stage are paramount, as the performance of the final instrument hinges on the precision of these internal components. Major manufacturers often establish long-term contracts with specialized component suppliers to ensure consistency and cost stability, creating high barriers to entry for new players in the upstream segment. The procurement process emphasizes materials that are biocompatible, autoclavable, and resistant to wear under extreme rotational stresses.

The core manufacturing and assembly stage involves high-precision engineering, requiring specialized tooling and cleanroom environments due to the microscopic tolerances required for turbine assembly. This midstream process is dominated by leading international players who possess the necessary intellectual property and economies of scale. Following manufacturing, the Downstream Analysis focuses on distribution channels. Direct distribution is common for large institutional buyers (major hospital networks, dental schools), allowing manufacturers to maintain tight control over pricing and customer service. However, indirect channels, involving authorized national or regional distributors, and specialized dental equipment dealers, are vital for reaching independent dental clinics and smaller practices, especially in fragmented international markets.

The distribution network is critical for the success of air turbine products, as it includes essential post-sales support, maintenance training, and rapid access to spare parts. Direct and indirect channels both play a crucial role; direct sales ensure brand loyalty and premium pricing maintenance, while indirect distribution provides geographical reach and localized customer support, which is vital for instruments requiring frequent servicing and technical assistance. Effective supply chain management, minimizing lead times for critical spares like rotors and bearings, is a key determinant of competitive advantage in the downstream segment of the Dental Handpiece Air Turbines Market.

Dental Handpiece Air Turbines Market Potential Customers

The primary End-Users and buyers of dental handpiece air turbines are dental professionals operating within various clinical settings, requiring instruments for high-speed procedures. The largest consumer base comprises general dentists who utilize these high-speed tools daily for routine restorative procedures, including decay removal and cavity preparation. Specialized end-users, such as prosthodontists and cosmetic dentists, represent a high-value segment, often prioritizing premium, feature-rich handpieces with superior illumination and ergonomic designs to facilitate complex aesthetic procedures. The procurement decision for these individual clinics is often influenced by cost-effectiveness, reliability, warranty coverage, and ease of maintenance.

Institutional purchasers form another crucial segment. This includes large public and private hospitals with comprehensive dental departments, university-affiliated dental schools and teaching hospitals, and government health services. These entities typically purchase air turbines in bulk through formalized tender processes, prioritizing durability, standardized coupling systems for inter-operability across different units, and compliance with stringent public health regulations regarding sterilization. Dental schools are particularly vital as they determine the initial brand loyalty of future practitioners, making them a strategic focus for market leaders.

Furthermore, ambulatory surgical centers (ASCs) focused on oral and maxillofacial procedures are increasingly adopting high-performance air turbines, driven by the shift of complex outpatient procedures from inpatient hospital settings to specialized centers. Finally, dental laboratories also constitute a segment of customers, though they typically require laboratory-specific handpieces often designed for slightly different materials and operational profiles than clinical air turbines. The continuous need for instrument upgrades due to technological advancements and regulatory requirements ensures a steady replacement market among all potential customer groups.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 710.8 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Dentsply Sirona, Kavo Kerr, NSK Nakanishi, W&H Dentalwerk, Bien-Air Dental, Morita Corp, Acteon Group, TT Dental, SciCan Ltd., A-dec Inc., Faro S.p.A., Dentatus, Lares Research, J. Morita USA, Yoshida Dental. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dental Handpiece Air Turbines Market Key Technology Landscape

The technology landscape of the Dental Handpiece Air Turbines Market is dominated by innovations focused on achieving higher rotational speeds, superior torque, reduced operational noise, and enhanced durability under rigorous clinical conditions. A pivotal technological shift has been the transition from traditional stainless steel ball bearings to advanced ceramic bearings (typically Silicon Nitride). Ceramic bearings significantly reduce friction, allowing for cooler operation and extended service life, while also being highly resistant to the high temperatures encountered during sterilization (autoclaving). Manufacturers are continually refining turbine geometry and materials to maximize power output while maintaining a compact and lightweight profile, crucial for reducing clinician fatigue during lengthy procedures.

Another critical area of development involves improving the cooling and illumination systems. Multi-port spray systems are standard, ensuring effective cooling of the tooth and bur, preventing pulp damage, and improving visibility by clearing debris. Fiber optic and LED illumination integrated into the handpiece head dramatically enhances the dentist's field of view, particularly in hard-to-reach areas, supporting more precise procedures. The technological focus is moving toward LED systems which offer brighter, whiter light and consume less power than traditional halogen or older fiber optic systems. Furthermore, quick-disconnect coupling systems (like KaVo’s MULTIflex or NSK’s PTL), which allow for easy attachment and detachment of the handpiece from the dental unit tubing, represent standardized technological advancements ensuring hygiene and efficiency.

Ergonomics and noise reduction technologies are also central to modern air turbine design. Companies are utilizing advanced computational fluid dynamics (CFD) modeling to optimize air flow within the turbine chamber, reducing the high-pitched whine historically associated with these instruments, thereby improving the patient and practitioner experience. Material science advancements, such as the use of lightweight yet robust titanium alloys for the outer casing, contribute to a lighter, more balanced instrument that can withstand frequent chemical exposure and sterilization cycles. Finally, the development of specialized lubrication and maintenance systems, often automated, ensures that these high-precision instruments receive optimal care, maximizing their operational lifespan and guaranteeing consistent performance.

To further elaborate on the technology landscape, the evolution of coupling technology plays a substantial role in market dynamics. Universal and proprietary coupling designs dictate compatibility between handpieces and existing dental units, influencing purchasing decisions and brand loyalty. Advanced systems now incorporate non-retraction valves (anti-suck-back mechanisms) to prevent the aspiration of contaminated water or debris into the waterline, a crucial safety feature that aligns with increasingly stringent infection control standards globally. This technological refinement, while subtle, significantly enhances the infection control capabilities of air turbine systems, making compliance simpler for high-volume practices.

The integration of micro-filtration systems within the air line connection of the dental unit is another subtle yet powerful technological advancement impacting handpiece longevity. Contaminants and moisture in compressed air are primary culprits in premature bearing failure in air turbines. Filtering these impurities prior to reaching the instrument dramatically extends the bearing life, especially ceramic ones. This symbiotic technology, though often external to the handpiece itself, is essential for maximizing the return on investment in premium air turbine instruments. Furthermore, the push towards standardized, color-coded identification systems for different speeds and applications aids clinical workflow efficiency, reducing the chance of procedural errors.

Regarding manufacturing precision, computer numerical control (CNC) machining and laser welding techniques are fundamental to the assembly of modern air turbines. These techniques ensure the ultra-fine balance and concentricity required for stable rotation at over 300,000 RPM. Any minute imbalance can lead to excessive vibration, noise, and early component wear. The investment required in this high-precision machinery limits the number of global manufacturers capable of producing top-tier handpieces, reinforcing the competitive position of established market leaders who continually invest in state-of-the-art production technology and quality assurance protocols.

Regional Highlights

The global Dental Handpiece Air Turbines Market exhibits diverse adoption patterns influenced by economic development, healthcare infrastructure, and regulatory environments across major geographic regions. North America, encompassing the United States and Canada, currently holds the largest market share. This dominance is attributed to high per capita healthcare spending, significant adoption of advanced dental technologies, the presence of a large number of skilled dental professionals, and robust insurance coverage promoting elective and restorative dental procedures. The region is characterized by early adoption of premium ceramic bearing handpieces and high demand for ergonomic, feature-rich instruments that comply with strict FDA standards.

Europe represents the second-largest market, driven by sophisticated dental care systems, a high awareness of oral health, and government initiatives promoting dental wellness, particularly across Western European countries like Germany, France, and the UK. The European market emphasizes quality, precision, and adherence to CE marking requirements. Leading European manufacturers such as W&H Dentalwerk and Bien-Air Dental maintain a strong regional presence, fostering continuous innovation in areas like reduced noise levels and sophisticated quick-coupling mechanisms. Demand in Eastern Europe is rapidly increasing as healthcare infrastructure modernizes and economic conditions improve.

The Asia Pacific (APAC) region is projected to be the fastest-growing market during the forecast period. This accelerated growth is primarily fueled by a massive, aging population requiring extensive dental care, increasing disposable incomes supporting private dental investments in countries like China, India, and South Korea, and the rapid expansion of dental tourism. While cost sensitivity remains high, leading to strong demand for value-segment and locally manufactured products, increasing educational levels and patient expectations are simultaneously boosting the adoption of high-end international air turbines in metropolitan areas. Significant governmental investments in public health facilities further solidify APAC's high-growth potential.

Latin America (LATAM) and the Middle East & Africa (MEA) collectively form emerging markets characterized by uneven economic development but substantial potential. In LATAM, countries like Brazil and Mexico are leading the adoption of modern dental equipment, driven by established dental professional communities and growing cosmetic dentistry trends. The MEA region, particularly the Gulf Cooperation Council (GCC) countries, shows strong potential due to significant government investment in luxurious private healthcare infrastructure and high demand for specialized dental treatments, often catering to medical tourists. Challenges in these regions include fluctuating currency values and the need for improved local distribution and maintenance support for sophisticated air turbine technology.

- North America: Dominates the market due to high healthcare expenditure, established dental infrastructure, and rapid adoption of premium ceramic bearing technology.

- Europe: Characterized by stringent quality standards (CE) and strong demand for quiet, highly ergonomic handpieces across countries like Germany and Switzerland.

- Asia Pacific (APAC): Expected to show the highest CAGR, driven by vast populations, rising disposable incomes, and infrastructural growth in China, India, and Southeast Asia.

- Latin America (LATAM): Growth centered in countries like Brazil and Mexico, focusing on balancing quality and affordability for general and cosmetic dentistry applications.

- Middle East & Africa (MEA): Emerging markets with high potential driven by substantial investments in private healthcare sectors, particularly in the GCC states.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dental Handpiece Air Turbines Market.- Dentsply Sirona

- Kavo Kerr (Envista Holdings Corporation)

- NSK Nakanishi Inc.

- W&H Dentalwerk International GmbH

- Bien-Air Dental S.A.

- Morita Corp.

- Acteon Group

- TT Dental

- SciCan Ltd. (Hu-Friedy Group)

- A-dec Inc.

- Faro S.p.A.

- Dentatus AB

- Lares Research

- J. Morita USA Inc.

- Yoshida Dental Mfg. Co., Ltd.

- MK-dent GmbH

- Anthogyr SAS

- Sirona Dental Systems GmbH

- Saeshin Precision Co., Ltd.

- Guangzhou Ajax Medical Equipment Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Dental Handpiece Air Turbines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between air turbine and electric dental handpieces?

Air turbine handpieces rely on compressed air to achieve ultra-high speeds (up to 450,000 RPM) necessary for rapid cutting, offering lightweight design and cost efficiency. Electric handpieces use a motor to deliver consistent, high torque at lower speeds (typically up to 40,000 RPM), prioritizing stability and precise control over raw speed.

Why are ceramic bearings preferred over traditional ball bearings in modern air turbines?

Ceramic bearings, typically made of silicon nitride, are preferred because they offer significantly reduced friction and heat generation, leading to quieter operation, minimal wear, and superior resistance to corrosion and high temperatures during rigorous sterilization cycles, thereby extending the instrument's lifespan.

How significant is the role of infection control in the air turbine handpiece market?

Infection control is critical, driving demand for handpieces with features like anti-retraction valves and seamless, autoclavable external housings. Compliance with strict standards (e.g., CDC and ISO guidelines) dictates mandatory heat sterilization, influencing material science and product design across the market.

Which geographical region is expected to show the fastest growth rate for air turbine adoption?

The Asia Pacific (APAC) region is forecasted to exhibit the highest Compound Annual Growth Rate (CAGR) due to rapid infrastructure development in healthcare, surging demand for cosmetic and restorative dentistry, and increasing investment capabilities in emerging economies like China and India.

What is the expected market size for the Dental Handpiece Air Turbines Market by 2033?

The Dental Handpiece Air Turbines Market is projected to reach an estimated value of USD 710.8 Million by the end of the forecast period in 2033, driven by ongoing technological refinement and global expansion of dental services.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager