Din Rail Type Industrial UPS Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432380 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Din Rail Type Industrial UPS Market Size

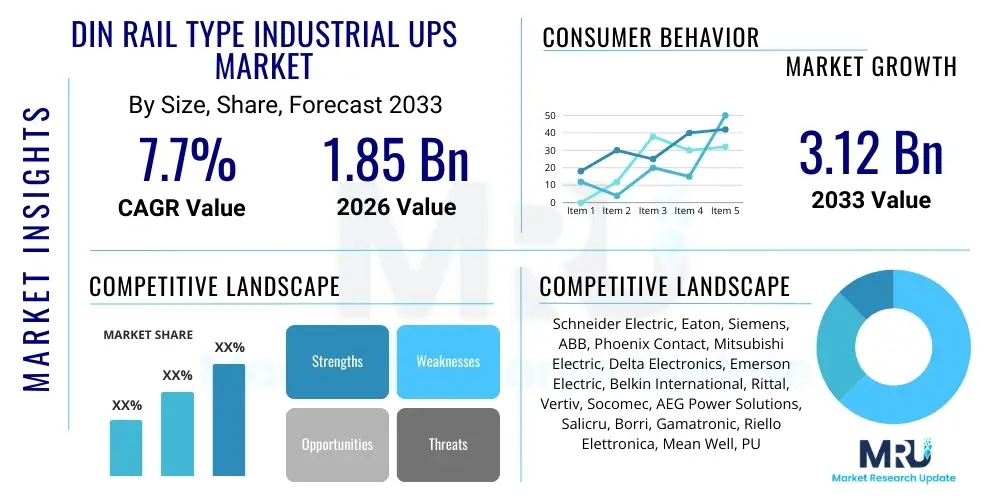

The Din Rail Type Industrial UPS Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.7% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 3.12 Billion by the end of the forecast period in 2033.

Din Rail Type Industrial UPS Market introduction

The Din Rail Type Industrial Uninterruptible Power Supply (UPS) market encompasses specialized power protection solutions designed for mounting on standard 35mm DIN rails, which are ubiquitous in industrial control cabinets, machinery, and automation systems. These devices are engineered specifically to provide seamless, reliable backup power to critical loads, such as PLCs (Programmable Logic Controllers), HMIs (Human Machine Interfaces), industrial PCs, sensors, and network switches, ensuring continuous operation despite power fluctuations, surges, sags, or complete outages. Their compact form factor, robust construction capable of enduring harsh environmental conditions (vibration, dust, extreme temperatures), and ease of installation within existing cabinet layouts make them indispensable for maintaining operational integrity and minimizing downtime in mission-critical industrial applications.

The primary applications driving the adoption of Din Rail Industrial UPS systems span across several high-growth industrial sectors, including factory automation, oil and gas pipelines, telecommunication infrastructure, water treatment facilities, and critical infrastructure within the power generation and distribution matrix. The inherent benefits of these systems are multifold: they offer superior system uptime, protect costly industrial equipment from damage caused by poor power quality, enhance data integrity by allowing controlled shutdown procedures, and significantly improve overall system safety and reliability, aligning perfectly with Industry 4.0 standards. The growing emphasis on smart factories and remote monitoring further necessitates localized, robust power conditioning, cementing the essential role of Din Rail UPS solutions.

Major driving factors include the rapid global deployment of Industrial Internet of Things (IIoT) devices and edge computing infrastructure, which requires highly distributed and protected power sources. Furthermore, increasingly stringent regulatory requirements regarding safety and operational continuity in sectors like chemical processing and pharmaceuticals compel organizations to invest in reliable backup systems. Technological advancements, particularly in battery chemistry (such as Li-ion) and sophisticated monitoring capabilities integrated into these compact units, are also expanding their performance envelope and appeal, thereby fueling sustained market expansion throughout the forecast period.

Din Rail Type Industrial UPS Market Executive Summary

The Din Rail Type Industrial UPS Market is experiencing robust growth fueled primarily by the global acceleration of digital transformation initiatives across the manufacturing and process industries. Key business trends indicate a shift towards modular and highly integrated power solutions that offer advanced diagnostic capabilities and remote management features, satisfying the needs of increasingly complex, interconnected industrial environments. Suppliers are focusing heavily on developing UPS units optimized for extended temperature ranges and certifications specific to hazardous locations (HazLoc), reflecting the intense demand from the oil & gas and chemical sectors for durable power protection equipment, thereby pushing the boundaries of traditional UPS design and functionality to ensure superior operational resilience.

Regionally, Asia Pacific (APAC) stands out as the highest-growth region, propelled by massive governmental investments in smart city infrastructure, expansion of domestic manufacturing capabilities, particularly in China, South Korea, and India, and the widespread adoption of industrial automation technologies across diverse sectors. North America and Europe, while mature, maintain strong market positions due to established regulatory frameworks mandating operational safety and continuous modernization efforts in legacy industrial plants. Segment trends highlight the growing preference for higher power ratings (above 1kVA) and the increasing integration of long-life lithium-ion battery technology, which addresses industrial demands for maintenance reduction and extended runtimes in critical processes.

Overall, the market structure is moderately consolidated, with major automation and power management conglomerates dominating through expansive product portfolios and entrenched distribution channels with System Integrators (SIs). The core strategy for market players revolves around miniaturization, increasing power density, and enhancing communication protocols (like Modbus TCP/IP and EtherNet/IP) to ensure seamless integration into sophisticated Programmable Logic Controller (PLC) and Distributed Control System (DCS) architectures. This convergence of hardware resilience and software intelligence is crucial for capturing market share within the evolving industrial technology landscape, positioning the market for consistent and stable expansion through 2033.

AI Impact Analysis on Din Rail Type Industrial UPS Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Din Rail Type Industrial UPS Market primarily center on predictive maintenance, optimization of battery lifespan, and enhancing system reliability through smart diagnostics. Users are keen to understand how AI algorithms can leverage the vast amounts of performance data generated by smart UPS units—such as load variations, temperature anomalies, and charging cycles—to forecast potential component failures or battery degradation proactively. The expectation is that AI integration will minimize the need for manual inspections, shift maintenance strategies from reactive or scheduled to predictive, and ultimately maximize the cost-efficiency and uptime of distributed industrial power protection systems, addressing critical concerns related to labor intensity and unplanned operational downtime.

The adoption of AI is fundamentally transforming the operational paradigm of industrial power infrastructure by enabling advanced energy management strategies. AI models can analyze energy consumption patterns in real-time, allowing the UPS system to intelligently manage load shedding during extended power outages or optimize charging profiles based on historical usage and external environmental factors, ensuring the battery is always in peak condition while simultaneously reducing overall energy costs and extending the useful life of the power conditioning components. This shift towards intelligent, self-optimizing power hardware is crucial as industrial processes become more complex and dependent on continuous, uninterrupted power quality.

Furthermore, AI facilitates highly sophisticated integration into wider Supervisory Control and Data Acquisition (SCADA) and Industrial IoT networks. By using machine learning to filter critical alarms from routine operational noise, AI ensures that facility managers are alerted only to events that genuinely threaten system integrity, significantly improving responsiveness and reducing alert fatigue. This capability not only enhances the reliability of the industrial control system but also elevates the Din Rail UPS from a passive backup device to an active, intelligent participant in the overall plant's digital ecosystem, thereby increasing its value proposition in highly automated environments focused on continuous improvement and data-driven decision-making.

- AI-driven Predictive Maintenance: Utilizing sensor data to forecast potential UPS component failures, including fans, capacitors, and internal power modules, long before operational impact occurs.

- Optimized Battery Life Management: Employing machine learning algorithms to fine-tune battery charging and discharging cycles based on real-time load and temperature profiles, extending service life.

- Intelligent Energy Management: AI systems enable dynamic load balancing and controlled power distribution during grid instability, prioritizing essential industrial loads to maintain core operations.

- Enhanced Anomaly Detection: Machine learning improves the identification of subtle, non-catastrophic power quality issues that could degrade equipment over time, allowing for early intervention.

- Seamless SCADA/DCS Integration: AI-powered communication modules provide contextualized data to control systems, moving beyond simple status reporting to offering actionable operational insights for automation platforms.

DRO & Impact Forces Of Din Rail Type Industrial UPS Market

The dynamics of the Din Rail Type Industrial UPS Market are shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively constitute the critical impact forces steering market trajectories. The primary driver is the accelerating global investment in industrial automation, smart manufacturing, and Edge Computing infrastructure, demanding highly reliable, compact, and standardized power backup solutions that can be easily integrated into distributed control cabinets across factory floors and remote field installations. Coupled with this is the increasing awareness and strict regulatory focus on operational safety and minimum downtime in critical sectors such as oil & gas, nuclear power, and specialized chemical manufacturing, which mandates the use of certified power protection equipment, thereby sustaining consistent demand for high-specification Din Rail units.

Conversely, significant restraints hinder growth potential, most notably the elevated initial capital expenditure associated with high-quality, industrial-grade power solutions compared to standard commercial UPS systems. Furthermore, the complexity involved in integrating these specialized UPS units into legacy or older industrial control architectures, especially concerning communication protocols and physical footprint constraints in already congested cabinets, poses a considerable implementation challenge for many brownfield projects. The critical reliance on battery performance means that replacement costs and the environmental disposal concerns related to industrial battery waste remain an enduring operational and logistical restraint impacting total cost of ownership (TCO) assessments for end-users.

Opportunities for sustained market expansion are abundant, particularly through the aggressive pursuit of technological advancements, including the widespread adoption of lithium-ion (Li-ion) batteries, which offer superior energy density, extended operational temperature windows, and significantly longer calendar life compared to traditional lead-acid alternatives. Furthermore, the expansion of the telecommunications infrastructure, especially the deployment of 5G networks, is creating new demand for ruggedized, distributed DC Din Rail UPS solutions to maintain connectivity at numerous cell sites and remote access points. Strategic focus on developing integrated UPS and power distribution modules that minimize cabinet space and installation complexity presents a high-potential avenue for key manufacturers to differentiate their offerings and capture untapped market segments.

Segmentation Analysis

The Din Rail Type Industrial UPS Market is comprehensively segmented based on parameters such as Type (AC Output, DC Output), Power Rating (Below 1 kVA, 1 kVA – 5 kVA, Above 5 kVA), and End-Use Application (Oil & Gas, Automation & Manufacturing, Power Generation, Telecommunications, Chemical & Petrochemical, Others). This detailed segmentation provides granular insights into specific market needs and growth pockets, reflecting the diverse power requirements found across the industrial landscape. The differentiation between AC and DC output is crucial, as DC systems are predominantly used for powering PLCs, relay logic, and control circuitry, while AC systems serve industrial PCs, sensors, and networking equipment, indicating specialized demand patterns within distinct industrial sub-sectors.

The Power Rating segment is highly indicative of the complexity and size of the industrial load being protected; while low power units (Below 1 kVA) dominate in sheer volume for localized device protection, the higher rating segments (1 kVA and above) command greater revenue share due to their use in protecting centralized, critical control cabinets hosting complex automation systems and distributed server racks. Analyzing end-use application segments reveals that the Automation & Manufacturing sector consistently contributes the largest revenue share, driven by rapid global factory modernization and the pursuit of fully automated production lines where continuity of power is paramount to economic viability and quality control.

- By Type:

- AC Output UPS

- DC Output UPS

- By Power Rating:

- Below 1 kVA

- 1 kVA – 5 kVA

- Above 5 kVA

- By End-Use Application:

- Oil & Gas

- Automation & Manufacturing

- Power Generation & Utilities

- Telecommunications

- Chemical & Petrochemical

- Transportation Infrastructure

- Pharmaceuticals & Life Sciences

Value Chain Analysis For Din Rail Type Industrial UPS Market

The value chain for the Din Rail Type Industrial UPS Market begins with upstream analysis, which involves the sourcing and processing of critical raw materials and components, including sophisticated power electronic modules (e.g., inverters, rectifiers), advanced semiconductor components, high-grade casings designed for industrial harshness, and, most crucially, battery cells (Lead-Acid or Lithium-ion). Key upstream suppliers are often specialized electronic component manufacturers and globally recognized battery producers. Success in this stage hinges on quality control, reliable supply chains for critical components, and effective management of commodity price volatility, particularly for metals used in battery production and power modules.

The midstream focuses on the manufacturing, assembly, and integration of the Din Rail UPS units, where market leaders leverage expertise in ruggedization, thermal management, and compact design engineering to produce certified industrial-grade products. Distribution channels, both direct and indirect, play a pivotal role. Direct channels involve sales directly to large Original Equipment Manufacturers (OEMs) who integrate the UPS into their industrial machinery or systems. Indirect channels are more pervasive, relying heavily on a network of authorized distributors, specialized System Integrators (SIs), and value-added resellers (VARs) who provide localized technical support, installation services, and customization necessary to meet specific end-user industrial control panel requirements.

Downstream analysis centers on the deployment, servicing, and end-of-life management of the UPS units at the end-user site. Effective post-sales support, including proactive monitoring services, prompt maintenance, and reliable battery replacement programs, adds significant value and ensures customer retention. The end-users, predominantly industrial operators, rely on the long-term reliability and serviceability provided by manufacturers and SIs to ensure continuous operation of their critical control systems, emphasizing the importance of robust product life cycle management and accessible technical expertise across the geographically dispersed industrial installations.

Din Rail Type Industrial UPS Market Potential Customers

The primary potential customers and end-users of Din Rail Type Industrial UPS systems are diverse organizations operating critical infrastructure and high-value manufacturing processes where power interruptions are highly costly or dangerous. These buyers typically include automation integrators (System Integrators) who design and install industrial control panels for their clients, large-scale manufacturing facilities (e.g., automotive, electronics assembly, food and beverage processing), and asset owners in the heavy industries. These buyers value the standardization, reliability, and compact footprint that Din Rail mounting provides, enabling them to protect distributed loads efficiently without sacrificing crucial cabinet space or compromising industrial safety standards.

Another major segment comprises utility and infrastructure operators, including electric power generation companies, water and wastewater treatment plants, and national telecommunications providers, especially those deploying remote network enclosures and 5G small cell sites. For these organizations, the key purchasing criteria revolve around the UPS unit's ability to withstand severe environmental conditions (e.g., high humidity, temperature extremes), compliance with specific industry certifications (e.g., marine or hazardous location ratings), and compatibility with DC power systems prevalent in telecom and control applications. They require robust, often fanless, designs that guarantee decades of maintenance-free operation in unsupervised locations, making the long-term reliability and total cost of ownership paramount in their procurement decisions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 3.12 Billion |

| Growth Rate | 7.7% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Schneider Electric, Eaton, Siemens, ABB, Phoenix Contact, Mitsubishi Electric, Delta Electronics, Emerson Electric, Belkin International, Rittal, Vertiv, Socomec, AEG Power Solutions, Salicru, Borri, Gamatronic, Riello Elettronica, Mean Well, PULS, MGE UPS Systems |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Din Rail Type Industrial UPS Market Key Technology Landscape

The technological landscape of the Din Rail Type Industrial UPS Market is evolving rapidly, driven primarily by demands for enhanced reliability, reduced footprint, and superior integration capabilities within the industrial control ecosystem. A paramount technological advancement is the shift from bulky, valve-regulated lead-acid (VRLA) batteries to compact, high-performance Lithium-ion (Li-ion) battery chemistries, such as Lithium Iron Phosphate (LiFePO4). Li-ion offers significantly greater energy density, allowing for smaller, lighter UPS units, and crucially, provides a much longer cycle life and wider operational temperature tolerance, directly addressing the core concerns of maintenance and longevity in harsh industrial settings. Manufacturers are also integrating sophisticated Battery Management Systems (BMS) directly into the UPS chassis to precisely monitor cell health, optimize charging, and enhance overall system safety and diagnostic reporting.

Furthermore, the market is characterized by advancements in power conversion topologies, including highly efficient Digital Signal Processor (DSP)-controlled systems that offer faster switching times, tighter voltage regulation, and significantly lower ripple noise, crucial for sensitive industrial electronics. Emphasis is placed on ruggedization techniques, incorporating encapsulated components, conformal coating of PCBs, and fanless designs (relying on natural convection cooling) to achieve ingress protection ratings (IP65/IP67) necessary for deployment in dusty, wet, or explosive atmospheres common in heavy industry and field applications. This focus on physical resilience ensures the reliability demanded by mission-critical operational standards, distinguishing industrial units from commercial counterparts designed for climate-controlled environments.

Connectivity and smart functionality represent the third pillar of technological innovation. Modern Din Rail UPS units are equipped with multiple industrial communication protocols, including Modbus RTU/TCP, EtherNet/IP, PROFINET, and SNMP, ensuring seamless integration with existing industrial control networks, DCS, and SCADA platforms. This allows for real-time monitoring of power quality, load status, and battery health remotely, facilitating centralized energy management and enabling AI-based predictive maintenance. The future trajectory involves greater integration with edge computing devices, transforming the UPS into an intelligent node that not only provides backup power but also contributes essential data regarding local power conditions back to the enterprise IT layer for holistic operational intelligence.

Regional Highlights

- Asia Pacific (APAC) Dominance: APAC is forecast to exhibit the highest CAGR, driven by massive infrastructure investments, rapid expansion of manufacturing capabilities (especially in automotive and electronics production in China, India, and Southeast Asia), and government initiatives promoting smart cities and factory automation. The high density of new industrial installation projects and the adoption of modern control systems fuel unprecedented demand for standardized Din Rail UPS solutions.

- North America Market Maturity and Modernization: North America holds a substantial revenue share, characterized by high technological maturity and a strong regulatory environment mandating reliable power systems, particularly in pharmaceuticals, data centers (colocation facilities), and oil and gas infrastructure. Demand is concentrated on replacing legacy systems with high-efficiency Li-ion UPS units that offer sophisticated remote diagnostics suitable for geographically dispersed assets.

- Europe's Emphasis on Industry 4.0: Europe maintains a stable growth rate, underpinned by stringent industrial safety standards and the widespread adoption of Industry 4.0 principles, driving demand for intelligent, connected power management devices. Germany, Italy, and the Nordic countries are leaders, focusing on modularity, energy efficiency, and products certified for highly specialized applications within complex process automation and machinery.

- Middle East and Africa (MEA) Infrastructure Growth: Growth in MEA is highly concentrated in the oil, gas, and utility sectors, particularly in the GCC countries, where new capital projects demand ruggedized, high-specification Din Rail UPS systems for protecting pipeline monitoring, remote pumping stations, and critical SCADA systems often exposed to harsh desert environments. The focus is heavily on durability and wide operating temperature ranges.

- Latin America (LATAM) Industrial Recovery: LATAM shows gradual market recovery, led by modernization efforts in mining, energy infrastructure, and general manufacturing in countries like Brazil and Mexico. The need for power stabilization in regions prone to grid volatility makes reliable UPS protection a necessity rather than an option for maintaining production continuity and minimizing equipment damage.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Din Rail Type Industrial UPS Market.- Schneider Electric

- Eaton

- Siemens

- ABB

- Phoenix Contact

- Mitsubishi Electric

- Delta Electronics

- Emerson Electric

- Belkin International (FSP Power Solution)

- Rittal

- Vertiv

- Socomec

- AEG Power Solutions

- Salicru

- Borri S.p.A.

- Gamatronic Electronic Industries Ltd.

- Riello Elettronica Group

- Mean Well Enterprises Co., Ltd.

- PULS GmbH

- MGE UPS Systems (now part of Eaton)

Frequently Asked Questions

Analyze common user questions about the Din Rail Type Industrial UPS market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the key advantages of using a Din Rail UPS over a standard rackmount or tower UPS in industrial environments?

Din Rail UPS systems are specifically engineered for installation inside industrial control cabinets, offering major advantages including space efficiency, standardized mounting compatibility (35mm DIN rail), superior vibration and shock resistance, and ruggedized casings with higher Ingress Protection (IP) ratings suitable for harsh industrial conditions where dust, humidity, and temperature extremes are prevalent. They facilitate distributed power protection closer to the critical load, enhancing overall system reliability and installation speed.

How is Lithium-ion battery technology transforming the Din Rail Industrial UPS segment?

The integration of Lithium-ion (Li-ion) batteries, particularly Lithium Iron Phosphate (LiFePO4), is fundamentally changing the market by providing significantly higher power density, reduced weight, and extended service life (often double or triple that of VRLA batteries). Li-ion technology also allows these UPS units to operate effectively across a wider range of ambient temperatures, substantially reducing maintenance costs and providing superior total cost of ownership (TCO) for critical industrial applications.

Which industrial sectors are the largest consumers of Din Rail Type Industrial UPS solutions?

The largest consuming sector is Automation and Manufacturing, driven by the global adoption of Industry 4.0 and the critical need to protect PLCs, controllers, and industrial network switches from power disturbances. Other major consumers include the Oil & Gas industry (for remote monitoring and control systems), Power Generation (for substation control and switchgear), and Telecommunications (for distributed DC power backup at cell sites and communication hubs).

What role does communication and connectivity play in modern Din Rail UPS systems?

Modern Din Rail UPS systems function as intelligent network components, supporting multiple industrial communication protocols such as Modbus TCP/IP, EtherNet/IP, and PROFINET. This connectivity allows for seamless integration into Supervisory Control and Data Acquisition (SCADA) and Distributed Control Systems (DCS), enabling remote monitoring, logging of power events, controlled system shutdowns, and diagnostic reporting crucial for predictive maintenance and overall centralized energy management within a smart factory environment.

What is the typical power rating range for Din Rail Industrial UPS units, and which segment is growing fastest?

Din Rail UPS units typically range from very low power (50 Watts) up to 5 kVA, though the majority fall below 2 kVA due to cabinet space constraints. The fastest-growing segment in terms of revenue is the 1 kVA to 5 kVA range, fueled by the increasing complexity of control cabinets and the consolidation of multiple critical loads onto fewer, yet more powerful, standardized power protection devices, particularly within large-scale automation projects requiring centralized battery backup capacity.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager