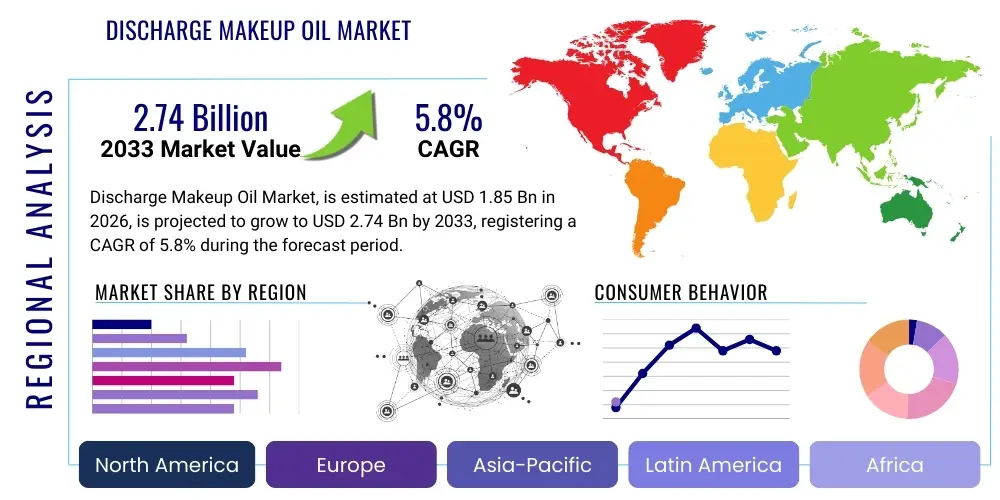

Discharge Makeup Oil Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437616 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Discharge Makeup Oil Market Size

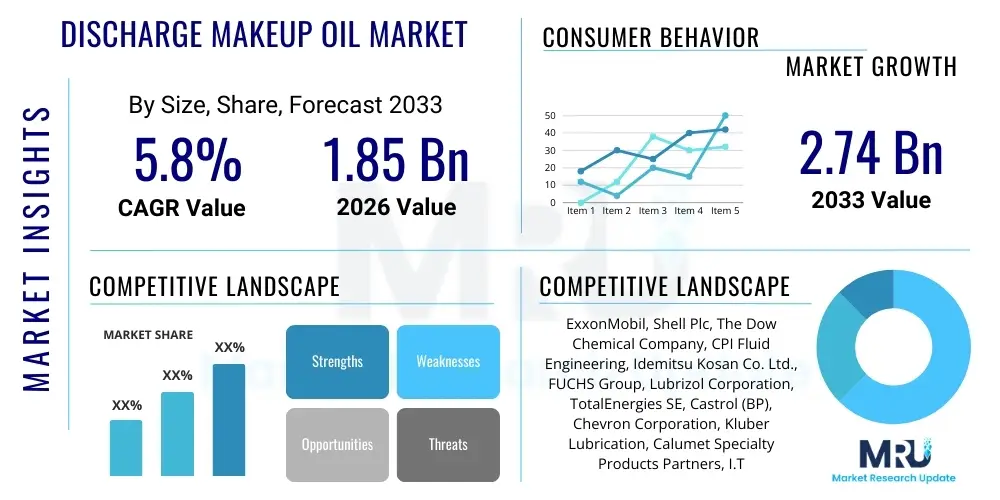

The Discharge Makeup Oil Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.85 billion in 2026 and is projected to reach USD 2.74 billion by the end of the forecast period in 2033. This consistent growth trajectory is primarily fueled by the accelerating demand for high-performance industrial compressors and advanced refrigeration systems globally, particularly within the Asia Pacific and Middle East regions undergoing rapid industrialization and infrastructure development.

Discharge Makeup Oil Market introduction

The Discharge Makeup Oil Market encompasses specialized synthetic and mineral-based lubricants designed to maintain optimal fluid levels and performance within closed-loop industrial systems, predominantly high-pressure compressors, and large-scale refrigeration units. These oils are critical for compensating for minor fluid losses (discharge) that occur during operational cycles, ensuring system efficiency, protecting internal components from wear and corrosion, and maintaining heat transfer capabilities. Unlike conventional lubricants, Discharge Makeup Oils must possess exceptional thermal stability, oxidation resistance, and compatibility with various refrigerants and process gases, making them indispensable components in capital-intensive machinery.

The primary application sectors driving demand include Heating, Ventilation, Air Conditioning, and Refrigeration (HVACR), oil and gas processing, and general manufacturing, where compressor reliability is crucial for continuous operations. Product varieties largely depend on the base stock, including Polyalphaolefins (PAOs), Synthetic Esters (POE, Alkylbenzenes), and highly refined mineral oils. The selection criteria for these fluids are stringent, focusing on viscosity index, volatility, miscibility with refrigerants (especially HFCs and HFOs), and adherence to strict environmental and safety regulations imposed by bodies such as the EPA and REACH.

The core benefits derived from utilizing high-quality discharge makeup oils include prolonged equipment lifespan, reduced maintenance frequency, minimized energy consumption due to improved compressor efficiency, and prevention of catastrophic system failure. Key driving factors underpinning the market expansion involve stringent regulations mandating the use of energy-efficient machinery, the expansion of cold chain logistics globally, and technological advancements in synthetic lubricant formulations that cater to new, environmentally friendly refrigerants (like R1234yf or ammonia systems). Furthermore, the increasing complexity and operating pressures of modern industrial compressors necessitate superior fluid performance that only specialized makeup oils can provide.

Discharge Makeup Oil Market Executive Summary

The Discharge Makeup Oil market is poised for significant expansion, characterized by a fundamental shift toward synthetic and bio-based formulations driven by global environmental mandates and the phase-out of high Global Warming Potential (GWP) refrigerants. Business trends highlight strategic partnerships between lubricant manufacturers and major Original Equipment Manufacturers (OEMs) to develop custom fluids optimized for next-generation compressor technologies, focusing heavily on enhancing thermal stability and reducing volatility under extreme operating conditions. Furthermore, consolidation among mid-sized specialty chemical producers is observed as companies seek to expand their geographic footprint and diversify their product portfolios to capture burgeoning demand in emerging economies, notably India, China, and Southeast Asia, which are heavily investing in industrial infrastructure and HVACR capacity.

Regionally, Asia Pacific (APAC) currently dominates the market share and is projected to exhibit the highest growth rate, fueled by rapid urbanization, massive industrial output, and the consequent surge in demand for commercial refrigeration and industrial gases. North America and Europe, while mature, remain crucial markets, characterized by high adoption rates of premium synthetic oils and a strong emphasis on regulatory compliance related to energy efficiency (e.g., minimum efficiency standards) and environmental protection (e.g., F-Gas regulation in Europe). The Middle East and Africa (MEA) are emerging as high-potential regions due to extensive investment in oil and gas infrastructure, large-scale construction projects, and the necessity for robust cooling systems in high-ambient-temperature environments.

Segment trends underscore the dominance of the Synthetic Esters (POE/PAG) segment due to their superior performance characteristics and excellent compatibility with newer HFO and CO2 refrigerants, aligning with sustainability goals. Application-wise, the Industrial Refrigeration segment, encompassing large cold storage facilities and chemical processing plants, represents the largest revenue generator. However, the Automotive HVAC segment is anticipated to witness accelerated growth, driven by the increasing integration of efficient air conditioning systems in electric vehicles (EVs) and the need for high-dielectric strength makeup oils in these applications.

AI Impact Analysis on Discharge Makeup Oil Market

Common user inquiries regarding AI's influence in the Discharge Makeup Oil market frequently center on how machine learning can optimize fluid life cycles, predict maintenance needs, and revolutionize product formulation. Users are keen to understand if AI-driven diagnostics can accurately monitor fluid degradation in real-time, thereby optimizing discharge schedules and reducing unnecessary consumption. Furthermore, there is significant interest in how AI can accelerate the R&D process for developing next-generation environmentally benign fluids by modeling complex interactions between base oils, additives, and various refrigerants under simulated extreme conditions. Key themes emerging from these questions involve supply chain resilience, predictive quality control, and the potential for personalized, system-specific fluid recommendations powered by deep learning algorithms analyzing vast operational datasets.

AI’s primary impact is transforming the entire value chain from manufacturing to end-use application. In manufacturing, AI algorithms analyze reaction parameters, ensuring batch-to-batch consistency and improving the yield of high-purity synthetic base stocks, crucial for the quality of the final makeup oil. For end-users, AI integrated into compressor monitoring systems utilizes sensor data (pressure, temperature, vibration) to predict when fluid replenishment or replacement is genuinely necessary, moving away from time-based maintenance schedules toward condition-based servicing. This shift maximizes the lifespan of the makeup oil, significantly lowers operational costs, and minimizes environmental waste associated with premature fluid disposal.

Moreover, AI is playing a critical role in addressing the complexity of regulatory transitions. As the industry moves away from established refrigerants to alternatives like R32 or R1234ze, lubricant manufacturers face challenges ensuring fluid compatibility and stability. AI models can rapidly test millions of formulation permutations virtually, identifying the most stable additive packages and base oil combinations that perform optimally with low-GWP gases, dramatically cutting the time and expense involved in traditional laboratory testing. This predictive capability ensures the market can quickly adapt to changing environmental legislation while maintaining high safety and performance standards for industrial applications.

- AI-driven Predictive Maintenance: Optimizes discharge and replenishment schedules based on real-time fluid health monitoring (viscosity, acid number).

- Enhanced Formulation Efficiency: Utilizes machine learning to model complex base oil/additive/refrigerant interactions, speeding up the development of stable, high-performance synthetic esters.

- Supply Chain Optimization: Forecasts demand for specific fluid types based on regional industrial growth trends and regulatory phase-out timetables.

- Real-time Quality Control: Implements vision systems and sensor fusion in manufacturing plants to ensure purity and consistency of finished makeup oil batches.

- Operational Energy Saving: AI monitors compressor operation and fluid performance to recommend optimal operating parameters, contributing to overall system energy efficiency.

DRO & Impact Forces Of Discharge Makeup Oil Market

The Discharge Makeup Oil Market dynamics are governed by a complex interplay of regulatory drivers and operational constraints, shaping innovation and demand. Key drivers include the global mandate for climate action, spurring the rapid transition to energy-efficient industrial equipment and low-GWP refrigerants (such as HFOs and natural refrigerants like R-290 and ammonia). This transition necessitates the development and adoption of specialized, high-quality synthetic makeup oils compatible with these new chemical compounds, thereby boosting premium product segments. Furthermore, the sustained expansion of critical infrastructure, particularly in emerging economies, including cold chain logistics, pharmaceutical manufacturing, and petrochemical processing, generates constant, underlying demand for reliable compressor and refrigeration lubricants.

Restraints primarily revolve around the volatile cost and supply of synthetic base stocks, particularly PAOs and high-grade esters, which are often petrochemical derivatives susceptible to fluctuating crude oil prices and complex refining processes. The specialized nature of these fluids also results in significantly higher initial costs compared to conventional mineral oils, sometimes deterring smaller or price-sensitive end-users. Additionally, the challenge of ensuring complete fluid compatibility across a highly diverse range of compressors and refrigerants requires extensive, expensive certification and testing, creating barriers to entry for new market participants and slowing the adoption cycle for innovative formulations.

Opportunities in the market are abundant, centered on sustainability and technological innovation. The growing focus on circular economy principles and bio-based lubricants presents a major avenue for growth, particularly in Europe where regulatory pressure favors renewable resources. Opportunities also lie in the integration of smart sensor technology for real-time fluid diagnostics (Condition Monitoring as a Service), allowing manufacturers to offer value-added services and maintain long-term customer relationships. The intense need for superior performance in extreme environments, such as deep-sea drilling or high-altitude aerospace applications, also opens niche markets requiring ultra-stable, non-flammable makeup oils. These factors collectively create significant impact forces on pricing strategies, product differentiation, and long-term research investment decisions within the sector.

Segmentation Analysis

The Discharge Makeup Oil market is meticulously segmented based on base oil type, viscosity grade, primary application, and geographic region, reflecting the highly specialized nature of the product and its dependency on the specific operating environment and equipment type. Understanding these segmentations is vital for manufacturers to tailor their product offerings, meet precise OEM specifications, and comply with varied international regulatory standards. The market differentiation is increasingly focused on technical performance, specifically thermal stability and compatibility with newer refrigerants, rather than solely on cost, driving innovation toward premium synthetic grades.

- By Base Oil Type:

- Synthetic Esters (POE, Alkylbenzenes)

- Polyalphaolefins (PAO)

- Polyalkylene Glycols (PAG)

- Mineral Oil (Highly Refined Hydrocarbons)

- Bio-Based/Renewable Oils

- By Application:

- Industrial Refrigeration (Cold Storage, Food Processing)

- Commercial HVAC Systems

- Automotive HVAC (Passenger and Commercial Vehicles)

- Industrial Compressors (Air, Process Gas, Natural Gas)

- Power Generation (Turbines and Auxiliary Equipment)

- By Viscosity Grade (ISO VG):

- Low Viscosity (VG 10, VG 15, VG 22)

- Medium Viscosity (VG 32, VG 46, VG 68)

- High Viscosity (VG 100 and above)

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East & Africa (MEA)

Value Chain Analysis For Discharge Makeup Oil Market

The value chain for the Discharge Makeup Oil market begins upstream with the procurement and refining of specialized raw materials. This stage involves sourcing high-purity feedstocks, such as alpha-olefins for PAOs, or natural oils/acids for synthetic esters, followed by complex chemical processes like polymerization, esterification, and hydrocracking to produce the required synthetic or highly refined mineral base oils. The integrity and consistency of this upstream supply directly determine the final product quality and price volatility. Key suppliers in this phase include major petrochemical companies and specialty chemical manufacturers that control the proprietary technologies for base stock synthesis. The concentration of high-quality base stock production significantly impacts the pricing power dynamics throughout the rest of the chain.

The midstream phase involves lubricant manufacturers, blenders, and compounders. These entities acquire the base stocks and incorporate specialized additive packages—including antioxidants, corrosion inhibitors, demulsifiers, and anti-wear agents—to meet specific performance requirements, such as thermal stability or refrigerant miscibility. The formulation expertise and intellectual property (IP) surrounding these additive packages are critical differentiators in this market. Strict quality control and compliance with ISO standards are mandatory during the blending process. Downstream activities involve distribution channels, which are typically bifurcated into direct sales to large OEMs and indirect distribution via specialized industrial distributors, wholesale agents, and maintenance service providers targeting the aftermarket.

The final stage involves reaching the potential customers and providing essential after-sales technical support. Direct channels are crucial for large volume sales to compressor OEMs (Original Equipment Manufacturers), who often require co-developed, certified fluids to be bundled with their machinery. Indirect channels serve the extensive aftermarket demand for fluid replenishment and scheduled maintenance across thousands of industrial sites. Due to the technical complexity of discharge makeup oils, the quality of the technical support and training provided to end-users regarding proper application, handling, and disposal heavily influences customer loyalty and market penetration, especially in sectors like food processing and pharmaceuticals where safety and environmental compliance are paramount.

Discharge Makeup Oil Market Potential Customers

The potential customers for Discharge Makeup Oil are concentrated within sectors that rely heavily on high-pressure fluid systems and complex thermodynamic cycles, where component protection and continuous operation are non-negotiable. These customers are primarily categorized by their intensive use of industrial compressors for process gas handling, or large-scale refrigeration and cooling equipment essential for their core business operations. Procurement decisions within these organizations are typically highly technical, involving extensive input from maintenance engineers, reliability managers, and sustainability officers, prioritizing fluid performance and OEM endorsements over initial cost considerations.

Major end-user segments include the commercial and industrial HVACR sectors, responsible for maintaining precise temperature control in cold storage warehouses, supermarket chains, and large commercial buildings. These applications require high-stability oils compatible with standard and next-generation refrigerants, ensuring longevity and compliance with evolving energy efficiency standards. Another significant customer base lies within the oil and gas industry, where compressors are integral to gas transmission, refining, and petrochemical synthesis. Here, the makeup oils must withstand extreme pressures, high temperatures, and potentially corrosive process gases, demanding premium synthetic formulations.

Furthermore, general manufacturing and power generation industries constitute critical customer groups. Manufacturing plants utilizing compressed air for automation and control systems, along with power plants operating turbines and auxiliary cooling loops, regularly require makeup fluids to maintain system operational integrity. The pharmaceutical and food processing industries are also high-value customers, requiring specialized, often non-toxic or food-grade certified, makeup oils due to the strict regulatory environment concerning product safety and potential contamination, placing an emphasis on certified POE and PAG products.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 2.74 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ExxonMobil, Shell Plc, The Dow Chemical Company, CPI Fluid Engineering, Idemitsu Kosan Co. Ltd., FUCHS Group, Lubrizol Corporation, TotalEnergies SE, Castrol (BP), Chevron Corporation, Kluber Lubrication, Calumet Specialty Products Partners, I.T.W. Global Brands (PCL), Sonneborn, BASF SE, Croda International Plc, Phillips 66, Hatco Corporation, Shrieve Chemical Company. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Discharge Makeup Oil Market Key Technology Landscape

The technology landscape in the Discharge Makeup Oil market is rapidly evolving, driven primarily by the need to engineer fluids that can withstand increasingly severe operational parameters while meeting stringent environmental targets. A central technological focus is the advancement of synthetic base oil manufacturing, particularly the development of high-performance Synthetic Esters (POEs) and Polyalkylene Glycols (PAGs) with tailored molecular structures. These next-generation synthetics are engineered to provide enhanced thermal and oxidative stability, superior miscibility with challenging refrigerants (such as R1234yf or CO2), and improved resistance to hydrolysis, ensuring system integrity and maximizing the Mean Time Between Failures (MTBF) for expensive machinery. Continuous innovation in additive chemistry is paramount, focusing on non-toxic, ashless additive packages that boost anti-wear properties without compromising the fluid's inherent stability or compatibility with system components.

Another crucial technological frontier is the development of advanced formulation techniques for bio-based and renewable makeup oils. While traditional bio-oils often suffer from poor oxidative stability or low-temperature performance, current R&D efforts are focused on chemically modifying natural fatty acid esters (e.g., through transesterification or hydrogenation) to achieve performance parity with, or superiority over, conventional synthetic alternatives. This involves utilizing advanced catalytic processes to ensure the bio-based fluid maintains necessary fire resistance, high viscosity index, and optimal shear stability across wide temperature ranges. The success of these bio-derived formulations is key to market growth in regions like Europe, where environmental legislation strongly favors renewable inputs and reduced carbon footprints across industrial supply chains.

Furthermore, the integration of digital technologies, particularly in Condition Monitoring and Internet of Things (IoT) systems, is transforming how makeup oils are used and managed. Sensor technology embedded within compressors can now monitor key fluid degradation parameters—such as acid number, water content, and particle count—in real-time. This data is leveraged by machine learning algorithms to predict the optimal replenishment interval for the discharge makeup oil, shifting the paradigm from preventative scheduling to predictive maintenance. This technological capability allows end-users to maximize fluid life, reduce operational downtime, and ensure peak energy efficiency, simultaneously enhancing performance monitoring and accountability throughout the system's operational cycle.

Regional Highlights

- Asia Pacific (APAC): APAC represents the largest and fastest-growing regional market, propelled by massive industrial infrastructure development, particularly in China and India. The region's rapid expansion in manufacturing, chemical processing, and cold chain logistics (driven by burgeoning e-commerce and urbanization) necessitates substantial investment in new compressor and refrigeration units, fueling demand for both cost-effective mineral oils and high-performance synthetics. Government initiatives promoting energy efficiency and sustainable development in countries like Japan and South Korea are accelerating the shift toward advanced POE and PAG formulations in high-end HVAC and industrial applications.

- North America: North America is a technologically mature market characterized by stringent energy efficiency standards and a strong focus on high-performance lubrication solutions. The region exhibits high consumption of synthetic base oils (PAOs and Esters) driven by demanding applications in the oil and gas sector, aerospace, and high-efficiency commercial HVACR. Regulatory frameworks, particularly those related to HFC phase-down and environmental mandates, incentivize end-users to invest in premium makeup oils that maximize system longevity and comply with environmental stewardship goals, maintaining steady growth in the value segment.

- Europe: Europe is defined by its leadership in environmental regulation, notably the F-Gas Regulation and REACH, which mandate the transition away from high-GWP refrigerants and restrict hazardous chemicals. This regulatory landscape strongly favors the adoption of low-toxicity, biodegradable, and synthetic specialty fluids compatible with natural refrigerants (like CO2 and ammonia). The region is a key pioneer in bio-based discharge makeup oil research and commercialization, primarily driven by strong sustainability commitments from large industrial manufacturers and significant investment in efficient heat pump and chilling technologies.

- Latin America (LATAM): The LATAM market is witnessing stable growth, correlated with the expansion of its manufacturing base and the need for modernizing aging industrial infrastructure, particularly in countries like Brazil and Mexico. Demand is segmented, with mineral and semi-synthetic oils dominating price-sensitive industrial compressor applications, while specialized POEs are increasingly adopted in growing food and beverage processing sectors requiring modern cold storage capabilities and adherence to international food safety standards.

- Middle East and Africa (MEA): The MEA region presents a high-growth potential segment, fundamentally driven by extensive investments in hydrocarbon processing (oil and gas) and large-scale infrastructural projects, including district cooling systems. The extreme ambient temperatures prevalent in the region necessitate makeup oils with exceptional thermal stability and low volatility to ensure reliability under harsh operating conditions, primarily driving demand for high-viscosity synthetic PAOs and specialized fire-resistant fluids, with petrochemical industries being the major consumers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Discharge Makeup Oil Market.- ExxonMobil Corporation

- Shell Plc

- The Dow Chemical Company

- CPI Fluid Engineering (A Subsidiary of Lubrizol Corporation)

- Idemitsu Kosan Co. Ltd.

- FUCHS Group

- TotalEnergies SE

- Castrol (BP p.l.c.)

- Chevron Corporation

- Kluber Lubrication (Freudenberg Chemical Specialties KG)

- Calumet Specialty Products Partners, L.P.

- I.T.W. Global Brands (PCL)

- Sonneborn LLC

- BASF SE

- Croda International Plc

- Phillips 66 Company

- Hatco Corporation

- Shrieve Chemical Company

- Valvoline Inc.

- Esterchem Ltd.

Frequently Asked Questions

Analyze common user questions about the Discharge Makeup Oil market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of Discharge Makeup Oil in industrial systems?

The primary function of Discharge Makeup Oil is to replenish fluid volume loss occurring during the operational cycles of closed-loop systems, typically high-pressure industrial compressors and refrigeration units. This replenishment ensures the maintenance of optimal lubricant levels, component protection against wear, efficient heat transfer, and sustained operational efficiency, preventing system failures and premature maintenance requirements.

How do regulatory changes regarding refrigerants affect the demand for specific makeup oil types?

Regulatory changes, such as the global phase-out of high Global Warming Potential (GWP) refrigerants (e.g., specific HFCs) in favor of alternatives (HFOs, R32, CO2, Ammonia), significantly dictate makeup oil demand. These new refrigerants often require specialized synthetic base oils like Polyol Esters (POEs) or Polyalkylene Glycols (PAGs) to ensure proper miscibility, stability, and compatibility within the system, accelerating the shift away from conventional mineral oils.

Which base oil type currently dominates the Discharge Makeup Oil market, and why?

Synthetic Esters (POEs) currently dominate the market, particularly in refrigeration applications. POEs offer excellent thermal and chemical stability, outstanding solvency, and, critically, superior miscibility with hydrofluorocarbon (HFC) and hydrofluoroolefin (HFO) refrigerants. Their high performance ensures long system life and compliance with modern energy efficiency standards required by OEMs and regulatory bodies worldwide.

What role does digitalization (IoT and AI) play in the future growth of this market?

Digitalization plays a transformative role by enabling Condition Monitoring (CM) via IoT sensors, providing real-time data on fluid degradation parameters (e.g., viscosity, water content). This data is analyzed by AI algorithms to shift maintenance from time-based to predictive, optimizing the timing for discharge makeup oil replenishment. This reduces unnecessary oil consumption, minimizes waste, extends equipment lifespan, and enhances overall energy efficiency.

What are the main challenges faced by manufacturers in developing new discharge makeup oils?

Manufacturers face key challenges including the high cost and volatility of synthetic base stock feedstocks, the necessity for extensive testing to certify compatibility with a wide array of specialized refrigerants and component materials (elastomers, metals), and adherence to increasingly stringent global environmental and safety regulations, requiring constant investment in complex, specialized formulation R&D.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager