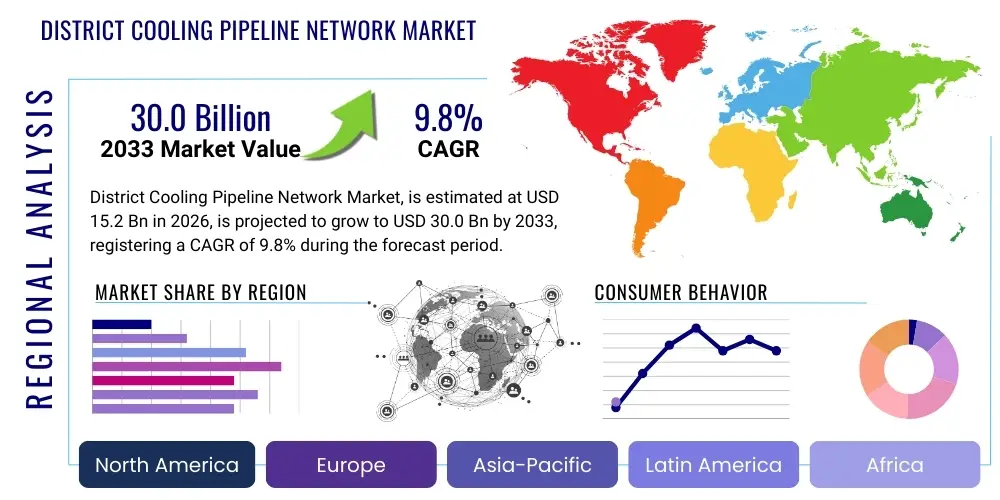

District Cooling Pipeline Network Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437560 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

District Cooling Pipeline Network Market Size

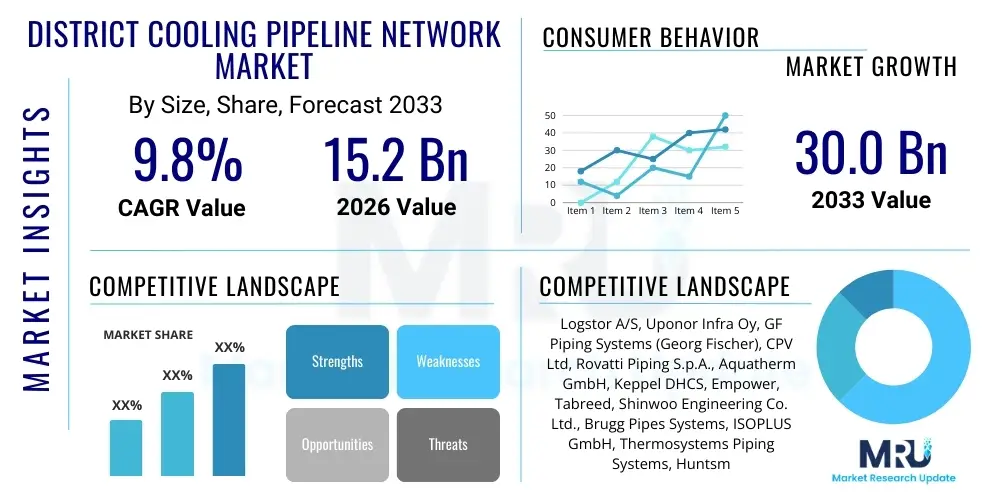

The District Cooling Pipeline Network Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.8% between 2026 and 2033. The market is estimated at USD 15.2 Billion in 2026 and is projected to reach USD 30.0 Billion by the end of the forecast period in 2033.

District Cooling Pipeline Network Market introduction

The District Cooling Pipeline Network Market encompasses the infrastructure essential for distributing chilled water or other cooling mediums from a centralized production plant to multiple end-users within a geographical area. This network primarily consists of high-efficiency, pre-insulated piping systems designed to minimize thermal losses and ensure consistent, reliable cooling services for residential, commercial, and industrial facilities. District cooling systems offer significant advantages over traditional, decentralized air conditioning units, including enhanced energy efficiency, reduced carbon emissions, lower peak electricity demand, and improved aesthetic quality due to the elimination of numerous individual cooling towers.

Major applications of district cooling pipeline networks span large urban developments, business districts, airports, universities, and massive commercial complexes where continuous, centralized cooling is economically and environmentally beneficial. Key benefits driving market adoption include the scalability of cooling capacity, operational savings derived from optimized plant maintenance, and compliance with stringent urban sustainability goals mandated by local and national governments globally. The foundational pipeline technology, utilizing durable materials like steel or high-density polyethylene (HDPE) encased in polyurethane foam insulation, is crucial for system longevity and thermal performance.

Driving factors propelling market expansion include rapid urbanization in emerging economies, increasing implementation of green building standards and energy efficiency codes, and substantial infrastructure investments by governments aiming to modernize their energy grids and reduce reliance on fossil fuels for cooling. Furthermore, the rising global temperatures necessitate more robust and sustainable cooling solutions, making district cooling a critical component of climate resilience strategies in densely populated metropolitan areas worldwide. The shift toward smart city initiatives also integrates advanced monitoring and control systems within the pipeline network, further enhancing operational efficiency and market value.

District Cooling Pipeline Network Market Executive Summary

The District Cooling Pipeline Network Market is poised for substantial growth, driven primarily by favorable regulatory environments promoting energy efficiency and massive infrastructure development across the Middle East, Asia Pacific, and North America. Key business trends indicate a strong move toward public-private partnerships (PPPs) to finance large-scale network deployments, fostering collaboration between governmental entities and specialized utility providers. Furthermore, technological innovation focuses heavily on enhancing pipe material resilience, improving insulation efficiency, and integrating digital twin technology for predictive maintenance and real-time flow optimization, thereby lowering the total cost of ownership for operators.

Regionally, the Middle East continues to dominate the market share, fueled by large-scale, climate-intensive cooling requirements for mega-projects and sustainable urban planning mandates in nations like the UAE and Saudi Arabia. Asia Pacific exhibits the fastest growth trajectory, driven by rapid industrialization and the urgent need for efficient cooling infrastructure in heavily populated urban centers such as China, India, and Southeast Asia. Europe and North America focus more on modernizing existing, aging networks and expanding service into dense city cores, leveraging stringent carbon neutrality targets as a primary market catalyst.

Segment trends underscore the dominance of the Pre-insulated Steel Pipe segment due to its robustness and applicability in high-pressure, long-distance urban deployments, though the adoption of non-metallic pipes (e.g., PEX and HDPE) is increasing, particularly in smaller distribution loops and residential areas due to lower installation costs. The commercial sector remains the largest end-user segment, but the residential segment shows accelerating growth as developers recognize the long-term energy savings and centralized billing convenience offered by district cooling. The market is increasingly competitive, with leading players focusing on strategic acquisitions and expanding their portfolio of advanced monitoring and leak detection technologies to maintain operational superiority.

AI Impact Analysis on District Cooling Pipeline Network Market

Common user questions regarding AI's impact on district cooling pipeline networks revolve around how artificial intelligence can minimize energy consumption, predict equipment failures, and optimize system operation in real-time across vast urban networks. Users are deeply concerned about ensuring reliability and maximizing the lifespan of expensive underground infrastructure. The key themes emerging from this analysis include the expectation that AI will transform predictive maintenance scheduling, significantly reducing unexpected downtime and massive repair costs associated with deep-buried pipes. There is also high anticipation for AI to dynamically adjust flow rates and temperatures based on predicted demand (weather forecasts, occupancy rates), moving operations from reactive control to proactive optimization. Concerns often center on the security of sensor data and the initial capital investment required for deploying the necessary smart sensors and centralized data analytics platforms.

AI’s influence is shifting district cooling operations from fixed-schedule, manual management to highly dynamic, data-driven optimization. Advanced machine learning algorithms analyze historical performance data, acoustic monitoring inputs, temperature readings, and pressure variances across thousands of kilometers of pipelines to identify minute deviations that signal potential issues like pipe corrosion, insulation failure, or incipient leaks long before catastrophic failure occurs. This predictive capability translates directly into enormous savings on chilled water loss and unplanned maintenance expenses. By forecasting cooling loads with high accuracy, AI ensures the central chiller plant operates at its most efficient partial-load point, preventing energy wastage associated with overproduction or unnecessary cycling of equipment.

Furthermore, AI-driven automation is essential for managing the complexity of multi-source cooling systems, such as those that integrate traditional chillers with thermal energy storage (TES) or utilize natural sources like deep lake water cooling (DLWC). AI algorithms determine the optimal time to charge or discharge the TES tanks, or to switch between cooling sources, based on fluctuating energy prices and real-time network demands, thus maximizing economic benefit while maintaining client comfort. The continuous learning capability of these AI models allows the pipeline network to adapt seamlessly to changes in urban density, climate patterns, and load profiles over the decades-long lifespan of the infrastructure, cementing AI as a pivotal technology for future market development and operational excellence.

- AI-driven predictive maintenance reduces pipeline failure rates by up to 30%.

- Optimized chiller loading based on AI forecasting minimizes peak energy consumption.

- Real-time leak detection using machine learning algorithms analyzes acoustic and pressure data.

- Automated flow balancing and valve adjustments maximize hydraulic efficiency across the network.

- Digital Twin creation through AI modeling enables accurate simulation of future expansion scenarios.

DRO & Impact Forces Of District Cooling Pipeline Network Market

The District Cooling Pipeline Network Market is shaped by a critical interplay of strong governmental mandates (Drivers) and high initial capital outlay (Restraints), creating significant long-term growth prospects (Opportunities). The driving forces are dominated by the global imperative for energy efficiency, aggressive decarbonization goals set by major economies, and the inherent scalability and operational cost efficiency of centralized cooling infrastructure in dense urban environments. Conversely, the market faces significant hurdles related to the substantial upfront investment required for laying extensive underground piping and the complexities associated with acquiring right-of-way permissions in established metropolitan areas. These restraints, however, often lead to a greater push toward innovative trenchless installation methods and streamlined regulatory processes.

Impact forces currently accelerating market adoption include the increasing frequency and intensity of extreme heat events globally, which fundamentally raises the baseline demand for reliable cooling solutions, forcing policymakers to seek large-scale, sustainable utility infrastructure. The opportunity landscape is vast, particularly in transitioning economies where massive new city developments (e.g., smart cities and economic free zones) are being planned from the ground up, allowing district cooling networks to be integrated seamlessly into the foundational infrastructure rather than retrofitted. Furthermore, technological leaps in material science, specifically the development of composite and polymer pipes with enhanced thermal resistance, offer new opportunities for reducing installation complexity and improving network longevity.

The market environment is highly sensitive to regulatory shifts, where mandatory requirements for energy performance certificates in new buildings often translate directly into increased demand for district cooling connections. The primary drivers ensure a consistent demand base, while opportunities focus on geographical expansion into underserved markets and leveraging new financing models, such as utility performance contracts. Managing the restraint of high capital costs is typically mitigated through robust governmental subsidies, long-term concession agreements, and the securitization of future utility revenue streams, making these massive infrastructure projects viable for private investment and sustaining market momentum throughout the forecast period.

- Drivers:

- Stringent government regulations promoting energy efficiency and low-carbon development.

- High operational efficiency and reduced maintenance costs compared to decentralized systems.

- Rapid urbanization and increasing density of commercial and residential developments.

- Restraints:

- High initial capital investment and long project implementation timelines.

- Complexities in obtaining right-of-way and navigating dense underground utility networks in established cities.

- Risk associated with fluctuating material costs (steel, insulation foams).

- Opportunities:

- Integration with renewable energy sources (e.g., solar thermal, geothermal).

- Expansion into smart city infrastructure projects and new planned urban zones.

- Technological advancements in non-metallic pipe materials and trenchless installation techniques.

- Impact Forces:

- Global climate change increasing the demand for consistent, high-capacity cooling.

- Favorable public-private partnership (PPP) models reducing investment barriers.

- Increased focus on resilience and reliability of utility infrastructure.

Segmentation Analysis

The District Cooling Pipeline Network Market is rigorously segmented primarily based on the Pipe Type, Material, Diameter, and End-User, allowing for a granular understanding of procurement patterns and technological preferences across various applications. The segmentation by Pipe Type, differentiating between primary (main distribution) and secondary (building connection) networks, highlights the necessity for varying material specifications and insulation levels based on distance and flow requirements. Analysis of these segments is crucial for manufacturers to tailor their product offerings, focusing on high-pressure capabilities for primary feeders and flexibility for secondary loops.

The Material segmentation—encompassing pre-insulated steel, HDPE, PEX, and composite pipes—is particularly sensitive to geographical regulations, local construction practices, and the climate envelope of the deployment area. While steel pipes dominate large-scale, high-temperature, and high-pressure applications, the non-metallic options are gaining traction for smaller distribution systems and environments where corrosion is a major concern. Furthermore, the segmentation by End-User (Commercial, Residential, Industrial, Institutional) reveals that the commercial sector, including large shopping centers and office towers, remains the backbone of demand due to their consistent, high cooling load requirements, driving the adoption of larger diameter, robust pipeline solutions.

Understanding these segments allows market participants to refine their strategic focus, prioritizing areas where material innovation or tailored network diameter solutions offer the greatest competitive advantage. For instance, the growing institutional segment (universities, hospitals) often demands highly redundant and reliable networks, influencing the choice of material robustness and the implementation of advanced monitoring systems, ensuring uninterrupted critical services. This detailed breakdown ensures accurate forecasting and targeted marketing strategies optimized for specific infrastructure needs worldwide.

- By Pipe Type:

- Primary Network Pipes (Large Diameter, High Pressure)

- Secondary Network Pipes (Smaller Diameter, Flexible)

- By Material:

- Pre-insulated Steel Pipes

- High-Density Polyethylene (HDPE) Pipes

- Cross-linked Polyethylene (PEX) Pipes

- Composite and Fiber-Reinforced Pipes

- By Diameter:

- Small Diameter (Below 300 mm)

- Medium Diameter (300 mm to 600 mm)

- Large Diameter (Above 600 mm)

- By End-User:

- Commercial Sector (Offices, Retail, Hospitality)

- Residential Sector (Multi-Family Buildings, Communities)

- Industrial Sector (Data Centers, Manufacturing Facilities)

- Institutional Sector (Hospitals, Universities, Government Buildings)

Value Chain Analysis For District Cooling Pipeline Network Market

The value chain for the District Cooling Pipeline Network Market is intricate, starting with the upstream supply of raw materials and culminating in the long-term operation and maintenance of the cooling utility. Upstream analysis involves the procurement of key raw materials, primarily specialized steel coils, polyurethane foaming chemicals for insulation, and protective high-density polyethylene jackets. Key challenges at this stage include managing price volatility of steel and maintaining a stable supply chain for high-quality insulation materials that meet stringent thermal performance standards. Manufacturers of pre-insulated piping systems then transform these raw materials, focusing on quality assurance, precise welding, and ensuring the integrity of the pipe-in-pipe structure against thermal and mechanical stress.

The midstream phase involves transportation, often complex due to the large, bulky, and custom lengths of the pipe segments, followed by specialized installation services. Distribution channels are predominantly direct, involving project-specific contracts between pipe manufacturers/suppliers and Engineering, Procurement, and Construction (EPC) firms responsible for the overall project execution. Indirect channels, involving specialized regional distributors, are more common for smaller network expansions or replacement projects where speed of delivery is critical. EPC contractors play a pivotal role, coordinating the intricate process of subterranean installation, which requires specialized trenching and welding expertise, often performed under strict regulatory timelines and urban constraints.

The downstream component involves the operational lifecycle of the network, including the connection to the central chiller plant and the delivery of cooling services to end-users. This stage is dominated by utility operators and District Cooling Service Providers (DCSs) who manage the flow, pressure, and temperature within the network. Revenue generation primarily occurs through long-term service agreements and volumetric charges to end-users. The continuous monitoring and maintenance of the pipelines—including advanced leak detection and cathodic protection systems—are essential for preserving the asset's value, completing the value cycle, and ensuring the economic viability of the entire district cooling project.

District Cooling Pipeline Network Market Potential Customers

The potential customer base for District Cooling Pipeline Networks is defined by entities that require large-scale, sustained, and reliable cooling capacity across clustered or high-density areas, prioritizing energy efficiency and reduced operational complexity over individual unit control. The primary end-users are large real estate developers undertaking new city constructions or major urban redevelopments, such as integrated resorts, massive corporate campuses, or mixed-use waterfront properties. These developers seek district cooling as an integrated utility solution that enhances property value, reduces utility installation clutter, and aligns with environmental, social, and governance (ESG) reporting requirements, simplifying building design and allowing for economies of scale.

A significant category of buyers includes municipal governments and public utility companies, which often initiate and finance these projects as part of city-wide infrastructure modernization or climate resilience programs. For instance, cities investing in high-density institutional zones (government centers, university campuses, major hospital systems) are prime candidates, as these entities require redundant, highly reliable cooling that can only be efficiently provided through centralized utilities. Furthermore, specialized industrial clients, particularly those managing large data centers or pharmaceutical manufacturing facilities that require strict temperature control 24/7, represent a premium buyer segment focused on minimizing downtime risk and maximizing energy efficiency metrics.

The shift towards integrating thermal energy storage (TES) components also expands the customer profile to include energy companies looking to leverage district cooling networks for grid balancing services. By offering cooling-as-a-service, District Cooling Service Providers effectively target facility management companies and property owners who wish to outsource the complexity and capital burden associated with owning and maintaining large individual chiller plants, thereby consolidating the demand for robust pipeline infrastructure across a broad spectrum of commercial activities.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 15.2 Billion |

| Market Forecast in 2033 | USD 30.0 Billion |

| Growth Rate | CAGR 9.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Logstor A/S, Uponor Infra Oy, GF Piping Systems (Georg Fischer), CPV Ltd, Rovatti Piping S.p.A., Aquatherm GmbH, Keppel DHCS, Empower, Tabreed, Shinwoo Engineering Co. Ltd., Brugg Pipes Systems, ISOPLUS GmbH, Thermosystems Piping Systems, Huntsman Corporation, Xylem Inc., Kamstrup A/S, NIBE Group, AERON Composite, Vital Energi, Zamil Steel Industries. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

District Cooling Pipeline Network Market Key Technology Landscape

The technological landscape of the District Cooling Pipeline Network Market is characterized by innovations focusing on material longevity, insulation performance, and digital monitoring capabilities. Central to this landscape is the advancement in pre-insulated piping systems, moving beyond standard steel pipes to include highly efficient composite materials and flexible polymer pipes (HDPE, PEX). Modern pre-insulated systems utilize advanced rigid polyurethane foam insulation with superior lambda values, significantly reducing heat gain (or loss) during chilled water transport, thereby maintaining the cooling medium's temperature stability over long distances and reducing pumping energy requirements. Furthermore, manufacturers are integrating diffused oxygen barrier layers within polymer pipes to prevent corrosion within the system components, extending the life cycle considerably.

A second crucial area is the proliferation of advanced network monitoring and leak detection systems. These technologies rely heavily on fiber optic sensing cables embedded directly within the pipe insulation layer, which can continuously monitor temperature anomalies and moisture ingress, providing instant localization of potential failure points. Acoustic emission technology and pressure wave analysis are also increasingly utilized to detect micro-leaks before they escalate into major failures. This shift towards smart infrastructure requires seamless integration of these sensors with Supervisory Control and Data Acquisition (SCADA) systems and, increasingly, AI-powered analytics platforms that manage the data streams from thousands of network nodes.

Finally, the growing adoption of trenchless installation methodologies, such as horizontal directional drilling (HDD) and pipe bursting, represents a significant technological advancement in the market. These methods minimize disruption to urban environments, drastically reduce construction timelines, and lower the associated costs of extensive open-cut trenching, particularly beneficial in dense metropolitan areas where traditional methods are logistically prohibitive. The combination of high-performance materials, sophisticated real-time diagnostics, and less invasive installation techniques defines the current standard of excellence in district cooling pipeline network deployment and management.

Regional Highlights

The regional dynamics of the District Cooling Pipeline Network Market are highly diversified, reflecting varying climate conditions, regulatory environments, and stages of urban development. The Middle East and Africa (MEA), particularly the Gulf Cooperation Council (GCC) countries, maintain a dominant market position due to extreme climate mandates and substantial investment in massive urban projects like NEOM, Lusail City, and Dubai’s expansion zones. These regions prioritize large-diameter, high-capacity, robust steel pipelines to handle enormous cooling loads over long distances, supported heavily by government long-term utility agreements.

Asia Pacific (APAC) represents the fastest-growing region globally. The escalating demand is fueled by explosive population growth, rapid industrialization, and the urgent need to address energy efficiency in highly dense metropolitan areas like Shanghai, Mumbai, and Singapore. While countries like China and South Korea already boast established systems, emerging economies in Southeast Asia are aggressively adopting district cooling solutions for new commercial centers and integrated townships, often favoring flexible, non-metallic pipes for speed and cost efficiency in installation.

North America and Europe offer mature markets focused on system modernization, expansion, and compliance with strict decarbonization goals. In North America, growth is concentrated around institutional campuses (universities, medical districts) and the revitalization of downtown business areas, often utilizing thermal storage integration. European market expansion, notably in Scandinavian countries and Central Europe, is tightly linked to the integration of waste heat recovery and combined cooling, heating, and power (CCHP) systems, driving demand for technologically advanced piping capable of handling both heating and cooling fluids efficiently, adhering rigorously to European Union standards for material quality and installation practice.

- Middle East & Africa (MEA): Dominant market share driven by extreme climate, mega-projects (e.g., KSA Vision 2030), and mandatory adoption policies for new developments.

- Asia Pacific (APAC): Highest CAGR, fueled by rapid urbanization, massive infrastructure projects in China and India, and increasing governmental focus on energy security.

- North America: Stable growth focused on campus systems, institutional end-users, and pipeline modernization/replacement in densely populated urban cores.

- Europe: Growth linked to integration with centralized heating networks (District Energy), CCHP systems, and strict adherence to environmental sustainability directives.

- Latin America: Emerging market with increasing adoption in large commercial and industrial zones, particularly in Brazil and Mexico, driven by economic development and cooling necessity.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the District Cooling Pipeline Network Market.- Logstor A/S

- Uponor Infra Oy

- GF Piping Systems (Georg Fischer)

- CPV Ltd

- Rovatti Piping S.p.A.

- Aquatherm GmbH

- Keppel DHCS

- Empower

- Tabreed

- Shinwoo Engineering Co. Ltd.

- Brugg Pipes Systems

- ISOPLUS GmbH

- Thermosystems Piping Systems

- Huntsman Corporation

- Xylem Inc.

- Kamstrup A/S

- NIBE Group

- AERON Composite

- Vital Energi

- Zamil Steel Industries

Frequently Asked Questions

Analyze common user questions about the District Cooling Pipeline Network market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary material used for district cooling pipelines in large-scale urban projects?

The primary material used for high-capacity, long-distance pipelines in large urban district cooling projects is pre-insulated steel. Steel offers the necessary structural integrity, high-pressure tolerance, and robustness required for demanding subterranean environments, complemented by rigid polyurethane foam insulation for thermal efficiency.

How does district cooling contribute to achieving urban sustainability goals?

District cooling significantly boosts urban sustainability by centralizing cooling production, which allows for vastly improved energy efficiency (up to 50% compared to individual AC units) and facilitates the use of non-conventional energy sources, thereby reducing overall electricity consumption, carbon emissions, and eliminating urban heat island effects associated with decentralized cooling towers.

What are the main financial barriers to the widespread adoption of district cooling pipeline networks?

The main financial barrier is the extremely high initial capital expenditure (CapEx) required for the manufacturing, acquisition, and complex subterranean installation of extensive pipeline networks. This necessitates long planning horizons, robust financing models, and significant governmental or utility backing to achieve economic viability over the asset's lifespan.

How is AI and advanced sensing technology being integrated into district cooling networks?

AI is integrated through advanced sensing (fiber optics, acoustic monitors) embedded in the pipeline insulation to provide real-time data on temperature, pressure, and moisture ingress. AI algorithms analyze this data for predictive maintenance, optimizing chiller operation based on forecasted demand, and providing early warning of potential leaks or insulation degradation.

Which geographical region is expected to show the fastest market growth rate for pipeline networks?

The Asia Pacific (APAC) region is projected to exhibit the fastest growth rate, primarily driven by accelerated urbanization, massive governmental investment in new smart city infrastructure, and the necessity for energy-efficient cooling in high-density population centers across countries like China, India, and various Southeast Asian nations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager