Desiccant Dryer Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440304 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Desiccant Dryer Market Size

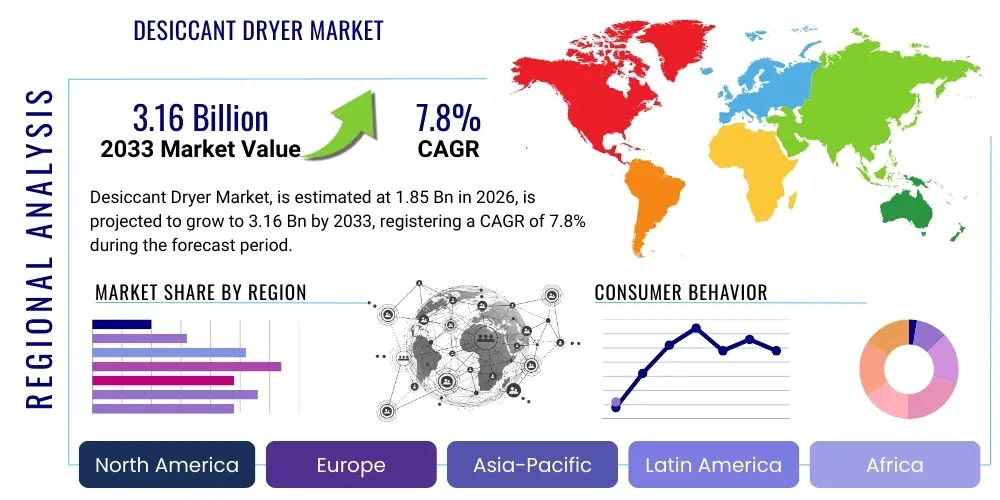

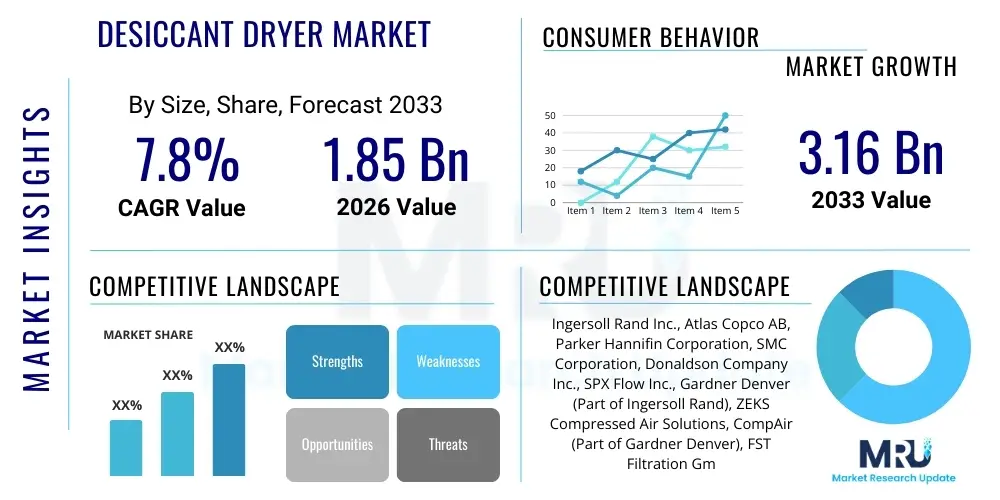

The Desiccant Dryer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 3.16 Billion by the end of the forecast period in 2033.

Desiccant Dryer Market introduction

The Desiccant Dryer Market encompasses the manufacturing, distribution, and sales of equipment designed to remove moisture from compressed air and various industrial gases. These systems are critical for maintaining the integrity and efficiency of sensitive industrial processes, preventing corrosion, product contamination, and downtime caused by moisture-related issues. Desiccant dryers typically employ adsorbent materials like activated alumina, molecular sieves, or silica gel to achieve very low dew points, often far below what refrigerated dryers can achieve, making them indispensable in applications requiring extremely dry air.

The primary function of a desiccant dryer is to protect pneumatic systems, control instrumentation, and final products from the detrimental effects of moisture. Major applications span across diverse industries, including general manufacturing, food and beverage processing, pharmaceuticals, chemicals, oil and gas, electronics, and automotive. In these sectors, even minute traces of moisture can lead to significant operational failures, compromise product quality, and increase maintenance costs, underscoring the vital role of effective moisture removal. The market offers various types of desiccant dryers, such as heatless, heated (blower purge, external heated, internal heated), and modular designs, each tailored to specific operational requirements and energy efficiency goals.

The key benefits of desiccant dryers include enhanced equipment longevity, improved process reliability, reduced product spoilage, and compliance with stringent industry standards for air quality. Driving factors for market growth include the global expansion of industrial manufacturing, increasing automation in production processes, rising awareness regarding the importance of dry air for operational efficiency and product quality, and the growing demand for energy-efficient drying solutions. Furthermore, advancements in desiccant materials and control technologies, coupled with a push towards lower operating costs, are continuously shaping market dynamics and fostering innovation.

Desiccant Dryer Market Executive Summary

The Desiccant Dryer Market is experiencing robust growth, primarily driven by the escalating demand for high-quality compressed air across a myriad of industrial applications. Business trends indicate a significant shift towards smart, energy-efficient, and IoT-enabled desiccant drying solutions, as industries seek to optimize operational costs and enhance system reliability. Manufacturers are increasingly integrating advanced control systems, remote monitoring capabilities, and predictive maintenance features into their products, catering to the evolving needs of modern manufacturing facilities. The competitive landscape is characterized by both established global players and niche specialists, all vying for market share through product innovation, strategic partnerships, and expanded service offerings. Furthermore, a growing emphasis on sustainability and environmental regulations is prompting the development of dryers with lower energy consumption and longer-lasting desiccant materials, influencing purchasing decisions across the industrial spectrum.

Regional trends highlight Asia Pacific as the most dynamic and rapidly expanding market for desiccant dryers, fueled by aggressive industrialization, infrastructure development, and the burgeoning manufacturing sector in countries like China, India, and Southeast Asian nations. North America and Europe, while mature markets, continue to demonstrate steady growth, driven by stringent quality standards, technological upgrades in existing facilities, and a strong focus on energy efficiency and automation. Latin America and the Middle East & Africa regions are also exhibiting promising growth, spurred by investments in oil and gas, chemical processing, and general manufacturing industries, which necessitate reliable dry air solutions to protect critical equipment and processes.

From a segmentation perspective, the market is witnessing strong demand for both heatless and heated desiccant dryers, with specific choices depending on desired dew points, energy costs, and application requirements. Heatless regenerative dryers remain popular for their simplicity and effectiveness, while heated dryers, particularly blower purge types, are gaining traction due to their lower energy consumption and operational efficiency for larger capacities. The manufacturing, food and beverage, and pharmaceutical industries represent the largest end-use segments, each presenting unique demands for moisture control to ensure product integrity and operational safety. There is a discernible trend towards customized solutions that address specific industry challenges, such as food-grade air requirements or explosion-proof designs for hazardous environments, indicating a nuanced evolution within the market.

AI Impact Analysis on Desiccant Dryer Market

The integration of Artificial Intelligence (AI) into the desiccant dryer market is generating significant interest among users, focusing primarily on enhancing operational efficiency, reducing energy consumption, and enabling predictive maintenance. Common user questions revolve around how AI can optimize regeneration cycles, extend desiccant life, provide real-time performance analytics, and ultimately lower total cost of ownership. Users are keen to understand the practical applications of AI in monitoring dew point fluctuations, anticipating potential failures, and automatically adjusting operating parameters to maintain desired air quality while minimizing energy waste. There is also curiosity about the feasibility of AI-driven remote diagnostics and autonomous control systems for managing dryer networks across multiple facilities, alongside concerns regarding data security, integration complexity, and the initial investment required for AI-enabled systems.

AI's influence is poised to transform desiccant dryer operations from reactive maintenance to proactive management. By continuously analyzing operational data—such as inlet air temperature, pressure, flow rates, and dew point—AI algorithms can identify patterns and deviations that indicate impending issues or inefficiencies. This capability moves beyond simple alarm systems, offering deep insights into the dryer's health and predicting when maintenance or desiccant replacement will be necessary, thereby minimizing unscheduled downtime and optimizing resource allocation. Moreover, AI can learn from historical performance data to dynamically adjust regeneration cycles, ensuring optimal moisture removal with the least possible energy expenditure, adapting to fluctuating process demands rather than operating on fixed schedules.

The long-term expectations for AI in this domain include the development of self-optimizing desiccant dryer systems that require minimal human intervention, offering unparalleled reliability and cost-effectiveness. The ability of AI to integrate with broader plant management systems (e.g., SCADA, DCS) further enhances its value, enabling holistic control and energy management across an entire facility's compressed air infrastructure. While initial concerns about implementation costs and data management persist, the overwhelming user sentiment points towards a strong desire for AI-driven solutions that promise smarter, more efficient, and more resilient desiccant drying operations, positioning AI as a pivotal technology for future market growth and competitive differentiation.

- Predictive maintenance for desiccant beds and valves, reducing unplanned downtime.

- Optimized regeneration cycles based on real-time demand and environmental conditions, leading to significant energy savings.

- Real-time performance monitoring and analytics, providing actionable insights into dryer efficiency and air quality.

- Autonomous fault detection and diagnostics, enabling quicker troubleshooting and reduced maintenance costs.

- Integration with broader industrial IoT platforms for centralized control and management of compressed air systems.

- Extended lifespan of desiccant materials through intelligent load management and regeneration sequencing.

- Enhanced data-driven decision-making for equipment upgrades and system design improvements.

DRO & Impact Forces Of Desiccant Dryer Market

The Desiccant Dryer Market is profoundly influenced by a complex interplay of drivers, restraints, opportunities, and external impact forces. A primary driver is the accelerating pace of industrialization and manufacturing across the globe, particularly in emerging economies, which inherently increases the demand for high-quality, moisture-free compressed air. Industries are increasingly adopting stringent quality standards for their production processes, necessitating the use of advanced desiccant dryers to protect sensitive equipment, prevent product contamination, and ensure consistent operational efficiency. Furthermore, the growing emphasis on energy efficiency and sustainability in industrial operations is prompting companies to invest in modern desiccant dryer technologies that offer lower operating costs and reduced environmental footprints, thereby fueling market expansion.

However, the market also faces notable restraints. The initial high capital investment associated with desiccant dryer systems, especially for larger industrial applications or advanced models, can be a significant barrier for smaller enterprises or those with limited budgets. Additionally, the operational costs, primarily related to energy consumption during regeneration cycles and the periodic replacement of desiccant material, can impact overall profitability. The availability of alternative drying methods, such as refrigerated dryers, which are more cost-effective for applications requiring less stringent dew points, also poses a competitive restraint. Moreover, the lack of awareness about the long-term benefits of dry air or insufficient technical expertise in selecting and maintaining desiccant dryers in some regions can hinder broader adoption.

Despite these challenges, numerous opportunities exist for market growth. The ongoing technological advancements in adsorbent materials, control systems, and smart features (e.g., IoT, AI integration) are creating new avenues for product differentiation and market penetration. Emerging economies, with their rapidly expanding industrial bases, represent significant untapped potential for desiccant dryer manufacturers. The increasing demand for customized drying solutions tailored to specific industry needs, such as medical air or food-grade applications, offers specialized market niches. Finally, regulatory pressures for improved air quality and reduced environmental impact, coupled with the drive for operational excellence across industries, present compelling opportunities for manufacturers to innovate and offer solutions that address these evolving demands, thereby shaping the future trajectory of the market.

Segmentation Analysis

The Desiccant Dryer Market is meticulously segmented across various dimensions to provide a comprehensive understanding of its intricate dynamics and diverse customer needs. These segmentation categories typically include dryer type, application, end-use industry, and geographical region, each offering unique insights into market preferences, technological adoption rates, and growth opportunities. Analyzing these segments allows market players to tailor their product offerings, marketing strategies, and distribution channels to effectively target specific customer groups and address their distinct requirements for moisture removal solutions. The precise understanding of these segments is crucial for identifying emerging trends, competitive advantages, and potential areas for innovation within the broader desiccant dryer landscape, enabling strategic business decisions and fostering sustainable growth.

- By Type:

- Heatless Regenerative Desiccant Dryers

- Heated Regenerative Desiccant Dryers

- Blower Purge Heated Desiccant Dryers

- External Heated Desiccant Dryers

- Internal Heated Desiccant Dryers

- Modular Desiccant Dryers

- Membrane Dryers (sometimes categorized with desiccant for ultra-dry air)

- Refrigerated-Desiccant Dryers (combination units)

- By Application:

- Compressed Air Systems

- Process Air

- Instrument Air

- Pneumatic Tools and Equipment

- Medical Air Systems

- Food Grade Air Systems

- By End-Use Industry:

- Manufacturing (General Industrial)

- Food and Beverage

- Pharmaceutical and Biotechnology

- Chemical and Petrochemical

- Oil and Gas

- Electronics and Semiconductor

- Automotive

- Healthcare

- Textiles

- Power Generation

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, UK, France, Italy, Spain, Rest of Europe)

- Asia Pacific (China, India, Japan, South Korea, ASEAN, Rest of APAC)

- Latin America (Brazil, Argentina, Rest of Latin America)

- Middle East and Africa (GCC Countries, South Africa, Rest of MEA)

Value Chain Analysis For Desiccant Dryer Market

The value chain for the Desiccant Dryer Market is a complex network involving multiple stakeholders, from raw material suppliers to end-users, each contributing to the product's final value and delivery. At the upstream end, the chain begins with the procurement of critical raw materials and components. This includes adsorbent materials like activated alumina, molecular sieves, and silica gel, which are fundamental to the drying process. Additionally, manufacturers source various metals such as steel and aluminum for dryer vessels, structural components, and piping, alongside electrical and electronic components for control systems, valves, sensors, and instrumentation. Specialized components like blower motors, heaters, and filtration media are also procured from a diverse base of suppliers, necessitating robust supply chain management to ensure quality, cost-effectiveness, and timely delivery of these essential inputs.

Moving further along the value chain, the manufacturing stage involves the design, engineering, assembly, and testing of the desiccant dryer units. This phase often includes sophisticated R&D activities focused on improving energy efficiency, enhancing desiccant life, and integrating advanced control technologies like PLCs and IoT sensors. Manufacturers convert raw materials into finished products, adhering to strict quality standards and safety regulations. This stage also includes the fabrication of pressure vessels, the installation of intricate piping systems, the wiring of electrical components, and the programming of control logic to ensure optimal performance and reliability of the dryer systems. The ability to innovate and produce high-performance, durable, and cost-competitive dryers is a key differentiator in this segment of the value chain.

The downstream segment of the value chain focuses on distribution, sales, installation, and after-sales services. Desiccant dryers reach end-users through various channels, including direct sales to large industrial clients, a network of distributors and resellers, and original equipment manufacturers (OEMs) who integrate these dryers into larger compressed air systems. Direct sales allow for closer customer relationships and customized solutions, while indirect channels provide broader market reach. Post-sale services, such as installation, commissioning, maintenance, spare parts supply, and technical support, are crucial for customer satisfaction and long-term retention. These services ensure the continuous optimal operation of the dryers, prolong their lifespan, and address any operational issues, thereby adding significant value throughout the product's lifecycle and forming a critical part of the overall customer experience.

Desiccant Dryer Market Potential Customers

Potential customers for desiccant dryers span a wide array of industries and applications where the presence of moisture in compressed air or other process gases can lead to detrimental outcomes. These end-users are primarily driven by the need to protect sensitive equipment, ensure product quality, comply with industry standards, and optimize operational efficiency. Manufacturing facilities across sectors, for instance, are significant consumers, relying on dry air for pneumatic tools, spray painting, sandblasting, and automated machinery to prevent corrosion, wear, and system failures. The diverse requirements of these industries mean that desiccant dryer manufacturers often need to offer a range of products with varying capacities, dew points, and design features to cater to specific operational demands.

In the food and beverage industry, potential customers include breweries, dairies, bakeries, and packaging plants. Here, ultra-dry, oil-free air is critical to prevent product contamination, inhibit microbial growth, and maintain the quality and shelf-life of food items. Desiccant dryers are essential for applications like conveying ingredients, bottle blowing, and aseptic packaging, where moisture can directly compromise consumer safety and product integrity. Similarly, pharmaceutical and biotechnology companies are vital customers, utilizing desiccant dryers to ensure sterile and dry conditions for manufacturing active pharmaceutical ingredients, tablet pressing, capsule filling, and packaging, where even minimal moisture can affect drug efficacy, stability, and regulatory compliance. These sectors often demand dryers that meet specific certifications and standards for medical or food-grade air.

Other significant potential customers include chemical and petrochemical plants, where dry air is crucial for process control, instrument air, and preventing corrosive reactions in pipelines and vessels, particularly in hazardous environments. The electronics and semiconductor industry relies heavily on desiccant dryers to maintain ultra-clean and dry conditions in cleanrooms and during sensitive manufacturing processes, as moisture can lead to short circuits and product defects. The oil and gas sector uses desiccant dryers for instrument air, wellhead control, and natural gas processing to prevent hydrate formation and corrosion. Healthcare facilities also represent a growing customer base, requiring medical-grade dry air for respirators, surgical tools, and laboratory equipment. Essentially, any industry that operates pneumatic systems, uses process air, or has critical equipment sensitive to moisture is a potential buyer for desiccant dryers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 3.16 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ingersoll Rand Inc., Atlas Copco AB, Parker Hannifin Corporation, SMC Corporation, Donaldson Company Inc., SPX Flow Inc., Gardner Denver (Part of Ingersoll Rand), ZEKS Compressed Air Solutions, CompAir (Part of Gardner Denver), FST Filtration GmbH, KAESER Kompressoren SE, Boge Kompressoren Otto Boge GmbH & Co. KG, Pneumatech (Part of Atlas Copco), Hiross (Part of Atlas Copco), Friulair S.p.A., Hankison (Part of SPX Flow), MTA S.p.A., Omega Air s.r.o., CDI, Aircel LLC. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Desiccant Dryer Market Key Technology Landscape

The desiccant dryer market is continually evolving, driven by advancements in material science, control systems, and connectivity, aiming to enhance efficiency, reliability, and ease of maintenance. A core technological aspect lies in the adsorbent materials themselves. Traditional desiccants like activated alumina and silica gel remain widely used for their cost-effectiveness and good performance, but there is an increasing adoption of molecular sieves for applications requiring extremely low dew points due to their superior moisture adsorption capabilities, even at elevated temperatures. Research and development efforts are focused on developing new generations of desiccants with higher adsorption capacities, longer lifespans, and improved regeneration efficiency, which directly translates to lower operational costs and reduced energy consumption for end-users. This continuous innovation in desiccant media is critical for pushing the boundaries of moisture removal performance.

Another significant area of technological advancement is in the control and monitoring systems of desiccant dryers. Modern dryers are increasingly equipped with sophisticated Programmable Logic Controllers (PLCs) or microcontrollers that allow for precise control over regeneration cycles, purge rates, and switching sequences between desiccant towers. The integration of advanced sensors, particularly high-accuracy dew point sensors, is paramount for real-time performance monitoring and feedback control. These sensors enable dynamic adjustment of dryer operations based on actual moisture loads, moving away from fixed-cycle operations towards demand-driven regeneration, which significantly reduces energy waste. Furthermore, pressure drop monitoring and flow control technologies are implemented to minimize air loss during regeneration and optimize overall system efficiency, contributing to substantial energy savings for industrial operators.

The rise of Industry 4.0 and the Internet of Things (IoT) has profoundly impacted the desiccant dryer market's technology landscape. Many contemporary dryers now feature IoT connectivity, allowing for remote monitoring, data logging, and cloud-based analytics. This enables predictive maintenance capabilities, where AI algorithms can analyze operational data to anticipate potential component failures or performance degradation, scheduling maintenance proactively rather than reactively. Remote diagnostics and fault notification systems minimize downtime and reduce the need for on-site inspections. Moreover, the integration of these dryers into broader plant management systems (e.g., SCADA, DCS) facilitates centralized control and optimizes the entire compressed air network, promoting seamless operation and contributing to overall plant efficiency. The emphasis on connectivity and smart features is transforming desiccant dryers into intelligent, self-optimizing components within industrial ecosystems.

Regional Highlights

- North America: This region represents a mature yet robust market, characterized by stringent industry standards for compressed air quality, particularly in pharmaceuticals, electronics, and automotive sectors. The adoption of energy-efficient desiccant dryer solutions is high, driven by increasing energy costs and a strong focus on operational efficiency. The presence of leading global manufacturers and a well-developed industrial infrastructure further contribute to its steady growth, with significant demand for advanced, smart, and IoT-enabled drying systems.

- Europe: The European market is defined by a strong emphasis on industrial automation, environmental regulations, and high technological adoption rates across its diverse manufacturing base. Countries like Germany, the UK, and France are at the forefront of implementing advanced drying technologies, including those with intelligent controls and lower carbon footprints. The pharmaceutical, chemical, and general manufacturing industries are key drivers, demanding highly reliable and efficient desiccant dryers to meet demanding production standards and sustainability goals.

- Asia Pacific (APAC): APAC is undeniably the fastest-growing region in the desiccant dryer market, propelled by rapid industrialization, burgeoning manufacturing sectors, and massive infrastructure development in countries such as China, India, and the ASEAN nations. The increasing investment in manufacturing facilities across various industries, coupled with a growing awareness of the benefits of dry compressed air, is fueling an unprecedented demand. While cost-effectiveness remains a key consideration, there's a rising trend towards adopting technologically advanced and energy-efficient dryers to improve productivity and product quality.

- Latin America: This region is experiencing steady growth in the desiccant dryer market, primarily due to expanding industrial activities, particularly in the automotive, food and beverage, and chemical sectors in countries like Brazil, Mexico, and Argentina. Investments in modernizing manufacturing facilities and an increasing focus on improving product quality and process reliability are driving the demand for effective moisture removal solutions. The market is also influenced by increasing foreign direct investment in manufacturing and processing industries.

- Middle East and Africa (MEA): The MEA market is witnessing gradual growth, largely driven by the robust oil and gas sector, petrochemical industries, and developing manufacturing capabilities. Desiccant dryers are crucial in these sectors for instrument air, pipeline protection, and general process applications, especially in environments characterized by high humidity and extreme temperatures. Investments in infrastructure projects and diversification of economies away from traditional oil revenues are creating new opportunities for market expansion, with a growing need for reliable and durable drying solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Desiccant Dryer Market.- Ingersoll Rand Inc.

- Atlas Copco AB

- Parker Hannifin Corporation

- SMC Corporation

- Donaldson Company Inc.

- SPX Flow Inc.

- Gardner Denver (Part of Ingersoll Rand)

- ZEKS Compressed Air Solutions

- CompAir (Part of Gardner Denver)

- FST Filtration GmbH

- KAESER Kompressoren SE

- Boge Kompressoren Otto Boge GmbH & Co. KG

- Pneumatech (Part of Atlas Copco)

- Hiross (Part of Atlas Copco)

- Friulair S.p.A.

- Hankison (Part of SPX Flow)

- MTA S.p.A.

- Omega Air s.r.o.

- CDI

- Aircel LLC

Frequently Asked Questions

What is a desiccant dryer and how does it work?

A desiccant dryer is an industrial device designed to remove moisture from compressed air or other gases by passing it through a bed of adsorbent material, known as desiccant. These dryers typically operate with two towers: one actively drying the air while the other is regenerated (dried) by a purge of dry air, heat, or a combination, ensuring a continuous supply of ultra-dry air with very low dew points.

What are the main applications of desiccant dryers?

Desiccant dryers are predominantly used in industries requiring extremely dry air to prevent corrosion, product spoilage, and operational downtime. Key applications include general manufacturing for pneumatic tools and processes, food and beverage processing, pharmaceutical manufacturing, chemical and petrochemical plants, oil and gas operations, and the electronics and semiconductor industry for cleanroom environments and sensitive component production.

What are the benefits of using a desiccant dryer in industrial settings?

The primary benefits of desiccant dryers in industrial settings include extending the lifespan of pneumatic equipment by preventing rust and wear, improving product quality by eliminating moisture contamination, reducing maintenance costs and unscheduled downtime, ensuring process reliability, and complying with stringent industry standards for air purity. They are essential for applications demanding very low dew points where refrigerated dryers are insufficient.

How do I choose the right desiccant dryer for my application?

Choosing the right desiccant dryer involves considering several factors: the required dew point (level of dryness), compressed air flow rate, inlet air temperature and pressure, ambient operating conditions, available utilities (power, cooling water), and budget constraints (both capital and operational costs). Consulting with a compressed air system specialist is recommended to select the optimal dryer type (e.g., heatless, heated, blower purge) and size for your specific needs.

What are the latest technological advancements in desiccant dryer technology?

Recent advancements in desiccant dryer technology focus on energy efficiency, smart controls, and enhanced reliability. This includes the development of more efficient adsorbent materials, sophisticated PLC and AI-driven control systems for demand-based regeneration, IoT connectivity for remote monitoring and predictive maintenance, and modular designs for increased flexibility and scalability. These innovations aim to reduce operational costs, improve performance, and integrate dryers seamlessly into Industry 4.0 environments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager