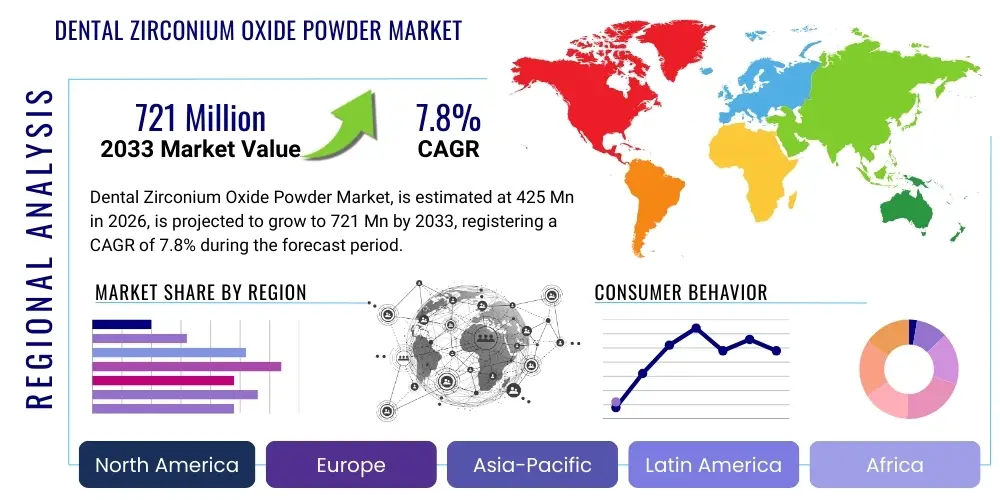

Dental Zirconium Oxide Powder Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439232 | Date : Jan, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Dental Zirconium Oxide Powder Market Size

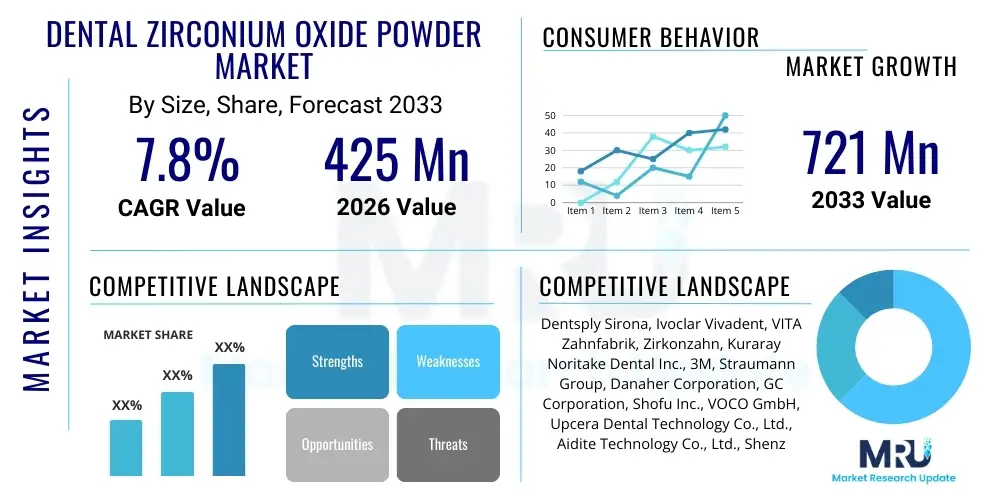

The Dental Zirconium Oxide Powder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 425 million in 2026 and is projected to reach USD 721 million by the end of the forecast period in 2033.

Dental Zirconium Oxide Powder Market introduction

The dental zirconium oxide powder market encompasses the global production and distribution of high-purity zirconia materials specifically engineered for various dental restorative and prosthetic applications. This advanced ceramic material has revolutionized modern dentistry due to its exceptional mechanical properties, biocompatibility, and aesthetic appeal. Zirconia-based restorations offer a compelling alternative to traditional metal-ceramic options, addressing growing patient demands for metal-free, durable, and natural-looking dental solutions. The market thrives on continuous innovation in material science and processing technologies, enhancing the performance and versatility of zirconia for an expanding range of clinical uses.

Product Description: Dental zirconium oxide powder is predominantly composed of yttrium-stabilized tetragonal zirconia polycrystals (Y-TZP) or cubic zirconia, processed into fine, consistent particles. These powders are typically pressed into blocks or discs, which are then milled using CAD/CAM technology to create precise dental prosthetics. Key features include high flexural strength (often exceeding 1000 MPa), fracture toughness, excellent wear resistance, and radiopacity. Modern advancements have led to the development of multi-layered zirconia, mimicking the natural gradient of dental enamel and dentin in terms of translucency and shade, further enhancing aesthetic outcomes.

Major Applications and Benefits: Zirconia powder is extensively used for manufacturing dental crowns, bridges, implant abutments, full-arch prostheses, and increasingly, orthodontic brackets. Its primary benefits include superior strength and longevity, reducing the risk of chipping or fracture compared to feldspathic ceramics. The material's exceptional biocompatibility ensures patient safety and integration with oral tissues, minimizing allergic reactions. Aesthetically, zirconia can be customized to match natural tooth shades, offering excellent translucency and esthetics, particularly with newer generations of materials. Driving factors for market growth include the rising global incidence of dental caries and periodontal diseases, an expanding geriatric population with increased demand for restorative dentistry, and the widespread adoption of digital dentistry workflows facilitated by CAD/CAM technology.

Dental Zirconium Oxide Powder Market Executive Summary

The Dental Zirconium Oxide Powder Market is experiencing robust growth, driven by an escalating demand for aesthetic and durable dental restorations coupled with significant advancements in digital dentistry. Key business trends include strategic mergers and acquisitions among leading manufacturers to consolidate market share and expand product portfolios. There is a strong emphasis on research and development, particularly in developing next-generation zirconia formulations offering enhanced translucency, improved milling characteristics, and broader shade ranges, catering to the nuanced requirements of modern cosmetic dentistry. Furthermore, strategic collaborations between material suppliers and dental CAD/CAM system providers are becoming prevalent, aiming to create integrated solutions that optimize workflow efficiency and clinical outcomes.

Regional trends indicate that the Asia Pacific (APAC) region is poised for the most rapid growth, fueled by a large and aging population, increasing disposable incomes, and improving access to advanced dental care. Emerging economies within APAC, such as China and India, are witnessing a surge in dental tourism and the establishment of sophisticated dental clinics equipped with cutting-edge technology. North America and Europe, while mature markets, continue to be significant contributors due to high awareness of dental aesthetics, well-established healthcare infrastructure, and consistent adoption of premium dental materials. Latin America and the Middle East & Africa are also showing promising potential, driven by healthcare infrastructure development and growing dental consumerism.

Segment trends highlight the dominance of CAD/CAM-compatible pre-sintered zirconia blocks and discs, which streamline the fabrication process in dental laboratories and clinics. The application segment sees dental crowns and bridges as the largest contributors, though demand for zirconia implant abutments and full-arch prostheses is steadily rising due reflecting advancements in implantology. The increasing adoption of multi-layered zirconia, which mimics the natural tooth structure's color and translucency gradient, represents a significant technological shift within the market. End-users such as large dental laboratories and specialized dental clinics are at the forefront of adopting these innovative materials, leveraging their benefits for superior patient satisfaction and operational efficiency.

AI Impact Analysis on Dental Zirconium Oxide Powder Market

The advent of Artificial Intelligence (AI) is poised to profoundly transform various facets of the Dental Zirconium Oxide Powder Market, addressing key user questions and concerns regarding precision, efficiency, and material optimization. Users frequently inquire about how AI can enhance the design and fabrication of zirconia restorations, reduce material waste, and improve patient outcomes. The central themes emerging from these inquiries revolve around AI's capability to introduce unprecedented levels of automation and intelligence into the dental workflow, from initial diagnostics to the final restoration. Expectations are high that AI will not only streamline existing processes but also unlock new possibilities for personalized and predictive dentistry.

Specifically, AI algorithms can analyze vast datasets of dental scans, patient histories, and material properties to recommend optimal zirconia types and designs for individual cases, considering factors like occlusal forces, patient anatomy, and aesthetic preferences. This data-driven approach minimizes guesswork and reduces the need for manual adjustments, leading to more accurate and predictable results. Furthermore, AI can play a crucial role in quality control during the manufacturing process of zirconia blocks and restorations, detecting minute flaws or inconsistencies that might compromise structural integrity or aesthetic quality. This predictive analytical capability ensures higher standards of product reliability, which is critical for long-term clinical success.

The impact extends to accelerating research and development efforts within the dental material sector. AI can simulate material behaviors under various clinical conditions, predict the performance of new zirconia formulations, and identify optimal compositions faster than traditional empirical methods. This not only shortens the development cycle for advanced zirconia powders but also enables the creation of materials with tailored properties for specific applications, such as enhanced translucency for anterior restorations or increased strength for posterior bridges. The integration of AI tools within CAD/CAM software also promises to empower dental technicians with intelligent design assistance, making complex restoration planning more intuitive and efficient, thereby democratizing access to high-quality zirconia prosthetics.

- AI-powered CAD/CAM design: Optimizing restoration contours, margins, and occlusal surfaces for precision and fit, reducing design time and errors.

- Predictive analytics for material selection: Recommending the ideal zirconia type (e.g., high strength, high translucency) based on clinical indication, patient data, and biomechanical requirements.

- Automated quality control: Utilizing computer vision and machine learning to detect defects in zirconia blocks or milled restorations, ensuring consistent quality.

- Enhanced manufacturing processes: AI algorithms optimizing sintering cycles and milling parameters to achieve superior material properties and minimize waste.

- Personalized treatment planning: AI assisting in assessing patient specific needs and recommending customized zirconia restoration solutions.

- Accelerated R&D of new materials: AI modeling and simulation for developing novel zirconia compositions with improved aesthetic and mechanical properties.

- Dental diagnostics and prognostics: AI aiding in early detection of dental issues and predicting the longevity of zirconia restorations.

DRO & Impact Forces Of Dental Zirconium Oxide Powder Market

The Dental Zirconium Oxide Powder Market is shaped by a complex interplay of drivers, restraints, and opportunities, alongside significant impact forces that influence its trajectory. Key drivers propelling market growth include the surging global demand for aesthetically pleasing and metal-free dental restorations. Patients increasingly prefer zirconia over traditional options due to its natural appearance and absence of metallic taste or allergic reactions. Furthermore, the burgeoning geriatric population, which often requires extensive restorative dental work, significantly contributes to the demand for durable and biocompatible materials like zirconia. The widespread adoption of advanced CAD/CAM technology in dental laboratories and clinics has also been a monumental driver, enabling precise and efficient fabrication of zirconia prosthetics, making the material more accessible and cost-effective.

Despite robust growth, several restraints challenge market expansion. The relatively high cost of zirconia materials and the specialized equipment (e.g., CAD/CAM systems, sintering furnaces) required for processing can be prohibitive for smaller dental practices or in developing regions with limited budgets. Technical sensitivity during fabrication, including precise milling and sintering protocols, demands skilled labor and strict adherence to manufacturing guidelines, which can pose a barrier to entry or consistent quality. Additionally, the emergence and continuous improvement of alternative restorative materials, such as advanced ceramics and composite resins, present a competitive threat, prompting ongoing innovation in zirconia to maintain its market edge.

Opportunities for market players are abundant, particularly in emerging economies where dental healthcare infrastructure is rapidly developing and disposable incomes are rising, leading to increased access to and demand for advanced dental treatments. Research and development into new zirconia formulations, such as those with enhanced optical properties, improved machinability, or antibacterial characteristics, offer avenues for product differentiation and market penetration. The integration of digital dentistry workflows, including intraoral scanners and advanced CAD/CAM software, presents further opportunities for streamlining processes and improving the accuracy and efficiency of zirconia restoration production. The impact forces within the market are characterized by moderate supplier power, as raw zirconia is a specialized commodity, but intense competitive rivalry among a growing number of manufacturers striving for innovation and market share. Buyer power is also considerable, especially from large dental laboratory chains and group practices, demanding competitive pricing and high-quality products. The threat of substitutes is moderate but constant, necessitating continuous product development.

Segmentation Analysis

The Dental Zirconium Oxide Powder Market is comprehensively segmented based on various critical parameters, providing a detailed understanding of its dynamics and growth prospects across different categories. This segmentation helps identify key demand patterns, technological preferences, and end-user adoption trends, which are crucial for strategic planning and market analysis. The market's structure is influenced by the specific forms of zirconia available, their primary applications in dentistry, and the distinct types of dental practitioners and facilities that utilize these advanced materials for patient care and research.

- Product Type:

- Pre-sintered Zirconia Blocks/Discs: These are partially sintered blocks that are easily milled into desired shapes using CAD/CAM technology, followed by full sintering. They offer excellent machinability and are the most widely adopted form.

- Fully Sintered Zirconia Blocks/Discs: These are densely sintered blocks, requiring specialized milling equipment for processing but offering immediate structural integrity post-milling.

- Liquid Zirconia Colorants: Solutions used to customize the shade of pre-sintered zirconia blocks, allowing for natural tooth matching before final sintering.

- Zirconia Powder (Raw Material): Fine powder used by manufacturers to produce blocks, discs, or other forms.

- Application:

- Dental Crowns: Single-tooth restorations, a major application due to zirconia's strength and aesthetics.

- Dental Bridges: Multi-unit restorations used to replace missing teeth, leveraging zirconia's durability.

- Dental Implants (Abutments and Prosthetics): Zirconia is increasingly used for implant abutments and full-arch prostheses due to its biocompatibility and aesthetic advantages.

- Dentures (Partial and Full): Used as a framework for dentures or in full-arch monolithic restorations.

- Orthodontic Brackets: Aesthetic alternative to metal brackets, offering transparency and strength.

- Inlays and Onlays: Used for conservative restorations, though less common than crowns and bridges.

- End-User:

- Dental Laboratories: The primary end-users, responsible for fabricating the majority of zirconia restorations using CAD/CAM systems.

- Dental Clinics: Increasingly adopting in-house CAD/CAM milling machines for same-day restoration services.

- Hospitals: Utilizing zirconia for complex oral surgeries and dental reconstructions.

- Academic and Research Institutes: Engaged in material science research, development of new applications, and training.

Value Chain Analysis For Dental Zirconium Oxide Powder Market

The value chain for the Dental Zirconium Oxide Powder Market begins with the upstream procurement and processing of raw materials, primarily zirconium silicate minerals. Specialized mining and refining companies extract zirconium minerals, which then undergo rigorous chemical purification processes to yield high-purity zirconium oxide. This refined oxide is then further processed into dental-grade zirconia powder by specialized material manufacturers. This upstream segment is characterized by strict quality control and advanced chemical engineering to ensure the powder meets the stringent biomedical standards required for dental applications, including precise particle size distribution, phase composition, and impurity levels. Suppliers in this phase typically operate globally, serving multiple industries beyond dentistry, which can influence pricing and availability.

Moving downstream, these dental-grade zirconia powders are supplied to manufacturers of dental blocks and discs. These manufacturers utilize advanced compaction, granulation, and pre-sintering technologies to transform the raw powder into semi-finished products—typically pre-sintered or fully sintered zirconia blocks/discs—that are compatible with CAD/CAM systems. This stage involves significant capital investment in machinery and expertise in ceramic processing. The products are then distributed through a network of specialized dental distributors, direct sales forces from large manufacturers, and sometimes directly to large dental laboratories or clinics. These distribution channels play a crucial role in market penetration, technical support, and product education.

The final stages of the value chain involve the end-users: dental laboratories, dental clinics, and hospitals. Dental laboratories form the largest customer base, acquiring zirconia blocks and discs, then utilizing CAD/CAM software for design and milling machines for fabrication, followed by sintering and finishing processes to create final restorations. Dental clinics increasingly adopt in-house CAD/CAM solutions for quicker turnaround times, while hospitals use zirconia for more complex restorative and surgical cases. The value chain concludes with the delivery of the final zirconia restoration to the patient, facilitated by the dental professional. Direct distribution from manufacturers to key accounts ensures efficient supply for large volume buyers, while indirect channels leverage regional distributors for broader market reach, particularly to smaller clinics and labs. Both channels emphasize technical support and training due to the specialized nature of zirconia materials and processing.

Dental Zirconium Oxide Powder Market Potential Customers

The primary potential customers for the Dental Zirconium Oxide Powder Market are professional entities within the dental industry that specialize in the fabrication and application of advanced dental prosthetics and restorations. These entities require high-quality, consistent zirconia materials to meet the demanding clinical and aesthetic needs of their patients. Dental laboratories represent the largest segment of potential customers. These facilities are equipped with sophisticated CAD/CAM systems, milling machines, and sintering furnaces, making them central hubs for the design and production of zirconia crowns, bridges, and implant components. Their demand is driven by the volume of referrals from individual dentists and dental clinics, as well as the increasing complexity and customization required for modern dental solutions.

Another significant customer segment includes dental clinics and group practices that have invested in in-house CAD/CAM technology. These clinics often purchase zirconia blocks and discs directly from manufacturers or distributors to offer same-day or expedited restorative services to their patients. The desire for greater control over the fabrication process, reduced turnaround times, and enhanced patient convenience drives their adoption of these materials. Hospitals with dedicated dental departments or oral and maxillofacial surgery units also constitute potential customers, particularly for complex cases requiring high-strength, biocompatible materials for reconstructive dentistry.

Furthermore, academic and research institutes focused on dental materials science and restorative dentistry represent a niche but important customer base. They procure dental zirconium oxide powder for experimental purposes, material characterization, development of new applications, and training future dental professionals. Their demand is often for specialized or raw powder forms for research rather than pre-milled blocks. Lastly, dental training centers and vocational schools also serve as potential customers, utilizing zirconia materials for educational purposes, teaching students about advanced dental ceramics and digital fabrication techniques, thereby contributing to the future workforce's proficiency with these materials. Each of these end-user segments is vital for the sustained growth and innovation within the Dental Zirconium Oxide Powder Market, with their evolving needs continually shaping product development and distribution strategies.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 425 million |

| Market Forecast in 2033 | USD 721 million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Dentsply Sirona, Ivoclar Vivadent, VITA Zahnfabrik, Zirkonzahn, Kuraray Noritake Dental Inc., 3M, Straumann Group, Danaher Corporation, GC Corporation, Shofu Inc., VOCO GmbH, Upcera Dental Technology Co., Ltd., Aidite Technology Co., Ltd., Shenzhen Upcera Dental Co., Ltd., AUSTROMED, Metalor Dental, Bego, Amann Girrbach AG, Ceramco Inc., White Peaks Dental Systems GmbH. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dental Zirconium Oxide Powder Market Key Technology Landscape

The Dental Zirconium Oxide Powder Market is inextricably linked with and driven by a rapidly evolving technological landscape, encompassing advancements in material science, processing techniques, and digital dentistry. At the core are sophisticated powder manufacturing technologies, such as spray drying, co-precipitation, and hydrothermal synthesis, which are critical for producing ultra-fine, homogenous zirconia particles with controlled morphology and consistent quality. These methods ensure that the raw zirconia powder possesses the optimal characteristics for subsequent shaping and sintering, directly influencing the mechanical and aesthetic properties of the final dental restoration. Innovations in stabilizing agents like yttria (Y2O3) are also paramount, enabling the creation of stronger, more fracture-resistant, and translucent zirconia formulations.

Further along the value chain, the proliferation of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems stands as a cornerstone technology. CAD software allows dental technicians to digitally design restorations with extreme precision, while CAM milling machines translate these designs into physical objects by precisely carving zirconia blocks or discs. The evolution of 5-axis milling machines, alongside advanced cutting tools and strategies, has significantly improved the efficiency and accuracy of zirconia processing, allowing for complex geometries and faster production times. This digital workflow minimizes manual errors, reduces material waste, and shortens the overall turnaround time for dental prosthetics, making zirconia a more viable and attractive option for a broader range of clinical applications.

Sintering technology is another critical component of the market's technological landscape. High-temperature sintering furnaces are essential for densifying the milled zirconia, transforming it from a porous, chalk-like state into a strong, monolithic ceramic. Recent innovations include faster sintering cycles without compromising material integrity, and specialized furnaces capable of precise temperature control and atmospheric conditions. Additionally, advanced characterization techniques, such as X-ray diffraction (XRD), scanning electron microscopy (SEM), and mechanical testing, are vital for ensuring the quality, phase stability, and clinical performance of both the raw powder and the finished restorations. These technologies collectively foster continuous innovation, enabling the development of zirconia materials with enhanced translucency, multi-layered aesthetics, and superior mechanical properties, thereby expanding the material's utility and market penetration in modern dentistry.

Regional Highlights

- North America: This region represents a mature and significant market for dental zirconium oxide powder, driven by high healthcare expenditure, strong adoption of advanced dental technologies like CAD/CAM, and a sophisticated consumer base with high awareness of aesthetic dentistry. The United States and Canada lead in technological advancements and early adoption of innovative zirconia formulations, with a robust presence of key market players and a well-established network of dental laboratories and clinics. The region also benefits from a high prevalence of dental diseases and a substantial aging population requiring prosthetic solutions.

- Europe: Europe is another key region characterized by strong research and development activities and stringent regulatory standards for dental materials. Countries like Germany, France, Italy, and the UK are major contributors, with Germany being a hub for high-quality dental material manufacturing and technological innovation. The increasing demand for metal-free restorations and the widespread integration of digital dentistry across the continent fuel market growth. European dental professionals often prioritize clinical evidence and long-term performance, leading to sustained demand for high-quality zirconia.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing market, propelled by an expanding middle class, rising disposable incomes, and significant improvements in dental healthcare infrastructure in countries like China, India, Japan, and South Korea. The region's large population, coupled with increasing dental tourism and a growing awareness of oral health and aesthetics, drives substantial demand for zirconia restorations. Local manufacturing capabilities are also developing rapidly, making zirconia more accessible and competitive in terms of pricing.

- Latin America: This region offers considerable growth potential, with increasing investments in healthcare infrastructure and a rising awareness of advanced dental treatments. Countries such as Brazil, Mexico, and Argentina are witnessing a gradual but steady adoption of modern dental materials and technologies. Economic development and urbanization are key factors contributing to the expansion of the dental market, creating new opportunities for zirconia product manufacturers and distributors.

- Middle East and Africa (MEA): The MEA region is an emerging market for dental zirconium oxide powder, characterized by significant disparities in dental healthcare access and technological adoption. However, countries within the GCC (Gulf Cooperation Council) such as UAE and Saudi Arabia are investing heavily in healthcare infrastructure and medical tourism, leading to increased demand for high-end dental restorative materials. In other parts of Africa, while market penetration is lower, there is a growing demand from urban centers and private clinics seeking advanced treatment options.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dental Zirconium Oxide Powder Market.- Dentsply Sirona

- Ivoclar Vivadent

- VITA Zahnfabrik

- Zirkonzahn

- Kuraray Noritake Dental Inc.

- 3M

- Straumann Group

- Danaher Corporation

- GC Corporation

- Shofu Inc.

- VOCO GmbH

- Upcera Dental Technology Co., Ltd.

- Aidite Technology Co., Ltd.

- Shenzhen Upcera Dental Co., Ltd.

- AUSTROMED

- Metalor Dental

- Bego

- Amann Girrbach AG

- Ceramco Inc.

- White Peaks Dental Systems GmbH

Frequently Asked Questions

Analyze common user questions about the Dental Zirconium Oxide Powder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is dental zirconium oxide powder used for?

Dental zirconium oxide powder is primarily used as a raw material for fabricating high-strength, aesthetic, and biocompatible dental restorations such as crowns, bridges, implant abutments, and full-arch prostheses. It is highly valued for its durability and natural appearance.

Why is zirconia preferred over other dental materials?

Zirconia is preferred due to its exceptional mechanical strength, fracture toughness, and superior biocompatibility, making it resistant to wear and allergies. It also offers excellent aesthetic properties, mimicking natural tooth translucency and color, unlike traditional metal-ceramic options.

What are the main benefits of zirconia dental restorations?

Key benefits include outstanding durability and longevity, natural aesthetics (tooth-like appearance), metal-free composition (eliminating allergic reactions), superior biocompatibility, and resistance to corrosion and plaque accumulation. It is also highly compatible with digital CAD/CAM workflows.

How has CAD/CAM technology impacted the dental zirconia market?

CAD/CAM technology has revolutionized the market by enabling highly precise, efficient, and cost-effective fabrication of zirconia restorations. It has streamlined the design and milling process, reducing laboratory turnaround times and making zirconia accessible for a broader range of clinical applications.

What are the latest trends in dental zirconia materials?

Current trends include the development of multi-layered zirconia with varying translucency and shade gradients for enhanced aesthetics, ultra-translucent zirconia for anterior restorations, and new formulations optimized for faster sintering protocols. The integration with AI-powered design and manufacturing processes is also a significant emerging trend.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager