Diverter Cartridges Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432744 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Diverter Cartridges Market Size

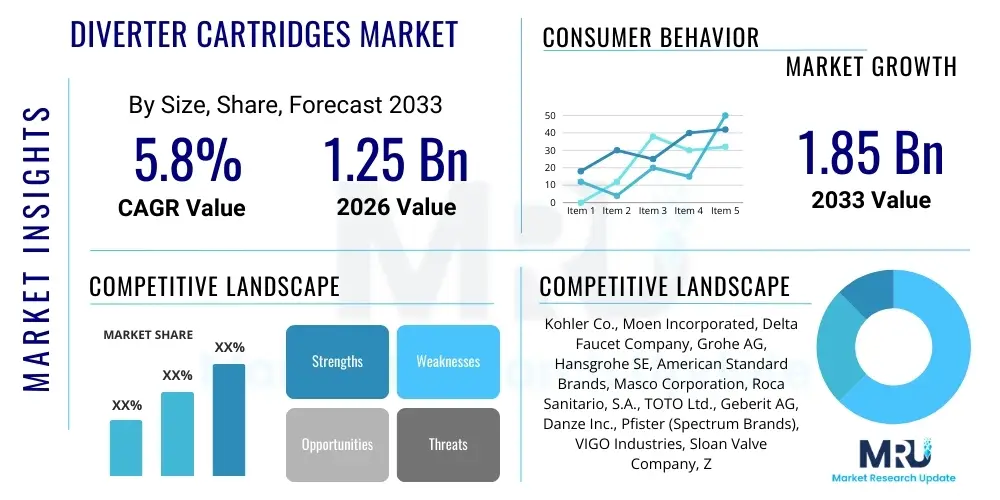

The Diverter Cartridges Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $1.25 Billion in 2026 and is projected to reach $1.85 Billion by the end of the forecast period in 2033.

Diverter Cartridges Market introduction

Diverter cartridges are specialized internal components within plumbing fixtures, primarily faucets and shower systems, designed to redirect the flow of water from one outlet to another. These critical functional elements are responsible for the seamless transition of water flow, for example, from a bathtub spout to a showerhead, or between different spray settings in a multi-function shower system. The market is fundamentally driven by the robust global construction industry, particularly the increasing demand for sophisticated and water-efficient bathroom and kitchen fixtures in both new builds and renovation projects. The evolution of diverter cartridge technology towards higher reliability, precision engineering, and improved longevity is a major underlying trend bolstering market expansion.

The product scope encompasses various types of cartridges, including ceramic disc diverters, pressure-balancing diverters, and thermostatic diverters, each offering distinct advantages in terms of leak prevention, operational smoothness, and temperature stability. Ceramic disc technology is currently dominating the market due to its superior durability and reduced maintenance requirements compared to older compression or stem-type mechanisms. Major applications are prominently observed in the residential sector, driven by consumer preference for luxury and smart bathroom solutions, and the expansive commercial segment, which includes hotels, hospitals, and large institutional facilities requiring high-performance and frequently used plumbing systems.

Key driving factors accelerating the adoption of advanced diverter cartridges include stringent regulatory mandates globally focused on water conservation and efficiency (such as LEED certification standards), coupled with the increasing disposable income in emerging economies fueling higher expenditure on home aesthetics and functional upgrades. Furthermore, the rising trend of do-it-yourself (DIY) home maintenance and the simplification of cartridge replacement procedures contribute to steady aftermarket growth. The inherent benefits these components provide—such as ensuring safety through anti-scald mechanisms in thermostatic models and enhancing user convenience—cement their status as essential elements in modern plumbing infrastructure.

Diverter Cartridges Market Executive Summary

The Diverter Cartridges Market is characterized by strong resilience supported by consistent demand in both new construction and repair & replacement cycles. Current business trends indicate a significant shift towards premiumization, where manufacturers are increasingly integrating advanced materials like high-grade brass, specialized polymers, and polished ceramics to improve product lifespan and operational precision. Supply chain optimization, particularly the reduction of reliance on singular geographic manufacturing hubs, is a critical strategic focus for major players aiming to mitigate global trade volatility and enhance inventory stability. Moreover, strategic mergers, acquisitions, and technological collaborations aimed at securing intellectual property related to innovative flow control mechanisms are defining the competitive landscape.

Segment trends highlight the dominance of the residential sector, which is rapidly adopting single-handle mixing valves incorporating complex diverter functions for enhanced convenience and water temperature control. Within the product type segment, ceramic disc diverters continue to gain market share due to their proven anti-leak performance and long life cycle, displacing older rubber-based cartridge designs. A key emerging trend is the demand for specialized, high-flow diverters in commercial applications, particularly in luxury hotels and spa facilities, where high water volume and consistent pressure are paramount for guest experience. Sustainability considerations are also pushing innovation, with a focus on producing cartridges from recyclable or eco-friendly materials.

Regionally, the Asia Pacific (APAC) stands out as the fastest-growing market, propelled by massive urbanization, infrastructure development in countries like China and India, and the rising middle-class propensity to invest in modern home amenities. North America and Europe, while being mature markets, exhibit high demand for replacement parts and premium, water-saving technologies, often regulated by strict efficiency standards. The competitive environment is intensifying, prompting companies to invest heavily in patented designs and smart manufacturing processes to ensure their diverter cartridges are compatible with diverse fixture designs and global plumbing standards. These factors collectively project a stable and upward trajectory for the global Diverter Cartridges Market throughout the forecast period.

AI Impact Analysis on Diverter Cartridges Market

User inquiries regarding the influence of Artificial Intelligence (AI) on the Diverter Cartridges Market primarily focus on optimizing manufacturing efficiency, enhancing product quality control, and developing next-generation predictive maintenance systems for plumbing installations. Users are keenly interested in how AI algorithms can reduce material waste during precision manufacturing of complex plastic and ceramic components, predict potential failure points in high-stress environments, and personalize fixture operation. Key themes revolve around AI-driven robotics for assembly (ensuring micron-level tolerances), machine learning models analyzing field performance data to inform design improvements (Durability-by-Design), and the integration of smart sensors into cartridges that communicate performance metrics to smart home systems, alerting users or maintenance professionals before a leak or failure occurs.

- AI-driven Quality Control: Utilization of machine vision systems and deep learning algorithms to inspect ceramic disc surfaces and plastic molding for micro-defects, ensuring zero-defect manufacturing critical for leak-free performance.

- Predictive Maintenance Integration: Incorporation of AI analytics into smart plumbing systems (faucets and showers) to forecast the end-of-life of the diverter cartridge based on usage patterns, water hardness, and temperature fluctuation data.

- Optimized Supply Chain Logistics: Application of machine learning models to predict material sourcing needs (brass, specialized polymers) and optimize inventory levels based on global construction forecasts and replacement market cycles.

- Enhanced Design Iteration: Use of Generative Design AI tools to optimize the internal geometry of diverter cartridges for maximum flow efficiency and reduced material consumption while maintaining structural integrity.

- Automated Manufacturing Processes: Deployment of robotic arms guided by AI for high-precision assembly of intricate cartridge components, minimizing human error and increasing production throughput.

DRO & Impact Forces Of Diverter Cartridges Market

The dynamics of the Diverter Cartridges Market are shaped by powerful Drivers (D) such as global construction growth and increasing renovation activities, offset by Restraints (R) including the high initial cost of premium, high-tech cartridges and the long product life cycles reducing replacement frequency. Opportunities (O) emerge from regulatory push for water efficiency and the untapped potential of smart plumbing integration. These forces interact significantly: the drive for water conservation (D) simultaneously creates an opportunity (O) for manufacturers producing innovative, low-flow diverters, while the primary restraint (R) of high cost is often mitigated by the long-term savings delivered by durable ceramic cartridges, creating a positive impact force towards premiumization and reliability.

The key driver remains the exponential growth in the global real estate sector, particularly in the APAC region, where new residential and commercial units require substantial installation of water fixtures. Furthermore, regulatory environments in developed economies are increasingly favoring products that ensure safe operation, leading to a higher demand for sophisticated thermostatic diverter cartridges that prevent scalding accidents. This regulatory push acts as a strong internal impact force, compelling manufacturers to adhere to stringent quality standards like ASME and ISO certifications, thereby raising the barrier to entry for lower-quality producers and promoting market consolidation among technologically advanced players.

However, the market faces significant restraints, notably the intense price competition from unorganized local manufacturers, particularly in developing regions, which often prioritize low cost over long-term quality, leading to market fragmentation and complexity for standardized players. The availability of substitute products, such as simpler, traditional three-valve systems (though less convenient), also poses a minor restraint. Nonetheless, the primary opportunity lies in the burgeoning smart home market. Integrating diverter cartridge functionality with IoT platforms allows for remote control and diagnostics, offering manufacturers a premium segment where they can command higher margins and unlock new revenue streams related to after-sales service and data utilization.

Segmentation Analysis

The Diverter Cartridges Market is extensively segmented based on the functional mechanism, the materials used, the end-user application, and the distribution channel. This multi-dimensional segmentation allows stakeholders to accurately gauge market demand shifts and target specific industry needs, ranging from large-volume, cost-sensitive residential projects to highly specialized, durable applications in commercial hospitality settings. The segmentation highlights the technical evolution of the market, moving predominantly from rubber and metal components toward sophisticated ceramic and engineered polymer composites which offer superior longevity and performance stability, vital for minimizing water wastage and system downtime.

- By Type: Ceramic Disc Cartridges, Pressure-Balancing Cartridges, Thermostatic Cartridges, Compression/Stem Cartridges, Piston/Slider Cartridges.

- By Application: Residential (Single-Family, Multi-Family), Commercial (Hotels & Hospitality, Office Buildings, Retail), Institutional (Hospitals & Healthcare, Educational Facilities).

- By Material: Brass/Metal Alloy, Engineered Polymer (Plastics), Ceramic Disc.

- By Sales Channel: OEM (Original Equipment Manufacturer), Aftermarket/Replacement (Retail, E-commerce, Plumbers/Contractors).

Value Chain Analysis For Diverter Cartridges Market

The value chain for Diverter Cartridges begins with the upstream procurement of critical raw materials, primarily high-grade brass, zinc alloys for external casings, specialized engineering polymers (such as PEEK and high-density polyacetal) for seals and functional components, and high-purity ceramic powder for the manufacture of durable ceramic discs. Upstream analysis reveals that raw material costs, especially fluctuations in global metal prices, significantly influence the final product cost structure. Manufacturers must maintain strategic relationships with specialized ceramic producers and metal foundries capable of delivering materials that meet the strict tolerances required for leak-proof performance, often necessitating vertical integration or long-term contractual agreements to stabilize supply and quality.

The manufacturing stage involves highly specialized precision engineering processes, including intricate injection molding for polymer components, high-tolerance machining for brass bodies, and sintering processes for ceramic discs. Quality control at this stage is paramount, utilizing automated testing rigs to verify functionality, flow rates, and pressure resistance before assembly. The distribution channel is bifurcated: Original Equipment Manufacturers (OEMs) supply directly to fixture producers (faucets, valves), forming the primary market volume, while the Aftermarket channel caters to replacement needs. The aftermarket relies heavily on extensive warehousing and efficient logistics to ensure rapid availability of a wide variety of cartridges compatible with diverse brands and models.

Downstream analysis focuses on the final customer interface, including direct sales to large construction projects and indirect sales through retail plumbing supply chains, large format hardware stores, and specialized plumbing contractors. Direct channels are crucial for large commercial projects where specifications are highly controlled, ensuring the correct certification and warranty compliance. Indirect distribution leverages extensive physical and e-commerce networks to reach individual homeowners and small contractors for repair and renovation work. The increasing importance of e-commerce platforms requires manufacturers to provide detailed product specifications and easy-to-understand installation guides to support the DIY consumer base effectively.

Diverter Cartridges Market Potential Customers

The primary potential customers for Diverter Cartridges encompass a broad spectrum of entities involved in construction, maintenance, and facility management, ranging from individual homeowners undertaking renovations to massive international hotel chains developing new properties. The largest volume of consumption is derived from Original Equipment Manufacturers (OEMs) of faucets and shower systems, such as Kohler, Delta, and Grohe, who integrate these cartridges as core components in their finished products. These OEMs require millions of units annually, demanding consistent quality, customized specifications, and competitive pricing, making them the most influential purchasing segment in terms of volume and design compliance.

The commercial sector represents another significant high-value customer base, including developers of luxury hospitality venues, healthcare facilities (hospitals and clinics), and high-traffic institutional complexes (universities and government buildings). These end-users prioritize extreme durability, water efficiency, and compliance with stringent public health and safety regulations (e.g., anti-scald requirements). Cartridges supplied to this segment must often be pressure-balancing or thermostatic in nature, capable of withstanding heavy, continuous usage and minimizing liability risks, thereby driving demand for premium, highly certified products.

Finally, the robust Aftermarket/Replacement sector consists of professional plumbers, specialized maintenance contractors, facility managers, and direct consumers (DIY market). This customer segment is highly sensitive to product availability, brand compatibility, and ease of installation. Facility managers and maintenance companies often purchase cartridges in bulk to maintain existing infrastructure, requiring reliable supply chains for quick turnover. The increasing complexity of modern fixtures necessitates specialized knowledge, ensuring that the role of professional contractors remains pivotal in this replacement market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.25 Billion |

| Market Forecast in 2033 | $1.85 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Kohler Co., Moen Incorporated, Delta Faucet Company, Grohe AG, Hansgrohe SE, American Standard Brands, Masco Corporation, Roca Sanitario, S.A., TOTO Ltd., Geberit AG, Danze Inc., Pfister (Spectrum Brands), VIGO Industries, Sloan Valve Company, Zurn Industries, Fluidmaster Inc., Kerox Kft., Cera Sanitaryware Ltd., Globe Union Industrial Corp., Neoperl GmbH. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Diverter Cartridges Market Key Technology Landscape

The foundational technology shaping the modern Diverter Cartridges Market is the adoption of high-performance ceramic disc mechanisms. These discs, typically made from aluminum oxide (alumina), are polished to near-perfect flatness, ensuring a watertight seal when closed and requiring minimal friction for rotation. This ceramic-based design dramatically reduces wear and tear compared to older rubber washer or compression cartridges, leading to leak-free performance and an operational life often exceeding 500,000 cycles. Manufacturers are continuously refining the material composition and polishing techniques to enhance scratch resistance and chemical inertness, making them suitable for areas with hard water or aggressive cleaning agents. The advancement in ceramic technology has become synonymous with cartridge quality and long-term value, driving out dated technologies from the mainstream market.

Another crucial technological development involves pressure-balancing and thermostatic technologies, which are essential for safety and comfort, particularly in shower systems. Pressure-balancing cartridges react to sudden changes in hot or cold water pressure (e.g., when a toilet is flushed) by automatically adjusting the mix to prevent scalding or freezing blasts. Thermostatic cartridges represent the apex of control technology, utilizing a wax or bimetallic element to sense and maintain a precise user-set temperature, regardless of variations in incoming water temperature or pressure. The integration of highly sensitive and reliable temperature control elements within the compact cartridge assembly represents significant precision engineering, directly impacting consumer safety standards and market penetration in regulated environments like hospitals and senior living centers.

Furthermore, material innovation, particularly in engineered polymers, is vital for reducing manufacturing costs and improving compatibility across diverse plumbing materials. Specialized plastic cartridges are increasingly utilized in specific low-cost applications or where weight reduction is prioritized, provided they meet stringent performance requirements regarding temperature resilience and chemical compatibility. Smart technology integration is also emerging, where some high-end cartridges include non-contact magnetic or electronic sensing mechanisms to manage flow redirection digitally, paving the way for fully computerized shower experiences. This shift moves the technology from purely mechanical function to electro-mechanical integration, offering greater precision and potential for IoT connectivity and remote diagnostics.

Regional Highlights

The global market for diverter cartridges exhibits distinct regional growth patterns dictated by local construction activity, plumbing standards, and consumer spending power. While North America and Europe provide stable, mature replacement markets focused heavily on quality and water conservation, the Asia Pacific region is the powerhouse of volume growth driven by rapid urbanization.

- North America: Characterized by stringent water efficiency regulations (e.g., EPA WaterSense) and high consumer demand for premium, multi-function shower systems. The market is dominated by replacement cycles and high adoption rates of thermostatic and pressure-balancing cartridges mandated by building codes to ensure safety. Substantial opportunities exist in the renovation segment, particularly in high-density metropolitan areas.

- Europe: Known for its historical adherence to high-quality brass and ceramic components, emphasizing longevity and minimalist design. Germany, the UK, and France are key markets, prioritizing sophisticated flow control and sustainability. Demand is strong for components compatible with standardized European plumbing systems (e.g., DIN standards).

- Asia Pacific (APAC): The fastest-growing region fueled by unprecedented residential and commercial construction in China, India, and Southeast Asian nations. While price sensitivity is present, the growing middle class is increasingly demanding high-performance, branded fixtures, shifting volume demand towards reliable ceramic disc technology. This region is critical for OEM sales growth.

- Latin America (LATAM): Growth is tied closely to fluctuating economic conditions, but large construction projects in Mexico and Brazil drive steady demand. The market often balances cost-effectiveness with necessary quality, leading to mixed demand for both high-end imported cartridges and more cost-effective localized production.

- Middle East and Africa (MEA): Significant demand stemming from high-profile construction projects in the Gulf Cooperation Council (GCC) countries (hospitality and luxury residential). These regions require highly durable cartridges capable of managing high water temperatures and potentially corrosive water quality, favoring brass and specialized polymer materials. Infrastructure modernization in parts of Africa also opens up long-term growth prospects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Diverter Cartridges Market.- Kohler Co.

- Moen Incorporated

- Delta Faucet Company

- Grohe AG

- Hansgrohe SE

- American Standard Brands

- Masco Corporation

- Roca Sanitario, S.A.

- TOTO Ltd.

- Geberit AG

- Danze Inc.

- Pfister (Spectrum Brands)

- VIGO Industries

- Sloan Valve Company

- Zurn Industries

- Fluidmaster Inc.

- Kerox Kft.

- Cera Sanitaryware Ltd.

- Globe Union Industrial Corp.

- Neoperl GmbH

Frequently Asked Questions

Analyze common user questions about the Diverter Cartridges market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the key differences between ceramic disc and thermostatic diverter cartridges?

Ceramic disc cartridges primarily function as a simple, durable mechanism for redirecting water flow between outlets (e.g., bath to shower) using two highly polished ceramic plates for sealing. Thermostatic diverters, conversely, incorporate advanced thermal sensing elements to not only redirect flow but also precisely maintain a safe, pre-set water temperature, actively compensating for fluctuations in incoming pressure and temperature to prevent scalding, making them mandatory in many commercial and institutional settings.

How do water conservation regulations influence the design of diverter cartridges?

Water conservation regulations, such as those set by EPA WaterSense or local building codes, mandate minimum flow rates and maximum leakage tolerances. This drives manufacturers to design diverter cartridges that offer precise flow control and exceptionally robust sealing mechanisms, predominantly favoring ceramic disc technology which ensures zero leakage when closed, thereby contributing directly to overall system efficiency and compliance with environmental standards.

Which segment—OEM or Aftermarket—is driving the current growth in the market?

The Original Equipment Manufacturer (OEM) segment typically drives the largest volume growth due to global expansion in new construction, especially in the Asia Pacific region. However, the Aftermarket segment, driven by replacement and renovation activities in mature markets like North America and Europe, is responsible for higher profitability and premium cartridge demand, as consumers and plumbers often choose higher-quality replacement parts than the original installation.

What is the typical lifespan of a high-quality ceramic diverter cartridge?

A high-quality ceramic diverter cartridge, when properly manufactured and installed, often boasts an operational lifespan exceeding 500,000 cycles, translating typically to 15 to 25 years of residential use under standard conditions. Factors such as water hardness (mineral content) and the frequency of use are the primary determinants affecting the actual longevity, requiring periodic maintenance or replacement to ensure optimal performance and prevent leakage.

What materials are essential for manufacturing durable diverter cartridges?

Essential materials for manufacturing durable diverter cartridges include high-purity aluminum oxide ceramics for the sealing discs, specialized engineered polymers (such as acetal or PEEK) for the housing and internal moving components due to their low friction and chemical resistance, and high-quality, corrosion-resistant brass or zinc alloys for the structural body and connections, particularly in applications involving high water temperatures or hard water conditions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager