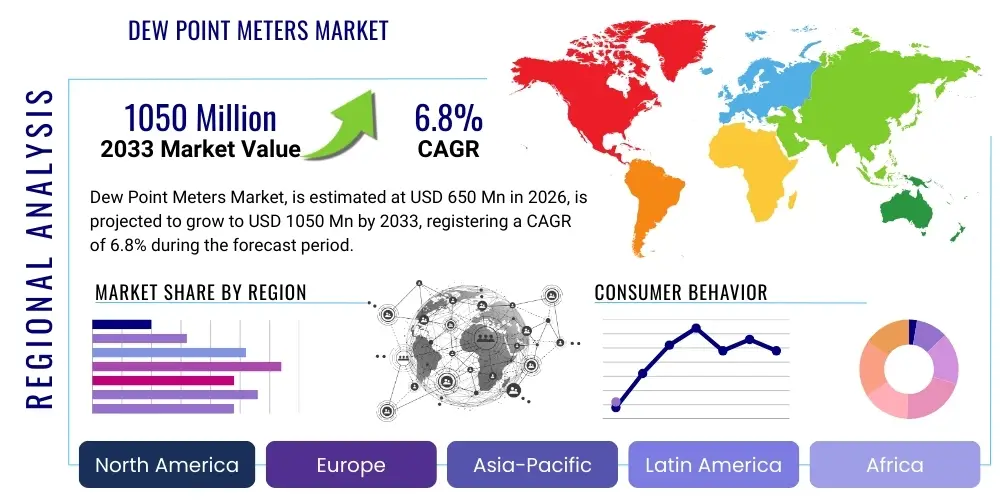

Dew Point Meters Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436077 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Dew Point Meters Market Size

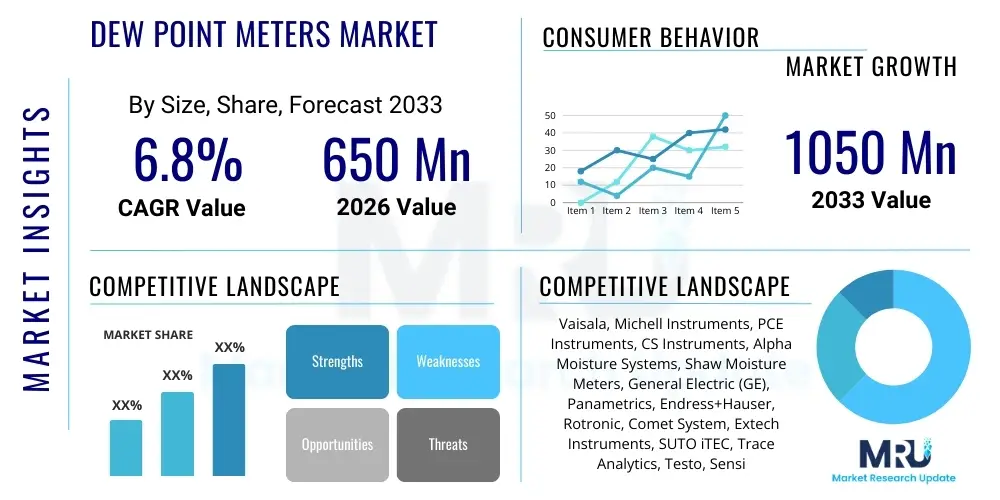

The Dew Point Meters Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 650 Million in 2026 and is projected to reach USD 1050 Million by the end of the forecast period in 2033.

Dew Point Meters Market introduction

The Dew Point Meters Market encompasses instruments designed to accurately measure the dew point temperature, which signifies the temperature at which air or gas must be cooled to become saturated with water vapor. These specialized instruments are crucial for monitoring moisture levels in various industrial processes, especially those involving compressed air, critical gases, and controlled environments. Maintaining precise moisture control is paramount in industries such as pharmaceuticals, petrochemicals, semiconductor manufacturing, and power generation, as excessive moisture can lead to corrosion, product contamination, reduced equipment efficiency, and operational failures. The primary applications of dew point meters include quality control in manufacturing processes, safeguarding sensitive machinery, ensuring compliance with stringent regulatory standards, and optimizing energy consumption in compressed air systems.

The core product range includes highly accurate chilled mirror devices, cost-effective capacitive thin-film sensors, and rugged aluminum oxide sensors, offered in portable, handheld, and fixed/wall-mounted configurations. These meters provide real-time data, enabling rapid response to deviations in moisture levels. Key benefits derived from the deployment of these meters include enhanced operational safety, extended lifespan of pneumatic equipment, prevention of costly downtime, and assurance of product quality, particularly for moisture-sensitive materials. The rising global emphasis on industrial automation, coupled with increasing regulatory mandates across high-purity gas applications, serves as a significant driving factor propelling market growth, necessitating high-precision moisture measurement solutions across diverse end-user sectors.

Dew Point Meters Market Executive Summary

The Dew Point Meters Market is experiencing robust expansion driven by the escalating demand for industrial compressed air quality management and stringent process control requirements across critical manufacturing sectors. Current business trends indicate a shift towards advanced digital integration, with manufacturers focusing on developing instruments equipped with Internet of Things (IoT) capabilities, enabling remote monitoring, predictive maintenance scheduling, and automated data logging. Technological advancements, particularly in chilled mirror and capacitive sensor accuracy and long-term stability, are reducing calibration frequency and improving overall measurement reliability. Furthermore, the increasing adoption of high-pressure applications, such as hydrogen fueling stations and specialized gas production, demands meters capable of handling extreme operational parameters, thereby fueling innovation in durable and high-range dew point sensing technologies.

Regionally, the Asia Pacific (APAC) stands out as the fastest-growing market, largely due to rapid industrialization, expansion of semiconductor fabrication plants, and heavy investment in infrastructure development, which requires extensive use of compressed air and process gases. North America and Europe maintain leading positions in terms of market size, characterized by mature regulatory frameworks (e.g., compliance with ISO 8573 standards for compressed air quality) and high adoption rates of sophisticated, high-end measurement tools in the pharmaceutical and aerospace sectors. Segment trends highlight the growing preference for portable and handheld meters that offer flexibility and ease of use for auditing and troubleshooting tasks, while the fixed/wall-mounted segment continues to dominate revenue generation in continuous process monitoring applications. In terms of technology, capacitive sensors lead the volume segment due to their cost-effectiveness, though chilled mirror technology maintains dominance in applications demanding the highest accuracy and primary standard traceability.

AI Impact Analysis on Dew Point Meters Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Dew Point Meters Market commonly center on themes such as enhanced predictive maintenance capabilities, the role of machine learning in improving sensor calibration stability, and the integration of large-scale moisture data analytics for process optimization. Users frequently ask how AI can detect subtle drifts in readings before physical failures occur, whether AI-driven algorithms can compensate for environmental variables affecting sensor accuracy, and how centralized data platforms leveraging AI can manage fleets of meters across vast industrial complexes. There is a clear expectation that AI will transition dew point monitoring from reactive measurement to proactive moisture management, significantly reducing operational expenditure (OPEX) and minimizing unexpected downtime.

The integration of AI and Machine Learning (ML) transforms raw data from dew point meters into actionable intelligence, moving beyond simple alarming thresholds. AI algorithms are particularly useful in analyzing historical moisture data patterns correlated with variables like ambient temperature, pressure fluctuations, and production schedules. This allows for the precise prediction of when critical moisture levels might be reached, facilitating optimized maintenance windows. Furthermore, AI contributes significantly to AEO strategies by ensuring data generated by meters is structured, contextualized, and easily searchable, improving both local diagnostic capabilities and global asset management visibility. This analytical layer makes dew point data central to overall Industrial IoT (IIoT) strategies.

- AI-driven Predictive Maintenance: Anticipating sensor degradation and scheduling proactive calibration/replacement based on historical data patterns.

- Optimized Calibration Cycles: ML algorithms analyze drift rates to extend calibration intervals without compromising accuracy.

- Enhanced Anomaly Detection: Identifying subtle, non-linear deviations in moisture trends indicative of impending system failure or leak development.

- Real-Time Data Fusion: Integrating dew point data with temperature, pressure, and flow measurements for holistic process monitoring via AI.

- Automated Reporting: Generating compliance and energy efficiency reports automatically, tailored to regulatory requirements.

- Remote Diagnostic Assistance: Using AI to interpret complex error codes and provide remote troubleshooting guidance.

- Energy Optimization: ML systems correlate moisture levels with compressor energy consumption to identify energy-saving opportunities in compressed air networks.

- Improved Sensor Linearity Correction: AI models dynamically adjust sensor outputs based on complex environmental influences, enhancing measurement reliability in fluctuating conditions.

- Centralized Fleet Management: Utilizing cloud-based AI platforms to monitor and manage thousands of distributed dew point sensors simultaneously.

- Cybersecurity Enhancements: AI algorithms monitor data transmission for anomalies, ensuring the integrity and security of moisture measurement data within IIoT networks.

DRO & Impact Forces Of Dew Point Meters Market

The Dew Point Meters Market is fundamentally shaped by a combination of stringent regulatory compliance requirements and the ongoing push for industrial efficiency and quality control. Key drivers include the global expansion of ISO 8573 standards for compressed air purity, particularly in sensitive manufacturing like food and beverage, and electronics. Restraints primarily involve the high initial capital expenditure associated with high-accuracy meters (like chilled mirror), coupled with the complexity and cost of routine calibration, which requires specialized facilities. Opportunities are abundant, especially in the integration of advanced sensors with IoT platforms for remote diagnostics and the nascent hydrogen economy, which demands extremely accurate moisture measurement to prevent catalyst damage. These forces collectively propel the market toward increased accuracy, miniaturization, and seamless digital integration.

The primary driving force remains the imperative to safeguard critical infrastructure. In pneumatic systems, moisture leads to corrosion, freezing, and eventual equipment failure, necessitating robust monitoring solutions. The increasing automation across heavy industries and the pharmaceutical sector mandates consistently dry environments to ensure product integrity and operational longevity. Conversely, the market faces resistance due to a perceived lack of technical expertise in smaller enterprises regarding dew point measurement fundamentals and the ongoing challenge of standardizing sensor performance across diverse atmospheric conditions. This knowledge gap often results in the purchase of less suitable or poorly maintained equipment, undermining the effectiveness of monitoring efforts.

Impact forces dictate the competitive landscape, emphasizing the need for innovation in sensor technology. The rapid evolution of capacitive sensors, offering improved long-term stability and faster response times, is increasing pressure on traditional technologies. Furthermore, the market dynamic is heavily influenced by the upstream supply chain for critical sensor components and microelectronics. Regulatory changes, such as stricter emissions standards or new purity requirements for medical gases, immediately translate into increased demand for certified, high-accuracy instruments, confirming regulation as a decisive impact force shaping market trajectory and adoption rates globally.

Segmentation Analysis

The Dew Point Meters market is highly segmented based on factors such as technology employed, the portability of the device, the specific application or end-user industry, and geographical region. This segmentation allows manufacturers to tailor solutions precisely to the required measurement range, accuracy threshold, and operational environment, ranging from extremely low dew points required in semiconductor fabrication to moderately low dew points needed in standard HVAC systems. The technology segment is crucial, differentiating between the high-precision, labor-intensive chilled mirror devices and the more versatile, cost-effective electronic sensors. Understanding these divisions is vital for stakeholders aiming to capture niche markets or optimize their product portfolios for high-volume industrial applications.

The market performance is heavily influenced by the application segment, with compressed air quality monitoring accounting for the largest share due to the ubiquitous nature of pneumatic systems across nearly all manufacturing sectors. However, the fastest growth is anticipated in specialized segments such as medical gas production and the emerging fields of hydrogen and fuel cell technologies, where moisture measurement is a critical safety and efficiency parameter. The continued miniaturization of sensors and the enhancement of battery life are key trends driving the success of the portable segment, fulfilling the need for flexibility in auditing and system troubleshooting across large plant environments. These segments demonstrate the dichotomy between high-volume, standard applications and high-value, specialized requirements.

- By Technology

- Chilled Mirror

- Capacitive Thin-Film (Polymer)

- Aluminum Oxide

- Ceramic

- Spectroscopic (Tunable Diode Laser Absorption Spectroscopy - TDLAS)

- By Portability

- Fixed/Wall-mounted

- Portable/Handheld

- By Application/End-use Industry

- Compressed Air Systems

- Oil & Gas (Natural Gas Processing, LNG)

- Pharmaceuticals & Biotechnology

- Power Generation (Turbine Monitoring, Transformer Oil)

- Semiconductor & Electronics Manufacturing

- Chemical & Petrochemical Processing

- HVAC & Building Automation

- Industrial Gases & Cryogenics

- By Measurement Range

- High Range (-20°C Dp and above)

- Mid Range (-40°C to -20°C Dp)

- Low Range (Below -40°C Dp)

Value Chain Analysis For Dew Point Meters Market

The value chain for the Dew Point Meters Market begins with upstream activities, primarily involving the sourcing and development of highly specialized sensor materials, such as thin-film polymers, aluminum oxide substrates, and advanced optical components necessary for chilled mirror technology. Raw material suppliers and component manufacturers, including specialized microelectronics firms, form the foundational layer, dictating the precision and overall cost structure of the final instrument. Critical upstream considerations include intellectual property surrounding sensor patents and the reliable supply chain for microprocessors and data logging modules, ensuring the final product meets stringent industrial standards for reliability and long-term accuracy, which is paramount in critical process control applications.

The manufacturing and assembly phase involves the integration of sensors with signal conditioning electronics, ruggedized enclosures, and user interface systems, followed by rigorous factory calibration traceable to international standards (e.g., NIST). This phase adds significant value through quality assurance and certification. The distribution channel then bridges the gap between manufacturers and diverse end-users. Distribution is multifaceted, involving both direct sales models for highly technical or custom fixed installations, and indirect channels relying on specialized industrial distributors, pneumatic equipment suppliers, and independent calibration service providers who often bundle the meters with comprehensive installation and maintenance packages. The complexity of the product often necessitates distributors with strong technical support capabilities.

Downstream activities focus on installation, regular maintenance, and calibration services, which are critical for the longevity and accuracy of dew point meters. End-users often require on-site training and post-sale technical support, driving service revenue for both the original equipment manufacturers (OEMs) and third-party maintenance providers. The effectiveness of the indirect distribution channel is high, particularly for standardized products sold into the vast compressed air market. For high-end applications like semiconductor manufacturing, the direct channel is preferred, enabling manufacturers to provide bespoke engineering consulting and integrated installation services, ensuring the instrument operates optimally within complex system architectures and specific environmental parameters.

Dew Point Meters Market Potential Customers

Potential customers, or end-users, of dew point meters span a broad spectrum of industrial and manufacturing sectors where the control and monitoring of moisture content in gases are non-negotiable for operational integrity and product quality. The largest volume of consumption comes from the manufacturing sector, specifically companies operating large compressed air generation and distribution networks, as mandated by efficiency and equipment protection standards. These buyers prioritize robust, low-maintenance instruments that comply with international standards like ISO 8573-1, seeking both fixed in-line monitoring and portable auditing capabilities to ensure system efficiency and prevent costly pneumatic component failures caused by moisture accumulation and rust.

A second major customer group includes high-value, highly regulated industries such as pharmaceuticals, biotechnology, and semiconductor fabrication. In these environments, moisture is a critical contaminant; therefore, buyers demand instruments with the highest possible accuracy (often requiring chilled mirror technology) and comprehensive data logging capabilities for regulatory compliance and audit trails. These customers often invest in fixed, continuous monitoring systems integrated into Environmental Monitoring Systems (EMS), requiring meters capable of measuring ultra-low dew points (below -60°C Dp) to maintain dry environments essential for sensitive production processes and cleanroom operations.

Further potential customers include the energy sector, encompassing natural gas processing plants, oil refineries, and power generation facilities, where moisture monitoring is essential to prevent hydrate formation in pipelines, corrosion in turbine systems, and maintain the dielectric integrity of transformer oil. Additionally, specialized industrial gas suppliers and cryogenic laboratories constitute a growing customer base, requiring high-pressure, explosion-proof, and specialty gas-compatible meters to certify the purity of gases like nitrogen, argon, and hydrogen. These customers focus heavily on product certification and reliability under extreme operating pressures and temperatures, often demanding explosion-proof (ATEX/IECEx certified) instruments for hazardous area installations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 650 Million |

| Market Forecast in 2033 | USD 1050 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Vaisala, Michell Instruments, PCE Instruments, CS Instruments, Alpha Moisture Systems, Shaw Moisture Meters, General Electric (GE), Panametrics, Endress+Hauser, Rotronic, Comet System, Extech Instruments, SUTO iTEC, Trace Analytics, Testo, Sensirion, Emerson Electric, Dräger, Fluke, Hygromer. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dew Point Meters Market Key Technology Landscape

The technology landscape of the Dew Point Meters Market is characterized by the coexistence of established, highly accurate primary standards, such as the Chilled Mirror technology, alongside rapidly evolving electronic sensors designed for ruggedness, cost-efficiency, and integration into modern digital systems. Chilled Mirror meters, based on fundamental thermodynamic principles, offer unparalleled accuracy and are frequently used as laboratory standards for calibrating other sensors. However, their complexity and need for precise temperature control mean that the bulk of industrial installations rely on sensor-based technologies. The current trend focuses intensely on improving the long-term stability and response time of capacitive and aluminum oxide sensors, minimizing the frequency and cost associated with recalibration, which is a significant factor in total ownership cost.

The primary innovation driving the commercial segment is the hybridization of sensor technology with advanced microelectronics and software. Modern dew point meters increasingly feature integrated data logging, enhanced diagnostic self-checks, and connectivity protocols (like Modbus, Ethernet/IP, and wireless standards) to support IIoT integration. Manufacturers are developing smart sensors capable of compensating for pressure and temperature fluctuations internally, providing pressure-normalized dew point measurements directly, thereby simplifying installation and improving real-world accuracy. Furthermore, in niche, high-value markets, spectroscopic methods like TDLAS are gaining traction, offering fast, contamination-resistant, and highly selective moisture measurement, particularly beneficial in natural gas pipelines where contaminants can rapidly degrade traditional sensors.

A significant technological focus area is the miniaturization of sensor elements, which facilitates the development of smaller, more ergonomic handheld devices and allows for easier integration into complex machinery where space is limited. Advances in battery technology are supporting extended field use for portable units. Crucially, the move toward digital, cloud-based calibration management services allows end-users to track sensor performance, predict maintenance needs using predictive analytics, and ensure compliance without relying solely on manual calibration records. This digital shift ensures that the technology landscape is focused not just on measurement accuracy, but on delivering comprehensive, integrated moisture management solutions across the industrial ecosystem.

Regional Highlights

- North America: The North American market commands a significant share, driven by stringent regulatory frameworks, particularly concerning environmental emissions, pharmaceutical manufacturing standards (FDA requirements), and critical infrastructure reliability. The U.S. and Canada are characterized by high adoption rates of advanced monitoring equipment across the energy, aerospace, and semiconductor sectors. The mature industrial landscape and the high prevalence of R&D activities necessitate continuous investment in high-accuracy, certified instruments. Furthermore, the strong push towards industrial IoT implementation means manufacturers in this region are early adopters of digitally integrated dew point monitoring solutions that support centralized data management and remote diagnostics.

- Europe: Europe represents a robust market, fueled by strict adherence to ISO 8573 standards for compressed air quality, especially in Germany, the UK, and Scandinavian countries known for precision manufacturing. Regulatory compliance in the pharmaceutical and food and beverage industries is a primary market driver. The European market exhibits a strong preference for high-quality, European-manufactured instruments with comprehensive certification (e.g., ATEX for hazardous areas). The region is also a leader in promoting energy efficiency, driving demand for dew point monitoring systems that help optimize dryer performance and reduce overall compressed air system energy consumption across manufacturing facilities.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, propelled by rapid industrial expansion, massive investments in semiconductor fabrication plants (particularly in South Korea, Taiwan, and China), and increasing demand for infrastructure development in countries like India and Indonesia. The booming electronics and automotive sectors necessitate extremely dry processing environments, boosting the demand for ultra-low dew point measurement capabilities. While pricing sensitivity remains a factor in developing nations within APAC, the sheer scale of industrial growth and the adoption of global quality standards are accelerating the transition from basic measurement tools to sophisticated, reliable dew point meters. This region also benefits heavily from local manufacturing capacity and strong supply chain networks.

- Latin America: The Latin American market, while smaller, is growing steadily, primarily driven by the expansion of the oil & gas industry in countries such as Brazil and Mexico, and the modernization of manufacturing facilities. Demand often centers on robust, cost-effective meters suitable for challenging environmental conditions and remote installations typical of large-scale energy infrastructure. Adoption is increasingly focused on integrating basic monitoring systems to improve efficiency and reduce maintenance costs in primary industrial sectors, gradually moving towards better compliance with international performance and safety benchmarks.

- Middle East and Africa (MEA): The MEA region's market growth is intrinsically linked to its expansive oil, gas, and petrochemical industries. Monitoring moisture content in natural gas is critical for pipeline integrity and safety, driving strong demand for specialized, high-pressure, and often intrinsically safe dew point meters (certified for use in explosive atmospheres). Large-scale infrastructure projects, coupled with significant investments in renewable energy and water treatment facilities, are also contributing to the demand for reliable environmental and process control instrumentation throughout the major economic hubs of the GCC countries and South Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dew Point Meters Market.- Vaisala

- Michell Instruments

- Endress+Hauser

- Panametrics (Baker Hughes)

- CS Instruments GmbH

- Alpha Moisture Systems

- Shaw Moisture Meters

- General Electric (GE) Measurement & Control

- Rotronic (Process Sensing Technologies)

- SUTO iTEC GmbH

- PCE Instruments

- Testo SE & Co. KGaA

- Trace Analytics

- Kahn Instruments

- Sensirion AG

- Comet System, s.r.o.

- Drägerwerk AG & Co. KGaA

- Fluke Corporation

- Emerson Electric Co.

- Hygromer (E+H sister company)

Frequently Asked Questions

Analyze common user questions about the Dew Point Meters market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the most accurate technology for dew point measurement?

The most accurate technology is the Chilled Mirror Hygrometer. It serves as a primary reference standard, offering high precision and traceability by directly measuring the condensation point of moisture vapor, independent of calibration drift over time, making it ideal for critical laboratory and regulatory environments.

How often do industrial dew point meters require calibration?

Calibration frequency typically ranges from 6 to 12 months, depending on the sensor technology and the criticality of the application. High-accuracy industrial sensors often require annual calibration, though AI-driven predictive maintenance systems are increasingly used to optimize and potentially extend these intervals based on observed performance drift.

What is the difference between pressure dew point and atmospheric dew point?

Pressure dew point (PDP) is the dew point measured at the actual operating pressure within a system (e.g., compressed air line). Atmospheric dew point (ADP) is the equivalent dew point temperature if the gas were expanded to atmospheric pressure. PDP is always higher than ADP for the same moisture content, and industrial systems require PDP measurement for process control.

Which industrial sectors are the primary drivers of market growth?

The primary drivers include the Compressed Air sector, due to ubiquitous industrial pneumatic systems, and high-purity sectors like Pharmaceuticals, Semiconductors, and Oil & Gas. These industries require stringent moisture control to maintain product quality, ensure equipment longevity, and adhere to strict international standards like ISO 8573.

Are portable dew point meters as accurate as fixed installation units?

Modern portable meters utilize similar high-quality sensors (Capacitive or Aluminum Oxide) as fixed units. While laboratory-grade fixed units (Chilled Mirror) offer the highest absolute accuracy, professional-grade portable meters offer excellent field accuracy and repeatability, suitable for auditing, spot checks, and troubleshooting purposes.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager