Dipping Basket Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440264 | Date : Jan, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Dipping Basket Market Size

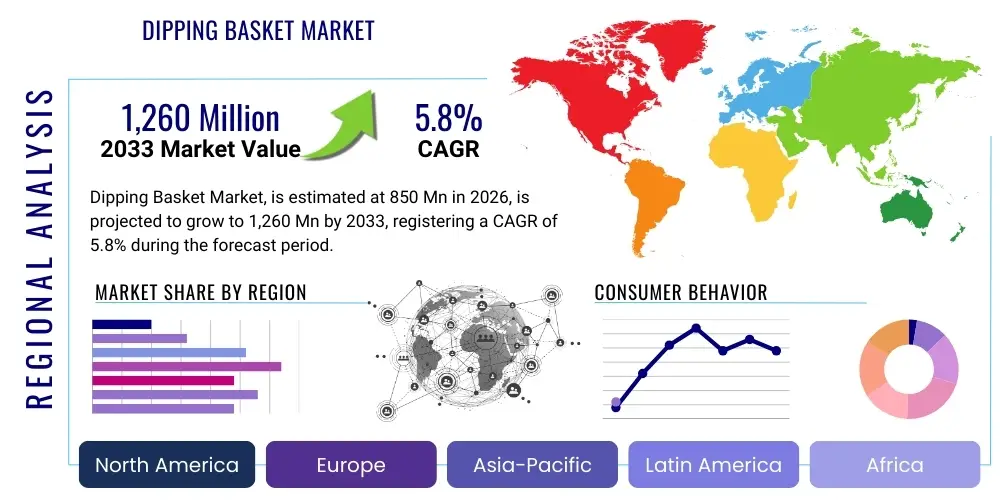

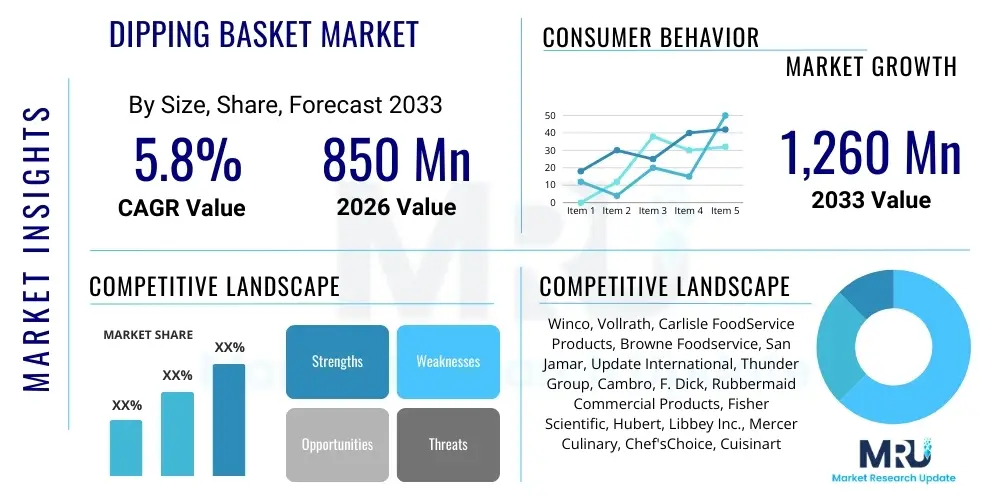

The Dipping Basket Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1,260 Million by the end of the forecast period in 2033.

Dipping Basket Market introduction

The dipping basket market encompasses a wide array of specialized containers primarily used for submerging food items or other products into liquids, typically hot oil, water, or cleaning solutions. These essential tools are foundational in various culinary and industrial applications, facilitating efficient and uniform cooking, washing, or treatment processes. Characterized by their perforated design, which allows for liquid drainage while retaining contents, dipping baskets are instrumental in achieving consistent results in high-volume environments and specialized home cooking tasks alike. Their robust construction and ergonomic designs contribute significantly to operational efficiency and safety across diverse sectors.

Major applications of dipping baskets span commercial kitchens, industrial food processing facilities, and residential settings. In the food service industry, they are indispensable for deep frying a variety of items such as french fries, chicken, and seafood, as well as for blanching vegetables or boiling pasta. Beyond culinary uses, industrial applications include parts washing, sterilization in medical and laboratory settings, and various chemical treatment processes where controlled immersion and retrieval are crucial. The market benefits from ongoing innovations in material science, design ergonomics, and manufacturing techniques, ensuring products meet evolving industry standards for durability, hygiene, and performance. The versatility of dipping baskets, from fine mesh strainers to heavy-duty frying baskets, underscores their critical role in numerous operational workflows.

Driving factors for the dipping basket market primarily include the sustained growth of the global food service industry, particularly the quick-service restaurant (QSR) segment and casual dining, which heavily rely on frying and blanching operations. The increasing popularity of convenience foods and home cooking trends, coupled with a rising consumer demand for specialized kitchen tools, also contributes significantly. Furthermore, stringent food safety and hygiene regulations globally necessitate the use of easy-to-clean and durable equipment, fueling demand for high-quality dipping baskets made from food-grade materials. The expansion of industrial sectors requiring precise washing and treatment of components also serves as a robust growth catalyst.

Dipping Basket Market Executive Summary

The Dipping Basket Market is experiencing dynamic growth, driven by an expanding global food service sector, increasing home cooking trends, and specialized industrial applications. Key business trends indicate a strong emphasis on material innovation, with stainless steel and high-temperature-resistant polymers dominating due to their durability and hygienic properties. Manufacturers are increasingly focusing on ergonomic designs, modular systems, and baskets tailored for specific culinary techniques to enhance operational efficiency and user safety. The market also observes a growing demand for sustainable and eco-friendly material options, aligning with broader consumer and corporate environmental objectives, alongside a push for automated and semi-automated dipping solutions in large-scale operations to optimize labor costs and consistency.

Regionally, North America and Europe continue to be significant markets due to established food service infrastructures and high consumer spending on convenience foods. However, the Asia Pacific region is emerging as a critical growth engine, propelled by rapid urbanization, a burgeoning middle class, and the proliferation of international and local fast-food chains. Latin America and the Middle East & Africa are also showing promising growth, fueled by economic development, increased tourism, and the adoption of modern culinary practices. These regions present substantial opportunities for market expansion, particularly through localized product offerings and optimized distribution networks to cater to diverse culinary traditions and operational scales.

Segmentation trends highlight the dominance of stainless steel baskets owing to their superior heat resistance, corrosion resistance, and ease of cleaning, making them ideal for commercial applications. The end-user segment sees commercial kitchens as the primary revenue generator, followed by residential users demonstrating a steady demand for specialized home cooking tools. Application-wise, deep frying remains the largest segment, but significant growth is observed in baskets designed for blanching, straining, and industrial parts washing. The market is also witnessing a niche but growing demand for specialized baskets for sous vide cooking and delicate food preparation, indicating a diversification of product utility beyond traditional frying applications and underscoring the market's adaptability to evolving culinary techniques and industrial needs.

AI Impact Analysis on Dipping Basket Market

Common user questions regarding AI's impact on the Dipping Basket Market often revolve around how such a traditional, mechanical product could be influenced by advanced technologies. Users frequently inquire about potential for smart features, automation in manufacturing, optimization of supply chains, and the indirect effects on the industries that utilize dipping baskets. Key concerns include whether AI could lead to more efficient basket designs, predictive maintenance for production machinery, or even play a role in optimizing the cooking processes where these baskets are used. There is also interest in AI's capability to forecast demand more accurately, thereby improving inventory management for both manufacturers and end-users, and its role in enhancing quality control in the manufacturing process.

- Manufacturing Optimization: AI-driven analytics can optimize the manufacturing processes of dipping baskets, leading to predictive maintenance for machinery, reducing downtime, and increasing production efficiency. This includes robotic welding and assembly, guided by AI for precision and consistency in basket construction.

- Supply Chain and Demand Forecasting: AI algorithms can analyze vast datasets to predict market demand for various types of dipping baskets, optimizing inventory levels for manufacturers and distributors, minimizing waste, and ensuring timely availability. This extends to optimizing raw material procurement and logistics.

- Quality Control and Material Science: AI can be employed in computer vision systems for automated quality inspection of finished baskets, detecting defects with high accuracy. Furthermore, AI-powered material science research can accelerate the development of new, more durable, heat-resistant, or sustainable materials for basket construction.

- Indirect Impact on End-User Industries: While dipping baskets themselves may not be "smart," AI's integration into commercial kitchen equipment (e.g., smart fryers, automated blanching systems) will drive demand for compatible, high-performance baskets designed for automation and optimized workflow.

- Customization and Design: AI-driven generative design tools can assist manufacturers in creating optimized basket designs for specific applications, improving fluid dynamics for better drainage, heat distribution, or structural integrity, leading to more efficient and effective products tailored to niche needs.

DRO & Impact Forces Of Dipping Basket Market

The Dipping Basket Market is significantly influenced by a complex interplay of drivers, restraints, and opportunities, shaping its growth trajectory and competitive landscape. Key drivers include the robust expansion of the global food service industry, particularly quick-service restaurants and catering services, which heavily rely on efficient deep frying and blanching solutions. Simultaneously, the sustained growth of the home cooking segment, fueled by culinary enthusiasts and a preference for homemade meals, contributes substantially to residential demand. Innovations in materials offering enhanced durability, heat resistance, and hygiene, such as specialized stainless steels and high-temperature polymers, further propel market expansion by improving product performance and lifespan. Moreover, increasing awareness of food safety standards globally mandates the use of hygienic and easy-to-clean kitchen equipment, thereby bolstering the demand for compliant dipping baskets.

Conversely, the market faces several restraining factors that could impede its growth. Fluctuations in raw material prices, especially for metals like stainless steel, directly impact manufacturing costs and, consequently, product pricing, potentially affecting market accessibility. Intense competition from alternative cooking methods and tools, such as air fryers and multi-cookers that offer perceived convenience without specialized baskets, presents a challenge, particularly in the residential segment. Issues related to product durability and the perception of dipping baskets as commodity items can also limit premium pricing and investment in advanced designs. Furthermore, the market's reliance on specific culinary trends means that shifts in consumer preferences away from fried or blanched foods could negatively affect demand in certain segments.

Despite these restraints, ample opportunities exist for market participants to innovate and expand. The growing emphasis on sustainable and eco-friendly materials offers a significant avenue for product differentiation and market capture, appealing to environmentally conscious consumers and businesses. The integration of dipping baskets with smart kitchen technology, though indirect, presents opportunities for manufacturers to design compatible products that enhance automated cooking processes. Expanding into niche industrial applications beyond food, such as precision parts cleaning in manufacturing or specialized laboratory uses, can diversify revenue streams. Moreover, strategic partnerships with leading kitchen appliance manufacturers and food service providers can unlock new distribution channels and facilitate broader market penetration. Customization options, catering to specific commercial requirements for size, mesh density, and handle design, also represent a viable growth strategy, allowing companies to meet specialized operational needs and establish strong client relationships.

Segmentation Analysis

The Dipping Basket Market is broadly segmented based on material type, application, end-user, and size, providing a granular view of market dynamics and consumer preferences across various operational scales. This comprehensive segmentation allows for a detailed understanding of the diverse needs driving demand, ranging from robust commercial-grade solutions to compact residential products. The inherent characteristics of each segment influence product design, manufacturing processes, and distribution strategies, enabling market players to target specific niches effectively. Analyzing these segments helps in identifying growth pockets, assessing competitive landscapes, and formulating tailored business strategies to capitalize on evolving market opportunities, considering both established and emerging trends across the global landscape.

- By Material Type

- Stainless Steel Dipping Baskets: Highly durable, corrosion-resistant, and suitable for high-temperature applications, dominating commercial and industrial use.

- Wire Mesh Dipping Baskets: Offer excellent drainage and versatility, used across residential and commercial settings for frying, blanching, and straining.

- Plastic/Polymer Dipping Baskets: Lighter, cost-effective, typically used for washing, draining, or blanching at lower temperatures; often heat-resistant polymers for specific applications.

- Silicone Dipping Baskets: Flexible, non-stick, and heat-resistant, gaining popularity in residential kitchens for delicate cooking tasks and ease of cleaning.

- Galvanized Steel Dipping Baskets: Primarily for industrial applications like parts cleaning, offering corrosion resistance in non-food environments.

- Coated Dipping Baskets (e.g., Non-stick coating): Enhance food release and ease of cleaning, found in specialized frying applications.

- By Application

- Deep Frying: The largest segment, encompassing items like french fries, chicken, seafood, and donuts in commercial and residential kitchens.

- Blanching & Boiling: Used for vegetables, pasta, and other items requiring immersion in hot water or broth for partial cooking or sterilization.

- Straining & Rinsing: For washing fruits, vegetables, pasta, and separating solids from liquids.

- Steaming: Specific designs allow for steaming applications, often used in conjunction with pots or steamers.

- Industrial Parts Washing & Treatment: Non-food applications involving cleaning, degreasing, or chemical treatment of small components in manufacturing and automotive sectors.

- Sterilization: Utilized in medical and laboratory settings for sterilizing instruments or equipment.

- By End-User

- Commercial: Includes restaurants, hotels, catering services, fast-food chains, institutional kitchens, and industrial food processing units. This segment accounts for the largest market share due to high volume usage and stringent quality requirements.

- Residential: Home cooks and culinary enthusiasts using dipping baskets for personal cooking needs, driven by convenience and culinary trends.

- Industrial: Manufacturing plants, laboratories, medical facilities, and other non-food sectors utilizing baskets for specific process requirements.

- By Size

- Small Dipping Baskets: Typically for individual portions or delicate items, common in residential and specialized commercial settings.

- Medium Dipping Baskets: Standard size for general-purpose frying and blanching, widely used across all end-user segments.

- Large Dipping Baskets: Designed for high-volume commercial and industrial operations, accommodating large batches for efficiency.

- Custom-Sized Dipping Baskets: Tailored to fit specific equipment or specialized industrial processes, offering unique dimensions and features.

- By Distribution Channel

- Online Retail: E-commerce platforms, brand websites, and online marketplaces offering a wide selection and convenience.

- Offline Retail: Supermarkets, hypermarkets, specialty kitchenware stores, wholesale clubs, and commercial kitchen supply stores.

Value Chain Analysis For Dipping Basket Market

The value chain for the Dipping Basket Market encompasses a series of interconnected stages, beginning with the sourcing of raw materials and extending through manufacturing, distribution, and final consumption. This intricate network ensures the efficient flow of products from primary suppliers to end-users, highlighting critical touchpoints where value is added and costs are incurred. Understanding this chain is crucial for identifying efficiencies, optimizing logistics, and addressing potential bottlenecks that could impact market supply and pricing. The initial stages involve procurement and processing of materials, which are then transformed into finished products through specialized manufacturing processes. Subsequent stages focus on making these products accessible to a diverse customer base, whether through direct sales or various intermediary channels.

Upstream analysis primarily involves the procurement of raw materials essential for manufacturing dipping baskets. This includes sourcing high-grade stainless steel wire, sheets, and mesh, which are paramount for durability and hygiene, especially in food-grade applications. For plastic and silicone baskets, the upstream segment involves chemical manufacturers supplying food-grade polymers and specialized resins. Suppliers of welding components, coatings, and handle materials also form a critical part of this stage. The quality and cost of these raw materials directly impact the final product's performance and market competitiveness. Relationships with reliable raw material suppliers are vital for ensuring consistent quality, managing supply chain risks, and controlling production costs, forming the foundational strength of the manufacturing process. Effective negotiation and long-term contracts with these suppliers are key strategic considerations.

Downstream analysis focuses on the distribution and sale of finished dipping baskets to various end-users. This involves a complex network of distribution channels, including direct sales to large commercial kitchens, industrial facilities, and institutional buyers, leveraging specialized sales teams and contract agreements. Indirect channels are equally significant, encompassing wholesale distributors who supply smaller restaurants and retail outlets, as well as e-commerce platforms and retail stores (supermarkets, hypermarkets, kitchenware specialty stores) that cater to residential consumers. The effectiveness of these distribution channels hinges on logistical efficiency, warehousing capabilities, and market reach. Direct distribution often allows for greater control over customer relationships and pricing, while indirect channels offer broader market penetration and reduced operational overheads for manufacturers. The choice of distribution channel significantly impacts market penetration, brand visibility, and overall sales volume.

Dipping Basket Market Potential Customers

The potential customers for dipping baskets are incredibly diverse, spanning across various sectors and consumer demographics due to the product's fundamental utility in immersing and retrieving items from liquids. At the core, these customers are individuals and businesses that engage in cooking, food preparation, industrial processing, or specialized cleaning and sterilization tasks where controlled immersion is critical. Their needs range from basic functionality and durability to highly specialized features tailored for specific operational environments. Understanding these varied customer profiles is essential for manufacturers and distributors to develop targeted marketing strategies, product innovations, and optimized distribution networks to capture market share effectively across different segments.

A primary segment of potential customers comprises the vast commercial food service industry. This includes independent restaurants, large restaurant chains, fast-food establishments, cafes, hotels, catering services, institutional kitchens (hospitals, schools, corporate cafeterias), and cruise lines. These professional kitchens require robust, high-capacity, and easy-to-clean dipping baskets for deep frying, blanching, boiling pasta, and straining various food items consistently and efficiently. Durability, heat resistance, ergonomic design for heavy use, and compliance with stringent food safety regulations are paramount for these commercial buyers, making them a significant and recurring revenue source for market participants focusing on high-volume, professional-grade equipment.

Beyond the commercial food service sector, significant demand arises from residential consumers and diverse industrial applications. Home cooks, culinary enthusiasts, and hobbyists represent a substantial customer base, driven by the increasing popularity of home cooking, gourmet trends, and the desire for specialized kitchen tools for tasks like making homemade fries, blanching garden vegetables, or precision cooking. In the industrial realm, potential customers include manufacturing facilities requiring baskets for parts washing, degreasing, or chemical treatment of components (e.g., automotive, electronics, aerospace industries). Additionally, medical and laboratory facilities utilize specialized dipping baskets for sterilizing instruments, cleaning glassware, or handling specimens, where material compatibility and sterilization efficacy are critical. These varied end-users underscore the dipping basket's indispensable role across a wide spectrum of applications, highlighting its versatility and broad market appeal.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1,260 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Winco, Vollrath, Carlisle FoodService Products, Browne Foodservice, San Jamar, Update International, Thunder Group, Cambro, F. Dick, Rubbermaid Commercial Products, Fisher Scientific, Hubert, Libbey Inc., Mercer Culinary, Chef'sChoice, Cuisinart, OXO, Norpro, Zojirushi, Tramontina. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dipping Basket Market Key Technology Landscape

The technology landscape for the Dipping Basket Market, while seemingly traditional, is underpinned by significant advancements in material science, manufacturing processes, and design engineering aimed at enhancing product performance, durability, and hygiene. Innovations primarily focus on optimizing the structural integrity of baskets, improving resistance to corrosion and high temperatures, and ensuring compliance with evolving food safety standards. The adoption of precision manufacturing techniques, such as advanced welding and stamping, plays a critical role in producing consistently high-quality and ergonomically designed products. These technologies collectively contribute to a more efficient, safer, and longer-lasting dipping basket, meeting the rigorous demands of both commercial and residential users.

Key technological developments include the widespread use of specialized stainless steel alloys, such as 304 and 316 grade, which offer superior resistance to rust, pitting, and chemical degradation, making them ideal for constant exposure to aggressive cooking environments and cleaning agents. The advancement of non-stick and other protective coatings, like PTFE or ceramic-based applications, provides added functionality, improving food release and simplifying cleaning processes, though their use must be carefully evaluated for high-temperature durability. Furthermore, innovative mesh weaving and perforation techniques ensure optimal drainage and retention of contents, while also minimizing the risk of food particles getting lodged, which is critical for hygiene and operational efficiency. The integration of robust handle designs, often utilizing heat-resistant polymers or reinforced steel, improves user comfort and safety during strenuous commercial use, reflecting a focus on ergonomic engineering.

Beyond material and structural enhancements, manufacturing automation and quality control technologies are increasingly influential. Robotic welding systems and automated assembly lines are employed to ensure precision, consistency, and scalability in production, reducing manufacturing defects and labor costs. Computer-aided design (CAD) and computer-aided manufacturing (CAM) software are utilized for rapid prototyping and simulating performance under various conditions, enabling faster product development cycles and optimized designs tailored to specific applications. Advanced surface finishing technologies, such as electro-polishing, contribute to smoother, more hygienic surfaces that are easier to clean and resistant to bacterial growth. These technological advancements not only enhance the intrinsic quality and functionality of dipping baskets but also drive competitive differentiation within the market, pushing manufacturers to continuously innovate and refine their product offerings to meet the evolving demands of a diverse customer base.

Regional Highlights

- North America: This region represents a mature yet robust market, characterized by a highly developed food service industry, including numerous fast-food chains, restaurants, and catering services. High disposable incomes and a strong culture of home cooking further bolster residential demand. Innovations in kitchen technology and stringent health and safety regulations drive demand for high-quality, durable, and compliant dipping baskets. The presence of major market players and strong distribution networks contributes to sustained market growth.

- Europe: Similar to North America, Europe is a significant market for dipping baskets, driven by a well-established culinary tradition, a vibrant food service sector, and high standards for kitchen equipment. Countries like Germany, France, and the UK demonstrate strong demand. Focus on quality, ergonomic design, and sustainability influences product preferences. The growth in artisanal food production and specialized cooking techniques also contributes to niche market segments.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, fueled by rapid urbanization, increasing disposable incomes, and the expansion of international and local quick-service restaurants. Countries like China, India, Japan, and Australia are key markets. The booming e-commerce sector further facilitates market penetration for dipping baskets. Cultural culinary practices involving deep frying and blanching also ensure a consistent demand for these essential kitchen tools.

- Latin America: This region exhibits steady growth, driven by an expanding middle class, increasing tourism, and the modernization of the food service industry. Economic development in countries like Brazil, Mexico, and Argentina leads to greater adoption of commercial kitchen equipment. Demand is influenced by local culinary preferences and the growth of both international and regional restaurant chains.

- Middle East and Africa (MEA): The MEA region is experiencing emerging growth in the dipping basket market, primarily attributed to infrastructural development in hospitality and tourism sectors, particularly in the GCC countries. Changing dietary habits and the proliferation of organized retail and food service outlets contribute to increased demand. However, market growth can be influenced by economic stability and regional geopolitical factors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dipping Basket Market.- Winco

- Vollrath Company LLC

- Carlisle FoodService Products

- Browne Foodservice

- San Jamar

- Update International

- Thunder Group Inc.

- Cambro Manufacturing Co.

- F. Dick GmbH

- Rubbermaid Commercial Products

- Fisher Scientific (Thermo Fisher Scientific Inc.)

- Hubert Company

- Libbey Inc. (Foodservice Division)

- Mercer Culinary

- Chef'sChoice (EdgeCraft Corporation)

- Cuisinart (Conair Corporation)

- OXO (Helen of Troy Limited)

- Norpro Inc.

- Zojirushi Corporation

- Tramontina USA, Inc.

Frequently Asked Questions

What materials are most commonly used for dipping baskets and why?

Stainless steel, particularly 304 and 316 grades, is the most common material due to its exceptional durability, corrosion resistance, high heat tolerance, and hygienic properties, making it ideal for food-grade applications and commercial use. Wire mesh variations provide excellent drainage and versatility. Plastic and silicone options are also used for lighter tasks and specific temperature requirements.

What are the primary applications of dipping baskets in commercial settings?

In commercial settings, dipping baskets are primarily used for deep frying a wide range of foods (e.g., french fries, chicken, seafood), blanching vegetables, boiling pasta, and straining various ingredients. They are critical tools for achieving consistent cooking results and managing high volumes in professional kitchens, catering services, and fast-food establishments.

How do I choose the right dipping basket for deep frying?

When selecting a dipping basket for deep frying, consider the material (stainless steel for durability and heat), mesh size (fine mesh for smaller items, wider for larger), handle design (heat-resistant and ergonomic for safety), and overall size to match your fryer and desired batch volume. Compatibility with your specific deep fryer model is also crucial for optimal performance and safety.

Are there dipping baskets designed for industrial, non-food applications?

Yes, specialized dipping baskets are widely used in industrial settings for tasks such as parts washing, degreasing, and chemical treatment of components in manufacturing, automotive, and electronics industries. They are also employed in laboratories and medical facilities for sterilization and cleaning instruments, often made from robust materials like galvanized or specialized stainless steel to withstand harsh chemicals.

What are the key factors driving growth in the dipping basket market?

The key growth drivers include the continuous expansion of the global food service industry, particularly the quick-service restaurant segment, and the sustained popularity of home cooking. Innovations in material science enhancing durability and hygiene, along with increasing adherence to food safety regulations, further fuel market growth by demanding high-quality and compliant products.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager