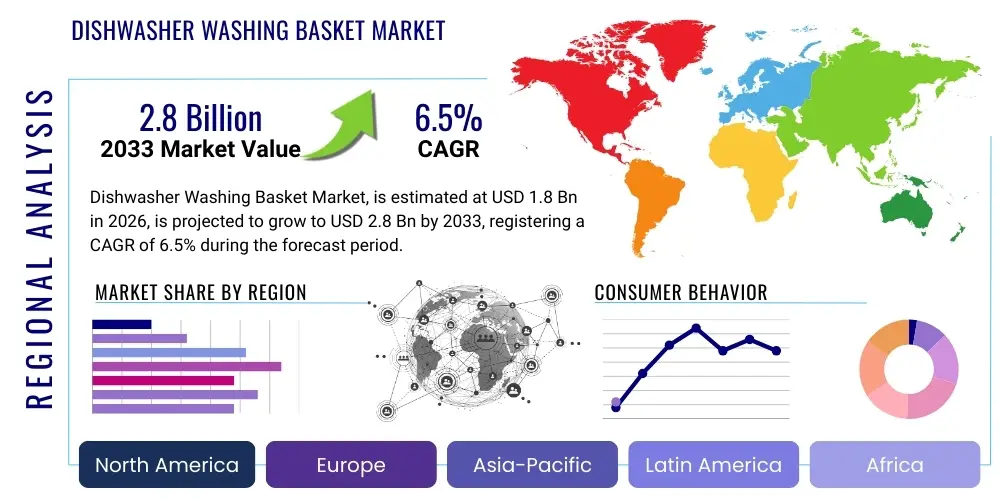

Dishwasher Washing Basket Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434632 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Dishwasher Washing Basket Market Size

The Dishwasher Washing Basket Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at USD 1.8 billion in 2026 and is projected to reach USD 2.8 billion by the end of the forecast period in 2033.

Dishwasher Washing Basket Market introduction

The Dishwasher Washing Basket Market encompasses the manufacturing, distribution, and sales of specialized racks and inserts designed to securely hold dishes, cutlery, and other kitchen items within automatic dishwashing machines. These baskets are critical components of a dishwasher's functionality, ensuring efficient water spray access, secure item placement to prevent chipping, and optimizing space utilization. The evolution of this market is closely tied to advancements in dishwasher technology, consumer preferences for specialty cleaning (e.g., specific wine glass racks, expandable cutlery holders), and the shift towards durable, high-temperature-resistant, and aesthetically pleasing materials, such as polymer-coated steel and advanced plastics. The primary products include standard lower racks, adjustable upper racks, and specialized cutlery baskets. The foundational importance of these baskets lies in their precision engineering; the spacing, angle, and coating must withstand years of aggressive chemical and thermal cycling while ensuring optimal water and detergent distribution across all loaded items, directly impacting the dishwasher’s effectiveness and overall rating.

Major applications of these washing baskets span residential, commercial (restaurants, hotels, catering services), and institutional sectors. In the residential segment, the demand is driven by increasing penetration of household appliances, replacement cycles, and the desire for modular and flexible loading options. Current design trends incorporate specialized zones for complex items, such as dedicated cup shelves, fold-down tines for large pots, and soft-grip materials to secure fragile stemware. Commercially, baskets are engineered for high-throughput and robust performance under continuous operation, often requiring specialized inserts for unique glassware or large serving ware to meet stringent health and safety regulations associated with food service equipment. The robustness and chemical resistance of commercial baskets far exceed residential requirements, necessitating different material formulations and structural reinforcement.

Key driving factors accelerating market growth include the steady increase in global household income leading to higher adoption rates of integrated kitchen appliances, stringent hygiene standards post-pandemic, and continuous innovation by original equipment manufacturers (OEMs) focusing on smart and customizable dishwasher interiors. The strategic partnership between basket manufacturers and appliance designers is crucial, resulting in baskets that maximize internal capacity without compromising water efficiency. Furthermore, the rising replacement demand for older, corroded, or damaged baskets—which often leads to poor cleaning results and operational noise—contributes significantly to the aftermarket segment, emphasizing longevity and material quality as key purchase criteria. Environmental regulations favoring long-lasting, recyclable materials also shape product development, pushing manufacturers toward more sustainable and durable component solutions, often involving TPEs (Thermoplastic Elastomers) and recyclable steel alloys to enhance the product’s lifecycle value.

Dishwasher Washing Basket Market Executive Summary

The Dishwasher Washing Basket Market is characterized by robust growth driven by urbanization and rising penetration of modern kitchen appliances globally. Business trends indicate a strong focus on customization and modularity, with manufacturers integrating flexible tines, adjustable height mechanisms, and specialized compartments to cater to diverse consumer loading requirements, moving away from rigid, one-size-fits-all designs. Regionally, Asia Pacific is emerging as the fastest-growing market, propelled by rapid residential construction, particularly in China and India, and increasing middle-class spending, while North America and Europe maintain dominance due to high appliance saturation and a mature, necessity-driven replacement market focused on premium materials and smart features. Segment trends highlight the growing preference for high-grade polymer-coated metal baskets due to their superior durability and corrosion resistance, alongside increasing demand for specialized cutlery and glassware inserts, signaling a movement towards premium, function-specific accessories that enhance overall dishwasher efficiency and protection of delicate items.

AI Impact Analysis on Dishwasher Washing Basket Market

User inquiries regarding AI's influence in this domain frequently center on how intelligent systems can optimize dishwasher loading patterns, predict basket wear-and-tear, and facilitate personalized cleaning cycles. Key themes include the integration of vision systems (AI-powered cameras) within dishwashers to recognize loaded items and automatically adjust water pressure, temperature, and spray patterns specific to the basket layout and item density. Concerns revolve around the complexity and cost associated with integrating sophisticated smart sensors and algorithms into a traditionally mechanical component, potentially raising the overall appliance price point. Expectations are high regarding predictive maintenance—using machine learning to analyze usage data, corrosion rates, and environmental factors (like localized water hardness) to recommend timely replacement of baskets or suggest optimal material choices, thereby significantly enhancing product longevity, reducing user frustration, and improving warranty management for both OEMs and end-users by proactively addressing potential hardware failures.

- AI-powered visual recognition optimizes spray angles and water intensity based on basket loading configuration and dish type detection.

- Machine Learning (ML) algorithms analyze usage patterns and material stress to predict basket component failure, triggering proactive replacement notifications.

- Smart dishwashers utilize sensor data linked to basket type (via embedded identifiers) to customize cleaning intensity, temperature, and cycle duration automatically.

- Optimized manufacturing processes utilizing AI for highly accurate robotic welding and real-time defect detection in polymer coating and assembly quality.

- AI supports personalized basket design recommendations and aftermarket sales by analyzing common user dish inventory and kitchen space constraints.

- Integration of AI with inventory management systems to forecast demand for specific basket accessories and replacement parts based on geographical sales trends.

- Development of AI-driven simulation tools to model fluid dynamics within complex basket structures, improving design efficiency before physical prototyping.

DRO & Impact Forces Of Dishwasher Washing Basket Market

The market is primarily driven by the increasing global adoption of automated dishwashing appliances, particularly in emerging economies, coupled with continuous advancements in material science that improve basket longevity and functional modularity. Major restraints include the fluctuating costs and supply chain volatility of key raw materials, specifically high-grade steel and specialized polymers used for anti-corrosion coatings, and the typically lengthy replacement cycles of dishwashers themselves, which limits the frequency of initial basket sales to OEMs. Significant opportunities lie in the development of sophisticated antimicrobial coatings for enhanced food safety and hygiene, and the rapid expansion of customization and premium aftermarket accessories, allowing users to configure baskets optimized for specific dishware sets or unique kitchen needs. The combined impact of robust residential construction activity globally, the integration of advanced technologies (e.g., modularity and TPE usage), and sustained consumer demand for time-saving, hygienic kitchen solutions ensures a moderately strong positive influence and sustained growth momentum on the market over the long-term forecast period.

Segmentation Analysis

The Dishwasher Washing Basket Market is segmented across several critical dimensions, including material type, application, end-user, and product type, reflecting the specialized requirements of different consumers and appliance models. Material composition is crucial for longevity and performance, differentiating between highly durable polymer-coated metallic structures (standard for most mid-to-high-end models), pure polymer or heavy-duty plastic baskets (common in entry-level or specialized industrial units), and modern hybrid designs that combine both materials for optimal weight and functionality. Segmentation by product type highlights the functional distinction between standard lower racks (designed for heavy items), highly flexible adjustable upper racks (for glasses and smaller items), specialized modular cutlery inserts, and bespoke flexible components that cater to specific user requirements. Furthermore, the market is meticulously analyzed based on end-user categories, rigorously separating high-volume, continuous commercial uses (Horeca sector) from standard residential applications, reflecting profoundly diverse durability standards, load requirements, and design specifications across these sectors.

- By Material Type:

- Polymer-Coated Metal (Steel/Wire): Dominant segment, valued for strength and superior coating.

- Plastic/Polymer (Nylon, Polypropylene, TPE): Used for specialized inserts and low-cost models.

- Hybrid Materials: Combining metal structure with specialized TPE flexible components.

- By Product Type:

- Lower Racks: Largest segment by volume, designed for plates and large items.

- Upper Racks (Adjustable/Non-Adjustable): Focus on lightweight and delicate item handling.

- Cutlery Baskets (Modular/Fixed): Increasingly modular designs gaining traction.

- Specialty Inserts (e.g., Wine Glass Holders, Bottle Cleaners): High growth potential in aftermarket.

- By End-User:

- Residential: Driven by new appliance sales and replacement cycles.

- Commercial (Hotels, Restaurants, Cafes, Institutional): Demands heavy-duty, high-capacity industrial units.

- By Distribution Channel:

- Original Equipment Manufacturers (OEM): Primary revenue channel, dictated by appliance production.

- Aftermarket (Retail, Online Sales, Authorized Service Centers): Growth driven by replacements and upgrades.

- By Coating Type:

- PVC Coating

- Nylon/Polyamide Coating

- Epoxy Powder Coating

Value Chain Analysis For Dishwasher Washing Basket Market

The value chain for the Dishwasher Washing Basket Market initiates with upstream activities, focusing on the highly selective sourcing of primary raw materials, including high-grade low-carbon steel wire (chosen for its excellent formability and structural strength), specialized corrosion-resistant polymers (such as high-density polyethylene or nylon powders, sourced from specialized chemical manufacturers), and technical injection-molded plastics (polypropylene, ABS, TPE). Sourcing decisions are highly influenced by global commodity price fluctuations, supply chain stability, and strict adherence to international material safety and chemical restriction standards, particularly concerning coatings. Ensuring a reliable supply of high-quality, traceable coating materials is paramount, as the coating integrity fundamentally determines the final product's long-term performance, aesthetic retention, and warranty validation.

Midstream activities encompass the core manufacturing processes which transform these raw materials into functional components ready for installation. These processes involve advanced techniques such as automated wire forming, multi-point resistance welding to create the structural grid with high precision, and the crucial anti-corrosion coating application, typically utilizing sophisticated fluidized bed dipping or electrostatic powder coating systems that ensure a thick, uniform, and durable layer. Injection molding is a vital complementary process used for fabricating complex plastic elements like wheels, handles, and flexible tines, which require high dimensional accuracy and chemical stability. Operational efficiency at this stage is achieved through lean manufacturing practices and the integration of precision robotics in welding and assembly to maintain the geometrical accuracy required for perfect alignment within modern, complex dishwasher hydraulics.

Downstream activities involve distribution, a critical phase that is essentially bifurcated into two main channels. The first is direct sales to major Dishwasher Original Equipment Manufacturers (OEMs), which represents the largest, high-volume segment governed by stringent specifications and long-term supply contracts requiring just-in-time logistics. The second is the indirect channel, which serves the higher-margin aftermarket segment. This channel relies extensively on large appliance wholesalers, authorized appliance part distributors, service and repair professionals, and a rapidly expanding e-commerce sector. The growth of digital platforms has dramatically increased the accessibility of replacement baskets and customized accessories for end-users, enabling manufacturers to engage directly with consumers and gather valuable feedback on product performance and desired enhancements.

Dishwasher Washing Basket Market Potential Customers

Potential customers for dishwasher washing baskets span a broad spectrum, categorized primarily into original equipment manufacturers (OEMs) and replacement market consumers, each presenting unique purchasing criteria and volume demands. Major OEMs, including global appliance giants such as BSH, Whirlpool, Electrolux, and Haier, represent the largest volume buyers, requiring millions of customized, high-specification baskets that are seamlessly integrated into their specific dishwasher models and production lines, demanding strict quality control and competitive pricing under long-term agreements. Their purchasing decisions prioritize compatibility, structural integrity, and consistency of anti-corrosion properties to uphold their brand warranty commitments.

The secondary, yet rapidly expanding, customer base comprises aftermarket consumers. This includes residential users seeking direct replacements for worn-out or structurally compromised standard baskets, or those looking for functional upgrades, such as specialized wine glass racks, modular fold-down sections, or enhanced cutlery holders designed to maximize cleaning efficiency. This consumer segment is heavily influenced by factors such as ease of installation, brand compatibility assurance, perceived durability, and price-to-value ratio, often leveraging online marketplaces for product selection and technical comparisons.

Furthermore, commercial entities constitute a highly specialized and lucrative customer group. This category includes high-volume foodservice providers (restaurants, hotels, catering companies), institutional facilities (hospitals, university cafeterias), and cruise lines. These customers require heavy-duty, industrial-grade washing baskets designed to withstand continuous, high-temperature sanitizing cycles and significant mechanical stress. Their procurement processes emphasize robust construction, compliance with sanitation regulations (e.g., NSF standards), and extended longevity to minimize downtime in demanding professional kitchen environments, driving demand for premium, stainless steel or high-specification polymer baskets.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | [USD 1.8 Billion] |

| Market Forecast in 2033 | [USD 2.8 Billion] |

| Growth Rate | [6.5% CAGR] |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Whirlpool Corporation, BSH Home Appliances (Bosch, Siemens), Electrolux AB, Miele & Cie. KG, Haier Group (GE Appliances), Ranco Industries, HMT Group, Zhejiang Hualing Industrial Co., Ltd., Summit Appliance, LG Electronics Inc., Smeg S.p.A., Fisher & Paykel Appliances Ltd., Middleby Corporation, ITW Food Equipment Group (Hobart), Ali Group S.r.l., Meiko Maschinenbau GmbH & Co. KG, Jackson WWS, Inc., CMA Dishmachines, Guangdong Xinbao Electrical Appliances Holdings Co., Ltd., Jiangsu Xinwei Mesh-Belt Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Dishwasher Washing Basket Market Key Technology Landscape

The technology landscape in the Dishwasher Washing Basket Market is primarily driven by continuous advancements in material science and precision manufacturing, targeting significantly extended product lifespan, enhanced user functionality, and seamless integration with smart appliances. Key technologies include the application of advanced anti-corrosion polymer coatings (like powder-coated epoxy, high-density nylon, or specialized polyvinyl chloride) utilizing sophisticated fluidized bed dipping or electrostatic application systems. These processes are critical for achieving maximum surface coverage and consistent thickness, essential attributes that enable the metal wire baskets to effectively withstand the severe environmental stresses imposed by highly concentrated detergents, extreme sanitizing temperatures (often exceeding 70°C), and continuous moisture exposure over the appliance's life.

Furthermore, complex engineering requirements necessitate extensive use of advanced injection molding technologies. This allows for the precise fabrication of highly functional, non-metallic components such as ergonomic handles, self-aligning wheels, modular clips, and flexible tines. These functional elements are frequently manufactured using high-grade engineering plastics (e.g., robust polypropylene or heat-resistant ABS) and Thermoplastic Elastomers (TPEs). TPEs are particularly valuable for soft-grip interfaces and adjustable folding tines, as they maintain structural integrity and flexibility over thousands of operational cycles, preventing fatigue failure while simultaneously protecting delicate dishware, significantly enhancing the overall consumer experience and perceived quality.

Recent technological innovations are increasingly focused on structural optimization and integration with connectivity. This includes leveraging sophisticated Finite Element Analysis (FEA) during the design phase to minimize raw material usage while maintaining high load-bearing capacity and mitigating operational noise through targeted vibration dampening. For the premium appliance segment, there is significant developmental work in embedding tiny, passive identifiers (such as RFID tags or magnetic strips) within the basket structure. These identifiers communicate essential data—including the specific basket configuration or the maximum load profile—to the dishwasher's central control unit, facilitating highly personalized and water-efficient wash programs, thus optimizing performance and supporting advanced Generative Engine Optimization capabilities for future appliance development.

Regional Highlights

Geographically, the Dishwasher Washing Basket Market exhibits diverse growth patterns influenced fundamentally by residential construction activity, household appliance penetration rates, and specific regional aesthetic and functional preferences. North America and Europe currently represent the most mature markets, characterized by high household ownership saturation and a consistent, necessity-driven replacement demand. In these regions, market emphasis is steadily shifting towards premium features, such as advanced polymer coatings with extended guarantees, fully height-adjustable upper racks that facilitate custom loading, and aesthetic finishes that align with high-end kitchen design trends. European manufacturers often prioritize compact, highly modular, and water-efficient designs to accommodate smaller kitchen footprints common across the continent, while adhering strictly to rigorous EU energy and material safety regulations.

Asia Pacific (APAC) is strategically positioned to be the fastest growing region throughout the forecast period, driven by powerful demographic and economic shifts. This accelerated growth is substantially underpinned by rapid urbanization, monumental growth in the middle-class demographic, and evolving consumer lifestyles that increasingly favor sophisticated, time-saving household appliances. While China and India lead in terms of absolute market potential due to massive population bases and escalating residential construction projects, affluent East Asian markets like South Korea and Japan drive demand for advanced, space-saving, and highly specialized basket designs tailored for smaller capacity dishwashers. The APAC market presents extensive opportunities for both localized and international manufacturers, but requires specific product adaptation to successfully accommodate regional cooking utensils (like woks and unique rice bowls) and customary serving ware sizes.

Latin America (LATAM) and the Middle East & Africa (MEA) remain strategically important emerging markets. In LATAM, market penetration is steadily increasing, particularly within major urban centers like São Paulo and Mexico City, supported by rising consumer credit availability and the adoption of modern housing standards. The market in MEA is often segmented, with high growth concentrated in affluent Gulf Cooperation Council (GCC) countries driven by luxury residential projects and high-end hospitality sectors. The institutional and commercial segments (hotels, large catering operations, and hospitals) in both these regions are essential customers, frequently requiring heavy-duty, robust, industrial-grade baskets suitable for demanding, high-volume operational cycles. Sustainable market penetration in these emerging areas relies heavily on improving infrastructural stability, reducing perceived appliance cost barriers, and effectively demonstrating the long-term utility and hygienic benefits of automated dishwashing technology.

- North America: High appliance saturation; Strong aftermarket demand; Focus on large capacity, durability, and premium, customizable features (e.g., third rack incorporation).

- Europe: Mature market; Emphasis on compact, water and energy-efficient designs; Strong regulatory pressure favoring sustainable and compliant materials; Significant OEM manufacturing cluster.

- Asia Pacific (APAC): Fastest growing region; Driven by new residential construction, rapid increase in disposable incomes, and cultural shifts; Adaptation required for local dishware profiles.

- Latin America: Gradual, consistent adoption rates; Market growth concentrated in high-density urban corridors; Price sensitivity strongly impacts material and feature choices in entry-level segments.

- Middle East & Africa (MEA): Emerging market with high commercial sector demand; Growth concentrated in urban centers and high-end hospitality; Focus on robustness for industrial use and luxury features for residential sales.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Dishwasher Washing Basket Market.- Whirlpool Corporation

- BSH Home Appliances (Bosch, Siemens)

- Electrolux AB

- Miele & Cie. KG

- Haier Group (GE Appliances)

- Ranco Industries

- HMT Group

- Zhejiang Hualing Industrial Co., Ltd.

- Summit Appliance

- LG Electronics Inc.

- Smeg S.p.A.

- Fisher & Paykel Appliances Ltd.

- Middleby Corporation

- ITW Food Equipment Group (Hobart)

- Ali Group S.r.l.

- Meiko Maschinenbau GmbH & Co. KG

- Jackson WWS, Inc.

- CMA Dishmachines

- Guangdong Xinbao Electrical Appliances Holdings Co., Ltd.

- Jiangsu Xinwei Mesh-Belt Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Dishwasher Washing Basket market and generate a concise list of summarized FAQs reflecting key topics and concerns.What materials are commonly used in high-durability dishwasher washing baskets?

High-durability dishwasher washing baskets primarily utilize heavy-gauge steel wire frames coated with specialized polymers, such as thick PVC, nylon, or epoxy powder coatings. These materials offer superior resistance to corrosion, high temperatures, and chemical degradation caused by abrasive detergents, maximizing the basket's lifespan and maintaining hygiene standards essential for long-term use.

How does the aftermarket segment influence the Dishwasher Washing Basket Market?

The aftermarket segment is crucial as it addresses replacement needs due to wear, physical damage, or consumer demand for functional upgrades like specialized cutlery or stemware inserts. It drives significant, stable sales volume independent of new appliance purchases, offering consumers flexibility and opportunities for customization, often facilitated through efficient direct-to-consumer e-commerce channels.

What are the primary design innovations driving consumer adoption in this market?

Primary design innovations focus intensively on modularity and enhanced user experience. This includes integration of quick-release adjustable tines, highly flexible folding sections to accommodate oversized pots and pans, dedicated soft-grip zones for delicate glassware, and smooth-gliding, height-adjustable upper racks, all engineered to optimize both cleaning performance and user convenience.

Which geographical region is expected to show the highest growth rate?

The Asia Pacific (APAC) region is strongly projected to exhibit the highest Compound Annual Growth Rate (CAGR) throughout the forecast period. This rapid acceleration is primarily fueled by extensive urbanization, significant infrastructure development, increasing household disposable income, and the consequent high penetration rate of integrated kitchen appliances across large emerging economies.

What role does corrosion resistance play in the market competitiveness of washing baskets?

Corrosion resistance is a non-negotiable core factor in market competitiveness. Failures in protective polymer coating lead rapidly to rust formation, which transfers staining onto dishware and drastically reduces the overall service life of the basket, necessitating premature replacement. Manufacturers leverage superior anti-corrosion materials and offer extended warranties as a key differentiator to build consumer trust and loyalty.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager