Disposable Electrosurgical Pencil Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435537 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Disposable Electrosurgical Pencil Market Size

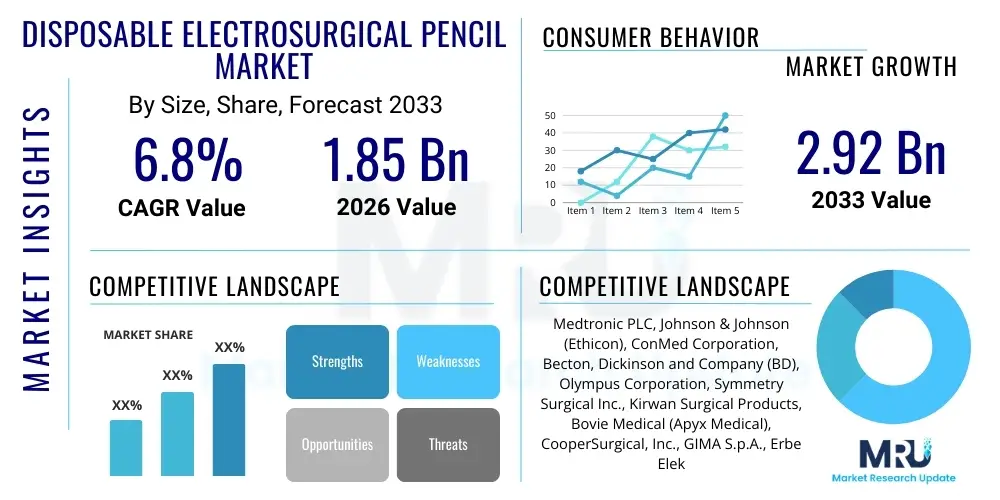

The Disposable Electrosurgical Pencil Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.85 billion in 2026 and is projected to reach USD 2.92 billion by the end of the forecast period in 2033. This consistent expansion is primarily fueled by the increasing global volume of surgical procedures, particularly in minimally invasive surgery, where disposable tools are favored for enhanced patient safety and reduced infection risk. Furthermore, the growing elderly population, which frequently requires surgical interventions for chronic diseases, contributes significantly to the sustained demand for these essential medical devices, driving steady revenue growth across all major geographical regions.

Disposable Electrosurgical Pencil Market introduction

The Disposable Electrosurgical Pencil Market encompasses the devices used for cutting, coagulating, and desiccating tissue during surgical procedures through the application of high-frequency electrical current. These single-use instruments, crucial across various surgical specialties including general surgery, gynecology, cardiology, and orthopedics, offer superior sterility and eliminate the risks associated with reprocessing reusable instruments, making them a preferred choice in modern healthcare settings. The primary product is typically an ergonomic pencil-shaped handpiece integrating an electrode, which delivers controlled electrical energy to the surgical site, ensuring precision and minimizing thermal damage to surrounding healthy tissue. The versatility, safety profile, and efficiency of these devices solidify their indispensable role in operating rooms globally.

Major applications of disposable electrosurgical pencils span complex surgical interventions, ranging from simple incision and excision to detailed tumor removal and vessel sealing. The benefits driving their adoption include reduced cross-contamination risk, consistent device performance, and cost-effectiveness in managing sterilization overheads associated with reusable equipment. Furthermore, advancements in pencil design, such as smoke evacuation features and integrated suction capabilities, enhance visibility and improve the safety environment for surgical teams, thereby accelerating market penetration in both developed and emerging economies. These technological enhancements are key drivers ensuring clinical preference for disposable solutions.

Key driving factors supporting the robust growth of this market include the global rise in healthcare expenditure, increasing incidence of chronic diseases requiring surgical treatment, and stringent regulatory mandates promoting single-use medical devices to mitigate Hospital-Acquired Infections (HAIs). The shift towards disposable solutions is also amplified by the logistical challenges and high maintenance costs associated with sterilizing complex electrosurgical instruments. Continuous innovation by manufacturers, focusing on improved ergonomics, advanced tip materials, and enhanced safety mechanisms, further solidifies the market's positive trajectory through the forecast period.

Disposable Electrosurgical Pencil Market Executive Summary

The Disposable Electrosurgical Pencil Market is characterized by robust business trends driven by high surgical procedure volumes and a strong institutional preference for single-use devices to ensure sterility and mitigate HAIs. Manufacturers are focused on integrating safety features, such as audible and visible indicators and better insulation, while optimizing manufacturing processes to meet increasing global demand efficiently. Business growth is particularly evident in the standardization of operating room (OR) protocols across large hospital networks favoring centralized procurement of disposable devices. This consolidation trend, coupled with strategic partnerships between medical device companies and group purchasing organizations (GPOs), is streamlining distribution and stabilizing pricing strategies across the highly competitive landscape.

Regionally, North America and Europe dominate the market, largely due to sophisticated healthcare infrastructure, high awareness regarding infection control, and early adoption of advanced surgical technologies. However, the Asia Pacific (APAC) region is projected to exhibit the fastest growth, fueled by rapidly improving healthcare access, increasing medical tourism, and substantial government investments aimed at modernizing surgical facilities in countries like China and India. The regional trends highlight a transition in emerging markets from traditional reusable equipment to safer, disposable alternatives, creating lucrative opportunities for market penetration and expansion focused on localized manufacturing and efficient supply chains.

In terms of segments, the market is primarily segmented by product type (push-button and rocker-switch), application (general surgery, gynecological, cardiovascular, orthopedic), and end-user (hospitals, ambulatory surgical centers, specialized clinics). The push-button electrosurgical pencils maintain market dominance due to their intuitive functionality and widespread use across diverse surgical specialties. The hospital segment remains the largest end-user, though ambulatory surgical centers (ASCs) are the fastest-growing segment, driven by the increasing trend of performing less complex procedures in outpatient settings, which significantly boosts demand for readily available disposable tools tailored for efficiency and speed.

AI Impact Analysis on Disposable Electrosurgical Pencil Market

User queries regarding AI's impact on disposable electrosurgical pencils frequently center on whether Artificial Intelligence (AI) can enhance the function, safety, or manufacturing of these otherwise simple devices, and how data generated during electrosurgery might be utilized. Users express expectations that AI could optimize energy delivery, potentially minimizing thermal spread and improving surgical outcomes, while simultaneously reducing the reliance on manual adjustments by the surgeon. Key concerns revolve around the ethical deployment of AI in medical device manufacturing logistics, predicting supply chain bottlenecks, and refining quality control systems to ensure zero-defect production of high-volume disposable instruments. The primary theme is leveraging AI/ML to transition from standard manufacturing practices to predictive, high-precision automated systems, offering significant improvements in device reliability and operational efficiency for high-volume, cost-sensitive medical consumables.

- AI-driven optimization of manufacturing lines enhances precision in assembly and reduces waste materials, critical for high-volume disposable items.

- Predictive maintenance models for manufacturing equipment minimize downtime, ensuring consistent supply chains for pencils.

- Machine learning algorithms can analyze real-time tissue impedance data during surgery (captured by the electrosurgical unit) to suggest optimal power settings, enhancing surgical precision.

- AI assists in analyzing post-market surveillance data, identifying potential material failures or design flaws in disposable pencils more rapidly than traditional methods.

- Logistical AI optimizes inventory management and distribution networks for disposable medical supplies, reducing stockouts in critical surgical settings.

- Computer vision systems powered by AI are utilized in quality control to inspect electrode tips and insulation integrity at microscopic levels during production.

DRO & Impact Forces Of Disposable Electrosurgical Pencil Market

The Disposable Electrosurgical Pencil Market is significantly influenced by powerful market dynamics, where the principal driver is the imperative for enhanced patient safety, strictly enforced by regulatory bodies prioritizing single-use devices to combat HAIs. Restraints often revolve around price sensitivity in emerging markets, where high-volume tenders pressure manufacturers to reduce margins, alongside environmental concerns regarding the increasing volume of non-biodegradable medical waste generated by disposable products. Opportunities are plentiful in emerging economies characterized by rapid healthcare infrastructure development and in the integration of specialized functionalities, such as advanced smoke evacuation systems or specialized non-stick coatings, into standard disposable pencil designs. These market forces collectively shape investment decisions, product development pathways, and regional penetration strategies, driving sustained innovation within the electrosurgery device ecosystem.

Key drivers include the global increase in surgical procedures across multiple specialties, particularly minimally invasive surgeries which require precise and reliable disposable instruments. The growing geriatric population necessitates a higher frequency of surgical interventions for cardiovascular, orthopedic, and oncological conditions, directly boosting the demand for electrosurgical pencils. Furthermore, the simplicity and immediate readiness for use, coupled with the elimination of complex sterilization protocols, make disposables highly appealing to busy surgical centers and hospitals seeking operational efficiencies and guaranteed sterility. Regulatory emphasis on reducing reprocessing failures acts as a significant catalyst for market growth.

However, major restraints impacting market expansion include stringent regulatory hurdles related to medical device approval, especially in economically mature markets, which lengthen the time-to-market for new innovations. The high volume of plastic and metal waste generated by disposable devices also raises serious sustainability concerns, prompting some healthcare providers to explore reusable alternatives or demand more environmentally friendly product designs. Additionally, intense pricing pressure, particularly in high-volume public healthcare systems, restricts profitability for smaller or less diversified manufacturers, leading to market consolidation and a focus on cost-efficient bulk production methods.

Opportunities for growth lie in the untapped potential of emerging markets, where healthcare access is expanding and the adoption of modern surgical techniques is accelerating. Technological opportunities include the development of smart electrosurgical pencils integrated with RFID or NFC technology for better inventory tracking and automated parameter setting, improving workflow efficiency. Furthermore, manufacturers focusing on specialty pencils tailored for specific procedures, such as bariatric or robotic surgery, can command premium pricing and capture niche market segments, driving overall market value upward through specialized, high-performance disposable tools.

Segmentation Analysis

The Disposable Electrosurgical Pencil Market is extensively segmented based on key parameters including product type, application, and end-user, reflecting the diverse requirements of the global surgical landscape. Understanding these segments is crucial for manufacturers to tailor their product development, marketing, and distribution strategies effectively. The performance and design variations across segments, such as the differentiation between push-button and rocker-switch models, directly influence clinical preference and procurement patterns across various surgical theaters. Analysis of these segments reveals that while general surgery constitutes the largest application base due to sheer volume, specialty segments like neurosurgery and cardiovascular procedures often drive demand for higher-specification, technologically enhanced disposable pencils.

Segmentation by product type typically focuses on the mechanism used to activate cutting or coagulation modes, with the push-button model offering clear, separate activation controls, making it popular for complex procedures requiring quick mode switching. The rocker-switch model, while often simpler and more cost-effective, also maintains a strong market presence, particularly in less specialized settings. Application segmentation is vital, as the specific requirements (e.g., length, tip material, insulation tolerance) for ophthalmic surgery differ significantly from those for orthopedic surgery, leading to product specialization and targeted sales efforts. The continued evolution of surgical techniques mandates that market players offer a comprehensive portfolio addressing these segmented needs.

End-user segmentation highlights the shifting dynamics within healthcare delivery. Hospitals, traditionally the dominant purchasers, continue to drive volume, but the accelerated growth of Ambulatory Surgical Centers (ASCs) is changing the consumption pattern. ASCs prioritize inventory efficiency and cost management for high-volume disposables, favoring standardized, reliable products that minimize setup time and operating costs. This segment growth represents a significant strategic focus area for manufacturers seeking to capitalize on the trend towards outpatient care, emphasizing the need for efficient logistics and tailored bulk packaging solutions for these high-throughput surgical environments.

- Product Type:

- Push-Button Electrosurgical Pencils

- Rocker-Switch Electrosurgical Pencils

- Pencils with Suction/Smoke Evacuation

- Application:

- General Surgery

- Gynecological Surgery

- Orthopedic Surgery

- Cardiovascular Surgery

- Cosmetic Surgery

- Neurosurgery

- End-User:

- Hospitals (Public and Private)

- Ambulatory Surgical Centers (ASCs)

- Specialized Clinics and Research Institutes

Value Chain Analysis For Disposable Electrosurgical Pencil Market

The value chain for the Disposable Electrosurgical Pencil Market begins with upstream activities involving the sourcing of specialized raw materials, primarily medical-grade plastics (e.g., PVC, polypropylene) for insulation and housing, and high-quality metals (e.g., stainless steel, tungsten) for the electrode tips. Key upstream processes include polymer extrusion, metal stamping, and specialized coating applications (like PTFE for non-stick surfaces), which must strictly adhere to ISO standards for biocompatibility and electrical safety. The complexity of regulatory compliance and the need for precision manufacturing mean that component suppliers often operate under long-term agreements with device manufacturers, guaranteeing material quality and traceable provenance for critical surgical tools.

Midstream activities involve the core manufacturing, assembly, sterilization, and packaging processes. Manufacturing involves high-precision molding of the pencil casing, manual or automated assembly of the switch mechanism and internal wiring, and the secure integration of the electrode tip. Sterilization, typically conducted using Ethylene Oxide (EtO) or radiation methods, is a crucial step ensuring the product is ready for surgical use upon delivery. Given the disposable nature of the product, optimization of mass production techniques, lean manufacturing practices, and rigorous in-line quality checks are essential to maintain high output volume at competitive costs, defining the success margins within the midstream segment.

Downstream activities focus on distribution, which is predominantly managed through both direct and indirect channels. Direct distribution involves large multinational manufacturers supplying major hospital networks and Group Purchasing Organizations (GPOs) through established contracts. Indirect distribution relies heavily on regional distributors and specialized medical supply wholesalers who manage localized logistics, inventory, and sales to smaller hospitals, ASCs, and clinics. The efficiency of the distribution channel is paramount, as electrosurgical pencils are high-turnover consumables requiring prompt and reliable restocking. Effective cold chain management, while not strictly required for pencils, is linked to the bundled delivery of temperature-sensitive surgical supplies, necessitating optimized logistics infrastructure across the entire supply network.

Disposable Electrosurgical Pencil Market Potential Customers

The primary end-users and buyers of disposable electrosurgical pencils are healthcare institutions where surgical procedures are routinely performed. Hospitals, encompassing large public university teaching hospitals and smaller private community hospitals, represent the largest customer base, purchasing these devices in high volumes for use across emergency rooms and specialized operating theaters. These institutions require robust supply chain mechanisms capable of handling continuous demand for standardized, reliable devices that meet strict clinical performance and sterility requirements. Procurement decisions in this segment are often centralized and influenced by GPO contracts focusing on bulk pricing and long-term supply stability.

Ambulatory Surgical Centers (ASCs) constitute the fastest-growing segment of potential customers. ASCs specialize in outpatient procedures and prioritize minimizing turnaround time and optimizing costs. For ASCs, disposable pencils are preferred as they eliminate the capital investment and operational overhead associated with sterilization equipment and personnel training required for reusable devices. Their purchasing behavior is highly sensitive to efficiency, preferring pre-packaged kits and standardized disposables that streamline surgical workflows and contribute directly to better cost management per procedure.

Other significant potential customers include specialized private clinics (e.g., plastic surgery, dermatology, endoscopy clinics) and academic research institutions. These entities often require specialized or niche disposable electrosurgical pencils (e.g., micro-tips or high-frequency models) for highly focused procedures or experimental research. Their purchasing volume may be lower than hospitals, but their demand for cutting-edge technology and specific design features allows manufacturers to target premium pricing strategies, emphasizing innovation and specialized clinical utility over sheer volume discounts.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 billion |

| Market Forecast in 2033 | USD 2.92 billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Medtronic PLC, Johnson & Johnson (Ethicon), ConMed Corporation, Becton, Dickinson and Company (BD), Olympus Corporation, Symmetry Surgical Inc., Kirwan Surgical Products, Bovie Medical (Apyx Medical), CooperSurgical, Inc., GIMA S.p.A., Erbe Elektromedizin GmbH, KLS Martin Group, Megadyne Medical Products Inc., AtriCure, Inc., Utah Medical Products, Inc., Smith & Nephew PLC, I.C. Medical, Inc., Teleflex Incorporated, Stryker Corporation, B. Braun Melsungen AG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Disposable Electrosurgical Pencil Market Key Technology Landscape

The technological evolution within the disposable electrosurgical pencil market is predominantly focused on enhancing safety, efficacy, and ease of use in the operating room. A core technological area involves advanced insulation materials and ergonomic design, ensuring the pencil remains cool to the touch and provides superior grip and handling for the surgeon during lengthy procedures. Modern designs incorporate high-fidelity micro-switches to prevent unintended activation, while advanced coaxial cables minimize energy loss and interference with other critical OR equipment. These refinements are essential for maintaining precision, especially in delicate minimally invasive and robotic surgeries where device reliability is paramount.

Another crucial technological development is the integration of specialized tips and coatings. Non-stick electrodes, often coated with PTFE (Polytetrafluoroethylene), significantly reduce tissue adherence, minimizing the need for frequent cleaning and maintaining consistent cutting performance throughout the procedure. Furthermore, the development of specialty electrode geometries—such as hooks, loops, and extended shanks—caters to specific surgical requirements in complex anatomical spaces, enabling surgeons to utilize the same device platform for a broader range of applications. This focus on material science and tip geometry ensures that the disposable pencil can perform as effectively, or often better, than reusable counterparts.

Perhaps the most impactful technology advancement is the proliferation of disposable electrosurgical pencils equipped with integrated smoke evacuation systems. Surgical smoke, generated during the electrosurgical process, contains harmful particles and potentially infectious agents. Pencils with built-in suction capabilities capture and filter this smoke at the source, significantly improving visualization for the surgeon and ensuring a safer working environment for the entire surgical team. This technology is becoming a standard requirement, driven by occupational health regulations and the increasing awareness of the hazards associated with surgical plumes, representing a major driver of innovation and market acceptance for high-end disposable models.

Regional Highlights

North America currently holds the largest market share in the Disposable Electrosurgical Pencil Market, primarily due to highly advanced healthcare infrastructure, high per capita healthcare spending, and favorable reimbursement policies for surgical procedures. The region benefits from the strong presence of key market players, stringent regulatory standards emphasizing infection control (driving demand for disposables), and a high adoption rate of modern surgical technologies, including robotic and minimally invasive techniques. The United States, in particular, drives significant demand owing to its massive volume of elective and non-elective surgeries performed annually, ensuring this region maintains its revenue dominance throughout the forecast period.

Europe represents the second-largest market, characterized by mature healthcare systems in Western European countries like Germany, France, and the UK, which prioritize patient safety and efficiency. While these markets exhibit slower population growth compared to APAC, the high quality standards set by bodies like the European Medicines Agency (EMA) favor certified, high-quality disposable devices. Additionally, the increasing trend toward outpatient surgical care in the European Union is boosting the usage of disposables in ASCs and specialized clinics, contributing to stable and predictable market growth across the continent.

The Asia Pacific (APAC) region is projected to be the fastest-growing market globally. This accelerated growth is attributed to massive improvements in healthcare access, rapid economic development leading to increased disposable income for medical services, and the expansion of modern hospital networks in populous nations such as China, India, and Japan. Government initiatives to improve surgical safety standards and combat endemic hospital infections are pushing healthcare facilities to transition from reusable to disposable electrosurgical tools, creating immense opportunities for both established global companies and local manufacturers to scale production and expand their distribution footprint.

- North America: Market leader; High expenditure on healthcare, robust regulatory framework, dominance of minimally invasive and robotic surgery, early adoption of high-tech disposables. Key countries: USA, Canada.

- Europe: Mature market; Strong focus on patient safety, growing prevalence of outpatient surgery (ASCs), stringent quality standards, high adoption in Western Europe. Key countries: Germany, UK, France.

- Asia Pacific (APAC): Fastest-growing market; Expanding healthcare infrastructure, rising medical tourism, large patient pool, increasing government focus on infection control and modernization of surgical facilities. Key countries: China, India, Japan.

- Latin America (LATAM): Developing market; Increasing foreign investment in healthcare, improving access to basic surgical care, driven by local governmental efforts to standardize hospital equipment. Key countries: Brazil, Mexico.

- Middle East and Africa (MEA): Emerging market; Growth centered around oil-rich Gulf Cooperation Council (GCC) states investing heavily in specialized medical services, coupled with a steady rise in surgical procedures related to lifestyle diseases. Key areas: UAE, Saudi Arabia, South Africa.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Disposable Electrosurgical Pencil Market.- Medtronic PLC

- Johnson & Johnson (Ethicon)

- ConMed Corporation

- Becton, Dickinson and Company (BD)

- Olympus Corporation

- Symmetry Surgical Inc.

- Kirwan Surgical Products

- Bovie Medical (Apyx Medical)

- CooperSurgical, Inc.

- GIMA S.p.A.

- Erbe Elektromedizin GmbH

- KLS Martin Group

- Megadyne Medical Products Inc.

- AtriCure, Inc.

- Utah Medical Products, Inc.

- Smith & Nephew PLC

- I.C. Medical, Inc.

- Teleflex Incorporated

- Stryker Corporation

- B. Braun Melsungen AG

Frequently Asked Questions

Analyze common user questions about the Disposable Electrosurgical Pencil market and generate a concise list of summarized FAQs reflecting key topics and concerns.What factors are driving the increased adoption of disposable electrosurgical pencils?

The primary drivers include the escalating global volume of surgical procedures, the critical necessity to reduce Hospital-Acquired Infections (HAIs) by eliminating reprocessing failures, and the operational efficiency gained by healthcare facilities through the use of sterile, single-use instruments that require no sterilization overhead.

How is the market segmented based on the mechanism of the electrosurgical pencil?

The market is predominantly segmented into Push-Button Electrosurgical Pencils, favored for precise control and mode switching, and Rocker-Switch Electrosurgical Pencils, which are often cost-effective and simpler, alongside specialized pencils incorporating smoke evacuation functionality.

Which geographical region exhibits the highest growth potential for this market?

The Asia Pacific (APAC) region is anticipated to demonstrate the fastest growth rate, fueled by substantial improvements in healthcare infrastructure, increasing surgical volumes, and government initiatives aimed at adopting higher standards of safety and infection control in developing economies.

What technological advancements are enhancing the safety of disposable electrosurgical pencils?

Key technological advancements include integrated smoke evacuation systems to protect OR personnel from surgical plumes, non-stick electrode coatings (e.g., PTFE) to ensure consistent performance, and advanced ergonomic designs with improved insulation and precision micro-switches to prevent unintended activation or thermal injury.

What is the primary restraint challenging the Disposable Electrosurgical Pencil Market?

A significant restraint is the growing environmental concern regarding the massive volume of medical waste generated by single-use plastic and metal devices. This restraint puts pressure on manufacturers to develop more sustainable materials and drives demand for recycling programs or eco-friendlier product designs in response to institutional sustainability mandates.

Do Ambulatory Surgical Centers (ASCs) favor disposable pencils, and why?

Yes, ASCs strongly favor disposable pencils because they are crucial for maximizing operational efficiency and minimizing per-procedure costs. Disposables eliminate the complex logistics, capital investment, and personnel time required for instrument cleaning, inspection, and sterilization, which is essential for high-throughput outpatient settings.

How does AI contribute to the manufacturing process of these high-volume devices?

AI is increasingly used in the manufacturing upstream for quality control via computer vision systems inspecting components for defects, and in logistical optimization using machine learning to predict supply chain needs and manage high-volume inventory efficiently, thereby maintaining consistent product availability and lowering production costs.

What types of specialized coatings are used on electrode tips, and what is their benefit?

Specialized coatings, such as Polytetrafluoroethylene (PTFE) or other ceramic-based materials, are applied to create non-stick electrode tips. The primary benefit is preventing tissue charring and adherence, which ensures the surgeon maintains consistent cutting and coagulation performance throughout the procedure without needing to frequently scrape or wipe the tip.

Which application segment accounts for the largest usage of disposable electrosurgical pencils?

General Surgery accounts for the largest application segment in terms of volume. This is due to the fundamental role electrosurgical pencils play in common procedures like incisions, excisions, and hemostasis across a vast range of routine and emergency operations, making them a staple consumable in almost every general operating room.

Why are stringent regulations considered both a driver and a restraint in this market?

Regulations act as a driver by mandating safety standards that often favor sterile, single-use devices to reduce HAIs. Conversely, they act as a restraint because the rigorous approval processes required by bodies like the FDA or EMA are time-consuming and costly, potentially delaying the market entry of new, innovative products.

How do GPOs (Group Purchasing Organizations) influence the procurement of disposable electrosurgical pencils?

GPOs wield significant influence by negotiating high-volume, long-term contracts with manufacturers on behalf of large hospital networks. They drive down unit costs through bulk purchasing agreements, standardize the product selection across their member institutions, and streamline the supply chain, forcing manufacturers to compete aggressively on price and reliability.

What role does material science play in the value chain of disposable pencils?

Material science is critical upstream, focusing on sourcing medical-grade, biocompatible plastics for the handle and superior conductive metals (like tungsten or stainless steel) for the electrode. Advances in polymer composition and insulation integrity ensure the device meets necessary electrical safety standards and ergonomic requirements for single-use application.

Is the integration of RFID technology becoming common in these disposable devices?

Yes, the integration of tracking technologies like RFID is an emerging trend. While not universally common yet, it is being adopted to enhance inventory management within ORs, allow for automated tracking of usage, and potentially enable electrosurgical units to automatically recognize and set optimal parameters for a specific attached pencil type.

How does the shift toward minimally invasive surgery (MIS) affect demand?

The shift toward MIS significantly boosts demand for high-precision disposable pencils, particularly those with smaller, more delicate tips, longer shanks, or specialized features compatible with robotic platforms. MIS often requires devices that guarantee sterility and consistent performance, favoring single-use options.

What key strategic focus areas should manufacturers prioritize in emerging markets?

Manufacturers should prioritize developing cost-efficient production models, ensuring robust local distribution networks, and securing regulatory approvals quickly. Furthermore, emphasizing educational programs on surgical safety and the benefits of disposables is crucial for accelerating adoption in emerging APAC and LATAM markets.

Explain the difference in end-user requirements between hospitals and specialized clinics.

Hospitals require high-volume, standardized pencils for general use, prioritizing bulk pricing and reliable supply. Specialized clinics, such as plastic surgery or dermatology centers, prioritize niche, high-specification pencils (e.g., fine-tip micro-pencils) that cater to highly specific, aesthetic, or delicate procedures, often willing to pay a premium for specialized features.

What is the estimated Compound Annual Growth Rate (CAGR) for the forecast period?

The Disposable Electrosurgical Pencil Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033, driven by sustained demand for surgical safety and rising procedure volumes globally.

How does competitive pricing impact manufacturer profitability?

Due to the high-volume, commodity nature of disposable pencils, intense competitive pricing, often driven by GPO contracts, significantly pressures manufacturer profitability. Success relies heavily on achieving high economies of scale, optimizing automated manufacturing processes, and strategically differentiating products through specialized features like smoke evacuation.

What is upstream analysis concerned with in the electrosurgical pencil value chain?

Upstream analysis focuses on the sourcing and preparation of essential raw materials, including medical-grade polymers and specialized metals for electrodes, ensuring they meet rigorous regulatory standards for biocompatibility, sterility, and electrical insulation before entering the core manufacturing phase.

In the context of electrosurgery, what is the major safety concern addressed by disposable devices?

The major safety concern addressed is cross-contamination and the risk of transmitting Hospital-Acquired Infections (HAIs). Disposables eliminate the potential for incomplete or failed sterilization cycles, guaranteeing a sterile device for every patient use, which is a paramount requirement in modern surgical practice.

How does the aging population worldwide specifically influence this market?

The aging population is directly correlated with an increased incidence of chronic diseases (cardiovascular issues, cancers, orthopedic degradation) that frequently require surgical intervention. This demographic shift inherently increases the overall volume of surgical procedures performed, thereby boosting the demand for disposable electrosurgical pencils.

What are the key functions performed by a disposable electrosurgical pencil?

A disposable electrosurgical pencil is designed to safely deliver high-frequency electrical current to tissue for three primary functions: cutting (vaporizing tissue quickly), coagulation (stopping bleeding by sealing vessels), and desiccation (controlled drying of tissue).

Why is insulation integrity critical for electrosurgical pencil performance?

Insulation integrity is crucial to prevent unintended thermal injury to non-target tissue and to ensure the electrical current is delivered precisely to the electrode tip. Failure in insulation can lead to burns in adjacent tissue or the surgeon's hand, making high-quality, durable insulation a mandatory safety requirement.

How are emerging markets accelerating their adoption of disposable electrosurgical technology?

Emerging markets are accelerating adoption by implementing international surgical guidelines, receiving increased medical technology investments, and focusing on infrastructure development. The comparative low cost and guaranteed sterility of disposables make them an attractive, accessible upgrade over outdated reusable equipment.

What distinguishes the purchasing behavior of a large public hospital from an ASC?

A large public hospital's purchasing behavior is dominated by GPO contracts, focusing on massive volume discounts and complex inventory systems. An ASC's purchasing behavior emphasizes speed, efficiency, and standardized kits, requiring smaller, more frequent deliveries of devices optimized for rapid outpatient turnover and minimal setup time.

What is the significance of the shift from reusable to disposable pencils?

The shift signifies a transition driven by patient safety concerns and operational efficiency. While reusable instruments require extensive, costly, and potentially flawed sterilization protocols, disposables guarantee sterility, simplify OR logistics, and reduce the risk of cross-contamination, aligning with modern clinical best practices.

How do manufacturers ensure quality control in mass production of disposable pencils?

Manufacturers implement rigorous, high-speed in-line quality checks, often leveraging automated systems and AI-powered computer vision to inspect critical components like insulation, wiring, and electrode tip integrity. This ensures that every high-volume, low-cost unit meets stringent regulatory and performance specifications before sterilization and packaging.

What is the projected market value of the disposable electrosurgical pencil market by 2033?

The market is projected to reach an estimated value of USD 2.92 billion by the end of the forecast period in 2033, driven by increasing global surgical volumes and persistent demand for enhanced safety devices in operating theatres worldwide.

How do advancements in robotics surgery affect the design requirements for disposable pencils?

Robotic surgery demands specialized disposable pencils that are much longer, thinner, and often articulated or compatible with specific robotic arm platforms. These pencils must offer extremely precise power delivery control and fail-safe insulation integrity suitable for highly technical, constrained operating fields.

What specific risk does surgical smoke pose, and how do pencils mitigate it?

Surgical smoke poses risks to OR staff health as it contains hazardous chemicals, biological materials, and potentially viral particles. Pencils mitigate this risk by integrating built-in active smoke evacuation systems that capture and filter the plume at the point of origin, significantly reducing airborne contamination and improving visibility for the surgeon.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager