Dilution Refrigerators Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432434 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Dilution Refrigerators Market Size

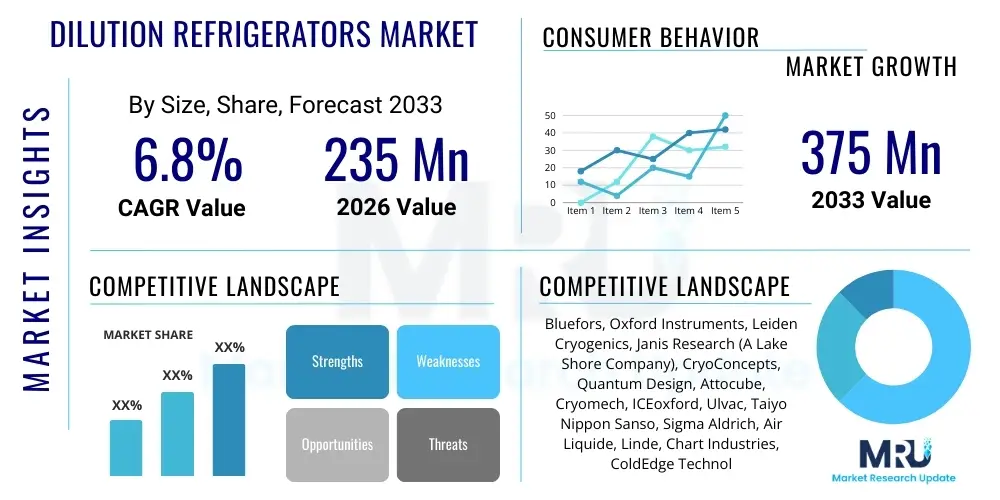

The Dilution Refrigerators Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $235 Million in 2026 and is projected to reach $375 Million by the end of the forecast period in 2033.

The specialized nature of dilution refrigerators, crucial for achieving temperatures below 100 millikelvin, positions this market within the high-growth quantum technology sector. Market expansion is fundamentally linked to increased global investment in quantum computing hardware development, condensed matter physics research, and the testing of highly sensitive superconducting devices. While unit volumes remain low compared to standard industrial refrigeration, the high average selling price (ASP) and the complexity of these cryogenic systems drive significant revenue growth, making it a critical component of the scientific instrumentation landscape.

Furthermore, continuous technological advancements focused on improving the cooling power, efficiency, and automation capabilities of these systems are major determinants of market size progression. Researchers and commercial entities are increasingly seeking automated, reliable, and large-capacity dilution refrigerators to scale up quantum processors and accelerate fundamental research. The competitive landscape is characterized by niche manufacturers innovating in dry (cryogen-free) systems, which significantly reduce operational complexity and cost, thereby broadening the accessibility of ultra-low temperature environments to a wider range of academic and industrial labs.

Dilution Refrigerators Market introduction

Dilution refrigerators (DRs) represent the apex of cryogenic technology, utilizing the mixing enthalpy of Helium-3 (³He) and Helium-4 (⁴He) isotopes to achieve the lowest sustained temperatures attainable through continuous refrigeration—typically in the range of a few millikelvin (mK), reaching as low as 2 mK. These instruments are indispensable tools in advanced scientific research, serving as the essential environment for studying quantum phenomena, superconductivity, exotic materials, and particle physics experiments that require near-absolute zero thermal conditions to isolate delicate quantum states or minimize thermal noise. Their complex architecture involves multiple cooling stages, including a pulse tube cooler for initial precooling, followed by a series of heat exchangers and a mixing chamber where the thermodynamic process of isotopic dilution occurs.

The primary applications of dilution refrigerators are concentrated in high-technology fields, dominated by the rapidly expanding quantum technology ecosystem. They are the core infrastructure supporting the development and testing of superconducting qubits (such as those based on transmons or fluxoniums) used in quantum computers, enabling these sensitive devices to maintain coherence for meaningful computational operations. Beyond quantum computing, DRs are vital for developing highly sensitive detectors for astronomy (e.g., bolometers for submillimeter astronomy), probing novel electronic states in two-dimensional materials, and advancing magneto-transport studies at ultra-low temperatures. The benefit derived from using a dilution refrigerator is the ability to conduct precise, repeatable experiments under thermal conditions where quantum mechanics dominates macroscopic behavior, providing unprecedented insight into fundamental physical laws.

Driving factors for the dilution refrigerators market include massive governmental and private sector investments in quantum computing initiatives across North America, Europe, and Asia Pacific, fueled by the race to achieve quantum advantage. Additionally, the shift towards cryogen-free (dry) systems, which eliminate the reliance on liquid helium baths and drastically reduce running costs and logistical burdens, is democratizing access to millikelvin temperatures. The ongoing miniaturization of components, coupled with enhanced cooling power capacity to handle larger heat loads from advanced quantum hardware, further stimulates demand. Furthermore, the necessity for reliable, stable, and automated ultra-low temperature platforms in industrialized quantum computing research centers ensures sustained market momentum throughout the forecast period.

Dilution Refrigerators Market Executive Summary

The Dilution Refrigerators Market is experiencing robust growth, primarily propelled by the exponential scaling requirements of the global quantum computing industry. Business trends indicate a clear pivot toward integrated, turnkey cryogenic solutions, where manufacturers are offering fully shielded, automated systems capable of cooling quantum processors with hundreds or potentially thousands of qubits. Key strategic initiatives within the market involve optimizing heat load management, reducing cool-down times, and incorporating advanced vibration isolation technologies, positioning manufacturers not merely as hardware suppliers but as critical enablers of quantum technological breakthroughs. The transition from custom-built, wet systems to standardized, industrial-grade dry dilution refrigerators is redefining manufacturing efficiency and customer support models, focusing on modularity and remote diagnostic capabilities.

Regionally, North America, particularly the United States, maintains market dominance due to high levels of government funding (e.g., through the National Quantum Initiative) and the presence of major technology giants (such as IBM, Google, and Microsoft) heavily invested in scaling superconducting quantum processors. Europe follows closely, driven by collaborative research programs and specialized cryogenics manufacturers headquartered in countries like Finland, the UK, and the Netherlands, focusing on fundamental physics research and advanced component development. The Asia Pacific region is rapidly emerging as a significant growth hub, led by substantial investments from China and Japan aimed at establishing domestic quantum computing capabilities and constructing large-scale national laboratory infrastructure requiring numerous high-capacity DR systems.

Segment trends highlight the significant growth of the dry dilution refrigerators segment, which offers superior operational convenience and cost-effectiveness compared to traditional wet systems, making them increasingly preferred across academic and industrial settings. By application, the quantum computing segment is the largest revenue contributor and is forecasted to maintain the highest CAGR, reflecting the immediate need for reliable mK environments to house growing qubit arrays. Furthermore, the specialized materials research segment, focusing on high-temperature superconductivity and topological materials, provides a steady stream of demand, emphasizing systems designed for integration with high magnetic fields and complex measurement instrumentation. This structural shift towards robust, commercially viable cryogenic platforms ensures sustained market valuation increases.

AI Impact Analysis on Dilution Refrigerators Market

User inquiries regarding AI's impact on Dilution Refrigerators primarily center on how artificial intelligence can enhance the operational efficiency, stability, and predictive maintenance of these complex cryogenic systems, which are vital for quantum computing. Users are keen to understand if AI can optimize the extremely delicate cooling cycles, detect micro-vibrations or subtle thermal drifts that could compromise qubit coherence, and automate the troubleshooting process, thereby reducing downtime and the reliance on highly specialized cryogenic engineers. Key themes revolve around leveraging machine learning for real-time temperature control optimization (especially in dynamic quantum experiments), integrating predictive analytics to forecast potential component failure (like pulse tube degradation or contamination issues), and accelerating the complex parameter tuning required to achieve the lowest possible temperatures efficiently and repeatedly across different experimental setups. The expectation is that AI will transform DRs from specialized, manually intensive instruments into highly autonomous, reliable components of the quantum computing stack.

AI is expected to significantly enhance the usability and performance reliability of dilution refrigeration systems. Sophisticated machine learning algorithms can analyze vast datasets collected from temperature sensors, pressure gauges, and flow meters within the DR system to model optimal operating parameters under varying experimental heat loads. This optimization is crucial for quantum computing, where maintaining stable temperatures in the millikelvin range is paramount for the quantum state integrity of qubits. By predicting thermal instabilities before they occur, AI allows for proactive adjustments to gas flow rates or heat switch operations, pushing the operational envelope closer to theoretical limits and ensuring extended periods of low-noise, ultra-stable experimental conditions.

Furthermore, the integration of AI models into the diagnostic and control architecture of dilution refrigerators facilitates rapid fault detection and resolution. Given the high cost and complexity of servicing these systems, predictive maintenance enabled by AI offers substantial value. Algorithms can analyze acoustic signatures, vibration patterns, and historical performance data to identify early signs of mechanical wear, such as contamination within the circulation system or impending failures in vacuum pumps or compressors. This capability translates directly into higher uptime, lower maintenance costs, and increased experimental throughput for users in demanding research and commercial quantum environments, cementing AI as an indispensable tool for future cryogenic operations.

- AI optimizes cooling cycle parameters and gas flow rates for maximum efficiency and stability.

- Machine learning models enable predictive maintenance, anticipating component failures in compressors or pulse tube coolers.

- Real-time data analytics improve thermal stability control, essential for maintaining qubit coherence in quantum computing applications.

- AI algorithms automate complex system calibration and tuning processes, reducing the need for constant expert supervision.

- Enhanced diagnostics driven by AI minimize system downtime and operational costs by accurately identifying fault origins.

DRO & Impact Forces Of Dilution Refrigerators Market

The Dilution Refrigerators Market is governed by dynamic forces shaped by technological dependency, financial requirements, and geopolitical competition in quantum technology. The primary drivers include massive global funding directed toward quantum research and the industrial scaling of superconducting quantum processors, creating persistent demand for ultra-low temperature platforms. Opportunities arise from the transition to automated, cryogen-free systems, which expands the market to institutions lacking extensive cryogenic expertise, coupled with the development of high-cooling power DRs capable of handling the increasing thermal load generated by larger qubit arrays. However, market growth is restrained by the high initial capital investment required for these systems, the intrinsic reliance on rare isotopes like Helium-3 (³He), and the scarcity of highly specialized personnel capable of operating and maintaining millikelvin refrigeration infrastructure. These interconnected forces dictate the market trajectory, emphasizing innovation in efficiency and accessibility.

A significant impact force is the volatile supply chain for Helium-3, a critical, non-renewable component essential for the dilution process. Geopolitical factors influence the availability and cost of ³He, presenting a substantial restraint on market expansion and driving research into alternative cooling mechanisms or closed-loop recycling systems that minimize loss. Conversely, the rapid advancement in competing quantum technologies, such as photonic or trapped-ion systems (which do not strictly require millikelvin temperatures), acts as a competitive restraint, though superconducting qubits currently hold a technological lead in scalability requiring DRs. Market growth is further impacted positively by the need for advanced material characterization in electronics, particularly the testing of novel semiconductors and high-temperature superconductors, necessitating reliable access to near-zero Kelvin environments for precision measurements.

The imperative for increased cooling power (up to 100 µW at 10 mK) is a crucial driver, directly linked to the roadmap of major quantum hardware developers who require systems robust enough to manage the dissipation from complex control wiring, high-density coaxial cables, and the qubits themselves. Manufacturers who successfully address this technical challenge gain a significant competitive edge. The market is also heavily influenced by regulatory standards concerning vibration isolation and electromagnetic shielding, as research systems demand increasingly stringent environments free from external noise. The overall impact forces compel manufacturers to invest heavily in integrated solutions that combine superior thermodynamic performance with robust, industrial-level reliability and complete cryogenic automation, thereby ensuring DRs remain foundational to the quantum industry's ongoing evolution.

Segmentation Analysis

The Dilution Refrigerators Market is segmented based on the type of cooling system employed (Wet vs. Dry), the maximum achieved base temperature (e.g., 10 mK, 5 mK), cooling power, and the specific end-user application. The segmentation reflects the diverse and highly specialized needs of various scientific and commercial customers, ranging from university research labs requiring flexibility to large corporations demanding scalable, high-throughput cryogenic infrastructure. Understanding these segments is crucial for manufacturers to tailor their offerings, particularly focusing on the rapid shift toward cryogen-free (dry) systems which dominate new installations due to their operational ease and lower lifetime cost compared to traditional liquid helium-dependent (wet) systems.

- By Type:

- Wet Dilution Refrigerators (Traditional, liquid helium-dependent systems)

- Dry (Cryogen-Free) Dilution Refrigerators (Utilizing pulse tube coolers for precooling)

- By Base Temperature:

- Below 5 mK

- 5 mK – 10 mK

- Above 10 mK

- By Cooling Power:

- Standard Power (< 50 µW at 10 mK)

- High Power (> 50 µW at 10 mK)

- By Application:

- Quantum Computing and Information Science

- Condensed Matter Physics Research

- Advanced Materials Testing and Characterization

- Astronomical Detector Cooling (e.g., Bolometers)

- Particle Physics Experiments

- By End User:

- Academic and Research Institutions

- Government Laboratories

- Industrial and Commercial Quantum Developers

Value Chain Analysis For Dilution Refrigerators Market

The value chain for the Dilution Refrigerators Market is highly specialized, beginning with the upstream supply of ultra-high purity materials and critical components, leading to sophisticated assembly and intense downstream deployment. Upstream activities are dominated by specialized suppliers providing rare isotopes, primarily Helium-3 (³He), which is sourced through geopolitical channels or nuclear material processing, and precision components such as pulse tube coolers, high-vacuum pumps, and proprietary heat exchangers. The reliance on these highly controlled inputs mandates strong, secure supply relationships. Manufacturing involves complex engineering and ultra-high precision machining, demanding specialized facilities to ensure vacuum integrity and thermal performance, ultimately yielding a high value-added product.

The core manufacturing process involves the integration of pre-cooling stages, often utilizing commercial pulse tube coolers, with proprietary internal components like the still, condensation lines, and the mixing chamber—where the actual dilution cooling takes place. Quality assurance, including extensive cryogenic testing and temperature calibration, is a critical step before market entry. Downstream activities involve distribution, which is predominantly direct due to the technical nature of the product. Manufacturers engage directly with research institutions and quantum technology companies, providing tailored systems engineering, installation, and extensive post-sale support, including on-site training and long-term maintenance contracts necessary for these highly sensitive instruments.

Distribution channels in this market are mainly direct, ensuring that complex specifications are met and that the intricate installation process, which often involves custom infrastructure integration (cryostats, vibration damping, shielding), is managed by factory-trained experts. Indirect distribution, though minimal, might occur through highly specialized regional scientific equipment distributors, particularly in emerging Asian markets where local representation is necessary for logistics and language support. The value capture is highest in the manufacturing, system integration, and post-sale service phases, reflecting the intellectual property embodied in the thermodynamic design and the requirement for continuous operational support to guarantee the millikelvin performance demanded by cutting-edge quantum research.

Dilution Refrigerators Market Potential Customers

The potential customer base for dilution refrigerators is highly concentrated within the global scientific and advanced technology community, specifically encompassing organizations focused on fundamental physics and the industrialization of quantum technologies. These end-users, or buyers, include major governmental research laboratories, such as national institutes of standards and technology, particle accelerators, and astrophysical observatories, which require stable, ultra-low temperature environments for complex long-duration experiments. Furthermore, prominent academic research institutions and universities globally, particularly those with leading programs in condensed matter physics, quantum mechanics, and materials science, constitute a consistent demand segment, driven by the need to equip doctoral candidates and research groups with state-of-the-art cryogenic tools for breakthrough discoveries.

The fastest-growing segment of potential customers comprises industrial and commercial entities, primarily large technology companies (e.g., Google, IBM, Intel) and specialized quantum computing startups focused on building and scaling superconducting qubit systems. For these commercial entities, the dilution refrigerator is not merely a research tool but a core piece of industrial production equipment, required for housing and testing quantum processing units (QPUs). These buyers demand systems characterized by high cooling power, enhanced reliability, full automation, and the capacity to accommodate large-scale wiring required for controlling hundreds or thousands of qubits, reflecting a shift from laboratory-grade instruments to industrialized cryogenic platforms.

Additional niche customers include manufacturers of advanced superconducting sensors, such as high-frequency antennas and highly sensitive bolometers used in medical imaging (MEG/EEG) or deep-space astronomy. These organizations require customized, often smaller-scale dilution cooling solutions that can be integrated seamlessly into complex sensor arrays, demanding systems with specific geometries and exceptionally low vibration profiles. Ultimately, the market is defined by customers who share the essential requirement for thermal environments stable and cold enough to suppress classical thermal noise, thereby isolating the delicate quantum mechanical properties of their experimental systems.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $235 Million |

| Market Forecast in 2033 | $375 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bluefors, Oxford Instruments, Leiden Cryogenics, Janis Research (A Lake Shore Company), CryoConcepts, Quantum Design, Attocube, Cryomech, ICEoxford, Ulvac, Taiyo Nippon Sanso, Sigma Aldrich, Air Liquide, Linde, Chart Industries, ColdEdge Technologies, Montana Instruments, Q-Tek, Cryogenics International, Advanced Research Systems. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dilution Refrigerators Market Key Technology Landscape

The technological landscape of the Dilution Refrigerators Market is defined by intense innovation aimed at improving cooling efficiency, increasing cooling power, and reducing system size and operational complexity. The most significant shift is the prevalence of dry dilution refrigerator systems, which integrate high-performance pulse tube coolers (PTCs) as the primary pre-cooling stage, eliminating the logistical burden and cost associated with liquid helium and nitrogen baths required by older wet systems. Modern PTCs are highly reliable, achieving temperatures down to 30-40 Kelvin for the first stage and around 3 Kelvin for the second stage, thereby providing a stable thermal anchor before the final, critical dilution cooling stages commence. Manufacturers are constantly refining heat exchanger designs, utilizing proprietary sintered materials and optimized geometry to maximize the surface area for efficient heat transfer between the circulating ³He and ⁴He mixtures, which is vital for achieving the lowest millikelvin temperatures.

Another crucial area of technological development involves enhanced vibration isolation and magnetic shielding. Quantum experiments are extraordinarily sensitive to external noise; thus, modern DR designs incorporate advanced mechanical decoupling mechanisms, active vibration cancellation systems, and multi-layer magnetic shielding (often combining superconducting materials and high-permeability alloys) to ensure the experimental volume is thermally and magnetically pristine. Furthermore, the increasing complexity of quantum circuits necessitates the integration of high-density wiring solutions. Manufacturers are developing custom coaxial cables and filters, such as superconducting cables and custom copper powder filters, designed to transmit control signals to the qubits while minimizing heat leakage and filtering microwave noise, ensuring the low-temperature environment is not compromised by the necessary electronic control infrastructure.

The move toward full automation and remote control software represents a major technological advancement, transitioning the operation of DRs from requiring expert technicians to being accessible via user-friendly interfaces. This includes software for automated cool-down, temperature stabilization, monitoring, and remote diagnostics. Future technological trends are focusing on developing high-power systems that can handle the projected heat load of fault-tolerant quantum computers, potentially involving alternative refrigeration cycles beyond standard ³He/⁴He dilution, or exploring hybrid systems that combine magnetic refrigeration techniques (adiabatic demagnetization refrigeration or ADR) with dilution cycles to achieve unprecedented stability and cooling performance at scale. This continuous drive towards industrial-grade reliability and scalability dictates the technological investment priorities across the industry.

Regional Highlights

- North America: This region holds the largest market share, driven primarily by massive investments from both the US government (through the National Quantum Initiative) and major technology corporations (IBM, Google, Microsoft) heavily focused on superconducting quantum hardware development. The high concentration of specialized universities, national laboratories, and private venture capital funding dedicated to quantum physics ensures sustained demand for high-end, high-power dry dilution refrigeration systems. Innovation centers in Silicon Valley, New York, and Boston are key deployment hubs.

- Europe: Europe represents a significant market, fueled by strong government-backed research programs like the European Quantum Flagship. Countries such as the Netherlands (Leiden Cryogenics), Finland (Bluefors), and the UK (Oxford Instruments) host some of the world's leading manufacturers and research institutions in cryogenics. The European market emphasizes fundamental physics research and developing precision instrumentation, contributing significantly to advancements in thermal stability and automation technologies.

- Asia Pacific (APAC): APAC is the fastest-growing market, primarily due to aggressive national quantum strategies in China, Japan, and South Korea. China, in particular, is heavily investing in building massive state-owned quantum computing infrastructure, necessitating bulk orders of high-capacity dilution refrigerators. This region is characterized by government-led initiatives seeking technological independence and establishing large-scale, domestically sourced cryogenic supply chains, driving both demand and local manufacturing capabilities.

- Latin America (LATAM): The market here is nascent but growing, confined mainly to major public universities and government research centers in countries like Brazil and Argentina, which focus on fundamental condensed matter physics. Demand is characterized by the need for robust, cost-effective systems, often favoring reliable dry systems but restricted by fluctuating national research budgets.

- Middle East and Africa (MEA): This region currently holds the smallest market share, with demand originating almost exclusively from specialized petroleum and materials science research centers, or newly established technology universities in wealthy Gulf states (e.g., UAE, Saudi Arabia) aiming to diversify their research economies by investing in emerging fields like quantum technology. Procurement is often reliant on external consulting and turnkey solutions from established European or North American manufacturers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dilution Refrigerators Market.- Bluefors

- Oxford Instruments

- Leiden Cryogenics

- Janis Research (A Lake Shore Company)

- Cryomech

- Quantum Design

- Attocube Systems AG

- ICEoxford

- CryoConcepts

- Ulvac, Inc.

- Taiyo Nippon Sanso Corporation

- Linde plc

- Air Liquide S.A.

- Chart Industries, Inc.

- ColdEdge Technologies

- Advanced Research Systems (ARS)

- Montana Instruments

- Q-Tek

- Nikkiso Co., Ltd.

- Brooks Automation (High Vacuum Division)

Frequently Asked Questions

Analyze common user questions about the Dilution Refrigerators market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a dilution refrigerator and why is it essential for quantum computing?

The primary function of a dilution refrigerator (DR) is to achieve and sustain ultra-low temperatures, typically between 2 mK and 100 mK (near absolute zero), using the thermodynamic mixing of Helium-3 and Helium-4 isotopes. It is essential for superconducting quantum computing because qubits require these extremely low temperatures to minimize thermal noise, maintain quantum coherence, and execute reliable operations.

What is the difference between wet and dry dilution refrigerators, and which type dominates the market?

Wet dilution refrigerators require external liquid cryogens (liquid helium and nitrogen) for pre-cooling, leading to high operational costs and complex logistics. Dry (cryogen-free) systems utilize built-in pulse tube coolers for initial cooling, making them easier to operate, more reliable, and significantly reducing running expenses. Dry systems currently dominate new market installations, especially in industrial and commercial quantum facilities.

What are the key technological challenges currently restraining market growth in the DR sector?

Key challenges include the high initial capital expenditure of sophisticated millikelvin systems, the geopolitical dependence and scarcity of the essential Helium-3 isotope, and the difficulty in developing high-cooling power refrigerators capable of managing the increased heat load generated by future large-scale, multi-qubit quantum processors while maintaining thermal stability.

How are Dilution Refrigerators expected to evolve to meet the needs of scaling quantum systems?

Future DRs will focus on modularity, significantly increased cooling power (up to 100 µW at 10 mK), and advanced automation incorporating AI for predictive maintenance and real-time thermal optimization. The evolution includes developing integrated solutions for high-density wiring and filtering to minimize signal noise and thermal leakage to accommodate thousands of qubits.

Which geographical region is leading investment and demand for advanced dilution refrigeration systems?

North America is currently leading both investment and demand, driven by substantial governmental funding and the presence of major commercial technology companies aggressively pursuing large-scale superconducting quantum processor development, requiring consistent deployment of high-performance, industrial-grade dry dilution refrigerators.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Cryogenic Dilution Refrigerators Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Cryogen Free Dilution Refrigerators Market Statistics 2025 Analysis By Application (Nanostructure Studies, Superconductivity Research, Low Temperature Detectors, Others), By Type (Single-Stage Pulse Tube, Two-Stage Pulse Tube), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Dilution Refrigerators Market Statistics 2025 Analysis By Application (Laboratory, Industrial, Others), By Type (Dry Dilution Refrigerators, Wet Dilution Refrigerators), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Cryogen Free Dilution Refrigerators Market Statistics 2025 Analysis By Application (Quantum Computing, Nano Research, Low Temperature Detection), By Type (Base Temperature 10mK, Base Temperature Between 10-20mK, Base Temperature 20mK), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager