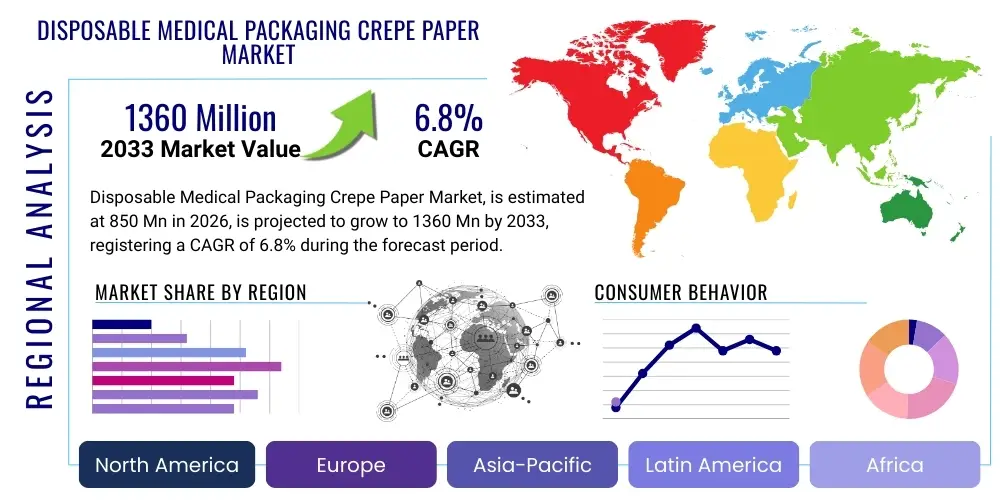

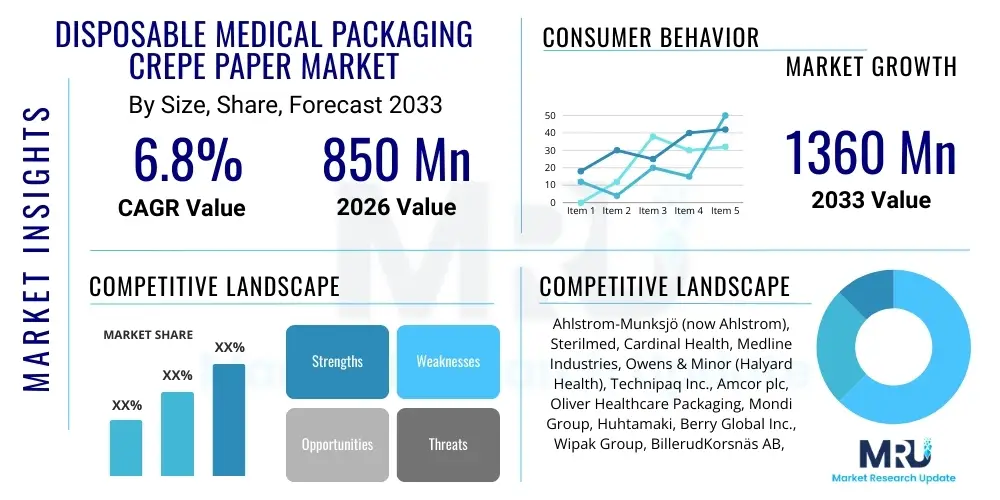

Disposable Medical Packaging Crepe Paper Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439390 | Date : Jan, 2026 | Pages : 253 | Region : Global | Publisher : MRU

Disposable Medical Packaging Crepe Paper Market Size

The Disposable Medical Packaging Crepe Paper Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1360 Million by the end of the forecast period in 2033.

Disposable Medical Packaging Crepe Paper Market introduction

The disposable medical packaging crepe paper market encompasses a specialized segment within the broader medical packaging industry, primarily focused on providing sterile barrier systems for medical devices and instruments. This market is driven by the imperative need for infection control in healthcare settings, ensuring that instruments remain sterile until the point of use. Crepe paper, known for its excellent porosity, breathability, and barrier properties, serves as a critical material for sterilization wraps, surgical drapes, and tray liners. These products are designed to allow sterilizing agents (such as steam, ethylene oxide, or hydrogen peroxide plasma) to penetrate while preventing the ingress of microorganisms, thereby maintaining the sterility of packaged items post-sterilization and during storage, transport, and handling. The single-use nature of these products reduces the risk of cross-contamination and eliminates the need for reprocessing, contributing to operational efficiency and patient safety within hospitals, ambulatory surgical centers, and clinics globally.

Product descriptions highlight the unique characteristics of medical-grade crepe paper, which typically includes a blend of cellulose fibers engineered for high strength, flexibility, and fluid resistance, without compromising breathability. The creped texture provides softness, drapability, and conformability, making it ideal for wrapping various shapes and sizes of medical devices and instrument trays. Major applications span across diverse medical fields, including general surgery, orthopedics, dentistry, and ophthalmology, where sterile instruments are paramount. The benefits of using disposable medical packaging crepe paper are multifaceted, encompassing enhanced patient safety through superior infection prevention, cost-effectiveness due to its single-use and disposable nature, and compliance with stringent international sterilization and packaging standards, such as ISO 11607 and EN 868 series. These regulations mandate specific performance criteria for medical packaging, ensuring that crepe paper products meet the necessary benchmarks for sterility maintenance and shelf-life. Furthermore, the inherent biodegradability of paper-based products offers an environmental advantage over certain plastic-based alternatives, aligning with increasing sustainability initiatives within the healthcare sector.

Key driving factors for the market's sustained growth include the global expansion of the healthcare sector, particularly in emerging economies where healthcare infrastructure is rapidly developing. The increasing volume of surgical procedures worldwide, driven by an aging population and rising prevalence of chronic diseases, directly translates to a higher demand for sterile instruments and, consequently, their packaging. Moreover, a heightened global awareness regarding hospital-acquired infections (HAIs) and the subsequent emphasis on stringent infection control protocols have made sterile packaging an indispensable component of medical practice. Regulatory bodies consistently update and enforce strict guidelines for medical device sterilization and packaging, further compelling healthcare providers to adopt reliable and compliant solutions like disposable medical packaging crepe paper. Continuous innovation in material science, leading to enhanced barrier properties, improved strength-to-weight ratios, and more environmentally friendly formulations, also contributes significantly to market expansion. The convenience, reliability, and established efficacy of crepe paper in various sterilization methods underscore its continued importance in the sterile supply chain, securing its position as a foundational element for patient safety and operational efficiency in medical facilities.

Disposable Medical Packaging Crepe Paper Market Executive Summary

The Disposable Medical Packaging Crepe Paper Market is undergoing significant evolution, characterized by dynamic business trends, evolving regional landscapes, and specific segment shifts. A prominent business trend is the growing emphasis on sustainable manufacturing practices and the development of eco-friendly products, driven by corporate social responsibility initiatives and increasing regulatory pressures regarding waste management in healthcare. This includes research into biodegradable coatings and alternative fiber sources that maintain essential barrier properties while reducing environmental impact. Furthermore, consolidation through mergers and acquisitions is observed as companies seek to expand their product portfolios, enhance market reach, and achieve economies of scale. Technological advancements in paper manufacturing, such as improved creping techniques and advanced coating applications, are also shaping the competitive landscape, allowing manufacturers to offer products with superior performance characteristics and broader sterilization compatibility. Supply chain resilience and diversification have become critical considerations post-pandemic, leading companies to reassess sourcing strategies and invest in localized production capabilities to mitigate future disruptions.

Regionally, the market exhibits varied growth trajectories. North America and Europe represent mature markets with high adoption rates of advanced medical packaging solutions, driven by well-established healthcare infrastructures, stringent regulatory frameworks, and a strong focus on infection control. Growth in these regions is often propelled by innovation, product upgrades, and the replacement of older packaging methods. In contrast, the Asia Pacific (APAC) region is emerging as a high-growth market, fueled by rapidly expanding healthcare spending, increasing surgical volumes, and the modernization of medical facilities, particularly in populous countries like China and India. Latin America, the Middle East, and Africa are also showing promising growth potential, albeit from a smaller base, as healthcare access improves and awareness regarding sterile practices intensifies. These regions present significant opportunities for market penetration and expansion as economic development and healthcare reforms continue to advance, necessitating robust and compliant sterile packaging solutions to meet rising demands for safe medical procedures.

Segment-wise, the market is experiencing notable trends across different product types, material compositions, and applications. The sterilization wraps segment continues to dominate, driven by the sheer volume of instruments requiring sterile packaging for various medical procedures. Within material types, there is a gradual shift towards high-performance crepe papers that offer enhanced barrier properties and compatibility with newer, more gentle sterilization methods like hydrogen peroxide plasma. The application segment sees hospitals remaining the largest end-user, but ambulatory surgical centers (ASCs) are exhibiting a faster growth rate due to the increasing trend of outpatient surgeries. Moreover, the demand for customized packaging solutions tailored to specific medical devices and sterilization protocols is on the rise, pushing manufacturers to offer a broader range of sizes, thicknesses, and configurations. The continuous innovation in material science and manufacturing processes aims to address the evolving needs of healthcare providers, ensuring efficient and effective sterile delivery of medical instruments across all segments.

AI Impact Analysis on Disposable Medical Packaging Crepe Paper Market

The integration of Artificial Intelligence (AI) into the disposable medical packaging crepe paper market primarily addresses key user concerns around operational efficiency, quality assurance, supply chain optimization, and predictive analytics. Users frequently inquire about how AI can enhance the precision and consistency of the manufacturing process, particularly in managing the delicate balance of material properties like porosity, strength, and barrier integrity. There's also significant interest in AI's role in improving quality control, identifying defects in real-time, and reducing waste, which are critical for cost-efficiency and regulatory compliance. Furthermore, stakeholders are keen on understanding how AI can optimize inventory management, forecast demand more accurately, and ensure a resilient supply chain for raw materials and finished products, especially given past global disruptions. The expectation is that AI will not only streamline production and distribution but also provide deeper insights into market trends and consumer preferences, enabling more responsive and strategic business decisions within the highly regulated medical packaging sector. Users anticipate AI will drive greater sustainability through optimized material usage and waste reduction, aligning with environmental objectives while maintaining safety standards.

- Enhanced quality control and defect detection through AI-powered vision systems, reducing human error and waste.

- Optimization of manufacturing processes, including machine learning algorithms for precise control of creping, coating, and cutting, leading to improved material consistency and reduced energy consumption.

- Predictive maintenance for production machinery, minimizing downtime and increasing operational efficiency.

- Improved supply chain management through AI-driven demand forecasting, inventory optimization, and risk assessment, ensuring timely delivery of raw materials and finished goods.

- Development of smart packaging solutions that could potentially incorporate AI for traceability, temperature monitoring, or authentication, though this is nascent for basic crepe paper.

- Data analytics to identify market trends, customer preferences, and areas for product innovation, guiding R&D efforts.

- Automation of administrative tasks and data analysis related to regulatory compliance and quality documentation.

- Resource optimization through AI models that can suggest ideal material blends and production parameters for sustainable product development.

DRO & Impact Forces Of Disposable Medical Packaging Crepe Paper Market

The Disposable Medical Packaging Crepe Paper Market is significantly shaped by a confluence of drivers, restraints, opportunities, and their combined impact forces. A primary driver is the continuous expansion of the global healthcare industry, marked by increasing healthcare expenditure, a rising global population, and improved access to medical services, all of which directly correlate with a greater volume of medical procedures requiring sterile packaging. The growing incidence of hospital-acquired infections (HAIs) and the subsequent emphasis on stringent infection control measures globally further fuel the demand for reliable, single-use sterile barrier systems. Moreover, evolving and tightening regulatory frameworks, such as those from the FDA, EMA, and ISO standards (e.g., ISO 11607 for packaging for terminally sterilized medical devices), mandate the use of effective and validated sterile packaging, pushing healthcare facilities towards compliant solutions like crepe paper. The inherent advantages of crepe paper, including its breathability, excellent barrier properties, and compatibility with various sterilization methods, cement its role as a preferred choice in medical packaging.

Despite these strong drivers, the market faces several restraints. Volatility in the prices of raw materials, particularly pulp and cellulose fibers, which are commodity-dependent, can impact manufacturing costs and profitability. Additionally, the increasing global scrutiny on single-use disposable products, driven by environmental concerns and sustainability initiatives, poses a long-term challenge, even though crepe paper is biodegradable. While generally preferred over plastic for its eco-friendliness, the sheer volume of disposable medical waste generated by healthcare facilities remains a point of contention. The market also experiences intense competition from alternative sterilization packaging materials, such as non-woven fabrics (SMS), plastic films (Tyvek), and rigid containers, which offer different sets of advantages in terms of strength, barrier performance, or reusability. Moreover, the need for specialized manufacturing processes and strict quality control to meet medical-grade standards can represent a barrier to entry for new players, limiting market dynamism and potentially affecting supply responsiveness.

Opportunities for growth are abundant, particularly in emerging markets where healthcare infrastructure is rapidly developing and awareness of infection control is increasing. These regions present untapped potential for market expansion and adoption of modern sterile packaging solutions. Furthermore, ongoing research and development into sustainable and enhanced-performance crepe paper products, including those with improved barrier properties, antimicrobial coatings, or reduced environmental footprints, offer avenues for innovation and differentiation. Customization of packaging solutions to meet the specific requirements of various medical devices and sterilization methods also presents a significant growth opportunity, allowing manufacturers to cater to niche segments and add value. The impact forces are thus a complex interplay: the escalating demand for sterile products due to healthcare growth and infection control mandates strongly pushes market expansion, while environmental pressures and competitive alternatives compel innovation towards more sustainable and high-performance solutions. Regulatory compliance acts as a constant upward pressure, ensuring quality and safety, but also increasing operational costs, ultimately driving the market towards greater efficiency and specialized product offerings that can navigate these competing demands effectively.

Segmentation Analysis

The Disposable Medical Packaging Crepe Paper market is meticulously segmented to provide a comprehensive understanding of its diverse components and growth dynamics. These segmentations allow for detailed analysis of product types, material characteristics, application areas, and compatibility with different sterilization methods, offering granular insights into consumer preferences and market opportunities. Understanding these segments is crucial for manufacturers to tailor their product offerings, for distributors to optimize their supply chains, and for healthcare providers to make informed purchasing decisions that align with their specific clinical and operational needs. The distinct attributes of each segment influence their adoption rates, market share, and future growth trajectories, reflecting the evolving landscape of medical device packaging and infection control protocols globally.

- By Product Type

- Sterilization Wraps

- Surgical Drapes & Gowns (Packaging component)

- Tray Liners

- Pouches & Bags (Crepe paper-based)

- Other Packaging Components

- By Material Type

- Standard Medical Grade Crepe Paper

- High-Performance Crepe Paper (Enhanced Barrier, Strength)

- Coated Crepe Paper (e.g., with water-repellent or antimicrobial layers)

- Recycled Content Crepe Paper

- By Application

- Hospitals

- Ambulatory Surgical Centers (ASCs)

- Clinics (e.g., Dental Clinics, Specialty Clinics)

- Diagnostic Centers

- Pharmaceutical & Medical Device Manufacturers

- Research Laboratories

- By Sterilization Method

- Steam (Autoclave) Sterilization

- Ethylene Oxide (EtO) Sterilization

- Gamma Radiation Sterilization

- Hydrogen Peroxide Gas Plasma Sterilization

- Other Low-Temperature Sterilization Methods

Value Chain Analysis For Disposable Medical Packaging Crepe Paper Market

The value chain for the Disposable Medical Packaging Crepe Paper Market begins with the upstream analysis, focusing on the sourcing and processing of raw materials. This stage involves suppliers of high-quality cellulose pulp, which forms the fundamental basis of crepe paper. These pulp producers, often large forestry companies or chemical pulp mills, are critical for providing consistent quality and volume. Additionally, various chemical suppliers provide additives such as wet-strength agents, sizing agents, and barrier coatings that impart specific properties to the paper, ensuring it meets stringent medical-grade specifications. The quality and sustainability of raw material sourcing, including certifications for responsible forestry, are increasingly important factors at this stage. Effective management of upstream suppliers is crucial for maintaining cost stability, ensuring consistent product quality, and complying with environmental regulations, which ultimately impacts the final product's performance and market competitiveness.

Moving downstream, the value chain encompasses the manufacturing processes, distribution channels, and the ultimate end-users. The manufacturing stage involves specialized paper mills that transform pulp into medical-grade crepe paper, followed by converting facilities that cut, fold, and package the crepe paper into final products like sterilization wraps, drapes, and tray liners. These converters often employ advanced machinery for precision cutting, printing, and packaging to meet specific client requirements and regulatory standards. The distribution channel is multifaceted, including direct sales from manufacturers to large hospital networks or pharmaceutical companies, as well as indirect distribution through medical device distributors, wholesalers, and group purchasing organizations (GPOs). These intermediaries play a vital role in reaching a broad base of healthcare facilities, managing inventory, and providing logistics support. The effectiveness of these channels directly impacts market penetration and product availability, ensuring that critical sterile packaging reaches healthcare providers promptly and efficiently across various geographic regions.

The final stage of the value chain involves the end-users, primarily hospitals, ambulatory surgical centers, clinics, and medical device manufacturers, who utilize the disposable medical packaging crepe paper for sterilizing and protecting their instruments and devices. The choice of distribution channel—direct or indirect—often depends on the size and reach of the manufacturer, as well as the scale and purchasing power of the customer. Large, integrated healthcare systems might engage in direct purchasing agreements to benefit from volume discounts and direct support, while smaller clinics and individual practitioners typically rely on indirect channels through medical supply distributors for convenience and access to a broader product range. The efficiency of this entire value chain, from sustainable raw material sourcing to effective distribution and end-user satisfaction, is paramount for the market's growth and stability. Innovations in each stage, such as automation in converting or improved logistics, contribute to overall efficiency and cost-effectiveness, strengthening the market position of players who can optimize these processes. Sustainability considerations are also becoming embedded throughout the value chain, from eco-friendly pulp sourcing to responsible disposal practices, influencing purchasing decisions and product development.

Disposable Medical Packaging Crepe Paper Market Potential Customers

The primary potential customers for the Disposable Medical Packaging Crepe Paper Market are diverse entities within the healthcare ecosystem that require sterile environments and practices for patient care and medical procedures. These end-users are driven by the absolute necessity of preventing hospital-acquired infections (HAIs) and adhering to strict regulatory standards for medical device sterilization. Hospitals, ranging from large university medical centers to community hospitals, constitute the largest segment of customers. They utilize vast quantities of crepe paper for wrapping surgical instrument sets, maintaining sterility in operating rooms, and packaging items for various departments like central sterile supply, emergency, and outpatient clinics. The volume and variety of procedures performed in hospitals make them a cornerstone of demand for sterile packaging solutions, with purchasing decisions often influenced by cost-effectiveness, reliability, and ease of use, alongside regulatory compliance.

Ambulatory Surgical Centers (ASCs) represent a rapidly growing customer segment. As more surgical procedures shift from inpatient hospital settings to outpatient facilities due to cost efficiency and advancements in minimally invasive techniques, ASCs have an escalating need for efficient and reliable sterile packaging. These centers prioritize quick turnaround times and streamlined processes, making disposable crepe paper an ideal choice for their instrument sterilization needs. Similarly, various types of clinics, including dental clinics, specialty clinics (e.g., ophthalmology, dermatology, podiatry), and diagnostic centers, also rely heavily on disposable medical packaging crepe paper to ensure the sterility of their instruments and supplies. Even though their individual volumes might be lower than large hospitals, their collective demand forms a substantial part of the market, driven by the critical importance of infection control in their daily operations and patient interactions.

Beyond direct patient care facilities, pharmaceutical companies and medical device manufacturers also serve as significant potential customers. These entities utilize disposable medical packaging crepe paper for internal sterilization processes during manufacturing or for packaging their own instruments and kits prior to distribution to healthcare providers. Research laboratories, particularly those involved in medical or biological research, also require sterile environments and instruments, making them potential buyers for crepe paper packaging. The purchasing decisions of these institutional customers are heavily influenced by product quality, adherence to international standards like ISO 11607, supplier reliability, and increasingly, by sustainability credentials. Manufacturers and distributors must therefore cater to a broad spectrum of needs, offering a range of crepe paper products that meet diverse sterilization requirements, operational workflows, and budgetary constraints across this wide array of potential customers, all unified by the common goal of maintaining sterility and ensuring patient safety.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1360 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ahlstrom-Munksjö (now Ahlstrom), Sterilmed, Cardinal Health, Medline Industries, Owens & Minor (Halyard Health), Technipaq Inc., Amcor plc, Oliver Healthcare Packaging, Mondi Group, Huhtamaki, Berry Global Inc., Wipak Group, BillerudKorsnäs AB, Smurfit Kappa Group, GP Cellulose, Domtar Corporation, International Paper Company, Twin Rivers Paper Company, Pactiv Evergreen Inc., Kimberly-Clark Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Disposable Medical Packaging Crepe Paper Market Key Technology Landscape

The Disposable Medical Packaging Crepe Paper Market is underpinned by a sophisticated array of technologies aimed at optimizing product performance, manufacturing efficiency, and compliance with stringent medical standards. At the core are advanced paper manufacturing techniques that enable precise control over fiber orientation, paper density, and creping extent, which directly influence the material's strength, porosity, and drapability. Innovations in pulp treatment and refining technologies are crucial for producing high-quality cellulose fibers that exhibit superior wet strength and barrier properties, essential for maintaining sterility in moist or humid conditions. Furthermore, multi-ply lamination and calendering techniques are employed to create multi-layered crepe paper products with enhanced tear resistance and barrier integrity without compromising the breathability required for effective sterilization. These technological advancements ensure that crepe paper maintains its structural integrity throughout the sterilization process and during storage, protecting sensitive medical instruments.

Beyond the fundamental paper-making processes, specialized coating and treatment technologies play a significant role in elevating the functionality of medical crepe paper. Antimicrobial coatings, for instance, are being explored to provide an additional layer of protection against microbial contamination, although their adoption in direct sterile barriers is highly regulated. Water-repellent or fluid-resistant coatings enhance the paper's ability to withstand accidental fluid splashes, thereby preserving the sterile field. Surface treatment technologies are also employed to optimize compatibility with various sterilization methods, ensuring that the paper does not react adversely with sterilizing agents like ethylene oxide (EtO), hydrogen peroxide gas plasma, or steam, and that it maintains its barrier efficacy. Quality control technologies, including automated optical inspection systems and real-time sensor monitoring during production, are critical for detecting imperfections, ensuring consistent material properties, and guaranteeing compliance with rigorous industry standards like ISO 11607 and EN 868.

The integration of automation and data analytics into the manufacturing process represents another key technological trend. Robotic handling systems and automated converting lines improve production speed, reduce labor costs, and minimize human contact, thereby reducing the risk of contamination. Data analytics and machine learning algorithms are utilized to optimize machine parameters, predict potential defects, and manage raw material consumption more efficiently, contributing to both cost savings and sustainability efforts. Traceability technologies, such as RFID tags or advanced barcoding, though more common in finished medical devices, are also relevant for tracking packaging materials through the supply chain, ensuring product authenticity and recall readiness. Ultimately, the continuous advancement in these diverse technologies, from raw material processing to final product conversion and quality assurance, is vital for driving innovation within the disposable medical packaging crepe paper market, enabling manufacturers to meet the evolving demands for safety, performance, and sustainability in healthcare packaging.

Regional Highlights

- North America: A mature market characterized by high healthcare expenditure, advanced healthcare infrastructure, and stringent regulatory frameworks. Dominates in terms of technology adoption and specialized packaging solutions. Growth driven by increased surgical volumes, aging population, and a strong emphasis on infection control. The U.S. is the largest contributor, with a robust presence of key players and a high awareness of sterile packaging importance.

- Europe: Exhibits steady growth, propelled by strict EU medical device regulations, rising demand for advanced sterile packaging, and a strong focus on sustainability. Countries like Germany, France, and the UK are major markets. Innovation in eco-friendly materials and adherence to European standards for medical devices and packaging drive market trends.

- Asia Pacific (APAC): The fastest-growing region, driven by rapidly expanding healthcare infrastructure, increasing medical tourism, a large and growing population base, and rising disposable incomes. Countries such as China, India, Japan, and South Korea are key contributors. Opportunities abound for market penetration due to increasing awareness of infection control and modernization of healthcare facilities.

- Latin America: An emerging market with significant growth potential, fueled by improving healthcare access, government initiatives to upgrade medical facilities, and increasing awareness of patient safety. Brazil and Mexico are leading the adoption of modern medical packaging solutions in the region. Economic development and healthcare reforms are key drivers.

- Middle East and Africa (MEA): Shows promising growth, albeit from a smaller base. Driven by rising healthcare investments, development of medical tourism hubs (especially in the UAE and Saudi Arabia), and efforts to control infectious diseases. The demand for sterile medical supplies is increasing, creating opportunities for market expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Disposable Medical Packaging Crepe Paper Market.- Ahlstrom-Munksjö (now Ahlstrom)

- Sterilmed (a subsidiary of Johnson & Johnson)

- Cardinal Health Inc.

- Medline Industries LP

- Owens & Minor Inc. (including Halyard Health)

- Technipaq Inc.

- Amcor plc

- Oliver Healthcare Packaging

- Mondi Group

- Huhtamaki Oyj

- Berry Global Inc.

- Wipak Group

- BillerudKorsnäs AB

- Smurfit Kappa Group

- GP Cellulose (a Georgia-Pacific Company)

- Domtar Corporation

- International Paper Company

- Twin Rivers Paper Company

- Pactiv Evergreen Inc.

- Kimberly-Clark Corporation

Frequently Asked Questions

Analyze common user questions about the Disposable Medical Packaging Crepe Paper market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is disposable medical packaging crepe paper primarily used for?

It is predominantly used as a sterile barrier system for medical instruments and devices, particularly for sterilization wraps, surgical drapes, and tray liners, to maintain sterility post-sterilization until the point of use in healthcare settings.

What are the main drivers for the growth of this market?

Key drivers include the expanding global healthcare industry, increasing volume of surgical procedures, heightened focus on infection control, and stringent regulatory mandates for medical device sterilization and packaging.

What challenges does the disposable medical packaging crepe paper market face?

Challenges include volatility in raw material prices, increasing environmental scrutiny on single-use disposables, intense competition from alternative packaging materials, and the complexity of meeting rigorous medical-grade manufacturing standards.

How does disposable medical packaging crepe paper contribute to patient safety?

It contributes by ensuring medical instruments remain sterile after processing and during storage, transport, and handling, thereby significantly reducing the risk of hospital-acquired infections (HAIs) and cross-contamination.

Are there sustainable alternatives or innovations in this market?

Yes, ongoing innovations focus on developing crepe paper with enhanced barrier properties, antimicrobial coatings, and, importantly, exploring sustainable material sources and processes, including recycled content and biodegradable coatings, to minimize environmental impact.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager