Disinfection Tunnels Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435720 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Disinfection Tunnels Market Size

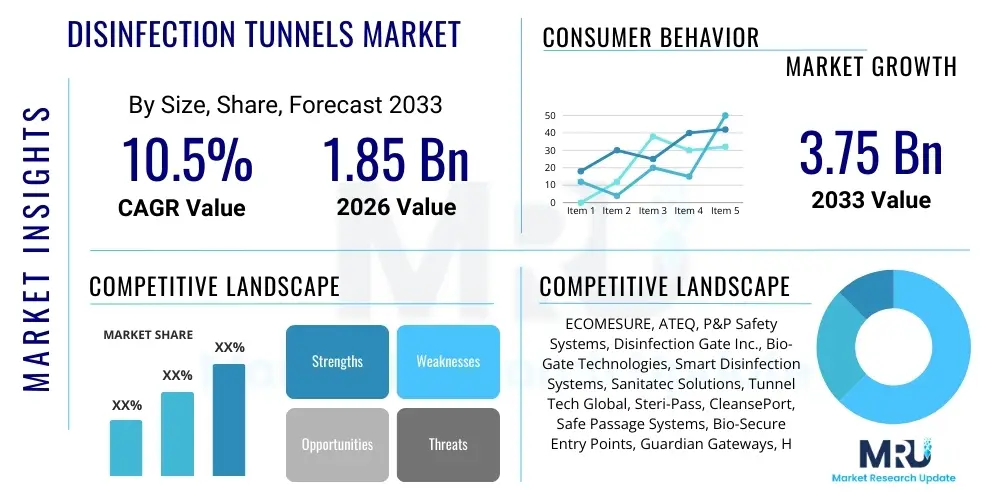

The Disinfection Tunnels Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 10.5% between 2026 and 2033. The market is estimated at USD 1.85 billion in 2026 and is projected to reach USD 3.75 billion by the end of the forecast period in 2033. This substantial expansion reflects the permanent shift in global infrastructure priorities toward proactive biosecurity and systematic pathogen mitigation strategies across key economic sectors. The valuation growth is not merely volume-driven but is significantly influenced by the rising adoption of premium, technology-intensive solutions incorporating advanced features such as AI-driven dosage optimization and non-chemical sterilization methods, which command higher average selling prices compared to the rudimentary systems deployed during the initial phase of the global health crisis. Furthermore, increasing regulatory clarity and the necessity for certified, long-term installations in critical infrastructure, including aviation, maritime logistics, and large-scale public facilities, underpin the steady growth trajectory and upward revision of market valuation throughout the forecast horizon, securing its position as a vital segment of the broader public safety technology market.

Disinfection Tunnels Market introduction

Disinfection tunnels, frequently branded as sanitized gateways or personnel decontamination chambers, represent a critical evolutionary step in public and institutional biosecurity infrastructure. These automated systems are engineered to administer a fine mist or aerosolized dry fog of approved disinfectant agents, or utilize non-chemical methods such as UV-C light, upon individuals, baggage, or vehicles traversing a designated entry point. The fundamental design premise is rooted in providing a rapid, non-contact method of decontaminating external surfaces, effectively mitigating the transmission pathways of pathogens, particularly viruses and bacteria carried on clothing, skin, or personal belongings. The product typology is varied, encompassing simple, temporary polyvinyl structures deployed during acute emergencies, to permanent, industrial-grade stainless steel portals integrated into major infrastructure, reflecting the specialized requirements of diverse end-user sectors such as aviation, healthcare, and large-scale manufacturing facilities where continuous operational sterility is paramount. The global impetus for their development and accelerated adoption stemmed directly from the necessity for scalable, systematic hygiene protocols necessitated by the sustained threat of infectious disease outbreaks, transitioning the technology from a niche application in biocontainment facilities to a mainstream public health solution, thereby institutionalizing hygiene control measures far beyond temporary mandates.

The operational mechanism involves several integrated subsystems, including a high-precision dosing system for chemical agents, anti-drip atomization nozzles, motion sensors to trigger the process only when occupied, and often, an integrated drainage or recirculation mechanism for spent disinfectant solutions. Recent innovations have significantly addressed earlier critiques regarding the efficacy and safety of chemical exposure, by moving towards ultra-low volume (ULV) fogging techniques that ensure optimal particle size for surface adhesion without causing discomfort or hazardous accumulation on personnel. Furthermore, the incorporation of thermal screening cameras for elevated body temperature detection and automated access control gates has transformed these tunnels into multifaceted biosecurity checkpoints. This evolution signifies a move beyond mere surface decontamination to integrated health monitoring, offering facilities management tools that combine physical security with advanced epidemiological surveillance capabilities, thereby justifying the substantial capital investment through enhanced safety and data-driven risk management. Manufacturers are increasingly focusing on modular designs that simplify transportation and installation while maintaining rigorous standards for chemical resistance and electrical safety under continuous high-humidity operation, which is critical for maximizing system longevity and reducing the maintenance footprint across varied global climates.

The primary applications are geographically and vertically diverse, yet consistently focus on high-density traffic areas or environments requiring clinical-level cleanliness. Airports and major public transportation hubs utilize high-throughput models to process thousands of travelers hourly, aiming to reassure the public and reduce environmental viral load. In the corporate and education sectors, tunnels serve as a visible commitment to employee and student safety, installed at building entrances to minimize the risk of internal transmission chains. Major applications are concentrated in sectors requiring stringent contamination control, such as food processing plants, pharmaceutical manufacturing facilities, and secure government buildings, where preventing external contamination is paramount to operational integrity and regulatory compliance. Driving factors for market expansion include escalating regulatory pressure from international health bodies (such as the WHO and local governmental health agencies) mandating proactive contamination controls, alongside continuous performance improvements in nozzle technology, pump reliability, and the development of safer, broad-spectrum, hospital-grade disinfectants suitable for human exposure. The economic imperative of avoiding costly operational shutdowns caused by outbreaks further accelerates institutional adoption across global supply chains and critical infrastructure sectors, solidifying the market’s long-term stability.

Disinfection Tunnels Market Executive Summary

The Disinfection Tunnels Market exhibits robust, normalized growth trajectories following the initial surge in demand, primarily fueled by the sustained focus on public health preparedness and the integration of smart, AI-driven technologies into decontamination processes. Business trends indicate a definitive strategic shift away from rudimentary, chemical-heavy spraying booths towards sophisticated, integrated biosecurity portals featuring UV sterilization, ozone technology, and comprehensive data logging capabilities crucial for compliance monitoring and liability management. Key market participants are aggressively concentrating on customization and vertical specialization, offering tailored solutions for high-risk segments such as pharmaceutical cleanrooms and highly sensitive customs checkpoints, demanding systems with superior efficacy verification. Furthermore, strategic alliances between disinfection technology developers and major facility management or building automation companies are becoming the primary mechanism for scaling market penetration and ensuring long-term contractual service provision, moving the revenue model towards recurring maintenance and supply agreements rather than relying solely on initial equipment sales.

Regional trends distinctly illustrate a divergence in maturity levels and technological preferences. The Asia Pacific (APAC) region continues to lead the market volume, initially driven by stringent governmental responses and the rapid deployment required by high population densities. However, North America and Europe are defining the high-value segment, characterized by slower but more sustainable growth driven by the permanent incorporation of advanced biosecurity standards into existing critical infrastructure—particularly in healthcare, aviation logistics, and data centers. Demand in these mature markets is weighted heavily toward non-chemical, certified UV-C solutions that meet rigorous occupational safety standards and offer seamless interoperability with legacy building control systems. Conversely, developing economies in Latin America and the Middle East and Africa (MEA) represent significant future opportunities, largely dependent on renewed government subsidies and increasing foreign direct investment into modernizing public infrastructure and transportation networks, thereby creating a sustained demand for scalable, cost-effective, and rapidly deployable sanitation solutions.

Segment trends underscore the enduring dominance of walkthrough (full-body) systems in terms of overall unit shipments, although specialized segments, particularly baggage, cargo, and dedicated vehicle disinfection tunnels, are rapidly gaining market share, directly correlating with the rebound in international trade volume and regulatory tightening around freight sanitation. In the technological segmentation, chemical disinfection remains the most widely deployed methodology due to its low initial cost and operational simplicity, yet the UV-C and non-chemical segment is projected to show the fastest Compound Annual Growth Rate over the forecast period. This rapid growth is a direct consequence of increasing regulatory stringency regarding chemical exposure and mounting consumer demand for environmentally safer, residue-free decontamination methods. The healthcare, manufacturing, and corporate sectors remain the leading end-users, increasingly adopting premium, sensor-equipped models that offer high levels of integration with existing Building Management Systems (BMS), prioritizing efficiency, real-time data transparency, and minimizing potential operational downtime caused by suboptimal manual hygiene procedures.

AI Impact Analysis on Disinfection Tunnels Market

User queries regarding AI’s profound influence on the Disinfection Tunnels Market frequently revolve around optimizing disinfectant usage, enhancing detection accuracy, and predicting peak usage times for resource allocation and energy management. Common public concerns center on whether AI systems can responsibly personalize disinfection based on individual risk profiles without violating privacy laws, and how completely autonomous systems might replace human monitoring of chemical levels, equipment calibration, and rapid incident response protocols. Industry stakeholders express high expectations for AI integration to fundamentally transform current tunnels from passive spray booths into smart, adaptive biosecurity checkpoints capable of real-time threat assessment. Specifically, AI is expected to excel in anomaly detection (identifying unauthorized bypass attempts) and ensuring user compliance with safety protocols, ultimately aiming for superior operational efficiency, verifiable efficacy, and a radical reduction in chemical waste, positioning the technology for wider acceptance in highly regulated environments.

AI and machine learning (ML) primarily impact the market by exponentially enhancing the operational intelligence and efficiency of disinfection systems, moving beyond simple automation to genuine adaptive control. Computer vision, a key component of AI, is utilized within tunnels through stereoscopic or depth-sensing cameras to accurately count personnel throughput, identify non-compliant individuals (e.g., those wearing inappropriate gear or failing to remain stationary for the requisite period), and integrate seamlessly with existing access control or turnstile systems. Furthermore, sophisticated ML algorithms are absolutely crucial for implementing predictive maintenance protocols. These models meticulously analyze heterogeneous sensor data—including parameters such as pressure, humidity, air density, disinfectant viscosity, and ambient temperature—to anticipate subtle mechanical degradations or electrical failures before they result in critical downtime. This predictive capability significantly reduces unplanned service interruptions, which is an invaluable benefit in high-throughput critical infrastructure settings like major international airports or complex pharmaceutical manufacturing plants where operational continuity is non-negotiable.

The most transformative and economically significant application of AI involves optimizing the disinfection process itself through dynamic control mechanisms. By continuously analyzing environmental variables (such as localized temperature and humidity, which affect droplet evaporation rates) and user-specific data (traffic volume density, time of day), AI models can dynamically adjust the spray duration, mist intensity, and even the precise concentration of the disinfectant mixture delivered. This immediate, data-driven optimization minimizes chemical expenditure, ensures precise compliance with necessary pathogen contact times for verified efficacy, and drastically reduces potential chemical exposure risks for the user, thereby improving both the cost-effectiveness and the crucial safety profile of the technology. Advanced data analytics provided by integrated AI components offer facility managers actionable, real-time insights into traffic flow patterns and potential peak contamination points, enabling highly targeted and resource-efficient biosecurity strategies across expansive organizational campuses and maximizing the effectiveness of every operational cycle.

- AI-driven personalized dosage based on user throughput and environmental data.

- Real-time anomaly detection and compliance monitoring using computer vision.

- Predictive maintenance scheduling for nozzles, pumps, and sensors.

- Integration of thermal imaging and facial recognition for risk-based access control.

- Optimization of disinfectant consumption and waste reduction via ML algorithms.

- Automated reporting and data logging for stringent regulatory compliance.

- Enhanced system diagnostics and remote fault resolution capabilities via connected AI platforms.

- Adaptation of mist particle size and intensity based on detected surface material types (e.g., sensitive electronics vs. industrial fabrics).

DRO & Impact Forces Of Disinfection Tunnels Market

The market dynamics of disinfection tunnels are shaped by a complex, intense interplay of structural Drivers, critical Restraints, and latent Opportunities (DRO), which collectively form the significant impact forces determining profitability and expansion. Key drivers compelling growth include the accelerated institutionalization of global biosecurity awareness, directly necessitated by successive pandemic events and the resultant governmental prioritization of long-term public health infrastructure spending worldwide. The core benefit of minimizing localized surface transmission in high-density environments, coupled with escalating regulatory pressure across sectors to maintain stringent, verifiable hygiene standards (particularly within food processing, medical device manufacturing, and pharmaceutical logistics), provides sustained and non-cyclical market momentum. Furthermore, continuous technological advancements, especially the development and certified deployment of safer, non-chemical sterilization methods such as high-intensity UV-C light and sophisticated hydrogen peroxide dry fogging techniques, significantly broaden the applicability and regulatory acceptance of these systems across diverse, highly regulated industry verticals, thereby substantially pushing long-term market expansion.

Conversely, the market growth faces notable, persistent structural restraints, predominantly centered on the high cost-benefit analysis and unresolved public safety perceptions. The substantial initial capital investment required for sophisticated, automated systems—especially premium models incorporating advanced sensor suites, AI features, and certified UV technology—poses a significant barrier to entry for Small and Medium Enterprises (SMEs) and many public sector entities in developing economies. A major limiting impact force remains the pervasive regulatory uncertainty and consumer apprehension concerning the long-term safety and proven efficacy of chemical disinfectants when applied repeatedly to humans. This skepticism necessitates manufacturers to invest heavily in costly clinical trials and secure stringent safety certifications, and this debate often limits widespread adoption in general public-facing areas in mature markets. Moreover, the necessity for robust, specialized maintenance, reliable supply chains for certified chemicals, and the inherent risk of equipment malfunction during continuous, 24/7 high-volume operation further dampens immediate growth potential, mandating comprehensive service level agreements to mitigate user risk.

The most promising opportunities for significant, sustained market growth are substantial and strategically reside in niche, high-value applications and aggressive geographical expansion. The burgeoning, largely unmet demand for specialized, high-capacity tunnels dedicated exclusively to freight, parcels, logistics equipment, and large vehicles presents a highly lucrative avenue, notably because this segment is entirely decoupled from the human exposure safety concerns that plague walkthrough systems. Furthermore, the systematic development of modular, easily deployable, and low-cost versions tailored specifically for mass transportation systems (e.g., subway networks, large railway stations) and temporary event infrastructure (e.g., international expos, sporting events) represents a substantial short-to-medium term growth opportunity, particularly in emerging economies where rapid deployment and cost-effectiveness are prioritized over premium features. The overriding global pivot towards sustainable sanitation solutions, leveraging non-toxic chemistry or purely physical sterilization methods (like UV-C and advanced thermal treatments), offers a crucial, regulatory-driven market pivot, successfully aligning the industry with increasingly stricter global Environmental, Social, and Governance (ESG) standards, thereby securing the technology’s regulatory and financial viability in the long run.

Segmentation Analysis

The Disinfection Tunnels Market is comprehensively segmented based on key functional attributes including the underlying technology employed, the specific end-user application environment, the required throughput capacity, and system mobility (fixed vs. mobile deployment). This detailed segmentation framework is indispensable for precise market sizing, identifying critical competitive white spaces, and enabling strategic tailoring of product offerings to meet the highly varied and distinct requirements of different industry verticals—ranging from the high-volume, continuous throughput needs of public transportation networks to the ultra-high sterility and verification standards required in pharmaceutical compounding or clinical research manufacturing facilities. The current market structure clearly reveals a competitive landscape where companies differentiate themselves by specializing in either cost-efficient, high-volume chemical-based solutions or premium, high-safety non-chemical solutions, with end-user regulatory requirements and operational environments ultimately dictating product customization concerning materials engineering, control software capabilities, and integration protocols, ensuring optimal functionality across the global spectrum of operational needs.

The primary technological segmentation separates the market into Chemical and Non-Chemical approaches. Chemical methods, while cost-effective, face mounting pressure, driving the rapid expansion of the Non-Chemical segment which includes UV-C, advanced Ozone generation systems, and specialized thermal or plasma sterilization techniques that leave no physical or chemical residue. Application segmentation highlights the divergence between human-focused walkthrough tunnels and high-value cargo/vehicle tunnels, which are critical for supply chain integrity. Furthermore, end-user segmentation clearly indicates distinct purchasing criteria: healthcare facilities prioritize verified efficacy and safety certifications, while transportation hubs prioritize robust build quality and high-speed throughput capacity, directly influencing the design and engineering specifications required from market vendors to effectively compete across these diverse functional requirements.

- Technology: Chemical Disinfection Tunnels (Fogging/Misting), Non-Chemical Disinfection Tunnels (UV-C Systems, Ozone Systems, Hydrogen Peroxide Vapor Systems).

- Application: Human Walkthrough Tunnels (Personnel Decontamination), Baggage/Cargo Disinfection Tunnels (Logistics Sanitation), Vehicle Disinfection Systems (Trucks, Vans, Mass Transit).

- End-User: Healthcare Facilities (Hospitals, Clinics, Research Labs), Corporate & Commercial Buildings (Offices, Retail), Educational Institutions (Universities, Schools), Transportation Hubs (Airports, Railways, Ports), Industrial & Manufacturing (Food Processing, Pharmaceuticals, Electronics), Government & Public Sector (Customs, Border Control).

- Type: Fixed/Permanent Tunnels (Integrated into facility infrastructure), Mobile/Portable Tunnels (Rapidly deployable, modular units).

- Operational Capacity: Low Capacity (500 passages/day), Medium Capacity (500–2000 passages/day), High Capacity (> 2000 passages/day).

Value Chain Analysis For Disinfection Tunnels Market

The comprehensive value chain for the Disinfection Tunnels Market initiates with the highly specialized upstream analysis, focusing on the procurement and manufacturing of sophisticated components critical to system function and longevity. This initial stage involves securing specialized high-pressure pumping systems, corrosion-resistant atomization nozzles (often requiring self-cleaning or anti-clogging technology), advanced sensor arrays (PIR motion detectors, thermal scanners, flow meters, chemical concentration sensors), and rugged industrial-grade control unit microprocessors (PLCs). A major upstream challenge involves securing a reliable supply chain for certified materials, predominantly high-grade stainless steel fabrication, which is essential to guarantee chemical resistance and structural longevity in corrosive, high-humidity operating environments. Efficiency in this upstream segment is critically important, as the quality and integrated cost of these specialized components directly dictate the final product’s reliability, price point, and maintenance demands, effectively distinguishing premium, long-lifecycle offerings from standard, temporary models.

Downstream activities encompass the complex, specialized processes of final system assembly, rigorous calibration, integration testing, and ensuring strict regulatory compliance prior to market deployment. Manufacturers must meticulously navigate complex and often divergent international regulatory environments to ensure the safety certification of both the specialized hardware and, crucially, the chemical agents intended for use, which requires extensive, documented testing validation and comprehensive compliance certification (e.g., FDA approvals, CE markings). The market features two primary distribution channels: direct sales channels are preferentially utilized for large, highly customized installations (such as major government security contracts, specialized industrial clients, or multi-site hospital networks), allowing manufacturers to provide comprehensive, integrated installation services and long-term, detailed service agreements. Conversely, indirect channels, involving regional third-party distributors, local systems integrators, and specialized safety equipment resellers, are leveraged for penetrating fragmented markets, targeting smaller commercial clients, and facilitating the rapid, regional deployment of standardized, modular tunnel units.

Effective logistics management, timely installation, and robust, ongoing post-installation service are paramount factors for ensuring long-term profitability and sustaining market leadership in this technically demanding sector. Given that these complex systems necessitate regular preventative maintenance, precise sensor calibration, prompt repair of wear components, and mandatory, timely chemical or UV lamp replenishment, establishing an extensive and reliable service network is fundamental to the overall business model. Critically, profitability margins are frequently stabilized and enhanced not just by the initial high-value equipment sale, but significantly by generating substantial, reliable recurring revenue streams derived from long-term Service Level Agreements (SLAs), essential replacement parts sales, and mandatory periodic operational and safety audits. Furthermore, due to the specialized nature of the necessary, certified disinfectants, developing strategic, exclusive partnerships with major chemical suppliers often becomes an essential, integrated component of the overall value proposition, guaranteeing product quality, supply chain consistency, and adherence to strict operational health and safety standards for the end-user base globally.

Disinfection Tunnels Market Potential Customers

Potential customers for Disinfection Tunnels are exceptionally diverse, spanning both the public and extensive private sectors, with procurement decisions systematically influenced by stringent occupational safety mandates, necessary public health requirements, and substantial insurance liability considerations. Primary end-users include large governmental entities, such as those responsible for border control, national defense installations, and maintaining centralized public health infrastructure, which typically necessitate the procurement of high-capacity, robust fixed installations designed for sustained operational readiness during acute health crises or long-term institutional biosecurity maintenance. The high-value corporate sector, particularly multinational corporations operating major industrial complexes, high-volume manufacturing facilities, or sprawling logistics and distribution hubs, represents a critical, high-volume purchasing segment, driven fundamentally by the need to guarantee worker safety, minimize costly operational disruptions, and visibly uphold investor and public confidence through comprehensive, transparent biosecurity protocols.

The critical healthcare sector, encompassing hospitals, specialized clinics, sophisticated bio-containment laboratories, and pharmaceutical development facilities, remains a perpetual core customer base. This sector consistently focuses demand on advanced, low-exposure disinfection technologies, often favoring certified non-chemical methods (such as UV-C or VHP) to effectively prevent cross-contamination between ultra-sensitive clinical areas and general public access points. Furthermore, the accelerating rebound of global commercial and leisure travel fundamentally necessitates the robust, systematic adoption of these systems by all major transportation hubs—including international airports, major seaports, and high-speed railway terminals—not only for mandatory passenger screening but, increasingly, for the highly efficient, systematic cargo and baggage decontamination required, aligning fully with evolving, complex international hygiene and customs regulations designed to mitigate transboundary pathogen spread.

In rapidly emerging urban centers, densely populated areas, and large commercial markets, the institutional education sector (major university campuses and expansive school complexes) and high-traffic commercial spaces (such as large shopping malls, sports stadiums, and convention centers) are adopting modular and mobile tunnel solutions with increasing frequency. These specific buyer segments predominantly prioritize ease of deployment, rapid installation, scalability based on event schedules, and critical cost-effectiveness. Crucially, purchasing criteria across all key segments are demonstrating a clear shift, increasingly favoring suppliers who can provide demonstrable, independent efficacy verification, offer comprehensive, non-negotiable long-term maintenance packages, and ensure robust integration capabilities with existing physical security infrastructure and complex Building Management Systems (BMS), viewing the disinfection tunnel not as a standalone purchase but as an essential, intelligent layer of modern, integrated facility risk management infrastructure.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 3.75 Billion |

| Growth Rate | 10.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ECOMESURE, ATEQ, P&P Safety Systems, Disinfection Gate Inc., Bio-Gate Technologies, Smart Disinfection Systems, Sanitatec Solutions, Tunnel Tech Global, Steri-Pass, CleansePort, Safe Passage Systems, Bio-Secure Entry Points, Guardian Gateways, Hygo-Tech Innovations, Aerosan Systems, EnviroGuard Solutions, Global Safety Solutions, Decon-Entry Systems, Precision Fogging Solutions, SecureFlow. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Disinfection Tunnels Market Key Technology Landscape

The technological landscape of the Disinfection Tunnels Market is undergoing rapid and crucial diversification, systematically moving far beyond rudimentary, single-function liquid-based spraying systems towards multi-modal, intelligent biosecurity platforms. The foundational technology in chemical-based systems involves sophisticated fluid mechanics and specialized fogging or misting systems, often utilizing ultra-low volume (ULV) atomization nozzles engineered to produce highly uniform micro-droplets (typically sized between 5 and 20 microns). This specific droplet size ensures maximum surface coverage efficiency and prolonged suspension time, critical for effective surface sterilization, while significantly minimizing the total liquid volume needed and reducing potential oversaturation or wetting effects on personnel. The chemical agents predominantly used remain variants of diluted sodium hypochlorite, advanced quaternary ammonium compounds (Quats), or stabilized hydrogen peroxide solutions, selected based on broad-spectrum efficacy and regulatory approval for use in public-facing applications. The persistent operational challenge involves precisely managing the necessary disinfectant contact time within the confines of a quick passage, which has driven innovations in tunnel length, internal airflow dynamics, and the integration of precision sensor systems designed to verify adequate exposure.

A key, rapidly accelerating technological segment is focused on certified non-chemical disinfection, predominantly led by high-intensity Germicidal Ultraviolet (UV-C) light technology. These systems strategically employ high-intensity emitters, either traditional low-pressure mercury vapor lamps or emerging, long-life solid-state UV LEDs, that precisely emit light energy in the critical germicidal spectrum (optimized around 254 nanometers). This specific energy delivery mechanism efficiently disrupts the fundamental DNA and RNA structure of pathogens, effectively neutralizing their ability to reproduce without introducing any chemical residue or requiring subsequent drying. While highly efficacious and eliminating all risks associated with chemical exposure, the system design mandates extremely stringent safety protocols; this includes robust internal radiation shielding, optical baffling systems, and multi-redundant, fail-safe sensor-based cut-offs that instantly terminate emitter function if direct or reflected UV exposure to occupants is detected. Similarly, advanced ozone generation systems and specialized hydrogen peroxide dry fogging (VHP) technologies are gaining substantial traction, particularly in high-demand niche applications requiring ultra-high levels of residual-free sterilization integrity, such as aerospace component manufacturing, pharmaceutical cleanrooms, and high-containment laboratories, offering superior penetration into complex geometrical surfaces and guaranteeing minimized residue buildup.

Future advancements and competitive differentiation are now heavily concentrated on maximizing integration, achieving seamless connectivity, and deploying genuine smart functionality. This includes systematically deploying comprehensive sensor suites—such as LiDAR for precise volumetric measurement, integrated thermal cameras for immediate fever screening, and highly accurate chemical sensors for monitoring airborne disinfectant concentration—all centrally managed by an advanced IoT-enabled control unit. The critical technological emphasis is rapidly shifting towards developing truly modular, software-defined, and fully adaptable systems capable of rapid configuration, intelligent pathogen risk assessment, and efficient deployment across significantly diverse environmental conditions and operational throughput requirements. Standardization efforts, particularly concerning chemical compatibility, API integration standards, and certified electrical safety protocols in high-humidity conditions, are driving premium manufacturers to adopt ruggedized, industrial-grade components and implement cloud-enabled reporting platforms for continuous, remote performance monitoring, advanced predictive diagnostics, and centralized data logging, ensuring verifiable compliance with stringent global occupational safety and public health standards while maximizing operational lifespan.

Regional Highlights

- Asia Pacific (APAC): Market leader due to high population density and governmental mandates; focus on high-volume throughput and diversified end-user adoption (public transport, commerce, education). This region drives significant demand for cost-effective, high-reliability systems and is rapidly increasing adoption of integrated biosecurity solutions in its massive manufacturing and logistics sectors, solidifying its volume dominance.

- North America: High-value market focused on permanent, advanced installations in healthcare and logistics; prioritizing UV-C technology and AI-driven predictive maintenance. Growth here is primarily driven by stringent regulatory compliance requirements and the high willingness of corporate and institutional buyers to invest in premium, long-term, certified safety solutions that minimize liability and operational risk.

- Europe: Driven by strict regulatory safety standards and ESG compliance; strong uptake in corporate offices and manufacturing, favoring non-chemical and certified systems. The emphasis in European markets is heavily placed on sustainability, validated efficacy, and systems that offer full integration with existing environmental and security management infrastructure, reflecting a mature and highly discerning buyer base.

- Latin America (LATAM): Growth catalyzed by rapid urbanization and infrastructure investment; demand for cost-effective and modular solutions for public use. Market expansion is concentrated in major urban hubs and hinges on public sector investment in improving transportation and tourism safety, with strong potential for mobile and rapidly deployable units.

- Middle East and Africa (MEA): Emerging market concentrated around major transport hubs and critical industrial zones; growth influenced by government tourism and biosecurity investments. Market activity is often project-based, linked to large-scale infrastructure developments, oil and gas operations, and governmental efforts to diversify economies through enhanced regional safety standards and technology adoption.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Disinfection Tunnels Market.- ECOMESURE

- ATEQ

- P&P Safety Systems

- Disinfection Gate Inc.

- Bio-Gate Technologies

- Smart Disinfection Systems

- Sanitatec Solutions

- Tunnel Tech Global

- Steri-Pass

- CleansePort

- Safe Passage Systems

- Bio-Secure Entry Points

- Guardian Gateways

- Hygo-Tech Innovations

- Aerosan Systems

- EnviroGuard Solutions

- Global Safety Solutions

- Decon-Entry Systems

- Precision Fogging Solutions

- SecureFlow

Frequently Asked Questions

Analyze common user questions about the Disinfection Tunnels market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected growth rate (CAGR) for the Disinfection Tunnels Market?

The Disinfection Tunnels Market is projected to exhibit a steady Compound Annual Growth Rate (CAGR) of 10.5% during the forecast period spanning from 2026 to 2033, driven by sustained global biosecurity investments and the permanent institutional adoption of decontamination technology across critical infrastructure sectors.

What are the primary restraints affecting market growth?

Key restraints include the relatively high initial capital expenditure required for advanced, certified systems, along with persistent public health debates, regulatory ambiguities regarding human exposure, and the lack of universal standardization across different international jurisdictions.

Which technology segment is expected to grow the fastest?

The Non-Chemical Disinfection Tunnels segment, specifically those utilizing UV-C light, advanced ozone, and dry hydrogen peroxide fogging technologies, is anticipated to record the fastest growth, propelled by increasing demands for superior safety, environmental sustainability, and adherence to strict residue-free operational standards.

How does AI impact the operational efficiency of disinfection tunnels?

AI integrates computer vision for robust, real-time compliance monitoring and utilizes machine learning algorithms to dynamically optimize disinfectant dosage and application timing based on real-time traffic volume, environmental conditions, and material detection, significantly reducing waste and improving verifiable operational efficacy and safety metrics.

Which region currently holds the largest market share for disinfection tunnels?

The Asia Pacific (APAC) region currently dominates the market share, primarily due to high population density, proactive, widespread government mandates for public health measures, and rapid, extensive deployment in public transport, large commercial infrastructure, and industrial sectors across the region.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager