Diboride Chromium Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439956 | Date : Jan, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Diboride Chromium Market Size

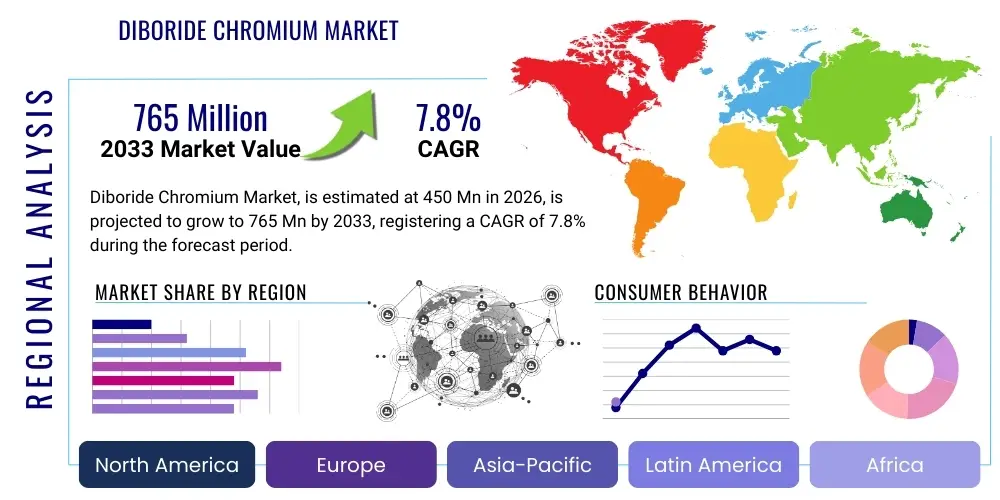

The Diboride Chromium Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 765 Million by the end of the forecast period in 2033. This growth is underpinned by escalating demand across diverse high-performance applications where extreme wear resistance, thermal stability, and electrical conductivity are paramount. The market expansion is largely driven by advancements in material science, leading to enhanced production capabilities and broader integration of diboride chromium into critical industrial processes. Furthermore, strategic investments in research and development aimed at improving material synthesis and application methods are contributing significantly to its market trajectory. The inherent properties of diboride chromium, such as its exceptional hardness and resistance to chemical degradation, position it as a material of choice in environments demanding superior performance, thereby ensuring sustained market growth throughout the forecast period.

Diboride Chromium Market introduction

The Diboride Chromium Market is characterized by the production and consumption of Chromium Diboride (CrB2), a refractory ceramic known for its remarkable physical and chemical properties. CrB2 is a transition metal boride recognized for its exceptionally high melting point, superior hardness, excellent wear resistance, good electrical conductivity, and outstanding corrosion resistance, particularly against molten metals and acidic environments. These intrinsic attributes make it a highly sought-after material in numerous high-performance and critical applications. Its primary applications span across diverse industrial sectors, including advanced ceramics, metallurgical processing, aerospace, defense, and electronics. In metallurgical applications, it is frequently utilized for crucibles, electrodes, and evaporation boats due to its chemical inertness and high thermal stability. Within the aerospace and defense industries, CrB2 is valued for its potential in lightweight armor, thermal protection systems, and high-temperature structural components where extreme conditions are commonplace. The material's electrical conductivity also makes it suitable for use in high-temperature heating elements and contacts. The significant benefits of diboride chromium include improved operational efficiency, extended product lifespan, and enhanced safety in demanding environments. Its ability to withstand severe mechanical, thermal, and chemical stresses translates into reduced maintenance costs and fewer replacements for end-users, offering a compelling value proposition. Key driving factors for this market include the increasing demand for advanced materials in rapidly expanding industries such as additive manufacturing, where CrB2 powders are gaining traction for producing complex geometries with superior mechanical properties. Additionally, the continuous pursuit of higher performance and durability in industrial tools and components, coupled with ongoing technological advancements in material synthesis and processing, further propels the adoption of diboride chromium, solidifying its pivotal role in modern industrial applications and ensuring robust market growth in the coming years.

Diboride Chromium Market Executive Summary

The Diboride Chromium Market is currently experiencing robust growth, driven by a confluence of evolving business trends, significant regional expansion, and diversification across key application segments. Business trends indicate a strong emphasis on innovation in material science, with manufacturers investing heavily in advanced synthesis techniques to produce higher purity CrB2 powders and components with enhanced mechanical properties. There is a growing trend towards customization, where suppliers are offering tailor-made diboride chromium solutions to meet specific industry requirements, particularly in demanding sectors like aerospace, defense, and high-temperature metallurgy. Furthermore, strategic partnerships and collaborations between research institutions, material producers, and end-users are becoming more prevalent, aiming to accelerate product development and market penetration. Companies are also focusing on optimizing production processes to reduce costs and improve scalability, making CrB2 more accessible for a wider range of industrial applications. Regional trends reveal North America and Europe as established markets, characterized by mature industrial infrastructure and significant R&D investments, driving demand for advanced materials in aerospace, medical, and defense sectors. The Asia Pacific region, led by China, Japan, and India, is emerging as the fastest-growing market, fueled by rapid industrialization, burgeoning manufacturing activities, and increasing government initiatives supporting advanced material research and application. Latin America, the Middle East, and Africa are also showing promising growth, albeit from a lower base, as industrial development and infrastructure projects drive the need for durable and high-performance materials. Segment trends highlight strong growth in the metallurgical applications sector, where CrB2 is increasingly used for crucibles, molten metal handling components, and protective coatings due to its excellent corrosion and wear resistance. The cutting tools and wear parts segment continues to expand, benefiting from the material's extreme hardness and thermal stability, leading to longer tool life and improved machining efficiency. Moreover, the emergence of additive manufacturing (3D printing) as a viable production method for complex diboride chromium parts represents a significant growth avenue, opening up new possibilities for customized components in various industries. The electronics sector is also contributing to market growth, with CrB2 finding applications in sputtering targets for thin-film deposition and high-temperature electrical contacts. Overall, the market is poised for sustained expansion, propelled by technological advancements, increasing industrial demand, and strategic market development initiatives across key geographies and application areas.

AI Impact Analysis on Diboride Chromium Market

User questions about AI's impact on the Diboride Chromium market frequently revolve around its potential to optimize material discovery, enhance manufacturing processes, and predict material performance. Users are keen to understand how AI and machine learning (ML) can accelerate the identification of novel CrB2 compositions, improve synthesis parameters to achieve superior material properties, and streamline quality control. There's also significant interest in AI's role in simulating the behavior of diboride chromium in extreme environments, reducing the need for extensive physical testing, and ultimately driving cost efficiencies and faster product development cycles. Concerns often include the accessibility of AI technologies for smaller manufacturers, the data requirements for effective AI models, and the necessary skill sets to implement these advanced analytical tools within the traditional materials science sector. Users are eager for insights into how AI can democratize access to advanced material design and processing, making high-performance materials like CrB2 more broadly available and cost-effective. The overarching expectation is that AI will be a transformative force, enabling unprecedented precision, efficiency, and innovation across the entire value chain of diboride chromium, from raw material sourcing to final application, ensuring enhanced material integrity and performance across its diverse industrial uses.

- AI-driven material discovery accelerates the identification of optimal diboride chromium compositions for specific applications, reducing R&D timelines.

- Machine learning algorithms optimize CrB2 synthesis parameters (temperature, pressure, precursor ratios), leading to higher purity, improved microstructure, and enhanced mechanical properties.

- Predictive analytics powered by AI models forecast the performance and lifespan of diboride chromium components under various operational stresses, minimizing physical prototyping and testing costs.

- AI-enhanced quality control systems ensure consistent material properties and detect defects in CrB2 products with greater accuracy and speed, improving overall product reliability.

- Robotics and automation, often integrated with AI, streamline the manufacturing and handling of diboride chromium powders and parts, increasing production efficiency and worker safety.

- AI facilitates the design of complex diboride chromium geometries for additive manufacturing, optimizing structural integrity and material utilization.

- Data analytics from industrial sensors provide real-time insights into CrB2 component wear and tear, enabling proactive maintenance and extending service life.

- Generative design tools, leveraging AI, explore vast design spaces for diboride chromium parts, suggesting innovative structures that were previously unimaginable.

- Supply chain optimization through AI improves the sourcing and logistics of raw materials for diboride chromium production, enhancing efficiency and reducing lead times.

- AI platforms enable personalized material solutions, allowing manufacturers to rapidly customize diboride chromium properties to meet niche market demands.

DRO & Impact Forces Of Diboride Chromium Market

The Diboride Chromium Market is profoundly influenced by a complex interplay of drivers, restraints, and opportunities, collectively shaping its trajectory and competitive landscape. The primary drivers for market growth include the escalating demand for high-performance materials in extreme operating environments across industries such as aerospace, defense, and high-temperature industrial processes. Diboride chromium's intrinsic properties, such as its exceptional hardness, wear resistance, thermal stability, and corrosion resistance, make it indispensable for applications requiring superior durability and reliability. Furthermore, the rapid advancements in additive manufacturing technologies are creating new avenues for CrB2 applications, allowing for the production of complex components with enhanced properties and reduced material waste. The continuous focus on improving energy efficiency and extending the lifespan of industrial components also fuels the adoption of diboride chromium, as it contributes significantly to these objectives. However, the market faces several restraints that could impede its growth. The high cost of raw materials and the specialized, energy-intensive manufacturing processes required for producing high-purity diboride chromium act as significant barriers, particularly for small and medium-sized enterprises. The relatively limited commercial production capacity and the niche nature of some applications also restrict broader market penetration. Additionally, the availability of substitute materials, while often inferior in specific performance metrics, can offer cost-effective alternatives, posing a competitive challenge. Navigating stringent regulatory frameworks, especially concerning material safety and environmental impact, further adds to the complexity for manufacturers. Despite these challenges, the market presents substantial opportunities for innovation and expansion. The burgeoning demand from emerging economies, driven by rapid industrialization and infrastructure development, offers significant untapped market potential. Continuous research and development efforts aimed at reducing production costs, improving material synthesis efficiency, and developing novel application areas for diboride chromium are expected to unlock new growth avenues. Opportunities also lie in the development of hybrid materials and composites that leverage the unique properties of CrB2, enhancing performance in multi-functional applications. Moreover, strategic collaborations between material scientists, manufacturers, and end-users can accelerate the commercialization of new diboride chromium products and expand its market footprint. The rising adoption of sustainable manufacturing practices and the push for circular economy principles also present opportunities for developing more environmentally friendly production methods and recycling initiatives for CrB2, aligning with global sustainability goals and fostering long-term market resilience. Addressing these forces effectively will be crucial for stakeholders aiming to capitalize on the inherent strengths of diboride chromium and mitigate potential risks in a dynamic market environment.

Segmentation Analysis

The Diboride Chromium Market is extensively segmented to provide a detailed understanding of its diverse landscape and to identify key growth pockets and strategic opportunities. This segmentation allows for a comprehensive analysis of various market dynamics, including material types, application areas, and geographical distribution, thereby offering granular insights into consumer preferences and industry specific demands. Understanding these segments is crucial for stakeholders to tailor their product offerings, marketing strategies, and investment decisions, ensuring optimal resource allocation and competitive advantage. The market is primarily segmented based on its form (powder, targets, components), purity levels (standard, high-purity), and end-use industries, reflecting the specialized nature of CrB2 applications across different sectors. Each segment exhibits unique growth patterns and demand drivers, influenced by technological advancements, regulatory environments, and specific industry requirements. This layered segmentation approach facilitates a more accurate forecast of market trends and enables businesses to focus on areas with the highest potential return on investment. Furthermore, the segmentation by application highlights the most impactful areas of use, providing clarity on where Diboride Chromium delivers the most significant value and where future innovation is likely to emerge. The detailed breakdown supports strategic planning for market entry, product differentiation, and competitive positioning within this specialized materials market.

- By Type:

- Diboride Chromium Powder

- Diboride Chromium Sintered Parts

- Diboride Chromium Sputtering Targets

- Diboride Chromium Composites

- By Purity:

- Standard Purity CrB2

- High Purity CrB2 (99% and above)

- By Application:

- Metallurgical Industry (crucibles, electrodes, evaporation boats)

- Aerospace and Defense (armor, thermal protection systems, structural components)

- Cutting Tools and Wear Parts (inserts, nozzles, bearings)

- Electronics Industry (sputtering targets for thin films, electrical contacts)

- Nuclear Applications (control rods, radiation shielding)

- Additive Manufacturing (3D printing powders)

- Refractory Materials (linings, high-temperature components)

- Chemical Processing (corrosion-resistant parts)

- By End-Use Industry:

- Manufacturing

- Automotive

- Energy

- Medical

- Construction

- Others

Value Chain Analysis For Diboride Chromium Market

The value chain for the Diboride Chromium Market is intricate, involving several distinct stages from raw material extraction to the final end-use application, each contributing to the material's overall value proposition and market accessibility. Understanding this value chain is critical for identifying potential bottlenecks, optimizing operational efficiencies, and enhancing competitive advantage across the industry. The upstream analysis typically begins with the procurement of essential raw materials, primarily chromium and boron, which are sourced from mining operations globally. The quality and availability of these precursor materials directly impact the purity and cost-effectiveness of the final CrB2 product. Following raw material acquisition, the manufacturing process involves advanced synthesis techniques, such as carbothermal reduction, borothermal reduction, or mechanical alloying, to produce diboride chromium powder. This stage requires significant capital investment in specialized equipment, highly skilled labor, and stringent quality control measures to ensure the desired material properties are achieved. The downstream analysis focuses on the transformation of CrB2 powders into various forms, including sintered parts, sputtering targets, or integrated components. This involves processes like pressing, sintering, hot isostatic pressing (HIP), and machining, tailored to specific application requirements. Value addition at this stage includes enhancing mechanical properties, achieving precise geometries, and applying surface treatments to optimize performance in demanding environments. The distribution channel for diboride chromium products is typically a mix of direct and indirect approaches. Direct sales involve manufacturers supplying directly to large industrial end-users, especially in niche applications like aerospace and defense, where technical specifications and customization are paramount. This direct interaction fosters strong customer relationships and facilitates tailored solutions. Indirect channels involve distributors, agents, and specialized material suppliers who serve a broader base of smaller to medium-sized enterprises (SMEs) and provide inventory management, logistical support, and technical assistance. These intermediaries play a crucial role in expanding market reach and ensuring timely delivery. The interplay between upstream suppliers, manufacturers, fabricators, and various distribution networks collectively determines the efficiency and responsiveness of the Diboride Chromium Market, influencing pricing, innovation cycles, and overall market growth. Optimizing each stage of this value chain, from sustainable raw material sourcing to efficient end-product delivery, is essential for maintaining a competitive edge and meeting the evolving demands of advanced industrial sectors.

Diboride Chromium Market Potential Customers

The Diboride Chromium Market caters to a diverse range of potential customers across various high-tech and industrial sectors, all seeking materials with exceptional performance characteristics in extreme conditions. These end-users and buyers are typically involved in applications where traditional materials fail to meet the stringent demands of hardness, wear resistance, thermal stability, and corrosion resistance. A primary segment of potential customers includes manufacturers of cutting tools and wear parts, such as those producing carbide inserts, drilling bits, nozzles, and industrial bearings, who require materials that can withstand intense friction, heat, and abrasive environments to extend tool life and improve operational efficiency. The aerospace and defense industries represent another significant customer base, valuing diboride chromium for its lightweight yet robust properties, making it suitable for armor plating, thermal protection systems, missile components, and high-temperature engine parts where reliability under extreme stress is critical. Metallurgical industries, including those involved in the production of specialty alloys and advanced metals, are key buyers, utilizing CrB2 for crucibles, molten metal handling equipment, and electrodes due to its inertness and resistance to molten metal corrosion. The electronics sector also presents a growing customer segment, particularly for companies manufacturing sputtering targets used in thin-film deposition for semiconductor devices, display technologies, and optical coatings, where high purity and consistent performance are paramount. Furthermore, the burgeoning additive manufacturing (3D printing) industry is emerging as a significant potential customer, with an increasing demand for high-quality diboride chromium powders to produce complex, high-performance parts with customized geometries for diverse applications. Research institutions and academic laboratories also constitute a specialized customer group, acquiring CrB2 for experimental studies, material characterization, and the development of new applications and composites. Companies involved in the nuclear energy sector use diboride chromium for control rods and radiation shielding due to its neutron absorption properties and stability in high-radiation environments. Lastly, manufacturers of refractory linings and high-temperature components for industrial furnaces and chemical processing plants are also key buyers, leveraging CrB2's excellent thermal and chemical resistance to prolong equipment lifespan and ensure operational safety. The appeal of diboride chromium to these diverse customers lies in its ability to significantly enhance product durability, improve performance metrics, and ultimately reduce operational costs in highly demanding industrial settings, making it an indispensable material for advanced technological applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 765 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Materion Corporation, American Elements, H.C. Starck GmbH, Stanford Advanced Materials, Beijing F.C.C. New Material Co., Ltd., ESPI Metals, AEM (Advanced Engineering Materials), Nanografi Nano Technology, Alfa Aesar (Thermo Fisher Scientific), Reade Advanced Materials, Luoyang Hongteng New Material Co., Ltd., Atlantic Equipment Engineers, Skyworks Advanced Materials, Strem Chemicals Inc., Angang Group Company Limited, Nanoshel LLC, S.T.M. Metallspritztechnik GmbH, Zibo Jingzong Chemical Co., Ltd., China Rare Metal Material Co., Ltd., Treibacher Industrie AG. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Diboride Chromium Market Key Technology Landscape

The Diboride Chromium Market is underpinned by a dynamic and evolving technology landscape, encompassing sophisticated manufacturing processes, advanced material characterization techniques, and innovative application methodologies. The production of high-quality diboride chromium primarily relies on several key technological approaches for powder synthesis. These include carbothermal reduction, where chromium oxide and boron carbide are reacted at high temperatures; borothermal reduction, involving the reduction of chromium oxide with boron; and mechanochemical synthesis or mechanical alloying, which uses high-energy milling to produce fine powders. Each method offers distinct advantages in terms of purity, particle size distribution, and cost-effectiveness, with ongoing research focused on optimizing these processes for greater efficiency and scalability. Furthermore, plasma synthesis techniques and chemical vapor deposition (CVD) are gaining traction for producing high-purity CrB2 coatings and thin films, enabling precise control over material microstructure and surface properties. Beyond synthesis, the fabrication of diboride chromium into functional components employs advanced sintering technologies such as hot pressing, hot isostatic pressing (HIP), and spark plasma sintering (SPS). SPS, in particular, allows for rapid consolidation at lower temperatures, preserving fine grain structures and achieving near-net-shape components with superior mechanical properties, which is crucial for high-performance applications. The advent of additive manufacturing (AM), specifically techniques like selective laser melting (SLM) and electron beam melting (EBM) with CrB2 powders, represents a significant technological leap. These AM processes enable the creation of complex geometries and customized components with optimized performance characteristics, minimizing material waste and lead times. Material characterization technologies play a pivotal role in ensuring the quality and performance of diboride chromium products. Techniques such as X-ray diffraction (XRD) for phase identification, scanning electron microscopy (SEM) and transmission electron microscopy (TEM) for microstructural analysis, and various spectroscopies (e.g., EDS, XPS) for elemental composition and chemical bonding are routinely employed. Mechanical testing methods, including Vickers hardness, indentation fracture toughness, and wear testing, are essential for validating the suitability of CrB2 for its intended applications. Advancements in computational materials science, including density functional theory (DFT) and molecular dynamics simulations, are also increasingly utilized to predict material behavior, design new compositions, and optimize processing parameters before physical experimentation. This integration of computational and experimental techniques accelerates the development cycle and reduces R&D costs. The continuous evolution of these technologies, from synthesis and fabrication to characterization and computational modeling, is instrumental in driving innovation, expanding the application scope, and enhancing the overall competitiveness of the Diboride Chromium Market, ensuring its sustained relevance in advanced industrial sectors.

Regional Highlights

- North America: This region holds a significant share in the Diboride Chromium Market, driven by robust aerospace, defense, and advanced manufacturing sectors, particularly in the United States. High R&D investments in materials science and strong demand for high-performance components in extreme environments propel market growth. The presence of key market players and a well-established industrial infrastructure further solidify its position. Canada and Mexico also contribute, albeit to a lesser extent, focusing on specialized industrial applications and export markets.

- Europe: Europe represents a mature and technologically advanced market for diboride chromium, with Germany, France, and the UK leading the demand. The region's strong automotive, industrial machinery, and energy sectors, coupled with stringent quality standards, necessitate the use of durable and high-performance materials. Extensive research initiatives and collaborations between academia and industry contribute to innovation and new application development, particularly in refractory materials and cutting tools.

- Asia Pacific (APAC): The APAC region is projected to be the fastest-growing market for Diboride Chromium, spearheaded by rapid industrialization and burgeoning manufacturing activities in China, India, Japan, and South Korea. Increased investments in infrastructure development, electronics, and automotive industries are fueling the demand for advanced ceramics and wear-resistant materials. The lower production costs and expanding industrial base make APAC a pivotal region for both consumption and production.

- Latin America: This region exhibits emerging growth in the Diboride Chromium Market, primarily driven by investments in mining, metallurgical, and energy sectors in countries like Brazil and Mexico. The increasing adoption of modern industrial practices and the need for more efficient and durable equipment contribute to market expansion. While smaller in scale compared to other regions, Latin America offers significant untapped potential as industrialization progresses.

- Middle East and Africa (MEA): The MEA region is experiencing gradual growth, mainly influenced by the expansion of the oil and gas industry, infrastructure projects, and defense expenditures. Countries like Saudi Arabia, UAE, and South Africa are leading the adoption of advanced materials for corrosion resistance and high-temperature applications. Investments in diversification strategies away from oil dependency are also fostering demand in manufacturing and other industrial sectors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Diboride Chromium Market.- Materion Corporation

- American Elements

- H.C. Starck GmbH

- Stanford Advanced Materials

- Beijing F.C.C. New Material Co., Ltd.

- ESPI Metals

- AEM (Advanced Engineering Materials)

- Nanografi Nano Technology

- Alfa Aesar (Thermo Fisher Scientific)

- Reade Advanced Materials

- Luoyang Hongteng New Material Co., Ltd.

- Atlantic Equipment Engineers

- Skyworks Advanced Materials

- Strem Chemicals Inc.

- Angang Group Company Limited

- Nanoshel LLC

- S.T.M. Metallspritztechnik GmbH

- Zibo Jingzong Chemical Co., Ltd.

- China Rare Metal Material Co., Ltd.

- Treibacher Industrie AG

Frequently Asked Questions

What is Diboride Chromium and its primary characteristics?

Diboride Chromium (CrB2) is a refractory ceramic compound known for its exceptional hardness, high melting point (around 2200°C), superior wear and corrosion resistance, and good electrical conductivity. These properties make it highly valuable in demanding industrial applications where extreme conditions are present.

Which industries are the main consumers of Diboride Chromium?

The primary consumers of Diboride Chromium include the metallurgical industry, aerospace and defense sectors, manufacturers of cutting tools and wear parts, the electronics industry, and companies involved in nuclear applications and additive manufacturing.

What are the key drivers for the growth of the Diboride Chromium Market?

Key drivers include the increasing demand for high-performance materials in extreme operating environments, advancements in additive manufacturing technologies, ongoing research and development in material science, and the continuous pursuit of improved energy efficiency and extended component lifespan across various industries.

What challenges does the Diboride Chromium Market face?

The market faces challenges such as the high cost of raw materials, complex and energy-intensive manufacturing processes, relatively limited commercial production capacity, the availability of substitute materials, and stringent regulatory requirements that can impact market expansion.

How is AI impacting the Diboride Chromium Market?

AI is significantly impacting the market by accelerating material discovery, optimizing synthesis parameters for enhanced properties, enabling predictive performance modeling, improving quality control, and streamlining manufacturing processes through automation and generative design, thereby fostering innovation and efficiency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager