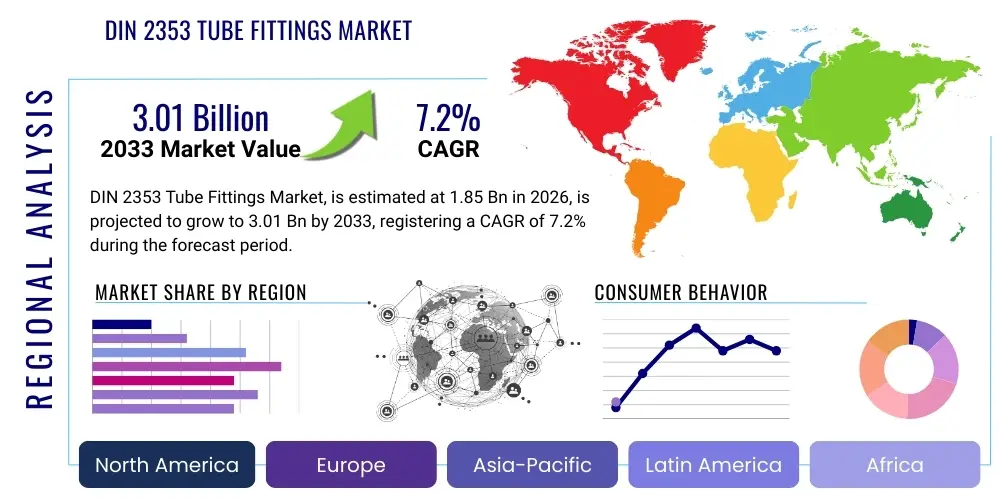

DIN 2353 Tube Fittings Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440508 | Date : Jan, 2026 | Pages : 253 | Region : Global | Publisher : MRU

DIN 2353 Tube Fittings Market Size

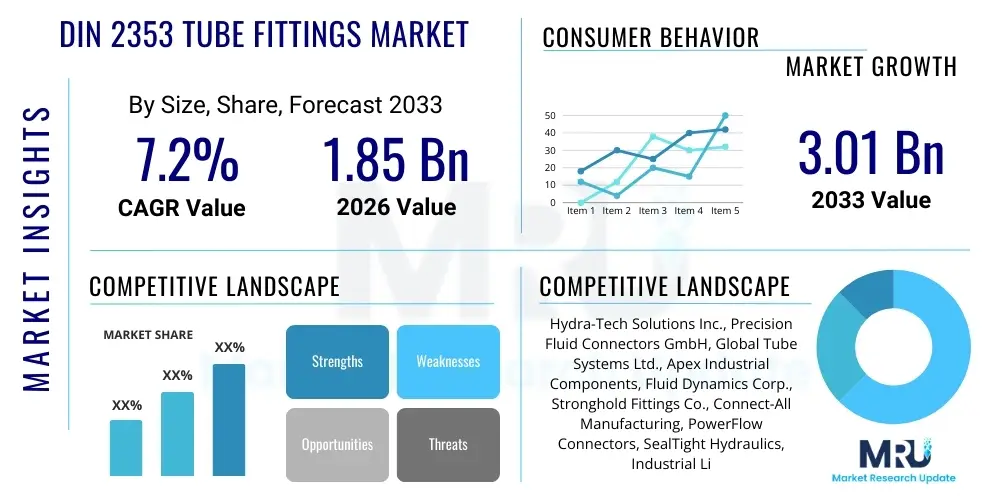

The DIN 2353 Tube Fittings Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 3.01 Billion by the end of the forecast period in 2033.

DIN 2353 Tube Fittings Market introduction

The DIN 2353 Tube Fittings Market encompasses components designed for high-pressure, leak-free connections in hydraulic and pneumatic systems, adhering strictly to the DIN 2353 (ISO 8434-1) standard. These fittings, primarily constructed from carbon steel, stainless steel, and other robust alloys, are engineered to provide secure and reusable connections without welding, significantly simplifying assembly and maintenance processes. The product range includes various pressure series, such as Light (L) and Heavy (S) series, each optimized for specific pressure ratings and application demands. Major applications span across critical industrial sectors including manufacturing, construction, agriculture, marine, and automotive industries, where reliability and operational efficiency are paramount.

The inherent benefits of DIN 2353 fittings, such as their exceptional resistance to high pressures, vibrations, and thermal cycling, coupled with their ease of installation and excellent reusability, make them indispensable in modern fluid power systems. They contribute to enhanced system integrity, reduced downtime, and improved safety standards across diverse operational environments. Driving factors for market growth include the global expansion of industrial automation, increasing demand for robust and reliable hydraulic solutions in heavy machinery, stringent regulatory requirements for system safety and environmental protection, and a growing replacement market for legacy fitting systems. Continuous technological advancements in material science and manufacturing processes further bolster their performance and application versatility, supporting their widespread adoption.

DIN 2353 Tube Fittings Market Executive Summary

The DIN 2353 Tube Fittings Market is currently experiencing dynamic shifts driven by evolving industrial landscapes and technological advancements. Business trends indicate a strong emphasis on product innovation, particularly in developing fittings with higher pressure capabilities, enhanced corrosion resistance, and integrated sensor technologies for predictive maintenance. There is also a notable trend towards consolidation among manufacturers, aiming to achieve economies of scale and expand global distribution networks. Sustainability considerations are increasingly influencing product development, with a focus on materials and processes that reduce environmental impact and improve recyclability. Furthermore, the market is witnessing a rise in demand for customized fitting solutions that cater to specialized application requirements, alongside a growing adoption of digital tools for design and procurement.

Regionally, the Asia Pacific market is poised for significant growth, fueled by rapid industrialization, burgeoning manufacturing sectors, and substantial infrastructure development projects, particularly in countries like China, India, and Southeast Asian nations. Europe maintains a mature yet stable market, characterized by stringent quality standards and a strong focus on advanced engineering and automation, driving demand for premium, high-performance fittings. North America exhibits consistent demand, propelled by modernization efforts in manufacturing, expansion of the oil and gas sector, and robust construction activities. Emerging economies in Latin America, the Middle East, and Africa present substantial growth opportunities as industrialization efforts gather pace, increasing the need for reliable fluid power components.

Segment-wise, the market is seeing increased penetration of stainless steel fittings due to their superior corrosion resistance and suitability for harsh environments, especially in chemical, marine, and oil & gas applications. The heavy series (S) fittings segment continues to gain traction, driven by the escalating demand for higher operating pressures in heavy-duty machinery across construction, mining, and agricultural sectors. From an end-use perspective, the hydraulics and pneumatics segment remains the largest consumer, with substantial growth also observed in the automotive and transportation sectors for specialized fluid transfer systems. Innovation in connection types, such as soft seal (EO-3) fittings, is also prominent, offering enhanced sealing performance and ease of assembly, contributing to their expanding market share.

AI Impact Analysis on DIN 2353 Tube Fittings Market

Users frequently inquire about how artificial intelligence (AI) will revolutionize the manufacturing, distribution, and application of DIN 2353 tube fittings. Key themes emerging from these questions center on AI's potential to optimize production efficiency, enhance product quality and design, predict maintenance needs, and streamline supply chain logistics. Concerns also touch upon the investment required for AI integration, the necessary skill development for the workforce, and the overall return on investment. Expectations are high for AI to deliver greater precision, cost savings, and a competitive edge through advanced automation and data-driven insights throughout the entire product lifecycle of fluid power components.

- AI-driven predictive maintenance for hydraulic systems, reducing downtime for fitting replacements.

- Optimized manufacturing processes using AI for quality control, defect detection, and resource allocation.

- AI-powered design optimization for fittings, simulating performance under various stress conditions to enhance durability.

- Automated inventory management and supply chain forecasting, ensuring timely availability of specific DIN 2353 fittings.

- Enhanced worker safety through AI-monitored equipment performance and early warning systems for potential failures.

- Personalized product recommendations and faster customer support through AI-driven sales and service platforms.

- Market trend analysis and demand forecasting through AI, enabling manufacturers to adapt production strategies effectively.

DRO & Impact Forces Of DIN 2353 Tube Fittings Market

The DIN 2353 Tube Fittings Market is propelled by several significant drivers, notably the continuous growth in global industrialization and manufacturing activities, which inherently demand robust and reliable fluid transfer components. The increasing adoption of automation and robotics across various sectors necessitates high-performance hydraulic and pneumatic systems, for which DIN 2353 fittings are crucial. Stringent safety standards and regulations in industries like construction, automotive, and oil & gas also mandate the use of certified, leak-proof connection technologies, further boosting market demand. Additionally, the ongoing maintenance and replacement cycles of existing industrial infrastructure represent a consistent and substantial market driver.

However, the market faces notable restraints that could temper its growth trajectory. The volatility of raw material prices, particularly for steel and other metal alloys, directly impacts manufacturing costs and profit margins. Intense competition among both established global players and regional manufacturers can lead to price erosion and reduced profitability. Furthermore, the lack of universal standardization across all regions, despite ISO 8434-1's prevalence, can create complexities in supply chains and market entry for some manufacturers. A shortage of skilled labor capable of installing and maintaining sophisticated hydraulic systems also poses a challenge, impacting the efficient deployment of these fittings.

Opportunities for market expansion are significant, especially in the development of customized fitting solutions tailored to unique industry requirements, such as specialized materials for extreme temperatures or corrosive environments. The integration of "smart" features into fittings, such as embedded sensors for real-time monitoring of pressure, temperature, and leakage, represents a promising avenue for value addition. Moreover, the vast untapped potential in emerging economies, driven by rapid industrialization and infrastructure development, offers substantial growth prospects. Manufacturers focusing on sustainable production practices and eco-friendly material alternatives can also capture a growing segment of environmentally conscious customers. The cumulative impact of these forces shapes the competitive landscape and strategic imperatives within the DIN 2353 tube fittings sector.

Segmentation Analysis

The DIN 2353 Tube Fittings Market is comprehensively segmented across various parameters, offering a granular view of market dynamics and consumer preferences. These segmentations are crucial for understanding demand patterns, identifying niche markets, and formulating targeted business strategies. The primary segmentation criteria include the material used for manufacturing, the pressure series they belong to, the specific connection type, and the diverse end-use industries where these fittings are deployed. Each segment exhibits unique growth characteristics and is influenced by distinct market forces, contributing to the overall complexity and opportunity within the industry.

- By Material:

- Carbon Steel: Dominates due to cost-effectiveness and good mechanical properties for general industrial applications.

- Stainless Steel: Preferred for corrosive environments, high-temperature applications, and industries requiring high hygiene standards.

- Brass: Used in applications requiring good electrical conductivity, ease of machining, and corrosion resistance in certain media.

- Other Alloys: Includes specialized materials for unique performance requirements, such as higher strength-to-weight ratios or extreme chemical resistance.

- By Pressure Series:

- Light Series (LL): Designed for low-pressure applications, offering economical solutions.

- Light Series (L): Suitable for medium-pressure applications, widely used across general industrial machinery.

- Heavy Series (S): Engineered for high-pressure systems, critical in heavy machinery, construction, and marine applications.

- By Connection Type:

- 24-degree Cone (EO-2): Standard connection providing robust sealing through metal-to-metal contact.

- Soft Seal (EO-3): Features an O-ring for enhanced sealing performance, suitable for applications demanding superior leak tightness.

- Cutting Ring (EO): The classic design, offering reliable and secure tube connections without flaring.

- By End-Use Industry:

- Hydraulics & Pneumatics: Core market segment, indispensable for fluid power transmission systems.

- Automotive & Transportation: Used in vehicle braking systems, power steering, and fuel lines.

- Construction & Mining: Critical for heavy equipment like excavators, bulldozers, and drilling rigs.

- Agriculture: Essential in farm machinery, irrigation systems, and agricultural implements.

- Oil & Gas: Applied in drilling equipment, pipelines, and offshore platforms due to high-pressure and corrosive conditions.

- Marine: Utilized in shipbuilding, offshore vessels, and port machinery for robust fluid connections.

- Process Industries: Found in chemical processing, food & beverage, and pharmaceutical plants for various fluid transfer tasks.

- Other Industrial Machinery: Encompasses a broad range of general industrial equipment and manufacturing tools.

Value Chain Analysis For DIN 2353 Tube Fittings Market

The value chain for the DIN 2353 Tube Fittings Market begins with upstream activities primarily centered on raw material procurement. This involves the sourcing of high-grade steel, including carbon steel and various stainless steel alloys, as well as brass and other specialized metals. Key suppliers in this stage are metallurgical companies and material processors who provide the necessary bars, tubes, and billets conforming to strict material specifications. The quality and cost of these raw materials directly impact the final product's performance and market competitiveness. Efficient inventory management and robust supplier relationships are critical at this stage to mitigate supply chain risks and cost fluctuations.

Moving downstream, the value chain encompasses the manufacturing, distribution, and end-user application phases. Manufacturing involves precision machining, surface treatment, assembly, and rigorous quality control processes to produce fittings that adhere to DIN 2353 standards. Once manufactured, these fittings reach the market through a dual distribution channel: direct sales and indirect channels. Direct sales typically involve manufacturers supplying large original equipment manufacturers (OEMs) who integrate the fittings into their machinery and systems. This direct approach often involves customized solutions and close technical collaboration between the manufacturer and the OEM.

Indirect distribution primarily involves a network of specialized distributors, wholesalers, and retailers who cater to a broader range of smaller OEMs, maintenance, repair, and overhaul (MRO) operations, and individual customers. These distributors play a crucial role in providing local stock, technical support, and logistical services, ensuring wider market penetration and accessibility for various end-users. Online platforms and e-commerce are also gaining prominence as efficient indirect channels, offering convenience and broader reach. The effectiveness of both direct and indirect channels is vital for optimizing market reach, ensuring timely product delivery, and providing comprehensive customer support throughout the entire product lifecycle.

DIN 2353 Tube Fittings Market Potential Customers

Potential customers for DIN 2353 tube fittings span a broad spectrum of industrial sectors that rely heavily on hydraulic and pneumatic systems for their operations. The primary end-users or buyers include manufacturers of heavy machinery such as construction equipment (excavators, bulldozers), agricultural machinery (tractors, harvesters), and mining equipment (drilling rigs, loaders), where high-pressure fluid transfer is fundamental to performance and safety. These OEMs are continuously seeking durable, reliable, and standardized fittings that can withstand demanding operational conditions and contribute to the longevity and efficiency of their products. The focus for these customers is on product integrity, ease of assembly, and compliance with international standards.

Beyond heavy equipment OEMs, other significant customer segments include automotive and transportation manufacturers, particularly for commercial vehicles, railway systems, and specialized transport applications where robust fluid connections are essential for braking, steering, and suspension systems. The marine industry, encompassing shipbuilding and offshore platform operations, also represents a substantial customer base, given the harsh, corrosive environments and critical performance requirements. Furthermore, companies in the oil & gas sector, chemical processing, food & beverage manufacturing, and pharmaceutical industries utilize DIN 2353 fittings for various fluid transfer applications, prioritizing material compatibility, leak-proof performance, and resistance to extreme temperatures and pressures. Maintenance, repair, and overhaul (MRO) service providers also constitute a significant customer group, purchasing fittings for replacement and servicing of existing equipment, driving a steady demand for standard and specialized components.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 3.01 Billion |

| Growth Rate | 7.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hydra-Tech Solutions Inc., Precision Fluid Connectors GmbH, Global Tube Systems Ltd., Apex Industrial Components, Fluid Dynamics Corp., Stronghold Fittings Co., Connect-All Manufacturing, PowerFlow Connectors, SealTight Hydraulics, Industrial Link Systems, MegaFit Engineering, Dynamic Fluidic Components, Uni-Pipe Solutions, Pro-Connect Fittings, Endurance Fluid Products, OptiFlow Systems, Steelgrip Components, Titan Connectives, Advanced Hydro-Parts, FlexiTube Innovations |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

DIN 2353 Tube Fittings Market Key Technology Landscape

The DIN 2353 Tube Fittings market is continuously evolving with advancements in manufacturing technologies and material science, all aimed at enhancing performance, reliability, and cost-efficiency. Precision manufacturing techniques, such as advanced Computer Numerical Control (CNC) machining, are fundamental to producing fittings with the tight tolerances and intricate geometries required for leak-proof and high-pressure applications. These technologies ensure consistent product quality, repeatability, and efficient material utilization, minimizing waste and optimizing production cycles. The adoption of multi-axis machining centers allows for the complex internal and external profiles to be manufactured in a single setup, improving accuracy and reducing production time.

Material science plays a critical role in developing fittings that can withstand increasingly demanding operational environments. Innovations focus on creating stronger, more corrosion-resistant alloys, such as specialized stainless steels and nickel alloys, for applications in harsh chemical processing, marine, and extreme temperature conditions. Surface treatment technologies, including various plating and coating methods (e.g., zinc-nickel, passivation), are also crucial for improving durability, preventing corrosion, and extending the service life of fittings, especially those made from carbon steel. These treatments enhance the chemical resistance and mechanical properties of the fitting surfaces, providing an added layer of protection against environmental degradation.

Furthermore, digital design and simulation tools, such as Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software, are extensively used for product development and optimization. These tools enable engineers to design new fitting configurations, simulate their performance under various stress conditions, and identify potential failure points before physical prototyping. The integration of automation in assembly and testing processes also contributes to the technological landscape, ensuring faster production speeds and more reliable quality checks. Emerging technologies like additive manufacturing (3D printing) are being explored for producing complex prototypes or specialized low-volume components, offering flexibility in design and material choice for niche applications.

Regional Highlights

- North America: A mature market characterized by robust industrial infrastructure, including significant manufacturing, automotive, and oil & gas sectors. Demand is driven by modernization of existing systems, strict safety regulations, and a strong focus on high-performance components. The U.S. and Canada are key contributors.

- Europe: A leading market driven by advanced engineering, automation, and stringent quality standards, particularly in Germany, France, and the UK. Focus on high-quality, precision-engineered fittings for hydraulic systems in machinery, aerospace, and construction, alongside a strong emphasis on environmental compliance and energy efficiency.

- Asia Pacific (APAC): The fastest-growing market, propelled by rapid industrialization, expansion of manufacturing bases, and significant infrastructure development in countries like China, India, Japan, and Southeast Asian nations. Increasing demand from construction, agriculture, and automotive industries.

- Latin America: An emerging market with growing industrialization and infrastructure projects, particularly in Brazil and Mexico. Demand is influenced by investments in mining, agriculture, and automotive manufacturing, leading to increased adoption of hydraulic systems and associated fittings.

- Middle East and Africa (MEA): A developing market primarily driven by investments in the oil & gas sector, infrastructure development, and industrial diversification initiatives. Demand for robust fittings is high in harsh environments, with growth opportunities tied to economic development and industrial expansion across the region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the DIN 2353 Tube Fittings Market.- Hydra-Tech Solutions Inc.

- Precision Fluid Connectors GmbH

- Global Tube Systems Ltd.

- Apex Industrial Components

- Fluid Dynamics Corp.

- Stronghold Fittings Co.

- Connect-All Manufacturing

- PowerFlow Connectors

- SealTight Hydraulics

- Industrial Link Systems

- MegaFit Engineering

- Dynamic Fluidic Components

- Uni-Pipe Solutions

- Pro-Connect Fittings

- Endurance Fluid Products

- OptiFlow Systems

- Steelgrip Components

- Titan Connectives

- Advanced Hydro-Parts

- FlexiTube Innovations

Frequently Asked Questions

What are DIN 2353 tube fittings and their primary use?

DIN 2353 tube fittings, also known as ISO 8434-1 fittings, are standard components used to create leak-free, high-pressure, and reusable connections in hydraulic and pneumatic systems. Their primary use is to connect tubes and hoses securely without welding, ensuring reliable fluid transfer in industrial machinery.

Which industries commonly utilize DIN 2353 tube fittings?

These fittings are widely utilized across a diverse range of industries, including construction and mining for heavy machinery, agriculture for farm equipment, automotive for vehicle systems, marine for shipbuilding, oil and gas for drilling and transport, and various general industrial manufacturing processes, especially those involving fluid power.

What are the key benefits of using DIN 2353 fittings?

The key benefits include superior leak-free performance under high pressure, excellent vibration resistance, easy and quick installation without welding, reusability for maintenance, and high reliability, all contributing to increased system efficiency and reduced operational downtime.

Are there different types or series of DIN 2353 fittings?

Yes, DIN 2353 fittings are available in various pressure series, primarily Light Series (L) and Heavy Series (S), to accommodate different operating pressures. They also come in distinct connection types like 24-degree cone (EO-2), soft seal (EO-3), and cutting ring (EO) designs, each offering specific sealing characteristics.

How do I select the appropriate DIN 2353 tube fitting for my application?

Selecting the appropriate fitting involves considering several factors: the required pressure rating (Light or Heavy series), the type of fluid and operating temperature (influencing material choice like carbon or stainless steel), the specific tube dimensions, the connection type needed (e.g., cutting ring for basic, soft seal for critical leak-tightness), and the specific environmental conditions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager