Distillation Testing Machinery Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439526 | Date : Jan, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Distillation Testing Machinery Market Size

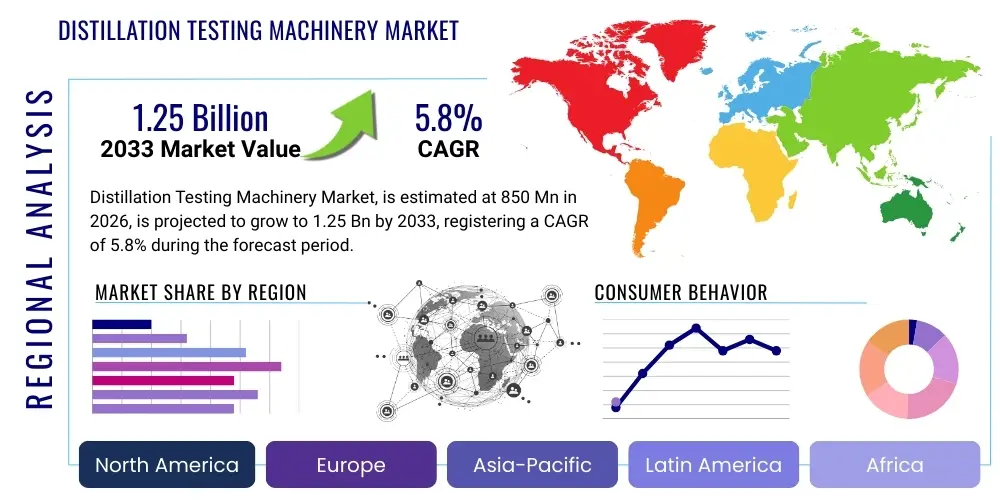

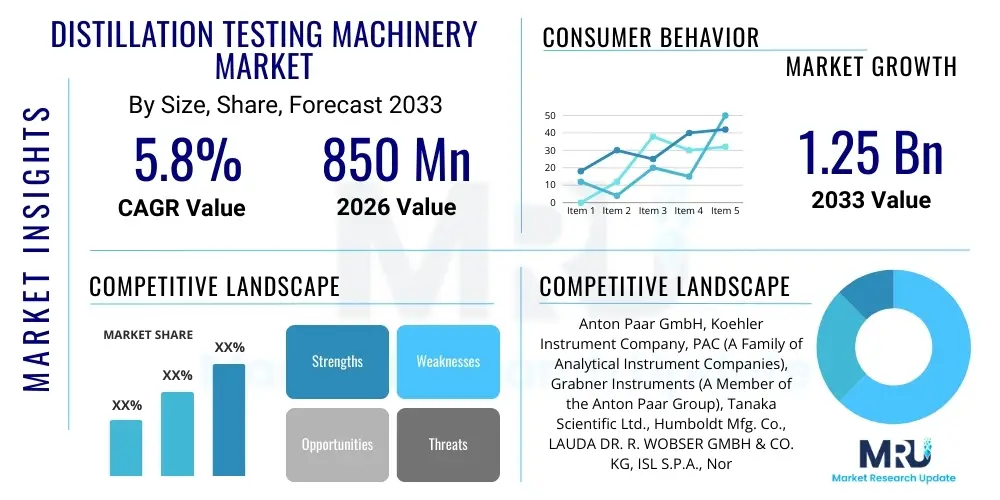

The Distillation Testing Machinery Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1.25 Billion by the end of the forecast period in 2033. This growth trajectory is underpinned by increasing industrialization, stringent quality control regulations across various sectors, and the continuous demand for product purity and consistency in manufacturing processes globally. The market's expansion is further fueled by technological advancements leading to more automated, precise, and efficient distillation testing solutions.

Distillation Testing Machinery Market introduction

The Distillation Testing Machinery Market encompasses a critical segment within laboratory and industrial instrumentation, providing essential equipment for evaluating the purity, composition, and physical properties of liquid samples through the process of distillation. These machines are designed to separate components of a liquid mixture based on differences in their boiling points, offering invaluable insights for quality control, research and development, and process optimization. The primary objective is to determine parameters such as initial boiling point, final boiling point, distillation range, and recovery volume, which are crucial for characterizing petroleum products, chemicals, pharmaceuticals, and various other industrial liquids. The market offers a diverse range of instruments, from manual glass apparatus to highly sophisticated automated systems, catering to different levels of throughput and analytical precision.

Products within this market range from atmospheric and vacuum distillation units, essential for analyzing petroleum fractions, to specialized fractional and crude oil distillation testers used in complex petrochemical processes. These machines typically feature precise temperature control systems, integrated safety mechanisms, automated data logging capabilities, and user-friendly interfaces, ensuring reliable and repeatable results. Major applications span a broad spectrum of industries, including petroleum refining, where they are vital for classifying crude oil and evaluating gasoline, diesel, and jet fuel; the chemical sector for quality assurance of solvents and reactants; and the pharmaceutical industry for assessing the purity of active pharmaceutical ingredients (APIs) and excipients. Furthermore, food and beverage industries utilize these testers for alcohol content determination and aroma profiling, while environmental agencies employ them for contaminant analysis.

The benefits derived from accurate distillation testing machinery are manifold, extending to enhanced product quality, improved process efficiency, and compliance with stringent international standards such as ASTM, ISO, and IP. These instruments enable manufacturers to optimize their production parameters, reduce waste, and ensure that their products meet specified performance and safety criteria. Key driving factors propelling the market forward include the rapid expansion of the petrochemical and chemical industries, particularly in emerging economies, coupled with an escalating demand for high-quality, standardized products. Additionally, the increasing focus on research and development activities across various scientific domains, the need for advanced material characterization, and the growing adoption of automation and digitalization in laboratories are significantly contributing to market growth.

Distillation Testing Machinery Market Executive Summary

The Distillation Testing Machinery Market is characterized by dynamic business trends driven by technological innovation and evolving industrial requirements. A significant trend is the shift towards fully automated and semi-automated systems, which offer enhanced precision, reduced human error, and improved efficiency compared to traditional manual methods. Integration with Laboratory Information Management Systems (LIMS) and other digital platforms is becoming standard, facilitating seamless data management, analysis, and reporting. Furthermore, manufacturers are increasingly focusing on developing modular and customizable solutions to cater to specific industry needs, alongside a growing emphasis on instruments with robust safety features and compliance with strict environmental regulations. The drive for sustainability is also influencing product design, with a focus on energy-efficient models and reduced solvent consumption.

Regional trends indicate that the Asia Pacific (APAC) region is poised for substantial growth, primarily due to rapid industrialization, expanding petrochemical and chemical manufacturing bases, and significant investments in research and development across countries like China, India, and South Korea. North America and Europe, while mature markets, continue to represent significant demand, driven by stringent regulatory frameworks, technological advancements, and the presence of leading pharmaceutical and chemical companies. These regions are often early adopters of advanced and automated distillation testing solutions. Latin America and the Middle East & Africa (MEA) are also showing promising growth, supported by investments in the oil and gas sector and a burgeoning industrial landscape, necessitating reliable quality control instrumentation.

Segmentation trends reveal that automated distillation testers are gaining significant traction, propelled by the demand for higher throughput, accuracy, and operational consistency. In terms of application, the petroleum and petrochemical sector remains the largest end-user, with a continuous need for precise fuel and lubricant characterization. However, the pharmaceutical and chemical industries are exhibiting robust growth in adopting these instruments due to their stringent quality requirements for raw materials and finished products. Furthermore, there is a rising demand for specialized fractional distillation testers for complex mixture analysis and an increasing market for compact, portable units suitable for field testing or smaller laboratory setups, reflecting a broader diversification in product utility and deployment.

AI Impact Analysis on Distillation Testing Machinery Market

User inquiries about AI's impact on distillation testing machinery frequently revolve around how artificial intelligence can enhance accuracy, automate complex processes, improve predictive maintenance, and provide deeper insights from large datasets. Common concerns include the initial investment cost, the need for specialized skills to implement and manage AI-driven systems, and the reliability of AI algorithms in critical testing environments. Users also express interest in AI's potential to optimize distillation parameters in real-time, predict equipment failures before they occur, and streamline regulatory compliance through intelligent data interpretation. The overarching expectation is that AI will transform distillation testing from a labor-intensive, often subjective process into a highly automated, precise, and data-driven analytical method, ultimately leading to superior product quality and operational efficiency.

- AI-driven predictive maintenance optimizes machine uptime by anticipating component failures based on operational data, reducing unexpected downtime and maintenance costs.

- Real-time parameter optimization using AI algorithms allows for dynamic adjustments during the distillation process, enhancing efficiency and improving the accuracy of separation.

- Automated data analysis and reporting powered by AI significantly reduces manual effort, providing instantaneous insights and accelerating decision-making for quality control and R&D.

- Enhanced quality control through AI-driven pattern recognition can detect subtle deviations in distillation curves or product characteristics that human operators might miss, ensuring consistent product purity.

- AI integration with sensor technology enables smarter instrument calibration and self-correction, leading to more reliable and repeatable test results over time.

- Development of intelligent algorithms for complex mixture analysis, allowing for more precise identification and quantification of components, particularly in challenging samples.

- AI supports advanced simulation and modeling of distillation processes, enabling virtual testing and optimization before physical experimentation, saving time and resources.

DRO & Impact Forces Of Distillation Testing Machinery Market

The Distillation Testing Machinery Market is influenced by a confluence of drivers, restraints, opportunities, and external impact forces. A primary driver is the unrelenting global demand for high-quality petroleum products, chemicals, and pharmaceuticals, which necessitates rigorous distillation testing at every stage of production for quality assurance and compliance. The expansion of industrial sectors worldwide, particularly in emerging economies, further fuels the need for precise analytical instrumentation. Moreover, increasingly stringent international and national regulatory standards for product purity, safety, and environmental protection compel industries to adopt advanced and reliable testing machinery. The growing emphasis on research and development across various scientific disciplines also drives innovation and demand for sophisticated distillation testers, as does the overarching trend towards automation and digitalization in laboratories seeking to enhance efficiency and reduce human error.

Despite significant growth potential, the market faces several restraints. The high initial capital investment required for advanced, automated distillation testing machinery can be a barrier for small and medium-sized enterprises (SMEs), particularly in developing regions. The complexity associated with operating and maintaining sophisticated instruments often necessitates a highly skilled workforce, which can be scarce or require substantial training investments. Additionally, the increasing scrutiny over environmental impact, including the disposal of waste products from distillation processes and the energy consumption of these machines, poses a challenge, prompting a need for more sustainable and eco-friendly solutions. Market saturation in developed regions for basic instruments also acts as a restraint, shifting focus towards upgrades and specialized units.

However, numerous opportunities exist for market expansion and innovation. Emerging economies, with their rapidly industrializing sectors and increasing investments in infrastructure, present significant untapped markets for distillation testing machinery. The growing demand for specialized and customized instruments, tailored to unique analytical challenges in fields like biofuels, nutraceuticals, and advanced materials, offers lucrative avenues for manufacturers. Integration with Industry 4.0 technologies, such as the Internet of Things (IoT) and big data analytics, provides opportunities for creating smart, interconnected laboratory environments. Furthermore, the development of green chemistry principles and sustainable manufacturing processes is opening doors for energy-efficient and environmentally benign distillation testing solutions, appealing to a broader, environmentally conscious customer base and aligning with global sustainability goals.

Segmentation Analysis

The Distillation Testing Machinery market is comprehensively segmented to provide a detailed understanding of its various facets, allowing for precise market analysis and strategic planning. These segmentations categorize the market based on the type of machinery, the specific applications it serves, the end-user industries that adopt these solutions, and the underlying technology employed. Each segment reveals distinct demand patterns, growth drivers, and competitive landscapes, reflecting the diverse needs and operational complexities across different industrial and research environments. This multi-dimensional approach to segmentation highlights key areas of growth, technological shifts, and emerging opportunities, enabling stakeholders to make informed decisions and tailor their product offerings to specific market niches. Understanding these segments is crucial for identifying target customers, assessing market potential, and developing effective marketing and sales strategies.

- By Type

- Atmospheric Distillation Testers

- Vacuum Distillation Testers

- Crude Oil Distillation Testers

- Fractional Distillation Testers

- Automated Distillation Testers

- Semi-Automated Distillation Testers

- Manual Distillation Testers

- By Application

- Petroleum & Petrochemical

- Chemical

- Pharmaceutical & Biotechnology

- Food & Beverage

- Research & Academic

- Environmental Testing

- Others (e.g., cosmetic, paints & coatings)

- By End-User

- Refineries

- Chemical Plants

- Pharmaceutical Manufacturing Companies

- Research Laboratories

- Quality Control Departments

- Government & Regulatory Bodies

- Academic Institutions

- By Technology

- Manual Systems

- Semi-Automatic Systems

- Fully Automatic Systems

Value Chain Analysis For Distillation Testing Machinery Market

The value chain for the Distillation Testing Machinery Market begins with the upstream activities involving the sourcing of raw materials and sophisticated components. This includes specialized glassware, high-grade metals (such as stainless steel for corrosion resistance), precision sensors for temperature and pressure, electronic components for control systems, and complex software for automation and data analysis. Suppliers in this upstream segment are critical, as the quality and reliability of their components directly impact the performance and durability of the final testing machinery. Manufacturers often engage in long-term relationships with key suppliers to ensure a consistent supply of high-quality, standardized parts, crucial for maintaining product integrity and meeting stringent industry standards. Research and development also plays a significant upstream role, driving innovation in design and functionality.

Moving further along the value chain, the manufacturing phase involves the assembly, integration, and rigorous testing of these components into complete distillation testing units. This stage requires specialized engineering expertise, advanced manufacturing facilities, and strict quality control protocols to ensure that each machine meets specified performance criteria and regulatory compliance. After manufacturing, the distribution channels play a pivotal role in delivering the products to the end-users. This typically involves a mix of direct sales by the manufacturers, especially for large industrial clients requiring custom solutions and direct technical support, and indirect sales through a network of distributors, agents, and resellers. These indirect channels often have established regional presence and expertise, providing logistical support, localized customer service, and technical training to a broader customer base, particularly for standard product offerings. Online platforms and e-commerce are also gaining traction for simpler, more standardized models, expanding market reach.

The downstream activities involve the end-users who utilize these machines for their specific analytical needs. This includes petroleum refineries, chemical plants, pharmaceutical companies, academic research institutions, and various other industrial and governmental laboratories. Post-sales services, such as installation, commissioning, maintenance, calibration, and technical support, form a critical part of the downstream value chain, ensuring optimal performance and longevity of the equipment. These services are often provided directly by the manufacturers or through certified service partners, establishing long-term customer relationships and generating recurring revenue streams. The efficiency and effectiveness of the entire value chain, from raw material sourcing to post-sales support, are crucial for competitive advantage in the Distillation Testing Machinery Market, emphasizing collaboration and specialized expertise at each stage.

Distillation Testing Machinery Market Potential Customers

The primary potential customers for Distillation Testing Machinery span a wide array of industrial, research, and regulatory sectors, all sharing a common need for precise liquid characterization and quality control. At the forefront are petroleum refineries and petrochemical plants, where these machines are indispensable for crude oil assay, quality control of refined products like gasoline, diesel, and jet fuel, and monitoring various intermediate processes. These large-scale industrial operations require robust, often automated, systems capable of high throughput and continuous operation to ensure product specifications are met and operational efficiencies are maintained. The significant investment in these facilities necessitates reliable and accurate testing equipment to prevent costly errors and comply with industry standards.

The chemical manufacturing industry represents another substantial customer segment, utilizing distillation testers for the quality assurance of raw materials, in-process monitoring of chemical reactions, and purity assessment of final chemical products such as solvents, acids, and polymers. Pharmaceutical and biotechnology companies are also critical end-users, where the purity and composition of active pharmaceutical ingredients (APIs), excipients, and other formulations are paramount for product efficacy and patient safety. These sectors demand instruments that meet stringent regulatory requirements (e.g., FDA, EMA) and offer high precision and traceability. Research and development laboratories, both within academic institutions and industrial settings, constitute a significant customer base, requiring versatile and accurate distillation equipment for new product development, material science studies, and fundamental research into liquid properties and separation techniques.

Furthermore, food and beverage manufacturers use distillation testing for quality control, such as determining alcohol content in spirits or assessing volatile compounds for flavor profiling. Environmental testing laboratories employ these machines for analyzing pollutants and contaminants in water and soil samples. Government agencies and regulatory bodies also serve as key customers, utilizing distillation testers for enforcing product standards, conducting forensic analysis, and ensuring compliance across various industries. The diverse needs of these end-users, ranging from basic analytical requirements to highly specialized research applications, drive the demand for a broad spectrum of distillation testing machinery, from basic manual units to advanced, fully automated, and integrated systems.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1.25 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Anton Paar GmbH, Koehler Instrument Company, PAC (A Family of Analytical Instrument Companies), Grabner Instruments (A Member of the Anton Paar Group), Tanaka Scientific Ltd., Humboldt Mfg. Co., LAUDA DR. R. WOBSER GMBH & CO. KG, ISL S.P.A., Normalab Analis, Scientific Glassware & Instruments, AD Systems, ORBIS, OptiDist, Analytik Jena AG (A Endress+Hauser Company), ELE International, Seta Analytics. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Distillation Testing Machinery Market Key Technology Landscape

The Distillation Testing Machinery Market is profoundly shaped by a dynamic technological landscape that continuously strives for enhanced precision, automation, and efficiency. Central to this evolution are advanced automated control systems that minimize manual intervention, ensuring highly reproducible results and reducing human error. These systems often incorporate sophisticated microprocessors and programmable logic controllers (PLCs) for precise regulation of heating, cooling, and reflux ratios, which are critical for accurate separation and analysis. The integration of high-resolution sensors for real-time monitoring of temperature, pressure, and distillation volume further contributes to the accuracy and reliability of the testing process. These sensors provide continuous data feedback, allowing for dynamic adjustments and more granular control over the distillation parameters.

Another significant technological advancement is the development of robust data acquisition and analysis software. Modern distillation testers are equipped with intuitive software interfaces that not only control the instrument but also automatically collect, process, and store large volumes of data. This software often includes features for generating comprehensive reports, performing statistical analysis, and comparing results against established standards. The advent of IoT (Internet of Things) connectivity has enabled remote monitoring and control of distillation units, allowing operators to oversee multiple instruments from a centralized location or even off-site. This capability enhances operational flexibility, facilitates troubleshooting, and enables proactive maintenance, thereby improving overall laboratory productivity and reducing downtime.

Furthermore, the incorporation of Artificial Intelligence (AI) and Machine Learning (ML) algorithms is beginning to revolutionize the market. AI-driven systems can analyze complex distillation curves, predict optimal operating parameters, detect anomalies, and even learn from historical data to improve performance over time. This leads to more intelligent process optimization, enhanced predictive maintenance capabilities, and a deeper understanding of sample characteristics. Modular design principles are also gaining traction, offering greater flexibility for customization, easier maintenance, and simplified upgrades. Coupled with enhanced safety features, such as automatic shutdown mechanisms and advanced fume management systems, these technological advancements are making distillation testing machinery more precise, user-friendly, safer, and integrated into modern, smart laboratory environments.

Regional Highlights

- North America: This region represents a mature yet robust market for distillation testing machinery, driven by stringent quality control regulations in the petrochemical, pharmaceutical, and chemical industries. Significant investment in research and development, coupled with a high adoption rate of advanced automation technologies, ensures a steady demand for sophisticated and highly accurate instruments. The presence of major industry players and an emphasis on environmental compliance further solidify its market position.

- Europe: Europe is another key market characterized by a strong focus on innovation, adherence to strict environmental standards, and a well-established industrial base. Countries like Germany, France, and the UK are leaders in chemical and pharmaceutical manufacturing, necessitating advanced distillation testing solutions. The region also emphasizes sustainable practices, driving demand for energy-efficient and environmentally compliant machinery.

- Asia Pacific (APAC): The APAC region is projected to be the fastest-growing market, primarily due to rapid industrialization, expanding manufacturing sectors (especially in chemicals, petroleum, and pharmaceuticals) in countries like China, India, and Southeast Asia. Increasing investments in infrastructure, rising R&D activities, and a growing emphasis on quality control are fueling the adoption of distillation testing machinery across diverse applications.

- Latin America: This region exhibits promising growth, largely driven by the expansion of the oil and gas sector and the development of new refining capacities. Countries such as Brazil and Mexico are investing in industrial infrastructure, leading to increased demand for robust distillation testing equipment for petroleum product analysis and quality assurance.

- Middle East & Africa (MEA): The MEA region's market growth is predominantly propelled by its significant oil and gas reserves and substantial investments in petrochemical projects. As these economies diversify and industrialize, the demand for accurate and reliable distillation testing machinery for quality control and process optimization in related industries is expected to rise considerably.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Distillation Testing Machinery Market.- Anton Paar GmbH

- Koehler Instrument Company

- PAC (A Family of Analytical Instrument Companies)

- Grabner Instruments (A Member of the Anton Paar Group)

- Tanaka Scientific Ltd.

- Humboldt Mfg. Co.

- LAUDA DR. R. WOBSER GMBH & CO. KG

- ISL S.P.A.

- Normalab Analis

- Scientific Glassware & Instruments

- AD Systems

- ORBIS

- OptiDist

- Analytik Jena AG (A Endress+Hauser Company)

- ELE International

- Seta Analytics

- Petrotest Instruments GmbH & Co. KG

- Atago Co., Ltd.

- DAKKAN

- Wiggens GmbH

Frequently Asked Questions

What is the primary purpose of distillation testing machinery?

Distillation testing machinery is primarily used to determine the boiling range characteristics of liquid samples by separating components based on their volatility. This process is crucial for quality control, product characterization, and compliance with industry standards in sectors like petroleum, chemicals, and pharmaceuticals.

How do automated distillation testers differ from manual ones?

Automated distillation testers offer enhanced precision, reproducibility, and efficiency by precisely controlling heating, cooling, and data collection without manual intervention. They reduce human error, provide real-time data logging, and often integrate with laboratory information systems, unlike manual systems that rely on operator judgment and physical observation.

What industries are the main users of distillation testing equipment?

The primary industries utilizing distillation testing equipment include petroleum refining and petrochemicals, chemical manufacturing, pharmaceutical and biotechnology, food and beverage, and academic or industrial research laboratories. Environmental testing agencies and governmental regulatory bodies also rely on these instruments.

What are the key benefits of integrating AI into distillation testing machinery?

AI integration offers benefits such as predictive maintenance to minimize downtime, real-time optimization of distillation parameters for increased efficiency, automated data analysis and reporting for faster insights, and enhanced quality control through intelligent anomaly detection. This leads to superior product consistency and operational savings.

How do global regulations impact the market for distillation testing machinery?

Global regulations, such as ASTM, ISO, and IP standards, significantly impact the market by mandating specific testing protocols and quality benchmarks for various products. This drives the demand for compliant, accurate, and often automated distillation testing machinery, compelling manufacturers to innovate and meet evolving international requirements.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager