Detonation Synthesis Nanodiamond Powder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433471 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Detonation Synthesis Nanodiamond Powder Market Size

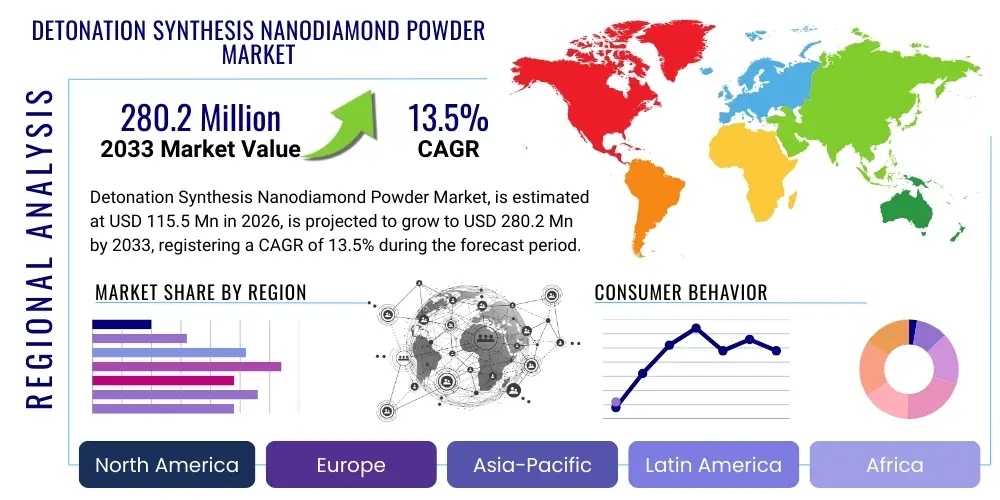

The Detonation Synthesis Nanodiamond Powder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 13.5% between 2026 and 2033. The market is estimated at $115.5 Million in 2026 and is projected to reach $280.2 Million by the end of the forecast period in 2033.

Detonation Synthesis Nanodiamond Powder Market introduction

The Detonation Synthesis Nanodiamond Powder (DSNDP) market encompasses the production and commercialization of ultra-fine diamond particles, typically ranging from 4 to 6 nanometers in diameter, generated through the detonation of carbon-containing explosives in a contained, non-oxidizing environment. This synthesis method yields unique material properties, including exceptionally high hardness, large specific surface area, excellent thermal conductivity, and chemical stability, making DSNDP a critical material in advanced technological applications. The inherent crystalline structure and tunable surface chemistry of these nanodiamonds allow them to interface effectively with biological systems and integrate into complex material matrices, positioning them as superior alternatives to conventional abrasive and composite fillers.

Major applications of DSNDP span several high-growth industries, notably electronics, aerospace, biomedical diagnostics, advanced tribology (lubricants and coatings), and precision polishing. In electronics, their high thermal conductivity is leveraged for thermal management in semiconductors and heat sinks, crucial for miniaturization and efficiency gains. The material's abrasive qualities are unparalleled, making it essential for chemical mechanical planarization (CMP) in wafer fabrication and ultra-precision polishing of hard drives and optics. Furthermore, their non-toxicity and high surface area are driving significant adoption in drug delivery systems and bio-imaging, offering targeted therapies and enhanced diagnostic capabilities.

Driving factors for this market’s expansion include the escalating demand for high-performance materials in semiconductor manufacturing, the stringent requirements for superior wear resistance in automotive and machinery components, and the burgeoning field of nanotechnology-enabled medical devices. The unique capability of DSNDP to functionalize surfaces for specific chemical interactions, coupled with continuous advancements in purification and surface modification techniques, enhances its versatility and opens new avenues in quantum computing and advanced energy storage solutions, ensuring sustained market growth throughout the forecast period.

Detonation Synthesis Nanodiamond Powder Market Executive Summary

The global Detonation Synthesis Nanodiamond Powder market is characterized by intense research and development focus, translating into continuous product innovation, particularly concerning surface functionalization and improved dispersion stability. Key business trends include strategic collaborations between academic institutions and commercial entities aimed at scaling up production and reducing per-gram costs, addressing a primary restraint. Furthermore, there is a clear movement towards vertical integration, where nanodiamond producers are expanding into formulating specialized end-products, such as advanced lubricants and composite precursors, thereby capturing higher value within the chain. Mergers and acquisitions remain modest but focused on acquiring proprietary purification and processing technologies that enable higher purity grades suitable for sensitive electronic and biomedical applications.

Regionally, the market exhibits a dichotomy, with the Asia Pacific (APAC) region leading in consumption, primarily driven by massive semiconductor manufacturing and consumer electronics production in countries like China, South Korea, and Taiwan. North America and Europe, while representing smaller volumes, lead in technological innovation, particularly in advanced applications such as quantum sensing and high-end biomedical research, supported by robust government funding for nanotechnology initiatives. Regional competition is fierce, compelling companies to establish specialized distribution channels tailored to the highly technical requirements of various end-user industries, ensuring product consistency and technical support across diverse geographies.

Segment-wise, the market is broadly segmented by application type and particle size/grade. The polishing and abrasion segment currently holds the dominant market share due to mature adoption in manufacturing processes, particularly in optics and CMP slurry production. However, the biomedical and drug delivery segment is poised for the highest growth rate (CAGR), reflecting increasing investment and regulatory approval for nanodiamond-based therapeutics. Trends within segments also highlight the importance of surface chemistry, with functionalized nanodiamonds (e.g., hydroxylated or carboxylated surfaces) commanding premium prices due to their enhanced utility in composite strengthening and targeted delivery applications, pushing overall market value upwards.

AI Impact Analysis on Detonation Synthesis Nanodiamond Powder Market

Analysis of common user questions regarding the impact of Artificial Intelligence (AI) on the Detonation Synthesis Nanodiamond Powder market reveals recurring themes focused on optimization, quality assurance, and accelerated material discovery. Users frequently inquire about how machine learning algorithms can enhance the efficiency and yield of the highly complex detonation synthesis process, a crucial area given the high cost of current manufacturing methods. Concerns also center on AI’s ability to ensure batch-to-batch consistency and purity, which is paramount for nanodiamonds used in electronics and biomedicine where impurities can significantly hinder performance. Furthermore, users are keenly interested in predictive modeling—specifically, using AI to simulate the performance of various nanodiamond functionalizations in end-use matrices (like polymers or lubricants) to rapidly identify optimal material compositions for specific applications, significantly reducing traditional R&D cycles.

AI’s influence is primarily concentrated in two critical areas: process optimization and application predictive modeling. In synthesis, machine learning models analyze parameters such as explosive composition, chamber geometry, pressure dynamics, and purification solvent ratios to dynamically adjust input variables, leading to superior yield and narrower size distribution of the resulting nanodiamonds. This data-driven approach minimizes experimental wastage and energy consumption. For quality control, computer vision and deep learning are employed to rapidly analyze TEM (Transmission Electron Microscopy) and Raman spectroscopy data, identifying subtle defects or agglomerations far faster and more accurately than human inspection, thereby standardizing quality across production batches crucial for high-stakes applications.

The long-term strategic impact of AI lies in its ability to unlock new applications by systematically exploring the vast chemical space associated with nanodiamond surface chemistry. AI tools can predict how specific surface groups (e.g., amine, carboxyl, or fluorine groups) will interact with target molecules (e.g., drug compounds or polymer chains), accelerating the development of novel smart materials and advanced drug carriers. This capability transforms nanodiamond production from a materials science challenge into an informatics problem, allowing manufacturers to quickly pivot to highly profitable, niche applications based on market needs identified through predictive analytics, fundamentally changing the competitive landscape.

- AI optimizes detonation parameters (pressure, temperature profiles) leading to increased synthesis yield and uniform particle size distribution.

- Machine learning algorithms enhance purification processes by predicting optimal solvent and acid treatment regimens, improving overall purity suitable for biomedical grades.

- Predictive modeling accelerates R&D by simulating the performance of functionalized nanodiamonds in various composite materials (polymers, ceramics).

- Computer vision systems automate quality control, detecting defects and agglomerations in bulk powder analysis using microscopy data.

- AI facilitates the discovery of novel nanodiamond applications, particularly in complex fields such as quantum sensing and advanced energy storage systems.

- Generative AI tools assist in designing customized surface chemistries for targeted drug delivery and enhanced material compatibility.

DRO & Impact Forces Of Detonation Synthesis Nanodiamond Powder Market

The growth trajectory of the Detonation Synthesis Nanodiamond Powder market is primarily driven by relentless technological miniaturization in electronics, necessitating materials with superior thermal management capabilities and abrasion resistance for precision manufacturing. Restraints, however, pose significant challenges, chiefly the high initial capital investment required for detonation facilities and subsequent purification equipment, coupled with the persistent difficulty in achieving stable dispersion of nanodiamonds in common solvents, leading to issues like particle agglomeration that hinder performance in high-tech slurries. Opportunities are vast, centered on the emergent fields of biomedical engineering—leveraging nanodiamonds’ biocompatibility and unique fluorescence for imaging and drug delivery—and the rapidly expanding clean energy sector, where they offer potential improvements in battery electrode materials and fuel cell catalysis. The impact forces acting on the market are defined by moderate barriers to entry due to proprietary synthesis techniques, coupled with increasing bargaining power from highly specialized end-users who demand rigorous quality specifications and customized products.

Specific drivers include the exponential growth in global semiconductor fabrication, which relies heavily on nanodiamond-based CMP slurries for precise wafer surface finishing. Additionally, the automotive sector’s shift towards electric vehicles (EVs) creates demand for advanced lubricants and coatings that minimize friction and wear in high-stress components, boosting performance and longevity. However, the market faces significant hurdles related to standardization; the lack of universally accepted regulatory frameworks for nanotechnology products, particularly concerning environmental impact and safety protocols, slows down large-scale commercial adoption in certain regulated industries. Furthermore, the availability of competitive, lower-cost nanomaterials (like graphene derivatives or carbon nanotubes) in less demanding applications acts as a substitution threat.

The impact forces stemming from Porter's Five Forces analysis indicate a market with moderate competition but high rivalry among existing players focused on purity and cost leadership. Supplier bargaining power is relatively low, as precursors (carbonaceous explosives) are generally commodity chemicals. Buyer bargaining power is high in established sectors like CMP slurry production, where buyers are large corporations demanding price concessions and rigorous quality control. The threat of substitutes is notable in lower-end mechanical applications but is significantly diminished in high-precision, high-purity fields like quantum sensing. Overall, the intensity of competitive rivalry is increasingly driven by continuous innovation in surface modification and the establishment of scalable, high-yield production infrastructure, dictating long-term market leadership.

Segmentation Analysis

The Detonation Synthesis Nanodiamond Powder market segmentation reflects the diverse range of industries utilizing the material’s unique properties, classifying the market primarily based on application type, particle size, and grade/purity level. This segmentation is crucial for understanding specific consumer requirements, as the necessary purity, surface functionalization, and dispersion characteristics vary dramatically between abrasive applications and biomedical uses. The application segment, which includes polishing, lubricants, composites, and biomedicine, dictates the market value hierarchy, with high-purity biomedical grade nanodiamonds commanding the highest price points, while the polishing segment drives overall volume demand. Understanding these segments allows manufacturers to optimize production processes and tailor specific product lines to meet stringent industry standards, thus maximizing revenue generation and market penetration across specialized verticals.

- By Application:

- Polishing and Chemical Mechanical Planarization (CMP) Slurries

- Advanced Lubricants and Oil Additives (Tribology)

- Composite Materials (Polymers, Ceramics, Metals)

- Electronics and Thermal Management (Heat Sinks, Semiconductors)

- Biomedical (Drug Delivery, Bio-imaging, Diagnostics)

- Electroplating and Electroless Plating

- Others (Quantum Sensing, Catalysis)

- By Grade/Purity:

- Technical Grade (Lower Purity, Higher Agglomeration)

- High Purity Grade (Electronics and Optics)

- Biomedical Grade (Ultra-High Purity, Functionalized Surface)

- By Particle Size Distribution:

- < 4 nm

- 4 nm – 6 nm

- > 6 nm (Aggregates)

Value Chain Analysis For Detonation Synthesis Nanodiamond Powder Market

The value chain for Detonation Synthesis Nanodiamond Powder is highly complex, beginning with specialized upstream activities centered around precursor selection and the highly controlled synthesis process. Upstream activities involve sourcing high-quality, carbon-rich explosive materials (typically TNT/RDX mixtures) and designing proprietary detonation chambers that ensure optimal energy confinement and yield. This stage is capital-intensive and requires specialized expertise in high-pressure physics and chemical engineering. Following synthesis, the crude soot must undergo rigorous purification, which is the most critical and value-adding step. This involves chemical oxidation, acid treatment, and sophisticated filtration methods to remove non-diamond carbon components and metallic impurities, defining the final grade and marketability of the product.

Midstream processing focuses on functionalization and formulation. Nanodiamonds are often surface-modified (e.g., carboxylated, hydroxylated, or functionalized with specific chemical groups) to enhance dispersion stability and compatibility with end-use matrices like polymers or biological fluids. This customization step significantly increases the product’s value. Distribution channels are typically dual-layered: Direct sales channels are preferred for high-volume or highly technical customers (e.g., major semiconductor manufacturers or pharmaceutical research labs) who require direct technical support and customized batches. Indirect channels involve specialized chemical distributors or regional agents focused on reaching smaller R&D labs, academic institutions, or manufacturers requiring technical grade material.

Downstream activities involve integration into final products. End-users incorporate the specialized nanodiamond powder into CMP slurries, advanced composite filaments, high-performance lubricants, or biomedical prototypes. The efficiency of the nanodiamond in these applications directly correlates with its initial purity and successful dispersion. Feedback from downstream users regarding performance metrics (e.g., polishing efficiency, wear reduction, biocompatibility) is crucial for driving upstream process improvements and functionalization R&D, creating a tight feedback loop that ensures the product meets evolving technological demands across the electronics, aerospace, and healthcare sectors.

Detonation Synthesis Nanodiamond Powder Market Potential Customers

The potential customer base for Detonation Synthesis Nanodiamond Powder is diverse and technically sophisticated, spanning industries that require ultra-high precision, extreme wear resistance, or advanced material integration. A primary customer segment includes manufacturers of chemical mechanical planarization (CMP) slurries used extensively in semiconductor fabrication to achieve ultra-flat surfaces on silicon wafers; these customers demand high volumes of consistent, aggregation-free nanodiamonds. Another significant segment involves advanced materials manufacturers specializing in high-performance polymer and metal matrix composites destined for the aerospace and automotive sectors, seeking enhanced mechanical strength, stiffness, and thermal stability in lightweight components.

Furthermore, companies in the tribology sector, specifically those producing high-end industrial lubricants, gear oils, and specialty greases, are key buyers. These customers utilize nanodiamonds as friction modifiers and anti-wear additives, significantly extending the lifespan and efficiency of critical machinery components. The biomedical and pharmaceutical sectors represent a high-value customer group, comprising research institutions and biotech firms investigating targeted drug delivery systems, advanced diagnostics, and bio-compatible coatings for implants, where the non-toxic nature and small size of the particles are indispensable assets for medical applications requiring rigorous safety and performance standards.

Other notable potential customers include manufacturers of hard disk drives (HDDs) and precision optics, where nanodiamonds are essential for achieving flawless surfaces. Research and development laboratories, both corporate and academic, continually acquire small, highly specialized batches for experimental work in fields like quantum computing, electrochemistry (for supercapacitor electrodes), and specialized catalysis, signaling future large-scale adoption as these technologies mature. The common requirement across all these diverse buyers is the demand for precise particle size distribution, exceptional purity, and specific, customizable surface functionalization tailored to their unique processing environment and performance specifications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $115.5 Million |

| Market Forecast in 2033 | $280.2 Million |

| Growth Rate | 13.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | NanoBlox, New Diamond Technology (NDT), PlasmaChem GmbH, Ray Techniques Ltd., Microdiamant AG, Carbodeon Oy, Sinton Nanotechnologies, FR&PC ALTAI, Advanced Nanodiamond Inc., Nanofor, ABC Nanotech, Adamas Nanotechnologies, Nanotech Industrial Solutions (NIS), Shanghai Nanodiamonds, Henan Jinhe Nanodiamond Co. Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Detonation Synthesis Nanodiamond Powder Market Key Technology Landscape

The core technology underpinning the Detonation Synthesis Nanodiamond Powder market involves precise control over the high-pressure, high-temperature environment generated by the explosion of carbon-rich materials. The critical innovation lies in the design of the detonation reactor vessel, which must contain the extreme forces while ensuring the rapid quenching necessary for forming nanometer-sized diamond nuclei rather than graphite or larger diamond structures. Recent technological advancements focus heavily on optimizing the internal chemistry of the reactor, including the use of specialized cooling media (often ice or water mixed with various solvents) to control the reaction kinetics and prevent the subsequent oxidation or dissolution of the formed diamond particles, which is essential for maximizing yield and minimizing post-synthesis purification load.

Beyond the synthesis itself, the purification and separation technologies represent a major technological focus, as the crude detonation soot contains significant impurities, primarily amorphous carbon and various metal contaminants originating from the explosive casing. Leading manufacturers employ multi-stage purification protocols, often involving harsh chemical oxidation (using strong acids or ozone plasma) followed by sophisticated air classification and centrifugal separation techniques to achieve ultra-high purity levels, particularly the biomedical grade (typically < 50 ppm metal content). Technological breakthroughs in plasma-assisted purification offer faster, more energy-efficient methods for removing non-diamond carbon, a crucial factor in reducing the overall manufacturing cost and making nanodiamonds commercially viable for high-volume applications.

Surface functionalization technology is equally critical, as the native nanodiamond surface is often hydrogenated or exhibits oxygen-containing groups (hydroxyl, carboxyl). Key technological developments revolve around controlled chemical grafting techniques to affix specific functional groups (e.g., polyethylene glycol (PEG) for biocompatibility, or specific amines for polymer cross-linking) onto the diamond lattice. These advanced surface modifications are typically proprietary and enable superior dispersion, critical for formulating high-stability CMP slurries and effective drug delivery vehicles. The ability to precisely tune surface chemistry determines performance in applications ranging from enhancing mechanical interfaces to enabling targeted cellular interaction, solidifying functionalization expertise as a central competitive technological advantage in the market.

Regional Highlights

The dynamics of the Detonation Synthesis Nanodiamond Powder market vary significantly across major geographical regions, influenced by industrial base, R&D intensity, and regulatory environment. Asia Pacific (APAC) dominates the global market in terms of volume consumption, driven primarily by the colossal manufacturing footprint in electronics, semiconductors, and precision optics located across China, South Korea, Japan, and Taiwan. The continuous expansion of fabrication plants and high demand for cost-effective CMP slurries and high-efficiency heat dissipation materials propel regional growth, making APAC the primary hub for production capacity and end-use demand for technical and high-purity grades.

- Asia Pacific (APAC):

- Market leader in consumption volume, anchored by dominance in semiconductor and consumer electronics manufacturing.

- High investment in large-scale CMP slurry production and advanced display technology (e.g., OLED/MicroLED).

- Key countries: China, Japan, South Korea, and Taiwan, which are major consumers of precision polishing materials.

- North America:

- High focus on innovation, research, and high-value niche applications, especially in aerospace, defense, and quantum computing.

- Strong regulatory support and significant venture capital funding for advanced nanotechnology startups specializing in biomedical and drug delivery applications.

- Demand is characterized by ultra-high purity and functionalized nanodiamonds, often commanding premium prices.

- Europe:

- Significant presence in advanced materials R&D, particularly in Germany (automotive, machinery) and the UK (materials science, life sciences).

- The primary driver is the demand for high-performance lubricants and anti-wear coatings aimed at enhancing industrial machinery efficiency and reducing carbon footprint.

- Strict adherence to REACH regulations necessitates complex approval processes, focusing on material safety and long-term environmental viability.

- Latin America (LA) and Middle East & Africa (MEA):

- Emerging markets with low current penetration, primarily consuming technical grade nanodiamonds for general industrial abrasive and metal finishing applications.

- Growth is projected to be slow but steady, driven by increasing localized manufacturing activity and infrastructure development projects that require robust composite materials and specialized industrial lubricants.

- Lack of specialized nanotechnology infrastructure and heavy reliance on imports constrain immediate market expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Detonation Synthesis Nanodiamond Powder Market.- NanoBlox

- New Diamond Technology (NDT)

- PlasmaChem GmbH

- Ray Techniques Ltd.

- Microdiamant AG

- Carbodeon Oy

- Sinton Nanotechnologies

- FR&PC ALTAI (Federal Research and Production Center Altai)

- Advanced Nanodiamond Inc. (AND)

- Nanofor

- ABC Nanotech

- Adamas Nanotechnologies

- Nanotech Industrial Solutions (NIS)

- Shanghai Nanodiamonds

- Henan Jinhe Nanodiamond Co. Ltd.

- Eminess Technologies

- Innovative Nanomaterials Corp.

- Diacel Corporation

- Quantum Diamond Technologies (QDT)

- Dynalene, Inc.

Frequently Asked Questions

Analyze common user questions about the Detonation Synthesis Nanodiamond Powder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Detonation Synthesis Nanodiamond Powder (DSNDP) and what are its primary competitive advantages?

DSNDP is an ultra-fine carbon material (4-6 nm) synthesized by detonating explosives in a controlled environment. Its advantages include superior hardness, high specific surface area, exceptional thermal conductivity, and tunable surface chemistry, making it ideal for precision polishing, advanced tribology, and biomedical applications where conventional materials fail due to size or performance constraints.

How does the purity of nanodiamond powder affect its use in high-tech industries like semiconductors?

Purity is paramount; metal contaminants or non-diamond carbon components must be minimized to parts per million (ppm) levels. High purity prevents defects during semiconductor fabrication (Chemical Mechanical Planarization/CMP) and ensures optimal thermal performance and minimal electrical interference, enabling the manufacture of advanced, high-reliability electronic components.

What are the key technological restraints limiting the widespread adoption of DSNDP?

The primary restraints are the high cost associated with the complex, multi-stage purification processes required to achieve electronic or biomedical grade material, and the persistent challenge of achieving stable, non-aggregating dispersion of nanodiamonds in various industrial solvents and composite matrices.

Which application segment is expected to drive the highest growth rate in the DSNDP market?

The Biomedical segment, particularly drug delivery and bio-imaging, is projected to exhibit the highest Compound Annual Growth Rate (CAGR). This acceleration is driven by the nanodiamonds’ inherent biocompatibility, low toxicity, ability to cross biological barriers, and capacity for customized surface functionalization to target specific cells or tissues.

How is Artificial Intelligence (AI) influencing the manufacturing efficiency of Detonation Synthesis Nanodiamonds?

AI is critically used for process optimization, employing machine learning to analyze and tune complex detonation parameters (pressure, temperature, cooling rate) to maximize yield and narrow particle size distribution, simultaneously accelerating the purification process by predicting optimal chemical treatments, leading to reduced production costs and enhanced batch consistency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager