Desiccant Breather Filter Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434313 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Desiccant Breather Filter Market Size

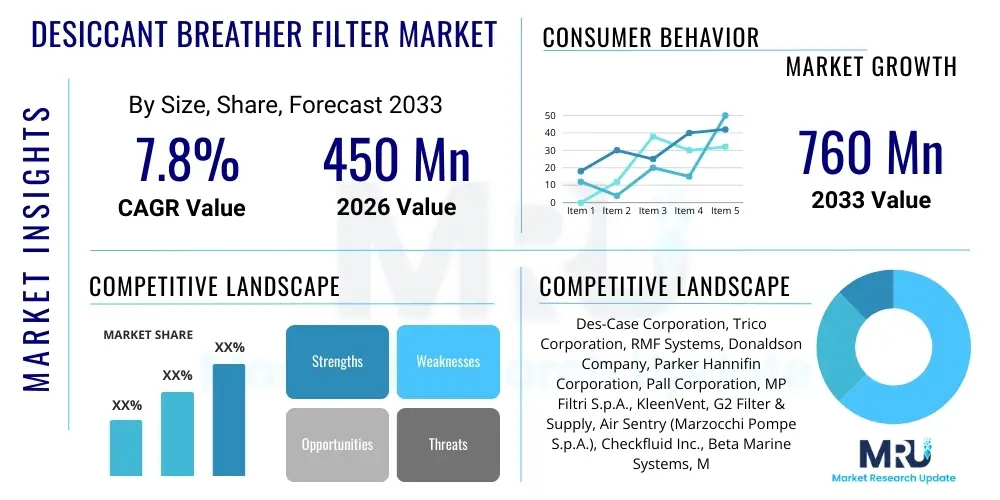

The Desiccant Breather Filter Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 760 Million by the end of the forecast period in 2033.

Desiccant Breather Filter Market introduction

The Desiccant Breather Filter Market encompasses specialized devices designed to protect industrial fluids and equipment, such as gearboxes, reservoirs, and hydraulic systems, from external moisture and particulate contamination. These breathers replace traditional, often ineffective, dust caps or open vents with a sophisticated filtration system incorporating desiccant material, typically silica gel, molecular sieve, or activated carbon. The primary function is dual: to dry the air entering the system as the fluid level drops or temperature fluctuates (breathing), and to filter airborne particulates, thereby preventing sludge formation, corrosion, and wear on internal components. This enhanced protection drastically extends the lifespan of lubricants and the machinery itself, making them indispensable components in modern preventative maintenance strategies across heavy industries.

Major applications for desiccant breathers span critical sectors including manufacturing, mining, oil and gas, power generation, and chemical processing. In hydraulic systems, they ensure the integrity of expensive fluids and precision components, minimizing downtime. For large power transformers and storage tanks, they manage atmospheric contamination, which is crucial for operational safety and regulatory compliance. The benefits derived from implementing high-quality desiccant breathers are substantial, focusing primarily on maintenance cost reduction and increased operational reliability. By controlling water ingress—a major cause of lubricant degradation and component failure—companies realize significant savings on fluid replacement and unscheduled repairs.

The market is currently driven by increasing industrial automation, stringent regulatory requirements concerning machinery lifespan and environmental protection, and a growing global focus on predictive and preventative maintenance strategies. The adoption of advanced synthetic lubricants, which are highly susceptible to moisture degradation, further necessitates the use of high-performance breathers. Moreover, continuous technological improvements in breather design, such as color-indicating silica gel for easy replacement scheduling and higher capacity filtering elements, contribute to market expansion. The shift towards optimizing total cost of ownership (TCO) over initial investment is a fundamental factor propelling the demand for these protective solutions across developed and emerging economies.

Desiccant Breather Filter Market Executive Summary

The Desiccant Breather Filter Market exhibits robust growth driven by the imperative to maximize asset reliability and minimize maintenance expenses across heavy industrial landscapes. Current business trends indicate a strong move towards integrated solutions that combine moisture absorption with superior particle filtration efficiency, often incorporating smart technology for real-time monitoring of saturation levels. Manufacturers are focusing on developing products with extended service life and enhanced chemical compatibility to suit challenging operational environments, particularly those involving aggressive contaminants or extreme temperature variations. The competitive landscape is characterized by innovation in material science, leading to third-generation breathers that offer improved airflow while maintaining high levels of contaminant exclusion, appealing directly to industries seeking peak operational efficiency and reduced waste.

Regionally, North America and Europe maintain leading positions, primarily due to well-established preventative maintenance cultures, stringent industrial safety standards, and the early adoption of advanced machinery health monitoring systems. However, the Asia Pacific (APAC) region is projected to register the fastest growth rate. This accelerated expansion is attributed to rapid industrialization, significant investments in infrastructure, and the increasing operational maturity of sectors such as manufacturing, construction, and mining in countries like China, India, and Southeast Asia. The transition from reactive to proactive maintenance in APAC, coupled with the installation of large fleets of new machinery, serves as a primary catalyst for demand, particularly in high-humidity climates where moisture control is critical.

Segment trends highlight the dominance of the silica gel-based breather type due to its cost-effectiveness and visible saturation indication. However, the demand for specialized desiccants like molecular sieves is increasing rapidly in high-temperature or extreme chemical environments where conventional silica gel performance may be compromised. Application-wise, hydraulic systems and large gearboxes remain the largest end-use segments, critical to ensuring continuous operation in manufacturing and energy sectors. Furthermore, the rising integration of IoT and sensor technology into desiccant breathers is establishing a new segment of ‘smart breathers,’ offering predictive failure warnings and optimizing replacement schedules, thereby solidifying their role in Industry 4.0 environments.

AI Impact Analysis on Desiccant Breather Filter Market

User queries regarding AI's influence on the Desiccant Breather Filter Market predominantly center around integration with Predictive Maintenance (PdM) platforms, optimization of replacement cycles, and the potential for AI-driven material science breakthroughs. Users frequently ask: "Can AI predict when a desiccant breather needs changing before the color indicator signals saturation?" and "How will machine learning leverage breather saturation data to improve overall machinery reliability models?" The core expectation is that AI will move the breather from a passive protection component to an active, data-generating sensor within a larger connected industrial ecosystem. Users are keen on understanding how AI algorithms can analyze variables like humidity spikes, operational cycles, and pressure differentials, alongside visual indicators, to create highly accurate, just-in-time maintenance alerts, minimizing both premature disposal and catastrophic equipment failure due to overdue replacement.

The application of Artificial Intelligence within the desiccant breather domain primarily focuses on data aggregation and advanced pattern recognition derived from integrated sensors (humidity, temperature, pressure drop). AI algorithms analyze vast datasets generated by fleets of machinery, learning the typical 'breathing' patterns associated with healthy operation versus patterns that signal impending desiccant exhaustion or filter clogging. This analysis allows for the development of precise, localized environmental models, leading to dynamic replacement schedules tailored to specific assets and geographical conditions, moving far beyond static time-based or color-based indicators. This refinement translates directly into cost savings and maximized uptime for end-users.

Furthermore, AI is beginning to influence the design and manufacturing side of the market. Machine learning is being utilized to simulate fluid dynamics and air flow through various filtration media configurations, accelerating the development of next-generation breather designs that offer higher efficiency and longer life while maintaining compact footprints. In the future, AI-driven feedback loops from field performance data will inform material engineers about optimal desiccant mixture ratios and housing designs, leading to highly customized, environment-specific breather solutions. This holistic integration of AI transforms the market from a component supply chain into a data-driven reliability service offering.

- AI enhances Predictive Maintenance (PdM) systems by integrating breather sensor data (humidity, differential pressure).

- Machine learning algorithms optimize desiccant replacement schedules, preventing premature disposal and avoiding late failures.

- AI facilitates anomaly detection, correlating unusual breather performance with potential underlying machinery faults.

- Generative AI tools assist in simulating new breather designs and optimizing filtration media geometry for superior performance.

- IoT-enabled smart breathers feed real-time saturation and contamination data directly into enterprise asset management (EAM) systems.

DRO & Impact Forces Of Desiccant Breather Filter Market

The dynamics of the Desiccant Breather Filter Market are fundamentally shaped by the constant tension between industrial reliability demands and cost pressures. Key drivers include the escalating global investment in infrastructure, especially in emerging economies, necessitating the protection of new, high-value mechanical assets. The pervasive shift towards highly efficient, precise industrial machinery, often coupled with sophisticated synthetic lubricants, significantly raises the cost of contamination and mandates higher levels of preventative maintenance, thus boosting breather demand. Furthermore, stricter environmental regulations concerning waste oil and machinery lifespan incentivize operators to adopt advanced filtration and protection technologies to prolong fluid life and reduce environmental footprint. These positive factors create a strong upward momentum in the market trajectory.

However, significant restraints temper this growth. The most persistent challenge is the lack of awareness and perceived high initial cost, particularly among smaller or conventionally managed industrial operations that still rely on outdated, non-desiccant vent caps. This inertia represents a significant barrier to entry, requiring extensive educational marketing efforts from manufacturers. Another restraint involves the challenges associated with proper disposal and recycling of used desiccant materials, which can contain absorbed contaminants and pose minor environmental concerns if not managed correctly. Moreover, the prevalence of low-quality, counterfeit products, particularly in loosely regulated markets, erodes consumer confidence and introduces performance variability, making it difficult for high-quality manufacturers to compete solely on price.

The key opportunities in this sector lie in the development and proliferation of ‘smart’ desiccant breathers equipped with integrated wireless monitoring capabilities (IoT), allowing for seamless integration into Industry 4.0 platforms. This innovation addresses the historical pain point of manual monitoring and unpredictable replacement timing. Another substantial opportunity resides in customizing breather solutions for extreme applications, such as high vibration, chemical processing, and very low-temperature environments, where standardized products fail. The increasing trend of retrofitting older machinery with modern protective technologies also provides a sustainable revenue stream. Impact forces, driven by increasing regulatory focus on machinery longevity and the high costs associated with unplanned downtime, ensure that reliability solutions, including desiccant breathers, remain a priority investment for capital-intensive industries globally.

Segmentation Analysis

The Desiccant Breather Filter Market is systematically segmented based on Type of Desiccant Material, Application, End-Use Industry, and geographic region. This segmentation provides a granular view of demand distribution and technological preferences across the industrial spectrum. The choice of desiccant material, whether silica gel, activated carbon, or molecular sieve, dictates the breather’s performance characteristics, specifically its moisture absorption capacity and suitability for environments requiring vapor or odor control. For instance, while silica gel dominates due to its visual indication capability, activated carbon is essential in chemical plants to mitigate exposure to fumes and hydrocarbon vapors.

The segmentation by Application is crucial as it dictates the required size and flow capacity of the breather. Heavy-duty applications like large hydraulic reservoirs in mining require high airflow capacity to handle rapid fluid displacement, whereas smaller gearboxes may only require micro-breathers. The primary functional segments—moisture absorption, particle filtration, and vacuum pressure relief—are often integrated into a single product, but product design must cater to the specific operational stress of the target system, such as oil sump vents, gear cases, or storage tanks. The trend is moving towards multi-stage filtration solutions that offer enhanced particle efficiency alongside superior moisture capture.

Furthermore, segmentation by End-Use Industry (e.g., Oil & Gas, Manufacturing, Mining) illustrates the varying adoption rates driven by industry-specific reliability standards and maintenance budgets. Industries that incur extremely high costs from downtime, such as power generation and critical manufacturing, exhibit higher willingness to invest in premium, high-capacity breathers and predictive monitoring solutions. Conversely, industries facing high dust loads, like mining and construction, prioritize durable housing materials and advanced particle filtration ratings, often employing specialized materials designed for resilience against extreme external contamination.

- By Type of Desiccant Material:

- Silica Gel (Color-indicating and Non-indicating)

- Molecular Sieve (For high-temperature/low-humidity applications)

- Activated Carbon (For odor/vapor absorption alongside moisture)

- By Application:

- Hydraulic Reservoirs

- Gearboxes and Transmissions

- Oil Sumps and Storage Tanks

- Transformers and Lubricant Drums

- By End-Use Industry:

- Manufacturing and Automotive

- Mining, Construction, and Quarrying

- Oil & Gas and Petrochemical

- Power Generation (Wind, Hydro, Thermal)

- Pulp and Paper

- Water and Wastewater Treatment

- By Breather Function/Capacity:

- Standard Disposable Breathers

- High-Capacity Breathers

- Self-Rechargeable/Rebuildable Systems

- Vacuum/Pressure Relief Valves Integrated Breathers

Value Chain Analysis For Desiccant Breather Filter Market

The value chain for the Desiccant Breather Filter Market begins with the upstream suppliers responsible for raw materials, primarily specialized plastics for housing, filter media (like fiberglass or cellulose), and the desiccant materials (silica gel, molecular sieves). Quality control at this stage is paramount, as the porosity of the filter media and the absorption efficiency of the desiccant directly determine the final product performance. Key upstream activities involve sourcing materials that meet industrial durability standards and ensuring consistent supply of highly effective desiccant material, often requiring specialized chemical processing capabilities. Innovations in this segment focus on developing bio-degradable housing plastics and highly efficient, recyclable desiccant formulations.

The midstream segment involves the core manufacturing process, where raw materials are assembled into the final breather product. This includes injection molding of plastic housing, precise filling of desiccant material, careful pleating and assembly of particle filtration media, and final sealing. Manufacturers invest heavily in automated assembly lines and rigorous testing protocols to ensure products meet specified micron ratings and flow rates. Differentiation in the midstream often occurs through proprietary designs, such as multi-stage filtration layers, integration of specialized pressure relief valves, and the incorporation of moisture indicators that offer greater visibility and longevity than standard market offerings.

The downstream segment encompasses distribution and end-user engagement, crucial for market success. Distribution channels are typically bifurcated: direct sales to major Original Equipment Manufacturers (OEMs) for new machinery installations, and indirect sales through specialized industrial distributors, maintenance, repair, and overhaul (MRO) suppliers, and lubrication service providers. Direct channels offer stability and volume, while indirect channels provide market penetration and reach smaller businesses. Lubrication specialists play a vital role in educating end-users about the necessity and economic benefits of desiccant breathers, often integrating them into comprehensive fluid management programs. Effective logistics and inventory management are critical to ensuring MRO suppliers can rapidly fulfill replacement orders, which are often demanded under urgent maintenance schedules.

Desiccant Breather Filter Market Potential Customers

Potential customers for desiccant breather filters are overwhelmingly concentrated in sectors utilizing large, expensive, and sensitive mechanical equipment requiring lubricant and fluid protection. The largest consumers are typically heavy industries where machinery is exposed to harsh environmental conditions, high duty cycles, or significant temperature fluctuations. Primary end-users include operators of hydraulic presses, large mobile earthmoving equipment, industrial gear drives in process plants, and bulk fluid storage tanks. These systems contain lubricants or insulating oils that are highly susceptible to moisture ingress, which can rapidly diminish fluid properties, cause rust on internal components, and lead to costly catastrophic failures. The investment in breathers is directly proportional to the replacement cost of the protected asset and the cost of associated downtime.

The customer base is further segmented by maintenance philosophy. Customers adhering to stringent preventative maintenance (PM) or predictive maintenance (PdM) schedules are more likely to procure high-quality, high-capacity breathers and invest in smart, sensor-enabled variants. These advanced users view breathers not merely as components, but as essential tools for maximizing Return on Asset (ROA). Conversely, customers in decentralized industries like agriculture or smaller construction firms focus on economical, standard disposable models but still represent a substantial volume market segment, driven by the need for basic compliance and protection.

Beyond traditional industrial applications, emerging potential customers include wind power generation facilities, where gearboxes are remote, expensive to service, and exposed to extreme weather variations, making protection critical. Additionally, data centers and telecommunications facilities, which utilize backup diesel generators and complex cooling systems, are increasingly adopting desiccant technology to protect fuel and hydraulic fluids from atmospheric moisture, ensuring reliability during critical operational windows. In essence, any organization reliant on continuous operation of fluid-filled machinery constitutes a potential customer, with procurement often managed by reliability engineers, plant managers, or MRO purchasing departments focused on long-term operational resilience.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 760 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Des-Case Corporation, Trico Corporation, RMF Systems, Donaldson Company, Parker Hannifin Corporation, Pall Corporation, MP Filtri S.p.A., KleenVent, G2 Filter & Supply, Air Sentry (Marzocchi Pompe S.p.A.), Checkfluid Inc., Beta Marine Systems, Martec, Oil-Rite Corporation, Stauff, Hydrotechnik, Lubrigard, Hy-Pro Filtration, Zinga Industries, United Filtration Systems. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Desiccant Breather Filter Market Key Technology Landscape

The technology landscape of the Desiccant Breather Filter Market is centered on enhancing three core performance metrics: moisture absorption efficiency, particle filtration efficacy, and overall system longevity. Modern breathers utilize advanced proprietary desiccant blends that often combine high-purity silica gel for initial absorption with molecular sieves to ensure optimal performance even at very low relative humidity levels or high operating temperatures. This multi-stage desiccant technology maximizes the absorption life and minimizes the frequency of replacements. Furthermore, many leading breathers now incorporate visual indicators, such as color-changing gels, which provide clear, immediate feedback to maintenance staff on the remaining capacity of the desiccant, moving beyond simple time-based replacement schedules to condition-based monitoring.

In terms of filtration, the industry is increasingly adopting highly efficient, pleated synthetic media with beta ratios (ßx>1000) that meet or exceed stringent ISO standards (e.g., ISO 4406 Cleanliness Codes). This commitment to high particle filtration efficiency (often 3-micron absolute or better) is essential for protecting modern, tight-tolerance hydraulic and lubrication systems. A significant technological advancement is the integration of high-flow check valve systems within the breather housing. These valves manage pressure equalization, ensuring that air is only drawn through the desiccant and filter media when necessary, optimizing desiccant life and preventing excessive moisture ingress during static periods. They also mitigate vacuum formation within the reservoir during system operation or cooling.

The most transformative current technology involves the integration of Internet of Things (IoT) sensors, creating the segment known as 'Smart Breathers.' These devices include sensors for measuring differential pressure across the particle filter, relative humidity/saturation levels within the desiccant, and operating temperature. They communicate wirelessly (e.g., via Bluetooth or specialized industrial protocols) to centralized monitoring dashboards or Enterprise Asset Management (EAM) systems. This technological leap allows for true predictive maintenance of the breather itself, reducing manual inspections, preventing unscheduled downtime caused by clogged filters, and providing crucial contamination data that feeds into overall machinery health assessments, aligning the breather market directly with broader Industry 4.0 digitalization efforts.

Regional Highlights

- North America: This region is characterized by high adoption rates driven by strict maintenance protocols, a large installed base of high-value industrial machinery in the Oil & Gas, mining, and aerospace sectors, and a strong preference for predictive and proactive maintenance technologies. The U.S. and Canada lead the market due to robust industrial safety standards and high labor costs, making the investment in components that reduce manual intervention (like smart breathers) highly attractive.

- Europe: Europe represents a mature market focusing heavily on sustainability and efficiency. Regulations like REACH influence material choices, favoring high-quality, long-life, and potentially recyclable breather components. Germany, France, and the UK are key markets, showing strong demand from the advanced manufacturing (e.g., automotive) and renewable energy (wind farms) sectors, prioritizing breathers that offer certified high particle efficiency and environmental compliance.

- Asia Pacific (APAC): Expected to be the fastest-growing region, APAC’s demand is fueled by massive infrastructure expansion, rapid industrialization, and significant investment in new manufacturing capacity, particularly in China and India. The high humidity levels prevalent in Southeast Asia and coastal areas make moisture control critical, driving the volume demand for both standard and high-capacity desiccant solutions across construction, mining, and maritime industries.

- Latin America: This region shows steady growth, driven primarily by the mining and raw material processing sectors (e.g., Brazil, Chile). Adoption is often tied to large multinational corporations operating locally, who implement global maintenance standards requiring high-performance fluid protection. Market growth is sensitive to commodity price fluctuations affecting capital expenditure in these heavy industries.

- Middle East and Africa (MEA): Growth is dominated by the Oil & Gas sector, where the protection of specialized extraction and refining equipment is paramount. High ambient temperatures and arid conditions necessitate robust breather designs capable of handling extreme operational environments while preventing the ingress of fine desert dust alongside intermittent moisture exposure. Investment is concentrated in Saudi Arabia, UAE, and South Africa, focusing on high-capacity, durable solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Desiccant Breather Filter Market.- Des-Case Corporation

- Trico Corporation

- RMF Systems (Stauff Group)

- Donaldson Company, Inc.

- Parker Hannifin Corporation

- Pall Corporation (Danaher)

- MP Filtri S.p.A.

- KleenVent

- G2 Filter & Supply

- Air Sentry (Marzocchi Pompe S.p.A.)

- Checkfluid Inc.

- Beta Marine Systems

- Martec

- Oil-Rite Corporation

- Stauff

- Hydrotechnik

- Lubrigard

- Hy-Pro Filtration

- Zinga Industries

- United Filtration Systems

Frequently Asked Questions

Analyze common user questions about the Desiccant Breather Filter market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a desiccant breather filter?

The primary function is the dual protection of industrial fluids and machinery reservoirs against atmospheric contamination. Desiccant breathers simultaneously remove airborne particulate matter down to specific micron ratings and absorb moisture vapor from the air entering the system during temperature fluctuations or fluid level changes, thereby preventing corrosion and lubricant degradation.

How does a "smart breather" differ from a standard desiccant breather?

A smart breather incorporates integrated electronic sensors (humidity, temperature, pressure drop) and communication technology (IoT). Unlike standard breathers, which rely on visual indicators or time intervals for replacement, smart breathers provide real-time data on saturation and performance status, enabling predictive maintenance scheduling and minimizing the risk of contamination failure.

Which desiccant material is best for high-temperature applications?

Molecular sieve desiccant is generally considered superior for high-temperature or low-humidity environments where standard silica gel may lose efficiency or become less effective at stripping trace moisture. Molecular sieves maintain their structure and high absorption capacity across a wider range of challenging operational temperatures, ensuring consistent fluid protection.

What are the key benefits of using desiccant breathers in hydraulic systems?

The key benefits in hydraulic systems include significantly extended fluid life by eliminating water contamination (which causes hydrolysis), reduced component wear by filtering fine particles, prevention of pump cavitation, and overall decrease in unplanned downtime. This results in substantial savings on lubricant replacement costs and critical component maintenance.

Is the Desiccant Breather Filter Market influenced by Industry 4.0 trends?

Yes, the market is highly influenced by Industry 4.0. The shift toward digitalization and connectivity is driving the demand for IoT-enabled desiccant breathers, which integrate seamlessly into centralized predictive maintenance platforms. This technological convergence optimizes maintenance practices and enhances overall asset management strategies globally.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager