Distilled Monoglyceride Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431531 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Distilled Monoglyceride Market Size

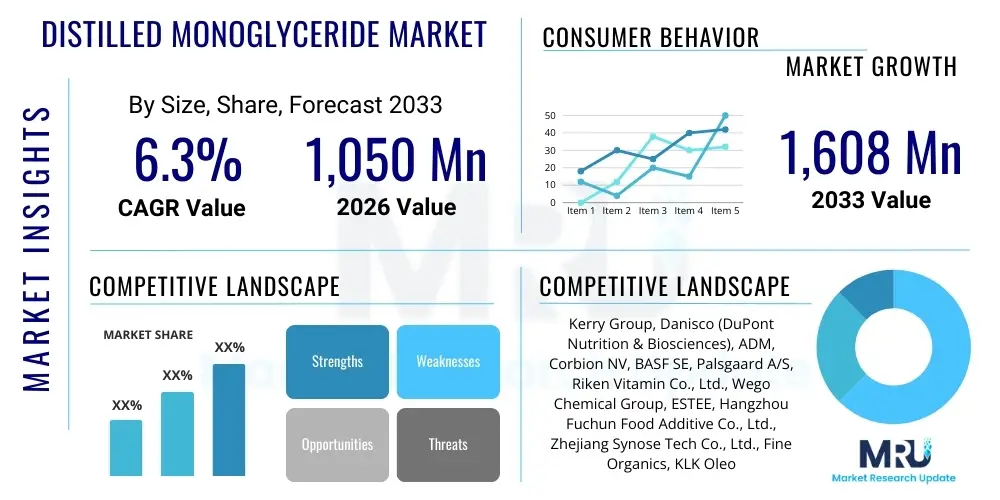

The Distilled Monoglyceride Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.3% between 2026 and 2033. The market is estimated at USD 1,050 million in 2026 and is projected to reach USD 1,608 million by the end of the forecast period in 2033.

Distilled Monoglyceride Market introduction

Distilled Monoglyceride (DMG) is a highly purified, non-ionic emulsifier widely utilized across the food, pharmaceutical, and cosmetic industries. Derived primarily from vegetable oils, such as soybean, palm, or rapeseed oil, DMG acts fundamentally as a surface-active agent, stabilizing oil-in-water and water-in-oil emulsions, thus preventing phase separation, enhancing texture, and extending shelf life. Its high purity level (typically over 90% monoglycerides) makes it superior to standard commercial monoglycerides, ensuring greater efficiency and better performance in sensitive applications like baked goods, dairy products, and specialized nutritional formulations. The primary function of DMG in the food sector is as an anti-staling agent in bread and a crystallizing agent in fat products.

The market expansion is strongly driven by the increasing global demand for processed and convenience foods, which heavily rely on functional ingredients like DMG to maintain quality and stability throughout complex supply chains. Furthermore, the rising consumer awareness regarding natural and plant-derived ingredients is bolstering the demand for DMG, as it is often sourced from sustainable vegetable origins, appealing to health-conscious consumers. The versatility of DMG extends beyond food; in the pharmaceutical industry, it serves as an excipient, solubilizer, and drug carrier, while in cosmetics, it functions as an emollient and stabilizer in creams and lotions. This broad application base ensures sustained growth and resilience across various economic cycles.

Key driving factors include the rapid industrialization of emerging economies, leading to higher consumption of processed food and baked goods, and continuous innovation in emulsification technology to meet stringent regulatory requirements. The benefits of DMG—such as improved texture, enhanced stability, and the ability to reduce fat content in certain applications—position it as an indispensable ingredient for manufacturers aiming for product excellence. However, fluctuations in the price and supply of raw vegetable oils and stringent food safety regulations pose challenges that necessitate robust supply chain management and compliance strategies within the market.

Distilled Monoglyceride Market Executive Summary

The Distilled Monoglyceride (DMG) Market is characterized by robust growth, primarily propelled by burgeoning demand from the global food and beverage sector, particularly in bakery, dairy, and confectionery applications, where DMG is essential for texture enhancement and shelf life extension. Business trends highlight a significant focus on research and development (RD) to create non-GMO and certified organic DMG variants, catering to evolving clean-label consumer preferences. Major players are expanding production capacities in Asia Pacific to capitalize on high population growth and increasing disposable income, which translates directly into higher consumption of processed foods. Consolidation and strategic partnerships among key manufacturers and ingredient suppliers are emerging trends aimed at optimizing supply chain logistics and securing consistent raw material procurement, especially concerning palm and soybean oil derivatives.

Regionally, Asia Pacific (APAC) dominates the market share due to its massive population base, rapid urbanization, and the corresponding shift towards Westernized dietary habits, demanding high volumes of shelf-stable food products. North America and Europe maintain steady growth, driven by advanced regulatory frameworks emphasizing food safety and a high adoption rate of sophisticated food processing technologies. Segment trends indicate that the food applications segment holds the largest revenue share, with bakery and confectionery sub-segments being the primary consumers. Furthermore, the powdered form of DMG is gaining traction over the solid or liquid forms, offering advantages in ease of handling, storage, and precise dosage control in industrial formulations, suggesting a shift towards highly refined and specialized product forms to meet specific functional needs.

AI Impact Analysis on Distilled Monoglyceride Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Distilled Monoglyceride market commonly center on optimizing synthesis processes, predictive quality control, and improving supply chain resilience against volatile raw material costs. Users are keen to know if AI can facilitate the rapid development of novel emulsifier structures that perform better than conventional DMG, or if it can optimize the fermentation process (for microbially produced monoglycerides) to enhance yield and purity. Key concerns revolve around the capital investment required for adopting AI-driven smart manufacturing systems and the ability of existing infrastructure to integrate complex AI algorithms for real-time feedstock analysis and predictive maintenance of distillation equipment. The consensus expectation is that AI will primarily enhance operational efficiency, reduce waste, and provide deeper market demand forecasts, thereby stabilizing pricing and supply.

- AI-driven optimization of reaction parameters (temperature, pressure, catalyst concentration) to maximize DMG yield and purity during glycerolysis and subsequent molecular distillation.

- Predictive maintenance analytics using machine learning to monitor distillation column performance, reducing unplanned downtime and operational costs associated with high-purity processing.

- Enhanced quality control systems utilizing computer vision and spectroscopy combined with AI for real-time contaminant detection and verification of specified ester levels (monoglyceride content).

- Optimization of raw material sourcing (palm oil, soybean oil, animal fats) by predicting price fluctuations and ensuring sustainable sourcing compliance, thus mitigating supply chain risks.

- Accelerated research and development through AI modeling of lipid interactions, enabling the quicker formulation of novel DMG derivatives tailored for specific end-user textures (e.g., low-fat applications).

- Demand forecasting and inventory management improvement through machine learning algorithms that analyze global consumption patterns across bakery, dairy, and cosmetic industries, optimizing production schedules.

DRO & Impact Forces Of Distilled Monoglyceride Market

The Distilled Monoglyceride market growth is fundamentally driven by the escalating demand for processed foods globally, particularly in densely populated and developing regions, where shelf stability and textural improvement are critical performance requirements. However, this growth is significantly restrained by the high volatility in the prices of key raw materials, primarily vegetable oils like palm oil and soybean oil, which directly impact production costs and profit margins. Opportunities are vast in the pursuit of sustainable and clean-label solutions, encouraging investment in non-GMO, organic, and plant-based sourced DMG, aligning with evolving consumer preferences. Furthermore, the expansion of applications into specialized areas such as nutraceuticals and targeted drug delivery systems presents lucrative avenues for market participants seeking product diversification and premium pricing.

Impact forces within the DMG market are multifaceted. The bargaining power of suppliers is moderate; while raw material costs fluctuate significantly, the availability of multiple oil sources (soy, palm, sunflower, rapeseed) helps mitigate risks associated with reliance on a single commodity. The bargaining power of buyers is high, especially for large multinational food corporations who purchase DMG in bulk and exert pressure on pricing and quality standards. The threat of new entrants is low to moderate, given the high capital investment required for high-ppurity molecular distillation technology and the stringent regulatory hurdles associated with food additives and emulsifiers. Conversely, the threat of substitutes is moderate, with alternative emulsifiers like lecithin, polysorbates, and specialized esters offering competing functionalities in specific applications, compelling DMG manufacturers to continuously innovate and maintain cost competitiveness.

The market faces external influence from geopolitical dynamics affecting agricultural trade and increasingly stringent environmental regulations regarding palm oil sourcing, necessitating robust certification and traceability systems. Technological advancement in manufacturing efficiency, such as continuous distillation and enzymatic production, acts as a pivotal force, driving down operational costs and improving product quality consistency. The cumulative effect of these drivers and opportunities outweighs the restraints and competitive pressures, positioning the Distilled Monoglyceride market for stable, long-term expansion, particularly within the APAC region and specialized pharmaceutical segments.

Segmentation Analysis

The Distilled Monoglyceride market is segmented across several crucial parameters, including Source, Form, Purity Level, and Application, providing a granular view of consumption patterns and key revenue drivers. Segmentation by source is critical, separating the market into plant-based (primarily palm, soy, and rapeseed) and animal-based sources, reflecting varying consumer preferences for vegetarian and vegan products. The application segmentation, spanning bakery, dairy, plastics, and pharmaceuticals, demonstrates the versatility of DMG as a functional ingredient. This structured analysis allows market participants to tailor their product offerings—such as producing powdered DMG for ease of use in dry mixes or high-purity grades for pharmaceutical excipients—to target specific high-growth sectors effectively.

- By Source

- Plant-Based (Soybean, Palm, Rapeseed, Sunflower)

- Animal-Based (Tallow, Lard)

- By Form

- Powder

- Liquid/Paste

- Beads/Flakes

- By Purity Level

- Food Grade (90% - 95% Monoglyceride Content)

- Pharmaceutical Grade (95%+ Monoglyceride Content)

- Industrial Grade

- By Application

- Food and Beverage

- Bakery Products (Bread, Cakes, Pastries)

- Dairy and Frozen Desserts (Ice Cream, Whipped Toppings)

- Confectionery (Chewing Gum, Chocolates)

- Fats and Oils (Margarine, Shortening)

- Plastics and Polymers (Antifogging Agents, Lubricants)

- Pharmaceuticals and Cosmetics (Emollients, Excipients)

- Others (Textiles, Agro-chemicals)

- Food and Beverage

- By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

Value Chain Analysis For Distilled Monoglyceride Market

The value chain for Distilled Monoglyceride begins with the upstream procurement of raw materials, primarily triglycerides sourced from vegetable oils (such as palm, soy, coconut) or animal fats. Raw material sourcing involves complex global commodity trading, making price stability and sustainable certification (e.g., RSPO for palm oil) paramount. Following procurement, the manufacturing phase involves glycerolysis—the reaction of fats or oils with glycerol—to produce crude monoglycerides, which are subsequently subjected to high-vacuum molecular distillation to achieve the high purity (distilled) form required by the market (typically over 90% alpha-monoglycerides). This distillation step is the most critical and capital-intensive part of the value chain, requiring specialized equipment and technical expertise to ensure product quality and functional efficacy.

The midstream phase focuses on formulation and preparation, where the purified DMG is processed into various forms—powder, flakes, or paste—to suit diverse end-user applications. Quality testing and regulatory compliance are integrated at this stage, ensuring the product meets specific food safety standards (like FDA or EFSA approvals) or pharmaceutical quality requirements. The downstream activities involve distribution and sales. Distribution channels are typically dual: direct sales to major multinational food and chemical processors that require high volumes and customized specifications, and indirect sales through specialized distributors and ingredient suppliers who serve smaller and medium-sized enterprises (SMEs) across fragmented geographic markets.

Direct distribution offers greater control over product specifications and client relationships, particularly for pharmaceutical-grade DMG, while indirect distribution leverages specialized logistics and market access in emerging regions like Southeast Asia and Latin America. Effective coordination between manufacturing and distribution is crucial, as the shelf life and storage conditions of certain DMG forms necessitate controlled logistics. The final stage involves the end-user application, where DMG is integrated into the final product, such as bakery ingredients, plastic films, or pharmaceutical capsules, generating the final market value. Efficiency and cost optimization at the distillation and distribution phases are key to maintaining competitive pricing and market penetration.

Distilled Monoglyceride Market Potential Customers

The primary customers for Distilled Monoglycerides are large-scale industrial manufacturers across several distinct sectors, with the Food and Beverage industry representing the most significant consumption base. Within this sector, key buyers include commercial bakeries (seeking anti-staling agents for bread and volume enhancers), confectionery manufacturers (using DMG for fat crystallization and bloom control in chocolate), and dairy processors (requiring stabilization in ice cream and whipped toppings). These customers prioritize high emulsifying power, consistency, and compliance with strict food additive regulations. Their procurement is highly centralized, focusing on long-term contracts with established DMG suppliers who can guarantee substantial volume and regulatory paperwork.

Beyond food, the plastics and polymer industry represents a substantial secondary customer base. These manufacturers utilize DMG primarily as an internal lubricant, mold release agent, and, crucially, as an anti-fogging agent in plastic films used for food packaging and agricultural applications. The demand here is driven by the need for regulatory compliance regarding packaging safety and improved film clarity. Pharmaceutical and cosmetic companies constitute the third major customer group. Pharmaceutical firms utilize high-purity DMG as excipients, bioavailability enhancers, and non-active ingredients in oral dosage forms and topical formulations. Cosmetic manufacturers use DMG for its emollient and thickening properties in skin creams, lotions, and hair care products, demanding ingredients that are hypoallergenic and compatible with active cosmetic compounds.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1,050 million |

| Market Forecast in 2033 | USD 1,608 million |

| Growth Rate | CAGR 6.3% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Kerry Group, Danisco (DuPont Nutrition & Biosciences), ADM, Corbion NV, BASF SE, Palsgaard A/S, Riken Vitamin Co., Ltd., Wego Chemical Group, ESTEE, Hangzhou Fuchun Food Additive Co., Ltd., Zhejiang Synose Tech Co., Ltd., Fine Organics, KLK Oleo, Guangzhou Kardn Chemical Co., Ltd., Stepan Company, Cargill Incorporated, Jiangsu Kolod Food Ingredients Co., Ltd., Spiga Nord S.p.A., Shandong Jianyuan Bioengineering Co., Ltd., Lonza Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Distilled Monoglyceride Market Key Technology Landscape

The core technology underpinning the Distilled Monoglyceride market is the process of molecular distillation, which is crucial for achieving the high purity levels required for food and pharmaceutical grades (typically above 90% monoglyceride content). This process involves subjecting crude monoglycerides, obtained via glycerolysis of fats, to high vacuum and temperature conditions. The advantage of molecular distillation is its ability to separate monoglycerides from unreacted glycerol, diglycerides, and triglycerides without causing thermal degradation, ensuring a high-quality, functional end product. Advances in thin-film and short-path distillation technologies have enhanced efficiency, reducing processing time and energy consumption, thereby lowering overall production costs and improving throughput capacity for major manufacturers.

Beyond traditional chemical synthesis, the market is witnessing growing adoption of enzymatic methods for monoglyceride production. Lipase-catalyzed esterification offers a 'greener' alternative, performing the reaction under milder conditions (lower temperatures and neutral pH), which minimizes energy usage and reduces the formation of undesirable byproducts. This technology is particularly appealing for manufacturers targeting the clean-label and natural ingredient segments, as it avoids harsh chemical catalysts. While enzymatic synthesis currently faces challenges related to enzyme stability and cost, ongoing research focused on enzyme immobilization and optimization promises to increase the feasibility and scalability of this method in the near future, making it a key technology driver for sustainable DMG production.

Furthermore, digital transformation is impacting the manufacturing landscape. Advanced sensor technology and process analytical technologies (PAT) are increasingly integrated into DMG production lines. These technologies allow for continuous, real-time monitoring of key quality attributes during the glycerolysis and distillation phases. The adoption of automation and data analytics facilitates proactive quality adjustments, minimizes batch variation, and ensures strict adherence to required specifications, particularly crucial for the sensitive pharmaceutical segment. The focus is shifting towards integrated manufacturing systems that utilize AI and machine learning to predict optimal process settings based on feedstock variability, maximizing consistency and operational resilience.

Regional Highlights

- Asia Pacific (APAC): APAC represents the fastest-growing and largest regional market for Distilled Monoglycerides. This dominance is attributed to rapid industrialization, massive population growth, and the corresponding escalation in demand for processed and packaged foods, particularly in China, India, and Southeast Asian nations. The region serves both as a major consumption hub and a crucial manufacturing base, benefiting from relatively lower operating costs and easy access to palm oil feedstock.

- North America: North America holds a significant market share, driven by mature food processing industries and high demand for functional ingredients in bakery, snacks, and convenience foods. Strict regulatory requirements by the FDA ensure high product quality, driving consumption towards pharmaceutical and high-purity food-grade DMG. Innovation in health and wellness, including demand for low-fat formulations requiring strong emulsification, further supports steady market expansion.

- Europe: The European market is characterized by stringent food safety standards (EFSA) and a strong consumer inclination towards clean-label, non-GMO, and sustainably sourced ingredients. Growth is stable, driven by the well-established dairy and confectionery industries. Emphasis on reducing food waste also boosts the demand for DMG as an effective anti-staling agent in baked goods across countries like Germany and the UK.

- Latin America (LATAM): The LATAM region shows promising growth, fueled by increasing urbanization and the expansion of the organized retail sector. Countries like Brazil and Mexico are experiencing higher adoption of processed foods, translating into increased industrial consumption of emulsifiers. Economic stability improvements are key drivers for industrial expansion in the food sector.

- Middle East and Africa (MEA): Growth in MEA is moderate but accelerating, primarily driven by investments in food security initiatives and expanding local food manufacturing capabilities, especially in the UAE and Saudi Arabia. The use of DMG in specialized applications like plastic production (anti-fogging films) and industrial lubricants is also contributing to localized market traction.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Distilled Monoglyceride Market.- Kerry Group

- Danisco (DuPont Nutrition & Biosciences)

- ADM (Archer Daniels Midland Company)

- Corbion NV

- BASF SE

- Palsgaard A/S

- Riken Vitamin Co., Ltd.

- Wego Chemical Group

- ESTEE

- Hangzhou Fuchun Food Additive Co., Ltd.

- Zhejiang Synose Tech Co., Ltd.

- Fine Organics

- KLK Oleo

- Guangzhou Kardn Chemical Co., Ltd.

- Stepan Company

- Cargill Incorporated

- Jiangsu Kolod Food Ingredients Co., Ltd.

- Spiga Nord S.p.A.

- Shandong Jianyuan Bioengineering Co., Ltd.

- Lonza Group

Frequently Asked Questions

Analyze common user questions about the Distilled Monoglyceride market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Distilled Monoglyceride (DMG) and its primary function?

DMG is a highly purified, non-ionic emulsifier, typically derived from vegetable fats. Its primary function is to stabilize emulsions, preventing fat separation, improving texture (especially anti-staling in baked goods), and extending the shelf life of processed food products, pharmaceuticals, and cosmetics.

Which segment holds the largest share in the Distilled Monoglyceride Market?

The Food and Beverage application segment holds the largest market share, with key consumption areas being bakery products, confectionery, and dairy. The demand for DMG in these sectors is driven by the necessity for optimal texture management and stabilization in mass-produced goods.

What are the main raw materials used for manufacturing DMG, and how does raw material volatility affect the market?

The main raw materials are triglycerides, primarily sourced from vegetable oils such as palm oil, soybean oil, and rapeseed oil. High volatility in the prices of these global commodities significantly impacts the manufacturing costs and profit margins for DMG producers, necessitating sophisticated supply chain hedging strategies.

How is the adoption of enzymatic production methods influencing the DMG market?

Enzymatic production methods, which utilize lipase catalysts, are influencing the market by offering a 'cleaner,' more sustainable manufacturing process under milder conditions. This supports the growing consumer demand for natural, non-chemically synthesized, and clean-label emulsifiers, particularly in North America and Europe.

Which geographical region is projected to exhibit the fastest growth in DMG consumption through 2033?

The Asia Pacific (APAC) region is projected to exhibit the fastest growth due to rapid urbanization, increasing per capita income, and the massive scale-up of the processed food industry in populous nations like China and India, making it the central hub for future market expansion.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Distilled Monoglyceride Market Size Report By Type (Food Grade, Industrial Grade), By Application (Bakery, Confectionery, Frozen Desserts, Plastics, Other), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Distilled Monoglyceride Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Food Grade DMG, Industrial Grade DMG), By Application (Bakery, Confectionery, Frozen Desserts, Plastics, Other), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager