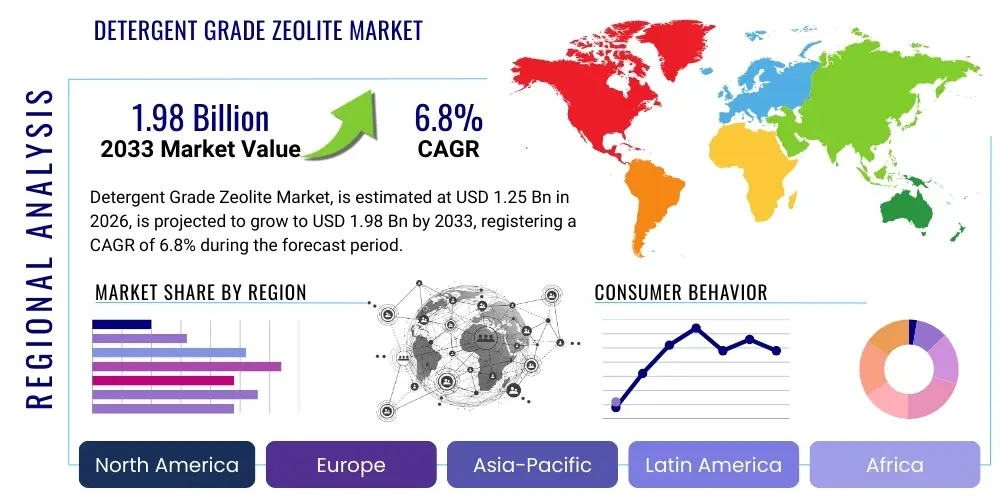

Detergent Grade Zeolite Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438385 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Detergent Grade Zeolite Market Size

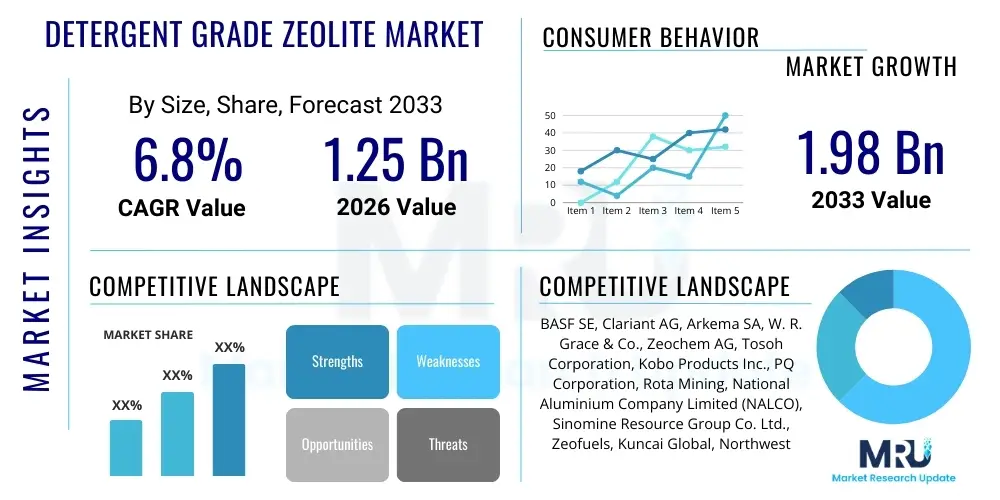

The Detergent Grade Zeolite Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.98 Billion by the end of the forecast period in 2033.

Detergent Grade Zeolite Market introduction

The Detergent Grade Zeolite Market is characterized by the production and utilization of synthetic crystalline aluminosilicates, primarily Zeolite A and Zeolite P, which serve as highly efficient builders and softening agents in laundry detergents. These specialized zeolites are critical in formulating phosphate-free detergent products, meeting stringent environmental regulations globally that restrict the use of phosphates due to their contribution to water body eutrophication. Zeolites function primarily by sequestering calcium and magnesium ions, thereby softening the water and enhancing the effectiveness of surfactants. This core functionality positions them as indispensable components in modern powder and compact detergent formulations across both household and industrial cleaning sectors.

The product description encompasses highly porous materials with a precise, uniform pore structure, exhibiting excellent ion-exchange capabilities, thermal stability, and low water absorption capacity relative to their high effectiveness. Major applications span standard laundry powders, concentrated powder detergents, automatic dishwashing tabs, and specialized industrial cleaning agents. The driving factors behind market expansion include the continuous global shift towards sustainability, reinforced by governmental bans on phosphate use in developed and rapidly developing economies. Consumer preference for effective, yet environmentally safe, cleaning products further fuels demand.

The primary benefits of incorporating detergent grade zeolites include improved washing performance, enhanced soil removal, stabilization of bleach agents, and reduction of scaling on machine parts. Furthermore, their non-toxic nature and widespread availability of raw materials (silica and alumina sources) ensure their commercial viability as a cost-effective alternative to traditional builders. Market growth is structurally linked to population increase, urbanization, and rising disposable incomes in APAC and Latin America, leading to higher consumption rates of packaged cleaning products, making market stability and sustained expansion highly probable.

Detergent Grade Zeolite Market Executive Summary

The Detergent Grade Zeolite Market demonstrates robust growth driven primarily by regulatory pressures and environmental consciousness. Business trends indicate a strong focus on producing customized zeolite types (such as Zeolite MAP or Zeolite P variants) that offer enhanced performance in cold water washing and concentrated formulations, aligning with manufacturer efforts to reduce packaging and transportation costs. Key market players are investing heavily in improving synthesis methods to achieve higher ion-exchange capacity and better dispersion properties, essential for premium detergent brands seeking competitive differentiation. Consolidation among smaller producers and strategic alliances between zeolite manufacturers and large FMCG corporations characterize the competitive landscape.

Regional trends highlight Asia Pacific (APAC) as the fastest-growing market segment, attributable to increasing penetration of washing machines, rising middle-class disposable incomes, and the gradual imposition of environmental regulations similar to those in Europe and North America. Europe remains a mature yet high-value market, primarily driven by stringent adherence to phosphate-free policies and a high demand for high-performance, compact detergent solutions. North America exhibits steady growth, influenced by the ongoing substitution of sodium tripolyphosphate (STPP) in industrial and institutional cleaning products, although liquid detergents dominate the household sector, marginally dampening Zeolite growth compared to powders.

Segmentation trends reveal that Zeolite 4A dominates the volume share due to its established efficacy and cost efficiency, particularly in standard powder detergent markets. However, the compact powder segment is experiencing accelerated growth, demanding optimized grades like Zeolite P or derivatives tailored for low-dosage, high-concentration products. Furthermore, the application segment shows strong growth in automatic dishwashing formulations, where zeolites contribute significantly to drying aids and anti-filming properties. The industry is witnessing a continuous push towards sustainable manufacturing practices and optimizing supply chain logistics to maintain cost competitiveness against alternative builders like citrates and polycarboxylates.

AI Impact Analysis on Detergent Grade Zeolite Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Detergent Grade Zeolite Market often revolve around operational efficiency, material science innovation, and supply chain resilience. Users are primarily concerned with how AI can optimize the highly energy-intensive zeolite synthesis process, reduce raw material waste, and predict quality variance. Another common theme is the role of machine learning in computational materials design, specifically accelerating the discovery of novel zeolite structures with superior ion-exchange properties or lower production costs compared to conventional Zeolite 4A. Expectations also center on predictive analytics for forecasting demand fluctuations in the volatile FMCG sector, thereby optimizing inventory levels and ensuring timely delivery of specific zeolite grades to global detergent manufacturers.

- AI-driven optimization of synthesis parameters: Utilizing machine learning algorithms to fine-tune reaction temperatures, pressures, and aging times in hydrothermal synthesis, maximizing yield and purity while minimizing energy consumption.

- Predictive maintenance for manufacturing equipment: Deploying sensors and AI models to anticipate failures in reactors, centrifuges, and drying units, reducing downtime and operational costs in zeolite production plants.

- Computational materials discovery (CMD): Employing deep learning models to screen millions of hypothetical inorganic frameworks, accelerating the identification and simulation of new zeolite structures with enhanced water-softening or surfactant-boosting characteristics.

- Supply chain risk management: Using AI for predictive analytics regarding global silica and alumina feedstock price fluctuations, logistics delays, and regional detergent demand shifts to ensure optimized inventory and procurement strategies.

- Quality control automation: Implementing computer vision and AI classifiers for real-time analysis of zeolite particle size distribution, crystallinity, and purity during the final processing stages, ensuring consistency for high-specification customers.

- Personalization in detergent formulation: AI tools assist detergent manufacturers in modeling the precise interaction between specific zeolite grades, surfactants, and enzymes to create highly targeted and efficient product lines for various consumer segments or water hardness conditions.

- Process intensification design: Simulation tools powered by AI for designing smaller, more efficient modular reactors for zeolite synthesis, potentially reducing the capital expenditure required for capacity expansion.

- Market demand forecasting: Advanced algorithms integrate macroeconomic indicators, competitor sales data, and climate trends to provide highly accurate forecasts for regional demand for detergent powders, guiding production scheduling for zeolite suppliers.

- Energy footprint reduction: AI platforms monitor and adjust energy usage in real-time across the production facility, significantly contributing to the market's overall sustainability profile and reducing carbon emissions associated with zeolite manufacturing.

- Automated compliance monitoring: AI systems track global changes in chemical regulations and packaging standards related to detergent ingredients, ensuring that zeolite products remain compliant across diverse international markets.

DRO & Impact Forces Of Detergent Grade Zeolite Market

The Detergent Grade Zeolite Market is primarily propelled by the worldwide legislative crackdown on phosphorus use, coupled with the increasing consumer focus on ecologically sound cleaning solutions. Restraints largely center on the competitive challenge posed by alternative builders like polymers, chelating agents, and silicates, which are gaining traction, especially in the fast-growing liquid detergent category. Opportunities lie substantially within the development of next-generation zeolites optimized for high-concentration, cold-water formulations and the untapped potential of emerging economies in Asia and Africa transitioning from soap bars to packaged powder detergents. These dynamics create significant market impact forces, necessitating constant innovation in synthesis technology and strategic capacity expansion to meet shifting global demand patterns.

Drivers include the widespread adoption of Zeolite 4A as the industry standard for phosphate replacement due to its efficiency and relatively low cost. The growing preference for powder detergents in price-sensitive but highly populated markets, such as India, China, and Brazil, further strengthens demand. Moreover, zeolites are increasingly recognized not just for water softening but also for their ability to enhance the effectiveness of other detergent components, providing a multi-functional benefit that secures their position as a preferred builder over other alternatives. The sustained advocacy by environmental NGOs and subsequent government policies enforcing stricter wastewater discharge standards continually reinforces the necessity of phosphate alternatives.

The principal restraints involve the bulk density and dusting issues associated with powder zeolites, which require specialized handling and may increase transportation costs compared to liquid builders. Furthermore, the market faces persistent competition from alternative polymers (like polycarboxylates) which offer superior performance in liquid and compact gel detergents, a format experiencing higher growth rates in mature Western markets. Opportunities are abundant in tailoring zeolite particle size and morphology to specific applications, such as improving solubility in automatic dishwashing (ADW) tablets or developing grades that function optimally in highly concentrated detergent formulas, offering manufacturers a pathway to premiumization and technological leadership.

Segmentation Analysis

The Detergent Grade Zeolite Market is comprehensively segmented based on product type, application, and geographical region, offering granular insights into consumption patterns and growth pockets. Segmentation by product type primarily distinguishes between Zeolite 4A, Zeolite P (including Zeolite MAP), and others, with Zeolite 4A dominating current consumption volumes. The application segment dissects the market into powder detergents, detergent bars, and automatic dishwashing (ADW) formulations. This structural breakdown helps stakeholders understand where investment in synthesis capacity and product development will yield the highest returns, focusing either on mass-market volume (powder detergents) or high-performance specialty segments (ADW and compact powders).

- By Product Type:

- Zeolite 4A

- Zeolite P (including Zeolite MAP)

- Other Grades (e.g., modified or custom zeolites)

- By Application:

- Laundry Detergent Powder

- Detergent Bars

- Automatic Dishwashing (ADW) Formulations

- Industrial and Institutional Cleaners

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East and Africa (MEA)

Value Chain Analysis For Detergent Grade Zeolite Market

The value chain for the Detergent Grade Zeolite Market begins with upstream analysis, which focuses on the procurement and processing of key raw materials: sodium silicate (source of silica), sodium aluminate (source of alumina), and caustic soda (sodium hydroxide). These raw materials are commodity chemicals, and their price volatility, influenced by energy costs and mining operations, directly impacts the profitability of zeolite manufacturers. Effective cost management at this stage involves securing long-term supply contracts and optimizing inventory management using advanced predictive tools to mitigate risk from input price fluctuations. The proximity of manufacturing facilities to raw material suppliers and major demand centers is a critical factor determining overall production costs and market competitiveness.

Midstream activities encompass the manufacturing process itself, involving the energy-intensive hydrothermal synthesis, crystallization, filtration, washing, drying, and eventual milling to achieve the precise particle size distribution required for detergent formulations. Technological efficiency in the synthesis process, particularly reducing energy usage during crystallization and drying, is a primary value driver. Direct distribution channels involve large-scale bulk supply agreements where major zeolite producers deliver directly to multinational detergent corporations (e.g., Procter & Gamble, Unilever). Indirect channels utilize specialized chemical distributors and agents, particularly important for reaching smaller regional detergent manufacturers or supplying specialized zeolite grades that require technical support.

Downstream analysis involves the integration of detergent-grade zeolites into final consumer products. Major detergent manufacturers focus on optimizing the formulation blend, ensuring that the zeolite interacts harmoniously with surfactants, bleach activators, and enzymes to maximize cleaning efficiency across various water conditions and temperatures. The performance of the zeolite in the final product directly influences brand reputation and consumer acceptance. End-users, the households and institutional buyers, are the final link, driven by product effectiveness, affordability, and increasingly, ecological footprint, meaning that a sustainably produced zeolite is gaining significant marketing advantage at the retail level.

Detergent Grade Zeolite Market Potential Customers

The primary customers for Detergent Grade Zeolites are manufacturers within the Fast-Moving Consumer Goods (FMCG) sector, specifically those specializing in home care and cleaning products. This includes global conglomerates and large national players who dominate the production of laundry powders, compact detergents, and automatic dishwashing agents. These customers prioritize bulk availability, consistent quality (specifically particle size and ion-exchange capacity), and reliable supply chains, given the massive scale of their manufacturing operations. They are constantly seeking cost-effective alternatives to comply with environmental regulations while maintaining or improving product performance compared to older phosphate-based formulations.

Secondary customers include producers of industrial and institutional (I&I) cleaning chemicals, such as large-scale laundries, food processing facilities, and hospitality service providers. These entities require highly specialized, high-performance cleaning concentrates where water hardness management is critical to efficiency and equipment longevity. For the I&I segment, customized zeolite grades that perform well under extreme temperature or pH conditions are highly valued. Furthermore, smaller regional detergent manufacturers and private label brands constitute a significant customer base, often relying on indirect distribution channels and requiring more flexible order volumes and specialized technical assistance for formulation adjustments.

The buying behavior of potential customers is heavily influenced by regulatory mandates (e.g., regional phosphate bans), which compel the purchase of zeolite builders regardless of minor cost implications, cementing their status as an essential raw material. Procurement decisions are also highly dependent on the stability of supply and the ability of the zeolite supplier to scale rapidly in response to unexpected demand surges or shifts in packaging trends (e.g., from standard powders to highly concentrated tablets). Loyalty often exists with suppliers who can demonstrate superior environmental standards in their manufacturing process and provide certifications supporting sustainable sourcing and production.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.98 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, Clariant AG, Arkema SA, W. R. Grace & Co., Zeochem AG, Tosoh Corporation, Kobo Products Inc., PQ Corporation, Rota Mining, National Aluminium Company Limited (NALCO), Sinomine Resource Group Co. Ltd., Zeofuels, Kuncai Global, Northwest Zeolite, Interfil, ZEOCHEM, Shanghai Hengchuan Zeolite Co., Union Carbide Corporation (Legacy Influence) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Detergent Grade Zeolite Market Key Technology Landscape

The technological landscape of the Detergent Grade Zeolite Market is centered around optimizing the hydrothermal synthesis process, aiming for higher purity, controlled particle size distribution, and increased ion-exchange capacity while reducing the energy footprint. Conventional production relies on batch processing, but there is an increasing shift toward continuous flow synthesis methods to improve yield consistency and scalability. Advanced synthesis techniques focus on crystallization control, utilizing structure-directing agents (SDAs) and specific temperature profiling to engineer zeolites like Zeolite P (MAP) which offer better performance in cold-water washing cycles and highly concentrated formulations, meeting the modern consumer demand for efficiency and sustainability.

Significant technological advancements also include post-synthesis modification, such as surface treatments and composite particle formation, aimed at enhancing the dispersibility of zeolite powders and minimizing dusting during detergent manufacturing. Furthermore, co-crystallization and rapid synthesis methods utilizing microwave heating or ultrasonic agitation are being explored to dramatically reduce the reaction time—often hours or days in traditional methods—and thus lower the overall production cost. The effective management and recycling of process wastewater, often rich in unreacted chemicals and byproducts, constitute another critical technological challenge that manufacturers are addressing through membrane filtration and advanced chemical separation techniques to comply with environmental standards.

The industry is also leveraging computational chemistry and simulation tools to understand the fundamental mechanisms of crystallization and structural stability. This aids in designing novel, tailored zeolite frameworks that can selectively sequester heavy metals or improve compatibility with niche surfactant systems, expanding the application scope beyond basic water softening. Nanotechnology is playing a role in developing ultra-fine particle zeolites to ensure rapid dissolution and prevent residues in high-efficiency washing machines. The adoption of smart manufacturing principles, including IoT sensors and centralized data analytics, is transforming plant operations into predictive environments, ensuring high-quality, high-volume production crucial for supplying the global FMCG giants.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to be the engine of growth for the Detergent Grade Zeolite Market, driven by high population density, rising urbanization, and increasing per capita consumption of packaged cleaning products. Nations like China and India are transitioning from traditional laundry methods to washing machine dependence, significantly boosting demand for powder detergents, which are often the preferred format due to cost-effectiveness. Furthermore, regulatory bodies in Southeast Asian nations are gradually introducing restrictions on phosphate content, necessitating a market shift towards zeolite alternatives. This region represents not only the largest consumption base but also a significant production hub, benefiting from lower labor and raw material costs.

- Europe: Europe is a mature but highly influential market, largely characterized by the earliest and most stringent bans on phosphates in laundry and dishwashing detergents. This regulatory framework ensures continued, stable demand for high-performance zeolite grades, particularly those suitable for compact and ultra-concentrated formulations preferred by European consumers seeking sustainability and convenience. Germany, France, and the UK are key markets, focusing on continuous product innovation, and driving demand for specialized grades like Zeolite MAP which offer superior performance in cold-water conditions, aligning with regional energy efficiency goals.

- North America: The North American market exhibits steady growth, mainly focused on industrial and institutional applications where stringent performance standards are required. While household laundry trends heavily favor liquid detergents (which typically use polymer builders), the powder segment, including heavy-duty industrial cleaners and automatic dishwashing powders/tablets, relies heavily on zeolite builders. Regulatory action in certain states imposing phosphate limits further supports market penetration, albeit at a slower pace than Europe or APAC. Innovation here often focuses on improving solubility and incorporating zeolites into complex multi-component ADW tablets.

- Latin America (LATAM): LATAM is considered a high-potential emerging market. Growth is fueled by increasing middle-class populations and improving access to washing appliances. Powder detergent remains the dominant format in major economies like Brazil and Mexico. Although phosphate regulations are less uniform than in Europe, consumer awareness regarding environmental impact is growing, encouraging local manufacturers to adopt zeolite-based builders proactively. Local suppliers are focusing on scaling up capacity to compete with imported products and cater to the specific water hardness characteristics found across the diverse geographical terrain.

- Middle East and Africa (MEA): The MEA region is characterized by substantial variation in market maturity. The Middle East, particularly the GCC countries, shows high consumption rates driven by high disposable incomes and urbanization, demanding both premium and standard detergent products. Africa, still heavily reliant on traditional laundry methods, presents long-term opportunity as infrastructure improves and packaged cleaning products become more accessible. Zeolites are essential in this region due to often extremely hard water conditions, requiring high ion-exchange capacity to achieve effective cleaning results.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Detergent Grade Zeolite Market.- BASF SE

- Clariant AG

- Arkema SA

- W. R. Grace & Co.

- Zeochem AG

- Tosoh Corporation

- Kobo Products Inc.

- PQ Corporation

- Rota Mining

- National Aluminium Company Limited (NALCO)

- Sinomine Resource Group Co. Ltd.

- Zeofuels

- Kuncai Global

- Northwest Zeolite

- Interfil

- ZEOCHEM

- Shanghai Hengchuan Zeolite Co.

- Union Carbide Corporation (Legacy Influence)

Frequently Asked Questions

Analyze common user questions about the Detergent Grade Zeolite market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of zeolite in detergent formulations?

The primary function of zeolite in detergents, specifically Zeolite 4A, is to act as a water softening builder. It achieves this by sequestering calcium and magnesium ions present in hard water through an ion-exchange process, preventing these ions from interfering with the efficacy of surfactant molecules and enhancing overall cleaning performance.

Why are detergent grade zeolites replacing phosphates globally?

Detergent grade zeolites are replacing phosphates due to stringent environmental regulations aimed at combating eutrophication. Phosphates, when discharged into water bodies, act as nutrients for algae, leading to oxygen depletion. Zeolites provide an effective, non-toxic, and environmentally safe alternative to maintain high cleaning efficiency without contributing to water pollution.

Which zeolite grade dominates the detergent market share?

Zeolite 4A currently dominates the detergent market share by volume. It is widely used in standard powder laundry detergents globally due to its excellent cost-to-performance ratio, high ion-exchange capacity, and established commercial availability, making it the industry standard for phosphate substitution.

How does the growth of liquid detergents affect the zeolite market?

The growth of liquid detergents, which primarily use polymer-based or silicate builders, poses a restraint to the detergent grade zeolite market, as zeolites are less effective in liquid formulations. However, the market compensates through robust growth in powder detergents in emerging economies and increased utilization in specialized segments like automatic dishwashing tablets.

What technological advancements are driving future zeolite performance?

Technological advancements focus on hydrothermal synthesis optimization and post-synthesis modification to improve performance characteristics. Key areas include developing tailored grades (like Zeolite P/MAP) optimized for cold-water cleaning, improving solubility for compact formulations, and utilizing AI-driven computational chemistry to design zeolites with enhanced ion-exchange kinetics and purity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager