Dental Plaster Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432381 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Dental Plaster Market Size

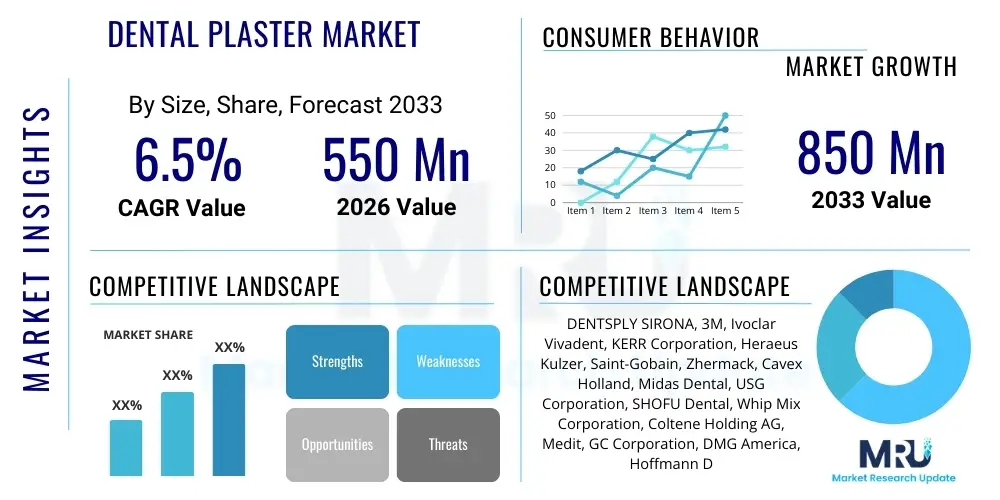

The Dental Plaster Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 550 Million in 2026 and is projected to reach USD 850 Million by the end of the forecast period in 2033.

Dental Plaster Market introduction

The Dental Plaster Market encompasses materials, primarily derived from gypsum, used extensively within dentistry for the creation of models, casts, dies, and investment molds. These materials are fundamental in prosthodontics, orthodontics, and restorative dentistry, providing a precise, stable replica of the patient's oral structures crucial for the fabrication of crowns, bridges, dentures, and other custom dental appliances. The reliability and dimensional accuracy of dental plaster directly impact the fit and longevity of the final restoration, making it a critical component of the dental workflow. Different types of dental plasters (Type I to Type V) are utilized depending on the required strength, expansion characteristics, and application specificity, ranging from simple mounting plaster to high-strength die stone.

Major applications for dental plaster span across commercial dental laboratories, academic institutions for educational purposes, and dedicated dental clinics. The primary benefits driving the sustained demand for dental plaster include its low cost, ease of use, excellent flow properties, and high compatibility with impression materials like alginates and silicones. Furthermore, advancements in chemical formulations have led to the development of higher-strength and lower-expansion gypsum products (Type IV and V) that meet the stringent requirements of precision restorative dentistry, particularly when dealing with complex implant-supported prostheses or full-arch restorations, ensuring that the master model accurately reflects intraoral conditions.

Key driving factors influencing market growth include the rising global prevalence of dental diseases, particularly periodontal issues and tooth loss, which necessitate complex prosthetic treatments. Furthermore, the increasing geriatric population worldwide, which requires frequent dental restorations and dentures, provides a steady demand base. Expanding dental tourism in developing economies, coupled with significant growth in disposable income leading to higher expenditure on elective cosmetic and restorative dental procedures, further fuels the market expansion. The continuous establishment of new dental clinics and laboratories in emerging economies, alongside technological upgrades in existing facilities, is instrumental in maintaining the upward trajectory of the dental plaster sector, ensuring robust material supply chains.

Dental Plaster Market Executive Summary

The Dental Plaster Market is experiencing consistent growth driven primarily by demographic shifts, specifically the aging global populace, and advancements in prosthetic dental materials and techniques. Current business trends indicate a strong move toward high-performance materials, particularly Type IV (High-strength stone) and Type V (High-strength, high-expansion die stone) plasters, as dental professionals demand superior surface hardness and precision for complex implantology and CAD/CAM restorative workflows, where minor dimensional inaccuracies are unacceptable. Consolidation among major material manufacturers and the increasing integration of digital dentistry tools, which necessitate highly accurate analog models for verification or hybrid workflows, are reshaping the competitive landscape. Supply chain resilience, especially concerning raw material (gypsum) extraction and processing, remains a critical operational focus for market leaders, alongside maintaining competitive pricing in a largely commoditized segment of the dental supply market.

Regionally, Asia Pacific (APAC) stands out as the fastest-growing market due to rapid improvements in healthcare infrastructure, substantial government investments in oral health programs, and a massive, underserved population base increasingly accessing modern dental care. North America and Europe, while mature markets, maintain high revenue shares driven by high procedural volumes, technological adoption, and favorable reimbursement structures for specialized dental treatments. These regions focus heavily on premium, technologically enhanced plaster formulations and integrated product solutions. Trends in Latin America and MEA are characterized by increasing urbanization and the establishment of sophisticated private dental clinics, transitioning away from rudimentary materials towards international quality standards, thereby spurring demand for medium to high-grade dental plasters necessary for advanced restorative processes.

Segment trends reflect a strong dominance of dental laboratories as the primary end-users, given their large-scale production requirements for casts and models. By product type, Type IV and Type V plasters command a growing share, reflecting the industry's focus on precision and durability, shifting prominence away from lower-grade Type I and Type II plasters, which are typically used for less critical applications like articulating models or preliminary casts. Furthermore, the growth trajectory of specialty plasters, such as those optimized for specific 3D printing applications or rapid-setting formulas designed to improve laboratory efficiency, highlights the industry's response to the productivity demands placed on dental technicians. The packaging segment reveals a preference for bulk packaging among high-volume laboratories, seeking cost efficiencies and streamlined inventory management compared to smaller, pre-weighed sachets favored by clinical settings.

AI Impact Analysis on Dental Plaster Market

User inquiries concerning the impact of Artificial Intelligence (AI) on the Dental Plaster Market predominantly revolve around the potential for digital workflows (driven by AI-assisted scanners and CAD/CAM software) to entirely eliminate the need for analog models, thereby rendering plaster obsolete. Users are concerned about whether AI-enhanced intraoral scanning, predictive modeling, and 3D printing will bypass the traditional impression-taking and plaster model pouring stages. Furthermore, questions arise regarding how AI might optimize material selection, perhaps by recommending the exact plaster type (e.g., Type IV vs. Type V) based on the restoration complexity and subsequent machining process, or if AI tools could monitor and predict material consumption rates in large laboratories to optimize inventory. While AI is rapidly enhancing diagnostic accuracy and treatment planning (driving the initial need for prosthetics), its direct impact on the material itself is primarily indirect, accelerating the shift towards digital verification models, though analog models remain critical for many stages of restoration fabrication and manual verification checks.

- AI-driven intraoral scanners increase accuracy, minimizing retakes and reducing the initial need for physical impressions, indirectly affecting the volume of Type I plaster used for immediate pouring.

- Predictive modeling powered by machine learning optimizes the design of dental appliances, requiring high-precision plaster casts (Type IV/V) for final verification before milling or 3D printing.

- AI integration into CAD/CAM workflows accelerates the transition to digital fabrication, yet analog models are frequently mandated for secondary checks, quality control, and articulation validation, maintaining a core requirement for high-stability die stone.

- Advanced algorithms can optimize laboratory logistics, including predicting optimal plaster mix ratios and setting times based on environmental factors, ensuring consistency and reducing material waste.

- AI may accelerate the development of hybrid workflows where digital design is validated against a highly accurate, yet conventionally produced, physical plaster model, ensuring the continued specialized role of Type V materials.

- Increased efficiency through AI in design and manufacturing places higher pressure on the dimensional stability and surface quality of the plaster casts used, demanding premium materials from manufacturers.

DRO & Impact Forces Of Dental Plaster Market

The dynamics of the Dental Plaster Market are governed by a complex interplay of growth drivers, inherent restraints, promising opportunities, and overarching impact forces that shape investment decisions and strategic planning. The primary drivers stem from global health trends, particularly the aging demographic and rising chronic oral disease burden, coupled with increasing consumer awareness regarding aesthetic and restorative dentistry. Simultaneously, the market faces restraints such as the persistent threat posed by the acceleration of digital impression technology and 3D printing, which aim to eliminate the physical model entirely. Opportunities lie significantly in developing high-performance, specialized plaster derivatives optimized for hybrid digital-analog workflows and capitalizing on the untapped potential of emerging Asian and African markets where traditional dentistry remains predominant.

Drivers: Significant investment in oral health infrastructure in developing nations coupled with favorable policies promoting dental care access acts as a powerful driver. Furthermore, the non-negotiable requirement for physical articulation and verification models in numerous specialized procedures, such as complex fixed prosthetics and orthodontics, ensures the sustained demand for high-quality die stone. The intrinsic cost-effectiveness of gypsum products compared to advanced resin-based model materials, especially for high-volume basic procedures, maintains its market presence. Additionally, continuous product innovation resulting in plasters with reduced setting expansion and superior mechanical properties addresses the precision needs of modern dental implantology.

Restraints: The market faces substantial resistance from the rapid adoption of intraoral scanners and sophisticated CAD/CAM systems, which potentially reduce the overall volume of plaster consumed by leading dental laboratories. Environmental concerns regarding the disposal of gypsum waste pose regulatory challenges in developed markets, pushing for sustainable alternatives. Price sensitivity, particularly in highly competitive markets where basic plaster is largely viewed as a commodity, limits profit margins and discourages extensive R&D investment into lower-grade products. Furthermore, the complex logistics and bulk weight of the product contribute to higher shipping and warehousing costs compared to digital alternatives.

Opportunities: Manufacturers can capitalize on the burgeoning demand for specialized plasters used in conjunction with 3D-printed materials, such as investment plasters for casting metal frameworks or specialized stone for mounting 3D-printed bases. Expanding educational and training programs in emerging markets to familiarize technicians with modern, high-precision plaster techniques represents a critical market opportunity. Developing advanced material blends that offer rapid setting times without compromising strength or dimensional stability addresses a key laboratory efficiency requirement. The market also presents significant opportunities for companies focusing on geographical expansion into underpenetrated regions where dental treatment volume is escalating rapidly.

Impact Forces: The overarching impact force is technological disruption; the pace at which digital dentistry displaces traditional analog workflows dictates the growth rate of plaster consumption, potentially polarizing the market into high-end specialized stone (Type IV/V) and diminishing the demand for general-purpose plaster. Regulatory stringency regarding material biocompatibility and quality standards impacts manufacturing costs. Economic volatility affects discretionary spending on restorative dentistry, thereby influencing procedural volumes. The competitive pressure from key material suppliers striving for market dominance through mergers and acquisitions continually reshapes distribution networks and pricing strategies globally, demanding consistent quality assurance.

Segmentation Analysis

The Dental Plaster Market is comprehensively segmented based on product type, application, end-user, and geographic region, allowing for a detailed understanding of market dynamics and targeted strategic development. The classification by product type (Types I through V) is crucial as it reflects the specific mechanical properties, strength, and expansion rates necessary for various dental procedures, dictating suitability for everything from simple articulation to complex master casts. Application segmentation highlights the primary procedures driving demand, notably fixed prosthetics and orthodontics. End-user categorization distinguishes between large volume consumers like dental laboratories and smaller volume consumers such as hospitals and individual clinics, offering insights into procurement and distribution requirements. This multidimensional segmentation helps manufacturers tailor their material specifications and marketing strategies to meet highly differentiated professional needs within the dental industry ecosystem.

- By Product Type:

- Type I Plaster (Impression Plaster): Low strength, used for mounting casts.

- Type II Plaster (Model Plaster): General-purpose use, commonly for study models and preliminary casts.

- Type III Plaster (Dental Stone): Medium strength, used for full arch models and working models.

- Type IV Plaster (High-strength Dental Stone, Low Expansion): High precision, preferred for crown and bridge work, highly critical master models, and die preparation.

- Type V Plaster (High-strength, High-expansion Dental Stone): Highest strength and hardness, used specifically for implantology and complex metal framework castings requiring controlled thermal expansion.

- By Application:

- Fixed Prosthetics (Crowns, Bridges, Inlays, Onlays): Requires Type IV and V due to high precision needs.

- Removable Prosthetics (Dentures, Partials): Primarily utilizes Type III and sometimes Type II.

- Orthodontics: Uses Type II for study models and initial diagnostic casts.

- Implants and Surgery Planning: Heavily relies on Type V for accurate positioning and surgical guide fabrication.

- By End User:

- Dental Laboratories: Largest segment, demanding high volumes across all types, especially Type III, IV, and V.

- Dental Hospitals and Clinics: Utilize smaller quantities, often pre-weighed sachets, for immediate patient procedures and minor lab work.

- Academic and Research Institutes: Use Type I and II primarily for training, education, and material testing purposes.

- By Packaging:

- Bulk Packaging (25kg bags, large containers): Favored by high-volume commercial laboratories for cost efficiency.

- Pre-weighed Sachets/Small Containers (1kg, 5kg): Preferred by small clinics for convenience and waste minimization.

- By Region:

- North America (US, Canada)

- Europe (Germany, UK, France, Italy, Spain, Rest of Europe)

- Asia Pacific (China, Japan, India, South Korea, Rest of APAC)

- Latin America (Brazil, Mexico, Rest of Latin America)

- Middle East & Africa (GCC Countries, South Africa, Rest of MEA)

Value Chain Analysis For Dental Plaster Market

The value chain for the Dental Plaster Market begins with the highly specialized process of upstream raw material extraction and refinement. The core raw material is natural gypsum (calcium sulfate dihydrate), which must be quarried, crushed, and then calcined (heat-treated) to produce hemihydrate gypsum, the chemical basis for all dental plasters. This upstream segment is capital-intensive and subject to geological availability and environmental regulations. Key stakeholders at this stage include global mining and chemical processing companies who ensure the purity and consistent quality of the hemihydrate powder, which is critical, as impurities can drastically affect the final setting time, strength, and expansion characteristics required by the dental industry.

The midstream process involves specialized manufacturing where the basic hemihydrate is mixed with various chemical modifiers—such as accelerators, retarders, coloring agents, and synthetic resins—to create the five distinct types of dental plaster (Types I to V) with precise mechanical properties tailored for dental applications. Manufacturers package the material, often under strict quality control measures, ensuring minimal moisture absorption and contamination. Distribution channels are highly varied; large, multinational dental material companies typically use a combination of direct sales forces for major laboratory chains and indirect distribution networks, leveraging regional dealers and specialized dental supply houses to reach smaller clinics and individual practitioners. The complexity of inventory management, given the product's bulk and shelf life, adds layers to the distribution logistics.

Downstream activities center on the end-users: dental laboratories, clinics, and hospitals. Laboratories act as the crucial link, consuming vast quantities of dental stone to fabricate restorations, representing the largest demand center. Direct distribution often caters to large contracts with leading dental laboratory groups, ensuring consistent supply and technical support. Indirect channels are essential for market penetration into thousands of smaller private clinics and specialized practices that rely on local dealers for immediate, smaller-volume purchases. The flow efficiency is highly dependent on timely delivery and technical training provided by the distributors to ensure end-users utilize the plasters correctly to achieve optimal clinical outcomes, thus completing the value transfer from raw material to finished product verification.

Dental Plaster Market Potential Customers

The primary and most significant potential customers for dental plaster products are commercial dental laboratories worldwide. These facilities constitute the backbone of the restorative dentistry industry, responsible for producing the vast majority of crowns, bridges, dentures, orthodontic retainers, and implant frameworks. Their high-volume consumption necessitates large, reliable material supplies, often favoring bulk packaging of high-strength stone (Type IV and V) for precision work and lower-cost stone (Type II and III) for routine models and articulation. Laboratories seek materials that offer excellent dimensional stability under different environmental conditions, high compressive strength to withstand manipulation, and compatibility with various die materials and separating agents, making them demanding customers focused on consistency and cost-per-unit production.

Secondary but equally important customer segments include standalone dental hospitals and private dental clinics, particularly those equipped with in-house laboratory facilities or those performing specialized procedures like implantology and complex cosmetic work. While their consumption volume is significantly lower than large commercial labs, they often require faster-setting or pre-portioned plasters (Type III or IV) for immediate chairside or small batch procedures, valuing convenience and minimal preparation time. These customers typically procure materials through local dental supply distributors rather than directly from the manufacturer, emphasizing rapid replenishment and comprehensive local support. Educational institutions, including dental schools and university research centers, also represent a stable customer base, primarily utilizing Type I and Type II plasters for student training in impression handling, pouring techniques, and model construction.

Finally, specialized segments focusing on forensic dentistry and industrial applications (where gypsum models are used for rapid prototyping or tooling verification) also utilize dental plaster, though in niche volumes. Emerging potential customers are hybrid digital laboratories that integrate 3D scanning and printing but still require physical models for complex articulators, ensuring the continued specialized demand for ultra-low expansion, high-precision Type V stone. Targeting these diverse customer groups requires manufacturers to maintain a broad portfolio, ranging from economical general-purpose plasters to premium, technologically enhanced products specifically designed to interface optimally with advanced digital dentistry equipment and techniques, catering to varied budgets and technical requirements globally.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 550 Million |

| Market Forecast in 2033 | USD 850 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | DENTSPLY SIRONA, 3M, Ivoclar Vivadent, KERR Corporation, Heraeus Kulzer, Saint-Gobain, Zhermack, Cavex Holland, Midas Dental, USG Corporation, SHOFU Dental, Whip Mix Corporation, Coltene Holding AG, Medit, GC Corporation, DMG America, Hoffmann Dental Manufaktur, Hi-Tec Dental, Promedica Dental Materials, J. Morita Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dental Plaster Market Key Technology Landscape

The technology landscape within the Dental Plaster Market is characterized by material science innovations focused on enhancing the precision and handling characteristics of gypsum products, even as the broader dental industry rapidly adopts digital tools. The primary technological advancements focus on chemical modification of the hemihydrate crystal structure to achieve ultra-low expansion properties, which is crucial for high-precision die stones (Type IV and V) used in intricate crown, bridge, and implant work. Manufacturers are investing in technologies to refine the particle size distribution of the gypsum powder, leading to smoother surfaces, increased hardness, and superior edge strength, mitigating the risk of chipping during laboratory manipulation and machining. Furthermore, the incorporation of specialized synthetic resins and polymers into the gypsum matrix allows for faster setting times without premature hardening, addressing the laboratory demand for increased workflow efficiency and dimensional accuracy across various casting environments.

A key technological intersection exists between traditional plaster manufacturing and digital verification methods. While intraoral scanners and CAD/CAM software reduce the reliance on plaster for initial model creation, the technology driving high-performance plasters is focused on supporting hybrid workflows. This includes developing plasters optimized for use with articulated digital models, serving as a physical control point against which 3D-printed or milled restorations are checked. Manufacturers are also improving the compatibility of gypsum materials with various types of impression materials, particularly hydrophilic silicones, ensuring optimal detail reproduction and minimizing the risk of surface contamination or reaction. The adoption of advanced automated mixing and vacuum apparatus in laboratories further highlights the technological push to eliminate air bubbles and ensure homogenous mixing, maximizing the material's potential physical properties as claimed by the manufacturers.

Looking ahead, emerging technology centers on developing truly 'smart' plasters or investment materials that integrate monitoring capabilities or are specifically tailored for integration with rapid prototyping technologies. This includes specialized investment plasters capable of high-temperature resistance and controlled thermal expansion necessary for casting metal frameworks utilizing advanced sintering technologies. Research is also ongoing into sustainable and biodegradable plaster alternatives to address environmental concerns associated with gypsum disposal. The shift towards proprietary color-coding systems for different plaster types (e.g., green for Type III, brown for Type IV) is a technological advancement in usability, minimizing errors in busy laboratory settings. Overall, the technological landscape is defined by continuous incremental improvements in physical properties, guided by the overarching need to maintain relevance and precision alongside the fast-evolving digital dentistry sector, making the material indispensable for final quality assurance.

Regional Highlights

- North America: This region maintains a high market share driven by advanced healthcare infrastructure, significant consumer awareness, and high adoption rates of sophisticated restorative procedures, including implant dentistry and full-mouth rehabilitation. The U.S. and Canada are characterized by a strong presence of large commercial dental laboratories that demand premium, high-strength Type IV and Type V plasters for complex cases. Market growth is stable, underpinned by high expenditure on dental aesthetics and a strong regulatory environment ensuring quality standards.

- Europe: Europe is a mature market focusing heavily on technological innovation and clinical excellence, particularly in Germany, France, and Italy. The adoption of hybrid digital-analog workflows is high, sustaining demand for precision die stone used in quality control and articulation. Regulatory emphasis on environmental sustainability drives demand for more environmentally conscious packaging and waste management solutions, influencing manufacturer strategies within the region.

- Asia Pacific (APAC): APAC is projected to exhibit the highest CAGR due to rapid economic development, increasing penetration of insurance schemes, and government initiatives to improve oral health access in populous nations like China and India. The market is characterized by a dual demand structure: high-end imported plaster in metropolitan areas and robust, cost-effective Type II and III plasters dominating smaller clinics and rural areas, leading to significant volume growth potential.

- Latin America: This region presents moderate growth, fueled by rising dental tourism and increasing foreign investment in specialized private clinics, particularly in Brazil and Mexico. Demand is steadily shifting from basic model plaster to high-quality stone as local laboratories upgrade their capabilities to meet international standards for fixed prosthetics and orthodontics. Price sensitivity remains a key factor, but quality consciousness is rising.

- Middle East and Africa (MEA): Growth is concentrated in the GCC countries, where wealth allows for high investment in advanced dental technology and treatment centers, driving demand for premium materials. The broader African market is nascent but shows potential due to expanding access to basic dental services and humanitarian efforts to improve oral healthcare provision, gradually increasing the consumption of entry-level and general-purpose plasters.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dental Plaster Market.- DENTSPLY SIRONA Inc.

- 3M Company

- Ivoclar Vivadent AG

- KERR Corporation (A subsidiary of Envista Holdings Corporation)

- Heraeus Kulzer GmbH

- Saint-Gobain S.A. (Through specialized material divisions)

- Zhermack SpA

- Cavex Holland BV

- Midas Dental Products

- USG Corporation (A subsidiary of Knauf)

- SHOFU Dental Corporation

- Whip Mix Corporation

- Coltene Holding AG

- Medit Corp. (Focus on digital integration/model interaction)

- GC Corporation

- DMG America LLC

- Hoffmann Dental Manufaktur

- Hi-Tec Dental Products Inc.

- Promedica Dental Materials GmbH

- J. Morita Corporation

Frequently Asked Questions

Analyze common user questions about the Dental Plaster market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the key differences between Type III and Type IV dental plasters, and which is suitable for implant models?

Type III plaster (Dental Stone) offers medium strength and is typically used for general working models and complete arch models. Type IV plaster (High-strength Dental Stone) provides superior hardness, compressive strength, and significantly lower setting expansion, making it highly dimensionally stable. For intricate implant models and precision die work where minimal expansion is critical for accurate restoration fit, Type IV or the even higher strength Type V plaster is strongly recommended to ensure clinical accuracy and material reliability in sophisticated prosthetic applications.

How is the rise of 3D printing and digital impressioning impacting the consumption volume of traditional dental plaster?

Digital impressioning and 3D printing technology exert a restraining force on general-purpose plaster consumption (Type I and II) by eliminating the need for many preliminary and study models. However, they simultaneously increase the demand for specialized, ultra-high-precision Type IV and V plasters. These superior plasters are still essential in hybrid workflows for physical articulation, verification of complex implant components, and providing a stable, hard substrate against which 3D printed or milled components are checked for final quality assurance, maintaining their critical role in the quality control phase.

What are the primary factors driving the growth of the Dental Plaster Market in the Asia Pacific region?

The APAC region’s robust growth is primarily fueled by rapid expansion of the middle class, leading to increased discretionary spending on dental health and cosmetic procedures. Government initiatives aimed at improving oral healthcare accessibility and the proliferation of new private dental clinics and laboratories across countries like China and India necessitate a steady, increasing supply of dental materials, including both economical and high-grade plasters, supporting sustained market expansion throughout the forecast period.

What challenges do dental plaster manufacturers face regarding environmental sustainability?

Manufacturers face environmental challenges primarily related to the sourcing and processing of gypsum, a natural mineral, and the disposal of used plaster casts, which contributes significantly to landfill waste. Regulatory pressures, especially in North America and Europe, are driving the need for more efficient production processes, reduced waste generation, and the potential development of biodegradable or more easily recyclable plaster formulations to mitigate the environmental footprint associated with high-volume usage in dental laboratories.

Which end-user segment dominates the demand for dental plaster and why is their requirement profile unique?

Commercial Dental Laboratories represent the dominant end-user segment due to their centralized role in the fabrication of virtually all fixed and removable dental prostheses. Their requirement profile is unique as they demand bulk packaging for operational efficiency, highly consistent material quality for predictable outcomes across large batches, and specific formulations (primarily Type IV and V) that offer superior mechanical strength and low expansion rates to support complex, high-precision, multi-unit restorations fabricated using sophisticated CAD/CAM and casting techniques.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager